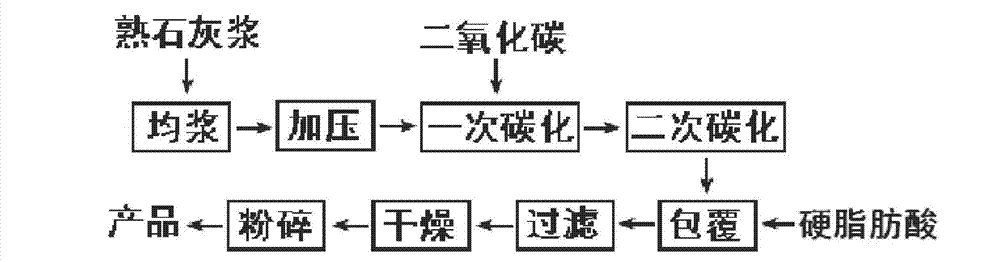

Carbonization method for preparing nano calcium carbonate

A technology of nano-calcium carbonate and carbonization reaction, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problems of affecting emulsification efficiency, low contact efficiency, slow mass transfer rate, etc., and achieve good economic benefits and Social benefits, excellent product performance, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

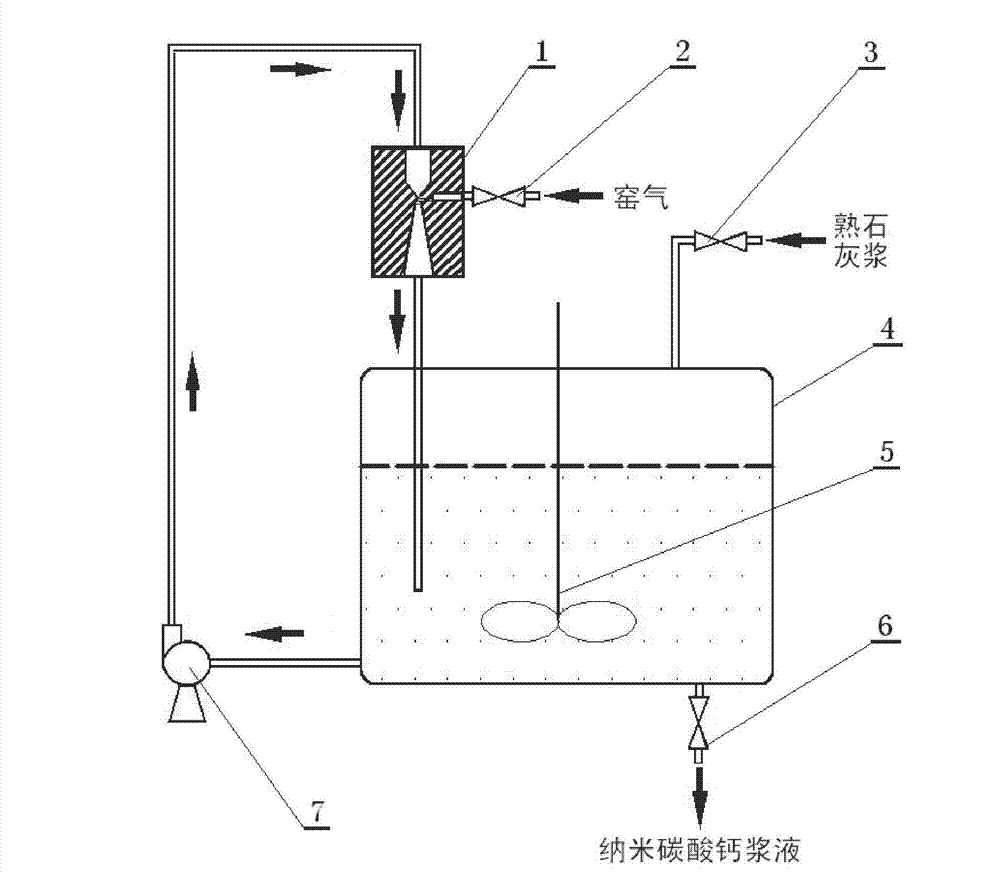

Embodiment 1

[0052] CaCO 3 Limestone with a content greater than 98.5% is calcined at 1050±1°C for 3 hours to obtain quicklime; the mass ratio of quicklime and water is 1:4 and fully digested at 80±1°C to obtain slaked lime slurry; Dilute to Ca(OH) 2 The weight concentration is 13%; close the discharge valve 6, open the slurry inlet valve 3, introduce the slurry into the reaction kettle 4 of the present invention, adjust the temperature of the slurry to 20±1°C; start stirring, and turn on the powerful pump 7 after 10 minutes, Powerful pump 7 flow rate Q=20m 3 / h, head H=25m, when the slurry enters the Venturi tube reactor 1, the nozzle diameter is 4mm, and the water outlet speed of the nozzle reaches 30m / s and is atomized into droplets with extremely small particle size, the kiln gas inlet valve 2 is opened to control the flow Kiln gas with a volume concentration of carbon dioxide of 17% is used for a carbonization reaction. The carbonization reaction liquid and excess kiln gas continue...

Embodiment 2

[0055] CaCO 3 Limestone with a content greater than 98.5% is calcined at 1050±1°C for 3 hours to obtain quicklime; the mass ratio of quicklime and water is 1:4 and fully digested at 80±1°C to obtain slaked lime slurry; Dilute to Ca(OH) 2 The weight concentration is 14%; close the discharge valve 6, open the slurry inlet valve 3, introduce the slurry into the reaction kettle 4 of the present invention, adjust the temperature of the slurry to 18±1°C; start stirring, and turn on the powerful pump 7 after 10 minutes, Powerful pump 7 flow rate Q=30m 3 / h, head H=28m, when the slurry enters the Venturi tube reactor 1, the nozzle diameter is 3mm, and the water outlet speed of the nozzle reaches 40m / s and is atomized into very small droplets, the kiln gas inlet valve 2 is opened to control the flow Kiln gas with a carbon dioxide volume concentration of 20% is injected to carry out a carbonization reaction. The carbonization reaction liquid and excess kiln gas continue to pass into ...

Embodiment 3

[0058] CaCO 3 Limestone with a content greater than 98.5% is calcined at 1050°C for 3 hours to obtain quicklime; quicklime and water are fully digested at a temperature of 80±1°C at a mass ratio of 1:4 to obtain slaked lime slurry; the lime slurry is sieved to remove slag and diluted with water to Ca(OH) 2 The weight concentration is 13%; close the discharge valve 6, open the slurry inlet valve 3, introduce the slurry into the reaction kettle 4 of the present invention, adjust the temperature of the slurry to 20±1°C; start stirring, and turn on the powerful pump 7 after 10 minutes, Powerful pump 7 flow rate Q=40m 3 / h, head H=30m, when the slurry enters the Venturi tube reactor 1, the nozzle diameter is 3mm, and the water outlet speed of the nozzle reaches 40m / s and is atomized into very small droplets, the kiln gas inlet valve 2 is opened to control the flow Kiln gas with a carbon dioxide volume concentration of 25% is injected for a carbonization reaction. The carbonizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com