Double-wedge-shaped hydraulic chuck for drilling machine

A hydraulic chuck and double-wedge technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of large space size of power pump and chuck, increase of system pressure, increase of action area, etc., and achieve novel and reasonable structure, The effect of small radial dimension and large clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

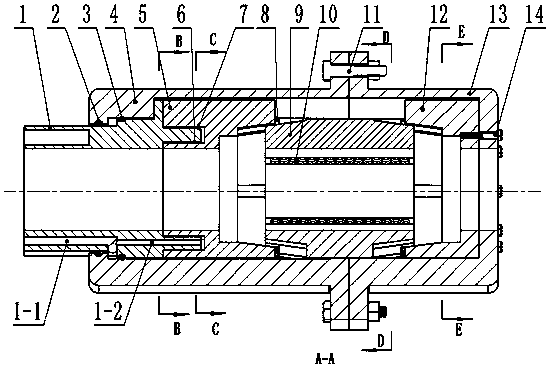

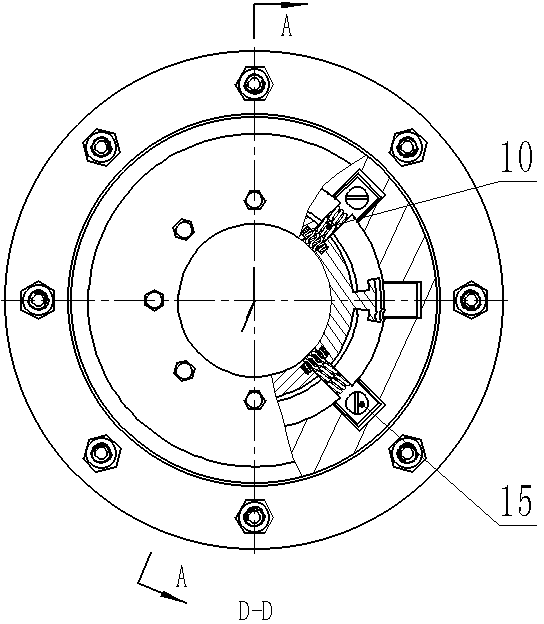

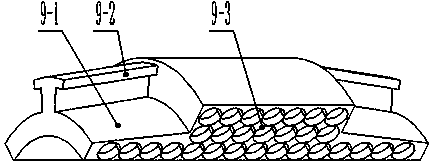

[0014] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 The present invention is further described.

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] The present invention is composed of inner cylinder body (1), inner cylinder body sealing ring A (2), inner cylinder body sealing ring B (3), rear outer cylinder body (4), rear ring sleeve (5), inner cylinder body- Small seal ring for ring sleeve (6), large seal ring for inner cylinder body-ring sleeve (7), buffer gasket (8), 4 double wedge slips (9), spring group (10), connecting bolts for outer cylinder body Group (11), front ring sleeve (12), front outer cylinder body (13), front cylinder body-front ring sleeve connecting screw group (14) and buffer washer locking screw group (15).

[0017] The inner cylinder body (1) is connected with the main shaft of the rotary device of the drilling rig or the main shaft connector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com