Preparing method for ultra-high molecular weight polyethylene fibers and washing device

A technology of polyethylene fiber and ultra-high molecular weight, applied in the direction of single-component polyolefin artificial filament, fiber treatment, fiber chemical characteristics, etc., can solve problems affecting the performance of ultra-high molecular weight polyethylene fiber, and achieve environmental protection , safe production process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of ultra-high molecular weight polyethylene fiber, comprises the following steps:

[0028] (1) Prepare spinning solution. Inject ultra-high molecular weight polyethylene (relative average molecular weight 3.5 million) powder, 70# solvent white oil and phenolic antioxidant into the unwrapping kettle at a mass ratio of 8:100:0.16, and shear under nitrogen protection. For 25 minutes, the shear rate is 3000 seconds-1, and the mixture is evenly mixed to prepare a polyethylene spinning solution.

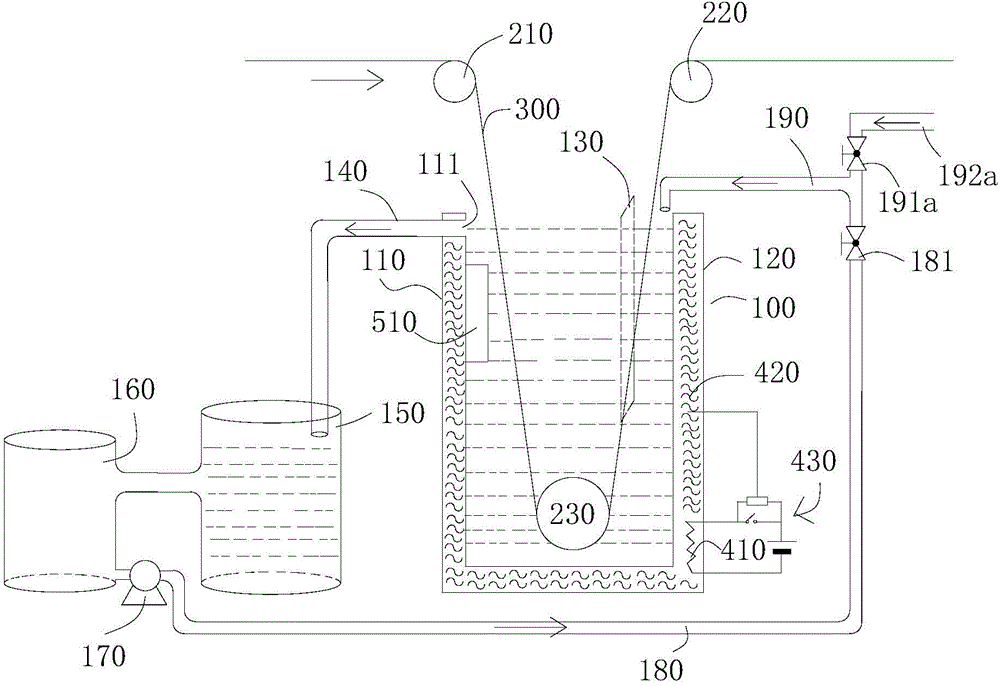

[0029] (2) spinning. Add the polyethylene spinning solution in step (1) into a screw extruder and extrude from the screw extruder. In this example, the screw extruder is twin-screw, the diameter of the screw extruder is 125mm, the ratio of length to diameter is 64, the temperature of the screw is 285°C, and the rotation speed is 180rpm. The extrudate output by the screw extruder passes through the filter, After the spin...

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of ultra-high molecular weight polyethylene fiber, comprises the following steps:

[0039] Steps (1) preparation of spinning solution, (2) spinning, (3) extraction, step (5) drying, (6) drawing in this example are the same as in Example 1, the difference lies in the water washing step of step (4) .

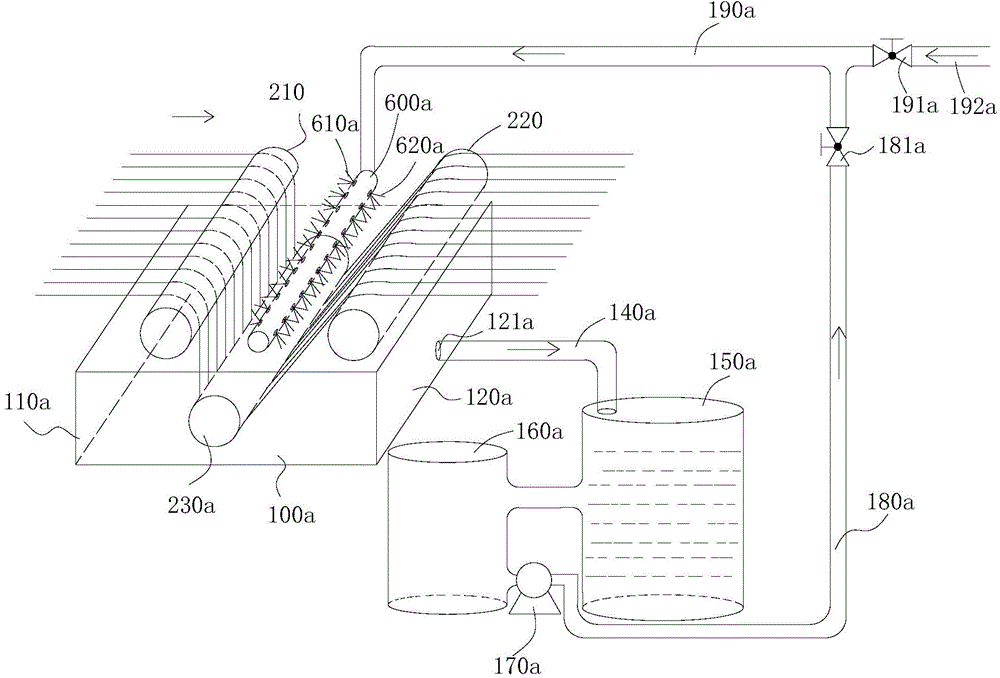

[0040] see figure 2 , the washing device used in the water washing step of this embodiment includes a washing tank 100a, the notch of the washing tank 100a is upward, and the two sides above the silk inlet side tank wall 110a and the silk outlet side tank wall 120a of the water washing tank 100a are Godet rollers 210a, 220a are arranged on the side, and a godet roller 230a is arranged at the bottom of the washing tank 100a; an overflow port 121a is arranged on the silk outlet side tank wall 120a of the washing tank 100a, and the overflow port 121a is connected to a The overflow return pipe 140a, the other end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com