Polymer solution steam stripping flocculation separation method and apparatus

A polymer solution and separation device technology, applied in steam distillation, sustainable manufacturing/processing, chemical industry, etc., can solve problems such as difficult to guarantee concentration effect, difficult to recover heat, energy waste, etc., to save equipment investment and electric energy , the residual solvent content is reduced, and the effect of improving the coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

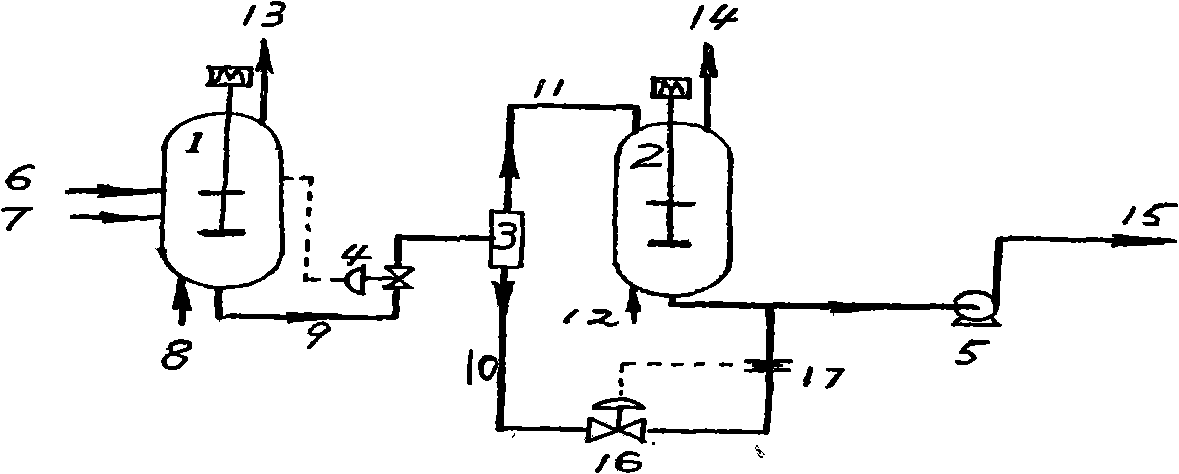

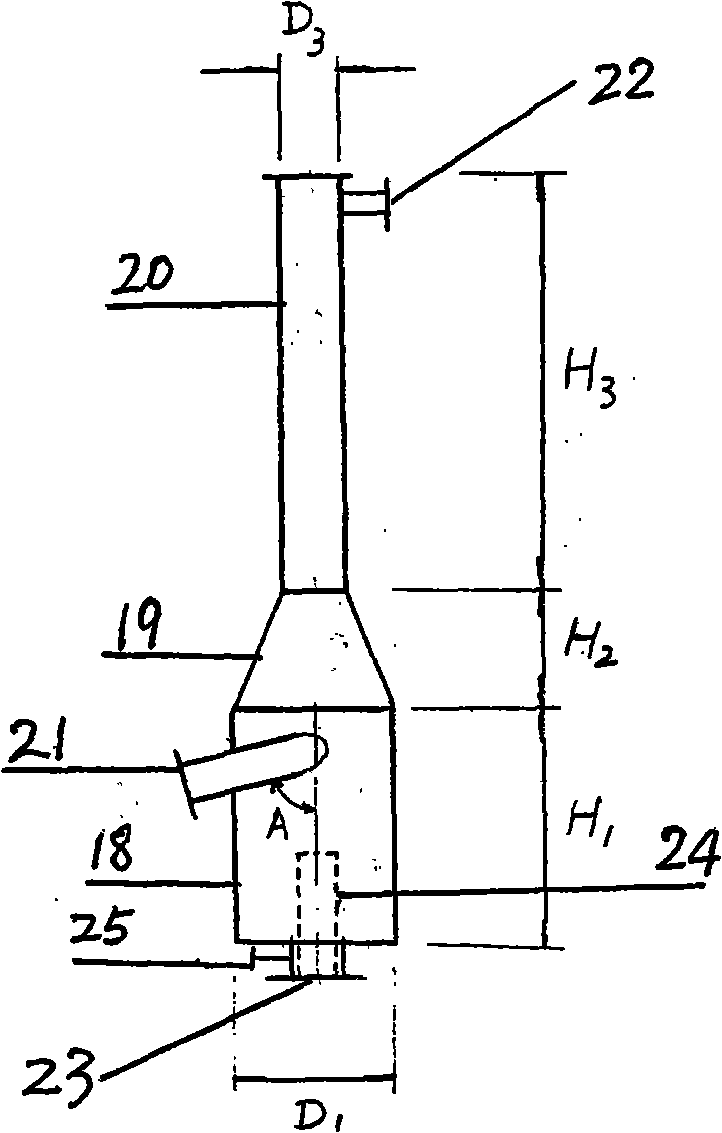

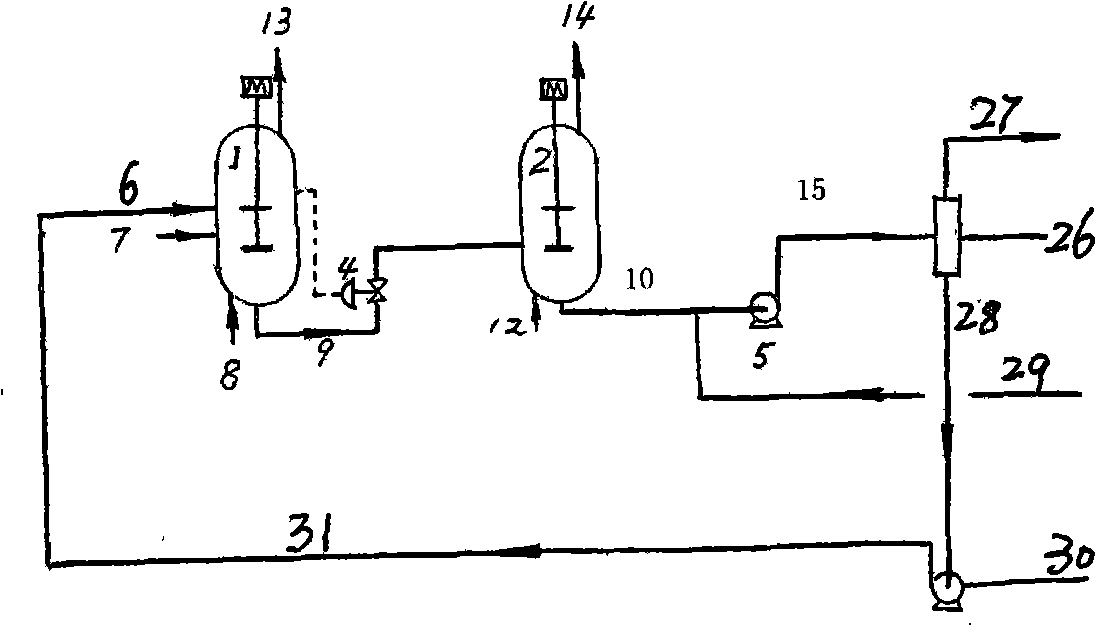

[0020] Embodiment 1: A polymer solution stripping coagulation efficiency enhancement and energy saving device.

[0021] The main body of this embodiment includes a first coagulation kettle 1, a second coagulation kettle 2, a thickening separator 3, a polymer particle water regulator 4, a polymer particle water pump 5, a circulating hot water pipeline 6 from post-treatment, and a polymerization Product solution pipeline 7, heating steam pipeline 8 and 12, the polymer particle water pipeline 9 that comes out from the first condensation kettle, concentrate water pipeline 10, the polymer particle water pipeline 11 that is concentrated, steam out from the first condensation kettle The steam pipeline 13, the steam steam pipeline 14 from the first condensation tank, the polymer particle water pipeline 15 for post-treatment, the concentrated water flow regulator 16 and the concentrated water flow meter 17.

[0022] The present embodiment comprises the first coagulation still 1 and the...

Embodiment 2

[0026] Embodiment 2: A polymer solution stripping coagulation synergistic energy-saving separation method.

[0027] 100 liters / hour of rare earth isoprene rubber glue with 15% glue concentration enters the first condensation kettle 1 from pipeline 7, and 1000 liters / hour of circulating hot water containing dispersant from aftertreatment enters the first coagulation kettle from pipeline 6. A condensation kettle 1, heated water vapor enters the first condensation kettle 1 from the pipeline 8; the temperature of the first condensation kettle 1 is 85°C, the pressure is 0.02MP(G), and the evaporated solvent and water vapor are condensed from the pipeline 13 Recovery system; the polymer particle water containing polymer 1% from the first coagulation kettle 1 enters the thickening separator 3 through the adjustment valve 4 from the pipeline 9, and extracts 500 liters / hour from the lower part of the thickening separator 3 after adjustment 16 and flow meter 17 enter the colloidal parti...

Embodiment 3

[0028] Embodiment 3: A method for stripping, coagulation, efficiency and energy-saving separation of polymer solution.

[0029] 100 liters / hour of rare earth isoprene rubber glue solution with 15% glue solution concentration enters the first coagulation kettle 1 from pipeline 7, and 500 liters / hour of circulating hot water containing dispersant from aftertreatment enters the first condensation kettle from pipeline 6. A condensation tank 1, heated water vapor enters the first condensation tank 1 from the pipeline 8; the temperature of the first condensation tank is 85°C, the pressure is 0.02MP(G), and the evaporated solvent and water vapor are condensed and recovered from the pipeline 13 System; the polymer particle water containing polymer 2% that comes out from the first coagulation kettle 1 enters the thickening separator 3 through the regulating valve 4 from the pipeline 9, and extracts 250 liters / hour from the thickening separator 3 bottom through the regulating valve 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com