Venturi tube reactor

A Venturi tube and reactor technology, applied in chemical/physical/physical-chemical nozzle reactors, calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problem of short droplet residence time, large droplet diameter, clogging and other problems, to achieve the effect of easy industrial application, excellent product performance, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

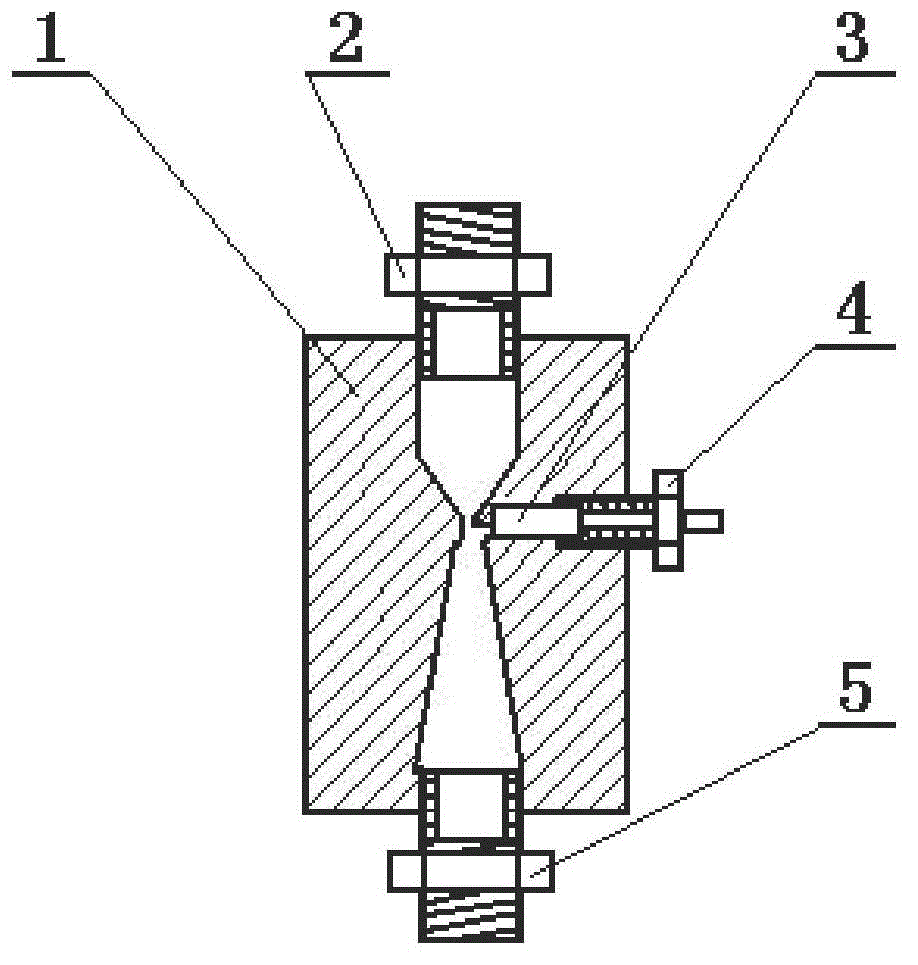

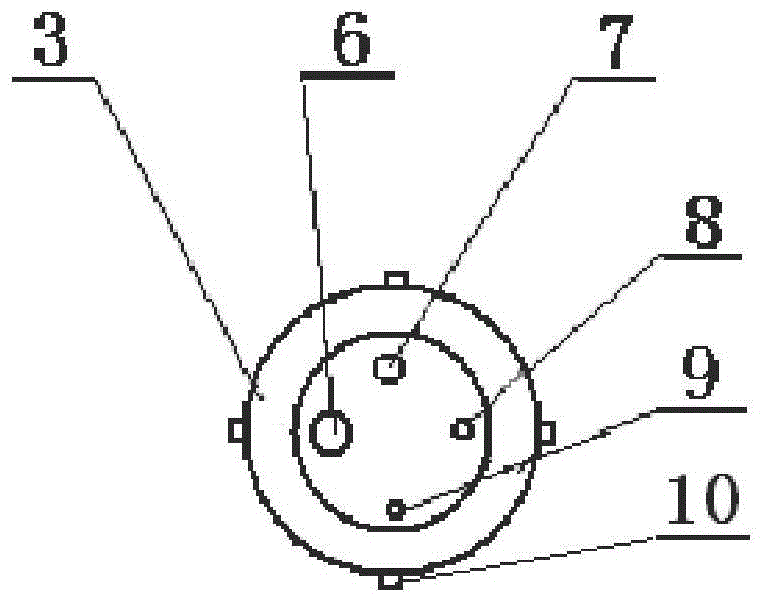

[0025] Venturi tube reactor setup includes pipe body 1, air inlet nozzle cylinder 3, air inlet joint 4, liquid inlet joint 2 and liquid outlet joint 5; Groove; the air inlet nozzle barrel 3 with two nozzles of 3 mm and 5 mm nozzle diameter is set, two positioning columns 10 are arranged outside the mouth end of the air inlet nozzle barrel 3, and the upper and lower ends of the air inlet nozzle barrel 3 with a nozzle diameter of 3 mm are selected to be sealed circle, and facing the installation hole of the Huai Venturi tube reactor, and then screw-fixed with the inlet joint 4; the upper and lower ends of the pipe body 1 are respectively provided with the liquid inlet joint 2 and the liquid outlet joint 5, and the liquid inlet joint 2 is connected to the powerful pump. The outlet joint 5 is connected to the reaction kettle.

[0026] When working, the CaCO 3 Limestone with a content greater than 98.5% is calcined at 1050±1°C for 3 hours to obtain quicklime; the mass ratio of qui...

Embodiment 2

[0029] Venturi tube reactor setup includes pipe body 1, air inlet nozzle barrel 3, air inlet joint 4, liquid inlet joint 2 and liquid outlet joint 5; pipe body 1 is provided with air inlet nozzle barrel 3 placement holes, and the placement holes are provided with three positioning holes Groove; the nozzle diameter is set to be the intake nozzle tube 3 of three nozzles of 3mm, 4mm and 5mm, three positioning columns 10 are arranged outside the mouth end of the intake nozzle tube 3, and the upper and lower two ends of the intake nozzle tube 3 with a nozzle diameter of 5mm are selected Set the sealing ring, and align with the placement hole of the Huai Venturi tube reactor, and then screw it with the inlet joint 4; the upper and lower ends of the pipe body 1 are respectively provided with the liquid inlet joint 2 and the liquid outlet joint 5, and the liquid inlet joint 2 is connected with a strong Pump, liquid outlet joint 5 is connected to reaction kettle.

[0030] When working,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com