Twin-worm drive swing driving device

A technology of rotary drive and double worm, which is applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of excessive worm clearance, inaccurate positioning, easy damage and failure, etc., and achieves convenient maintenance, simple installation and good structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] How to implement the present invention will be described below in conjunction with the accompanying drawings.

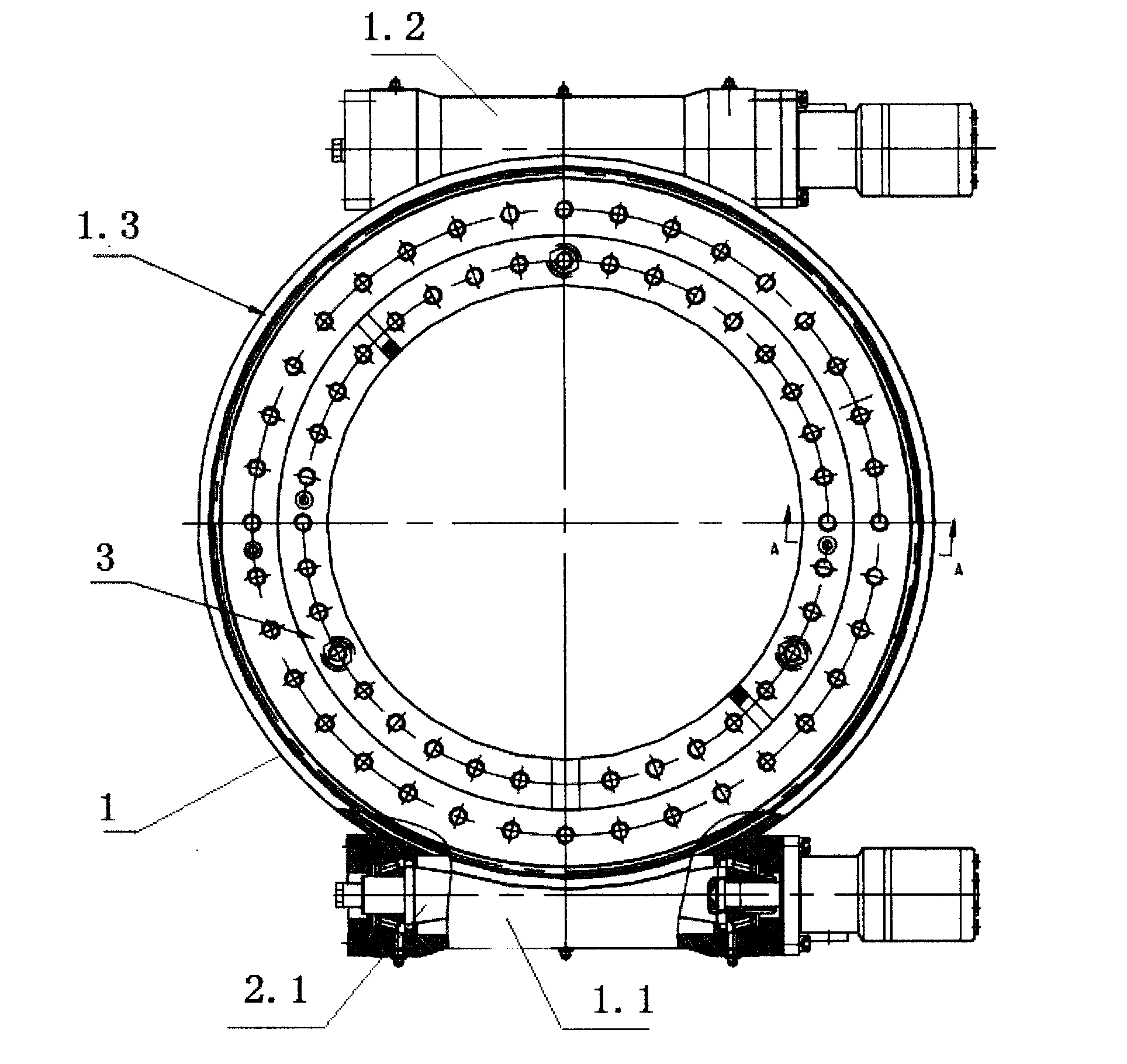

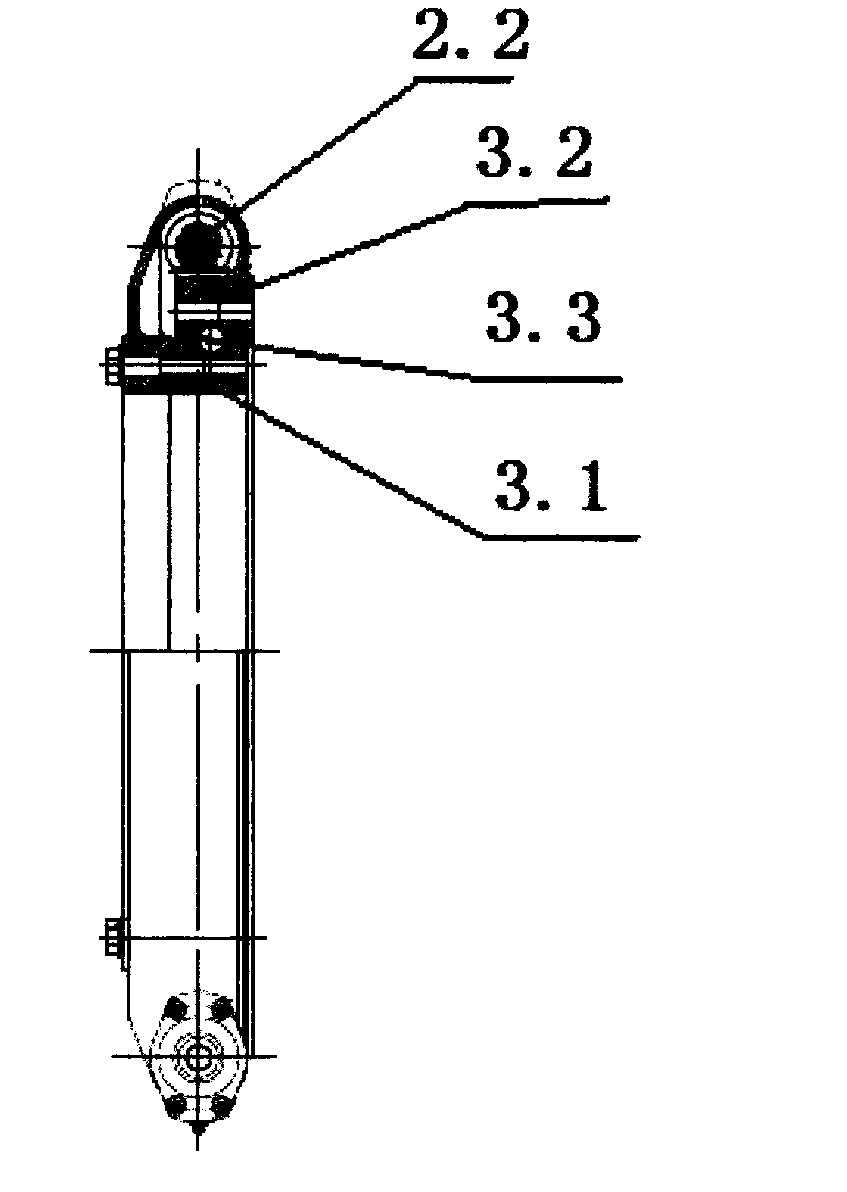

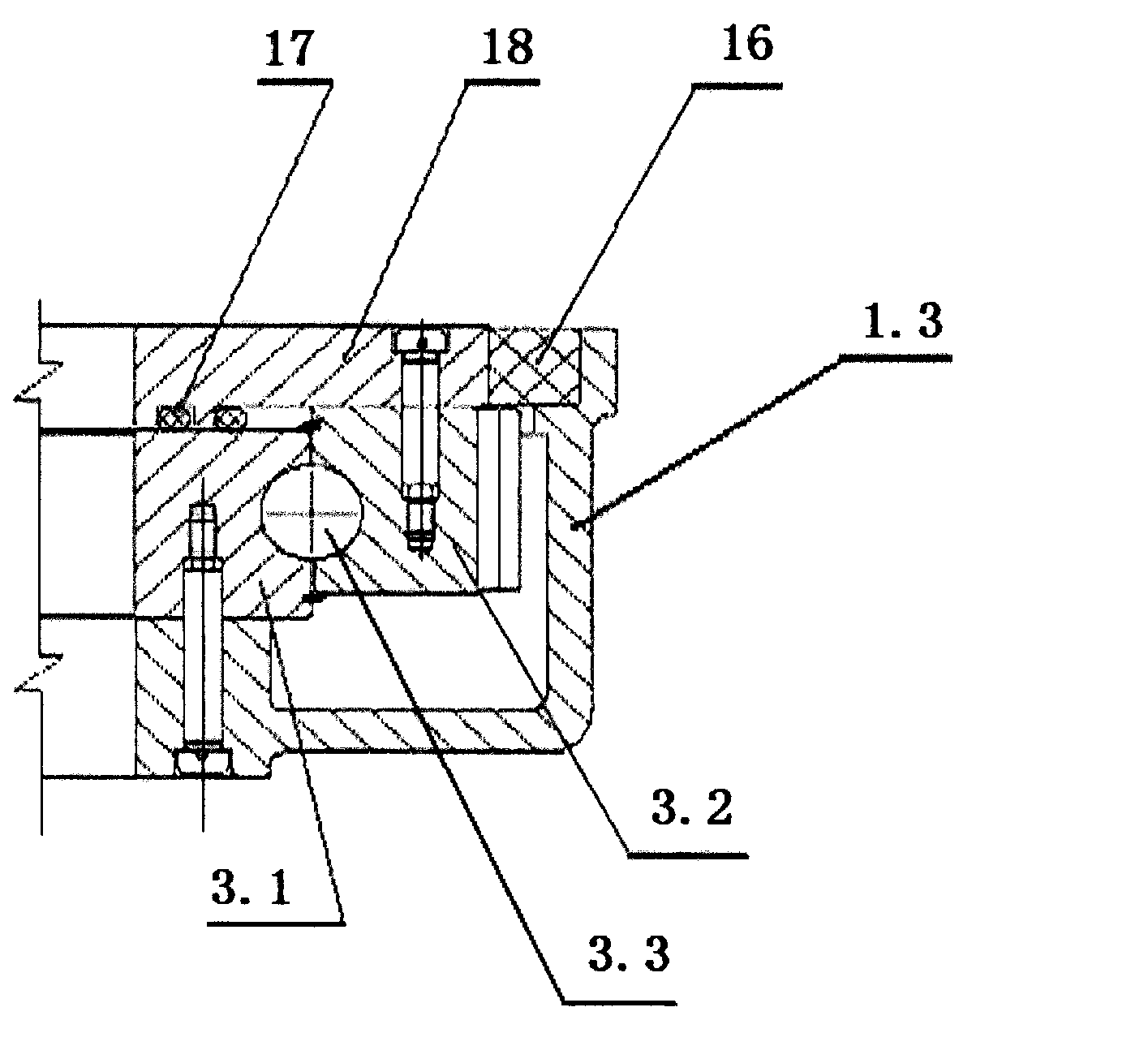

[0019] like figure 1 , 2 , 3, the double worm drive slewing drive device of the present invention can be implemented in the following manner, including a base 1, a slewing support 3, and the slewing support 3 includes an inner ring 3.1, an outer ring gear 3.2 and embedded in the inner ring 3.1 and The balls 3.3 between the outer ring gear 3.2, the outer ring gear 3.2 are provided with several mounting screw holes, the inner ring 3.1 is fixed above the seat ring 1.3 of the base 1, and the outer ring 1.3 of the base 1 is also provided with a second A shaft housing 1.1 and a second shaft housing 1.2, the axis lines of the first shaft housing 1.1 and the second shaft housing 1.2 and the axis line of the seat ring 1.3 are perpendicular to each other in space, and the first shaft housing 1.1 is installed with The first worm 2.1, the second shaft housing 1.2 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com