Olefin polymerization catalyst, and preparation method and application thereof

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalyst and its preparation, which can solve the problems of poor particle shape, high apparent density, and rareness, and achieve the effect of low content and improved particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

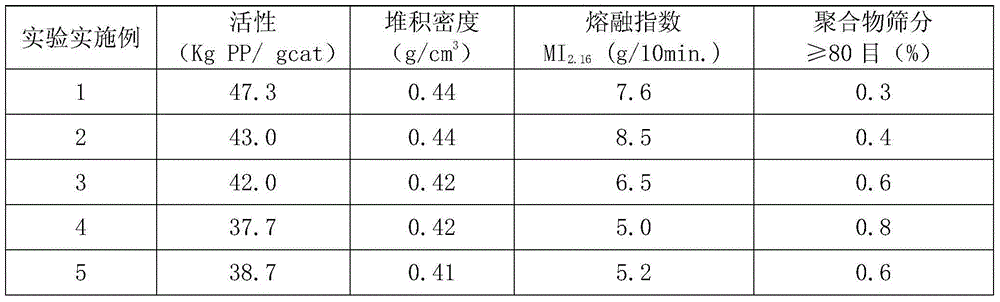

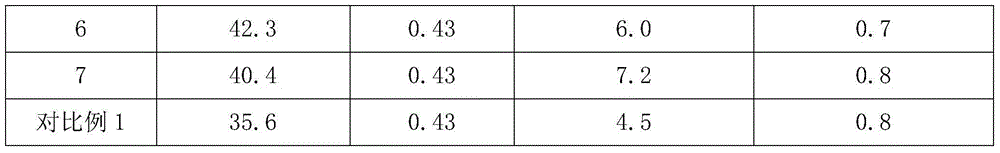

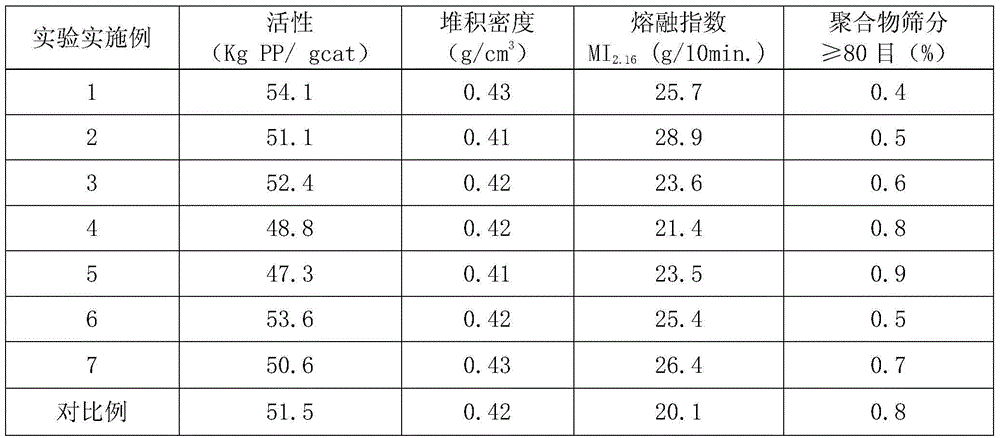

Examples

Embodiment 1

[0052] In the normal-pressure reaction kettle repeatedly replaced by high-purity nitrogen, 4.8 grams of anhydrous magnesium chloride, 70 milliliters of toluene, 4.0 milliliters of epichlorohydrin, 12.5 milliliters of tributyl phosphate and 0.5 milliliters of ethylene glycol monoethyl ether were added successively. Under the condition of 60°C, react for 1 hour, add 1.4 g of phthalic anhydride and 30 ml of toluene, continue the reaction for one hour, cool to -28°C, add 56 ml of titanium tetrachloride dropwise (dropping speed 1 ml / min ), gradually raised the temperature to 85°C (the heating rate was 5°C / min), added 1.1 ml of di-n-butyl phthalate (DNBP) at 80°C, kept the temperature for one hour, filtered, washed the solid with toluene twice, and then Add 48 ml of titanium tetrachloride and 72 ml of toluene, filter at 110° C. for 0.5 hour, repeat this step twice, wash the obtained solid with hexane for 5 times, and dry it in vacuum to obtain an olefin polymerization catalyst.

Embodiment 2

[0054] The preparation method was consistent with that of Example 1, except that the amount of ethylene glycol monoethyl ether was 1.0 mL.

Embodiment 3

[0056] The preparation method was consistent with that of Example 1, except that the amount of ethylene glycol monoethyl ether was 0.3 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com