Catalyst component for olefin polymerization, preparation method thereof, catalyst and application of

A technology for olefin polymerization and catalyst, which is applied in the field of catalyst and its application, catalyst component for olefin polymerization and its preparation, can solve the problems of rising fine powder content and breaking, and achieve the effect of low fine powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The second aspect of the present invention provides a kind of preparation method of above-mentioned catalyst component, and this preparation method comprises:

[0043] Step S1, preparation of mother liquor: contact electron donor compound, magnesium halide, titanium-containing compound and organic compound, and react to prepare mother liquor;

[0044] Step S2, carrier blending: adding inorganic oxide carrier fillers for blending during or after step S1 to obtain a slurry suspension;

[0045] Step S3, spray forming: the slurry suspension obtained in step S2 is spray-dried to obtain the catalyst component.

[0046] The blending of inorganic oxide carrier fillers can be added at any time when the mother liquor is prepared; for example, in the electron donor compound, magnesium halide, inorganic oxide carrier fillers, titanium-containing compounds and organic compounds are mixed and reacted to obtain silt The slurry material is then spray-molded, and the resulting slurry i...

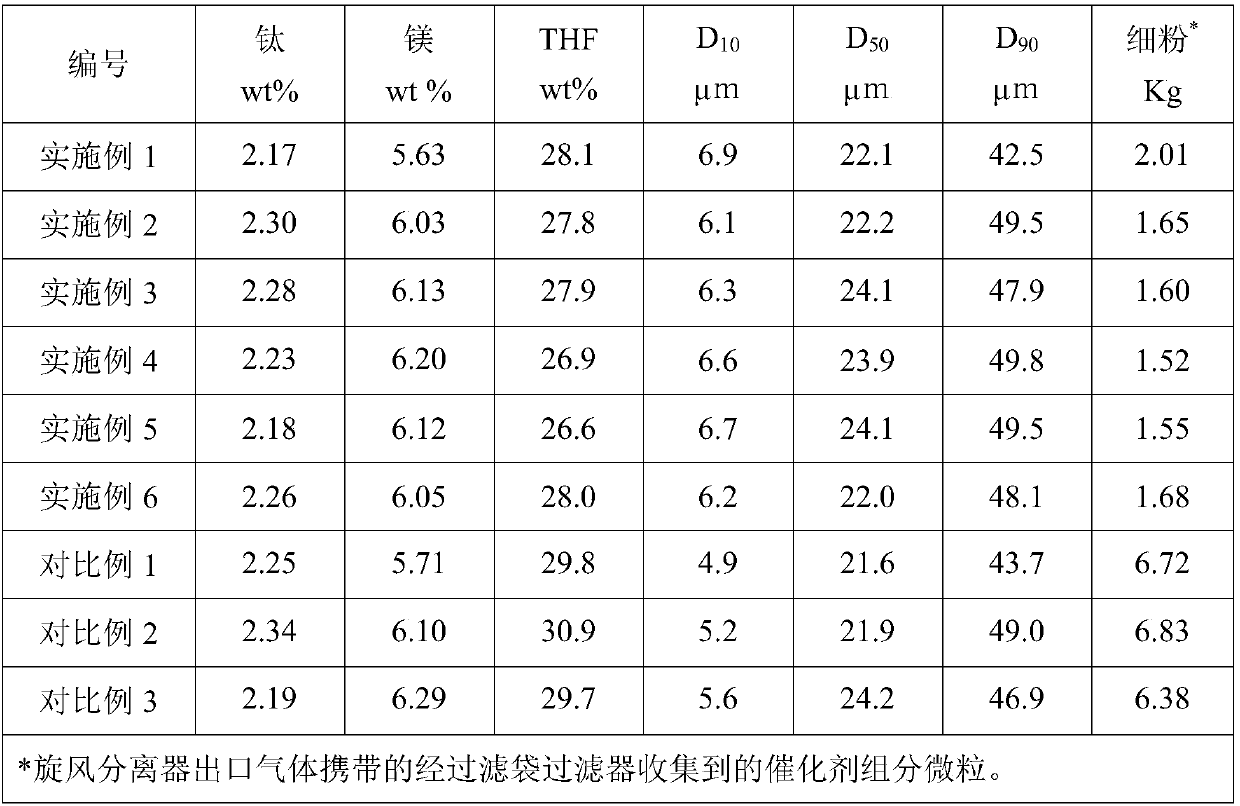

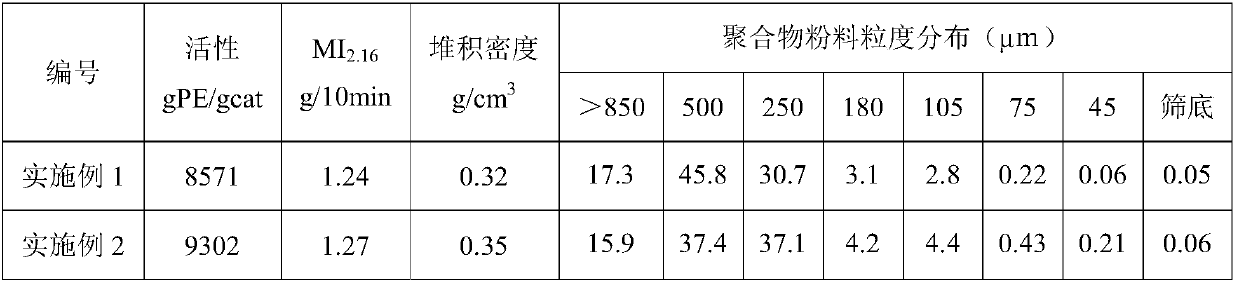

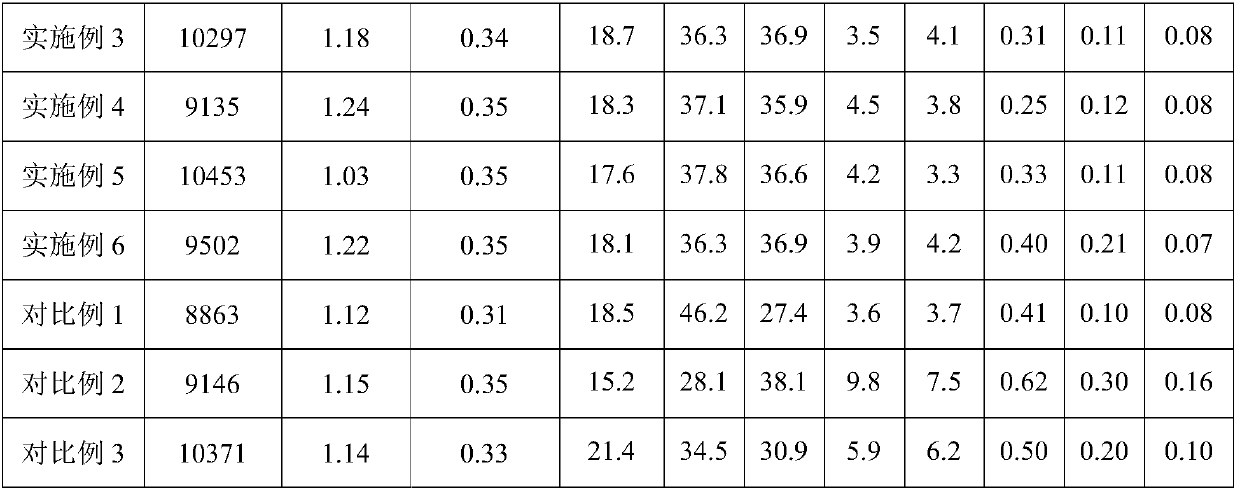

Embodiment 1

[0068] (1) Preparation of catalyst components

[0069] Add 845 liters of tetrahydrofuran (THF), 31.5 kg of magnesium chloride, and 7.5 liters of TiCl to a 2-cubic-meter kettle that has been purged with nitrogen and equipped with a pressure-temperature controller and a stirrer. 4 , 6.34 liters 68 # White oil (2 O), under stirring, the temperature was raised to 67° C., and the mother liquor was prepared by constant temperature reaction at this temperature for 3 hours. During this process, it has been kept in a nitrogen atmosphere (2 O);

[0070] Add 54.6 kilograms of silica gel (Cabot Corporation TS-610, particle diameter is 0.1~1 micron) to a 2 cubic meter kettle that is equipped with pressure temperature controller and agitator through nitrogen blowing, and the above-mentioned Add the mother liquor and continue stirring at 67°C to completely disperse the silica gel in the mother liquor to obtain a slurry suspension. During this process, it has been kept in a nitrogen atmosp...

Embodiment 2

[0076] (1) Preparation of catalyst components

[0077] In a 2 cubic meter kettle equipped with a pressure temperature controller and a stirrer, 845 liters of tetrahydrofuran (THF), 45.0 kilograms of magnesium chloride, and 17.7 kilograms of TiCl were successively added under stirring. 3 1 / 3AlCl 3 (reduction of TiCl by aluminum 4 obtained), 6.34 liters of 68 # White oil (2 O), under stirring, the temperature was raised to 67° C., and the mother liquor was prepared by constant temperature reaction at this temperature for 3 hours. During this process, it has been kept in a nitrogen atmosphere (2 O);

[0078] Add 60.9 kilograms of silica gel (Cabot Corporation TS-610, particle diameter is 0.1~1 micron) to a kettle of 2 cubic meters that is equipped with pressure temperature controller and agitator through nitrogen blowing, and the above-mentioned Add the mother liquor and continue stirring at 67°C to completely disperse the silica gel in the mother liquor to obtain a slurry su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com