Convertible milling edge-type milling cutter bar for processing constant-depth tooth arc-bevel gear

A technology of equal-height teeth and milling edges, used in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of easy wear and failure of diamond-shaped blades, and achieve the effect of improving life, avoiding regrinding and reloading, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

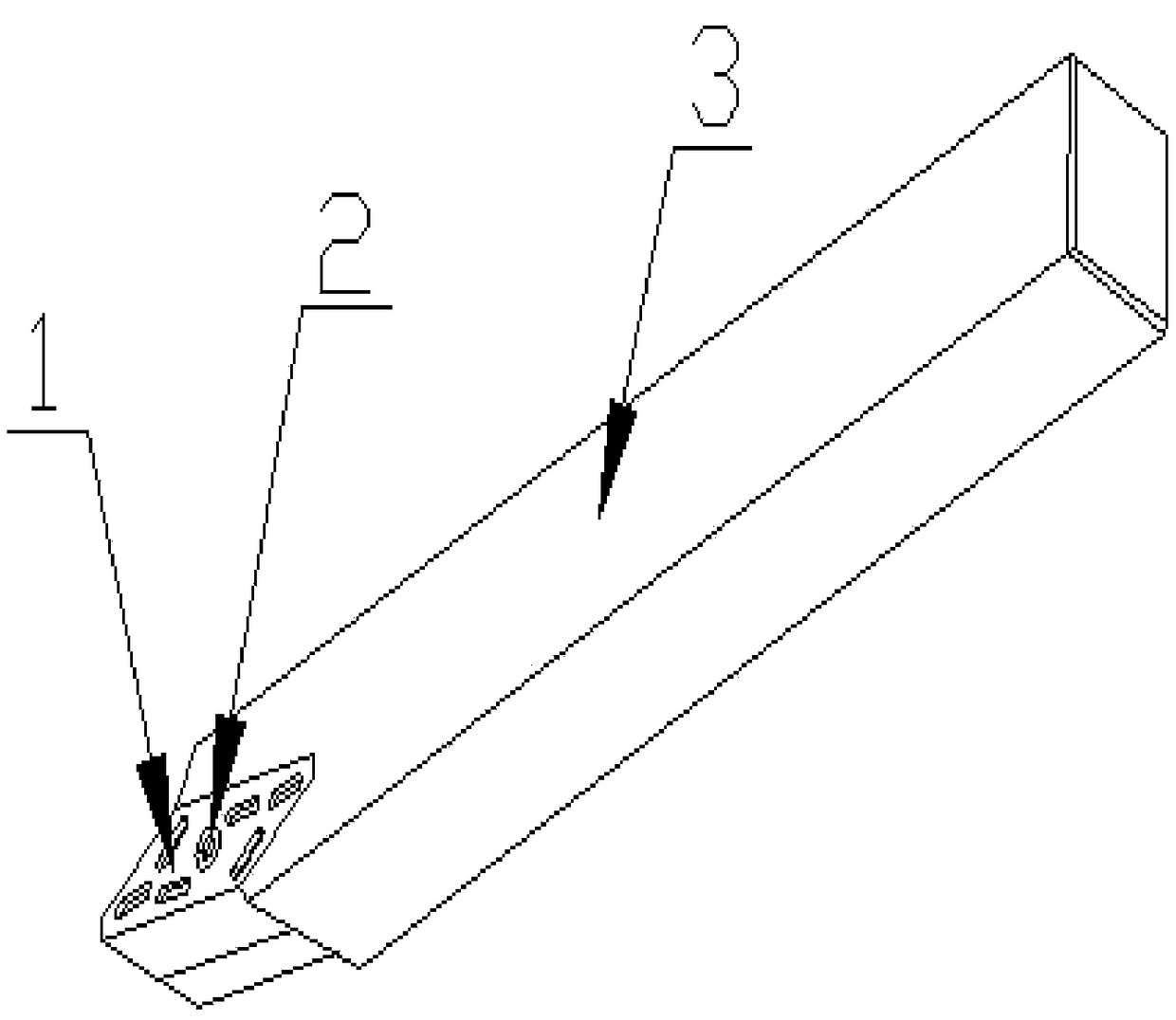

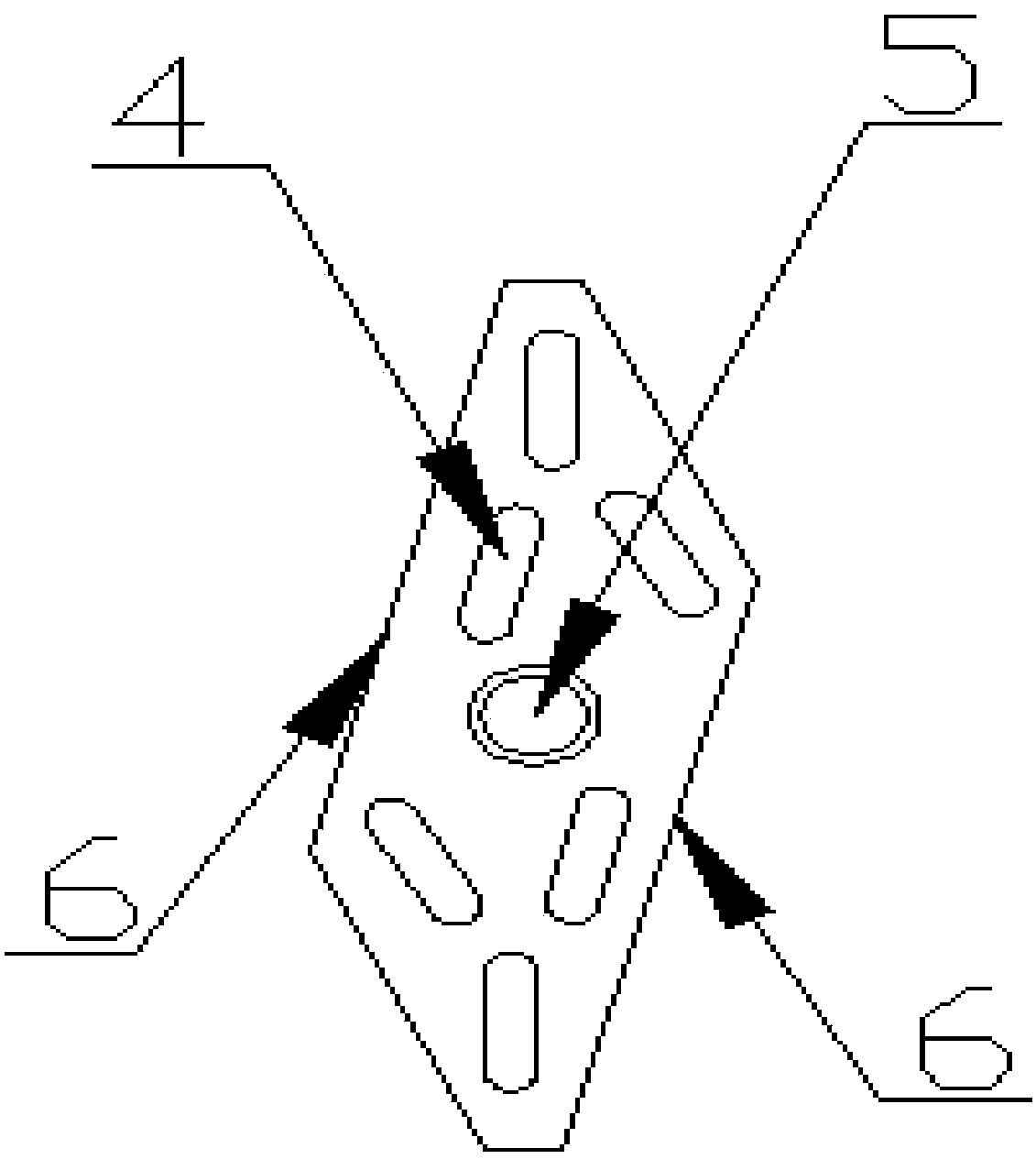

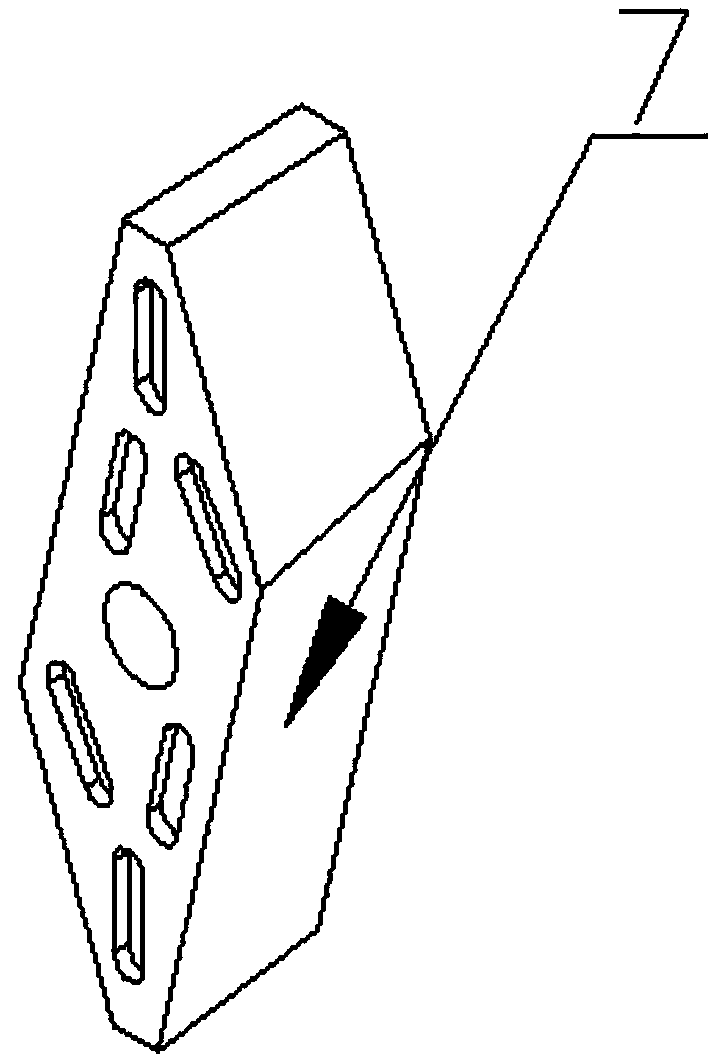

[0013] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a convertible milling edge milling cutter bar for processing equal-height arc bevel gears, including a diamond-shaped blade 1, a screw 2, and a cutter body 3; the cutter body 3 is a cuboid structure, and the cutter body 3 One end is provided with a half diamond-shaped groove, and the bottom of the groove is provided with a diamond-shaped bearing piece 10, and the diamond-shaped bearing piece 10 is integrally arranged with the cutter body 3; the center of the diamond-shaped bearing piece 10 is provided with a countersunk screw hole (5); Set on the diamond-shaped bearing sheet 10, half of the diamond-shaped blade 1 is set in half of the diamond-shaped groove of the cutter body 3, and the center of the diamond-shaped blade 1 is provided with a countersu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com