Seat

a seat and seat technology, applied in the field of seats, can solve the problems of adjusting mechanism noise, unfavorable seat-adjusting mechanism adjustment, and spindle unit being jammed against the end stop of the seat-adjusting mechanism,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

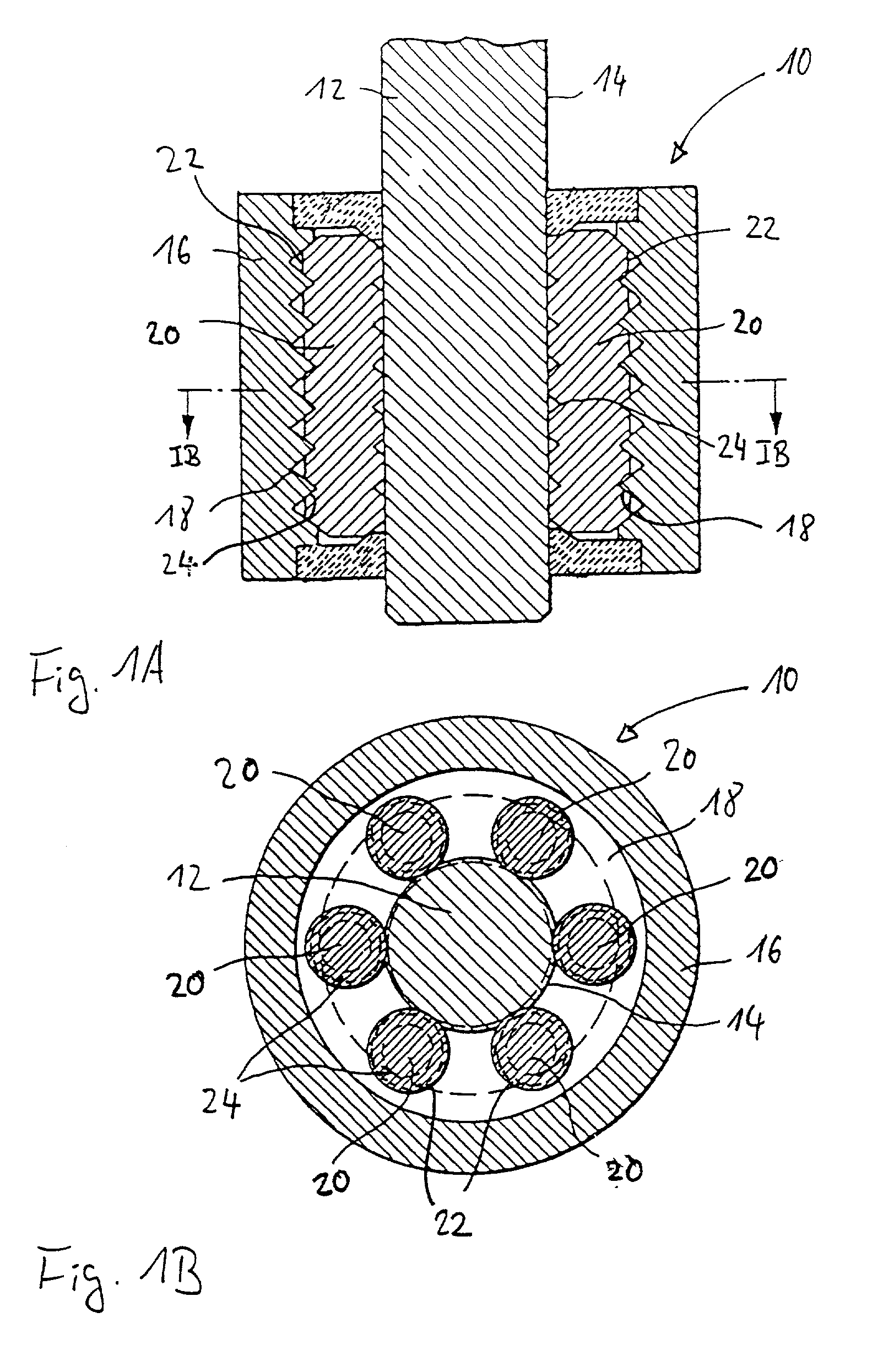

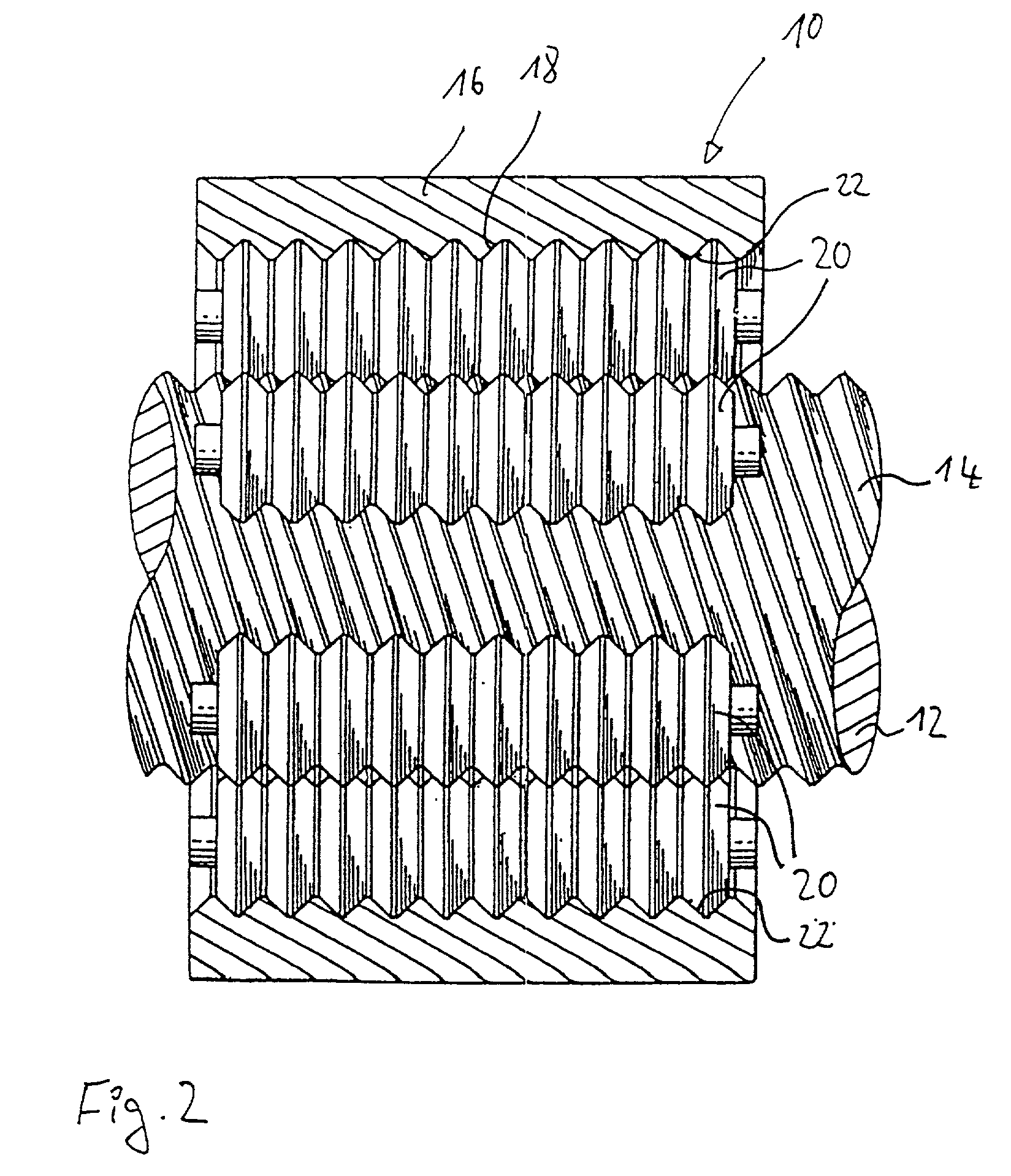

[0031] FIGS. 1A and 1B show a first exemplary embodiment of a spindle unit 10 suitable for incorporation into a seat according to the invention. FIG. 1A shows an axial section through the spindle unit 10 and FIG. 1B shows a section along the line IB-IB in FIG. 1A. A spindle unit of this type is disclosed for example in EP 0 320 621 B1 herewith incorporated by reference. In the case of a seat according to the invention, it is possible to provide a spindle unit having all the features disclosed in EP 0 320 621 B1.

[0032] The spindle unit 10 illustrated in FIGS. 1A and 1B comprises a spindle 12 having an outer thread 14 and a hollow cylindrical nut 16 which surrounds the outside of the spindle 12 radially and has a plurality of coarse V-shaped grooves 18. Six rollers 20 are arranged in planetary manner between the spindle 12 and the nut 16. Each of the rollers 20 has two different, radially outer profiled portions in the form of a first grooved profile 22 and a second grooved profile 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com