Ultrafine fly ash production technology

A technology of ultra-fine fly ash and production process, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems that affect the performance of fly ash products and their economic value, and the low proportion of coarse particles , to achieve compact structure, increase cement strength, and improve cement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

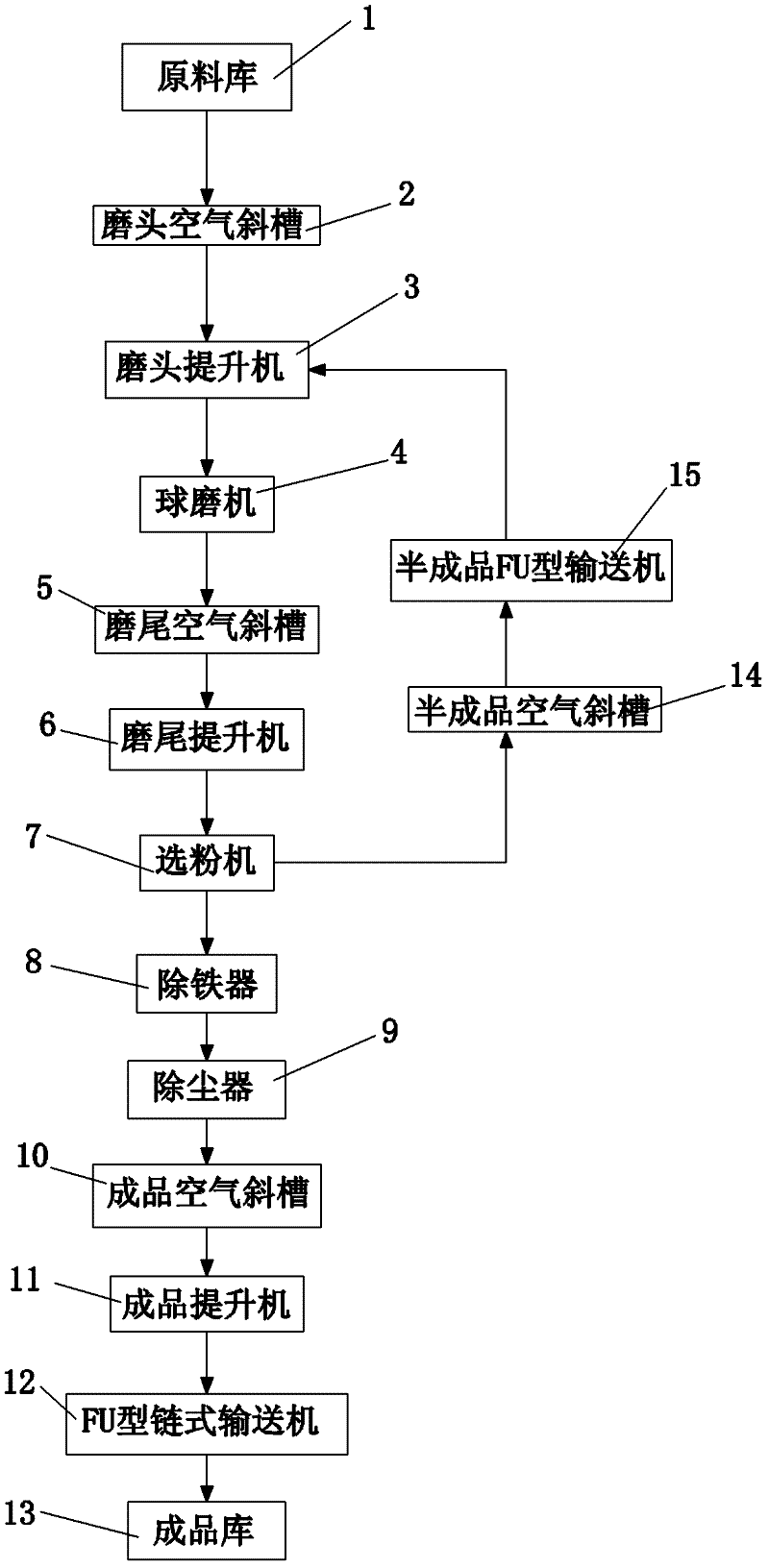

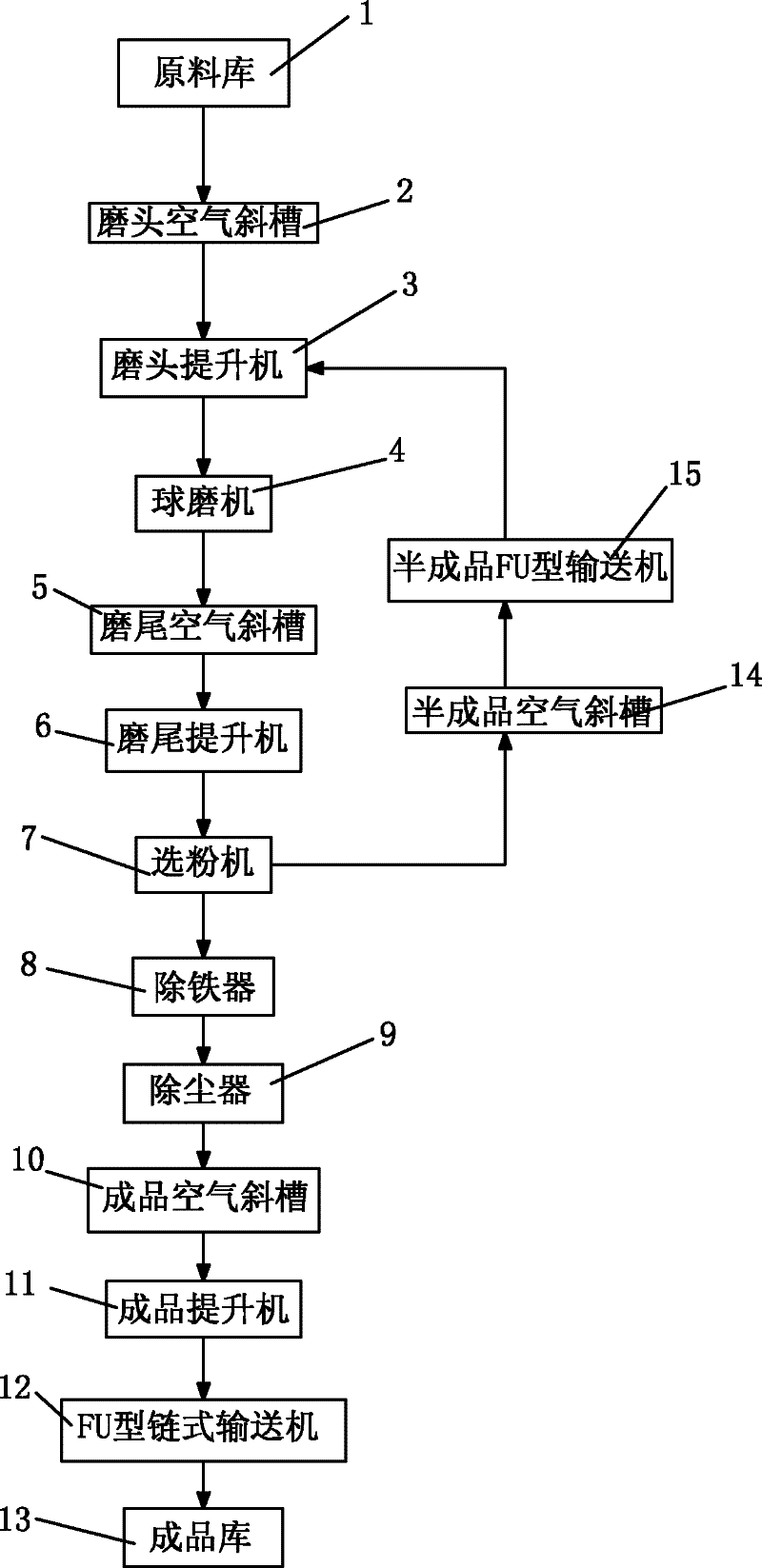

[0010] Such as figure 1 Shown, the production technique of superfine fly ash of the present invention comprises the following steps:

[0011] (1) After the microcomputer metering and flow ratio control are carried out in the raw material warehouse 1, the raw material fly ash is put into the air chute 2 of the grinding head according to the set flow rate; (2) The material is conveyed by the air chute 2 of the grinding head into the grinding head The elevator 3 is lifted by the grinding head elevator 3 and enters the ball mill 4; (3) In the ball mill 4, the material first enters the coarse grinding chamber, and in the coarse grinding chamber, the material enters the separation chamber sieve after being impacted by the grinding body with a larger diameter. points, the material that is too coarse is the R of the material 32 If the sieve residue is greater than 8%, it will be sifted out and returned to the coarse grinding bin, R 32 The finer materials with less than 8% screened e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com