Elastic coupling of one-way precise diaphragm

A technology of elastic couplings and precision membranes, applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problem of small bending moments of input shafts and driving shafts, small ability to withstand alternating loads and impact loads, etc. problem, to achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

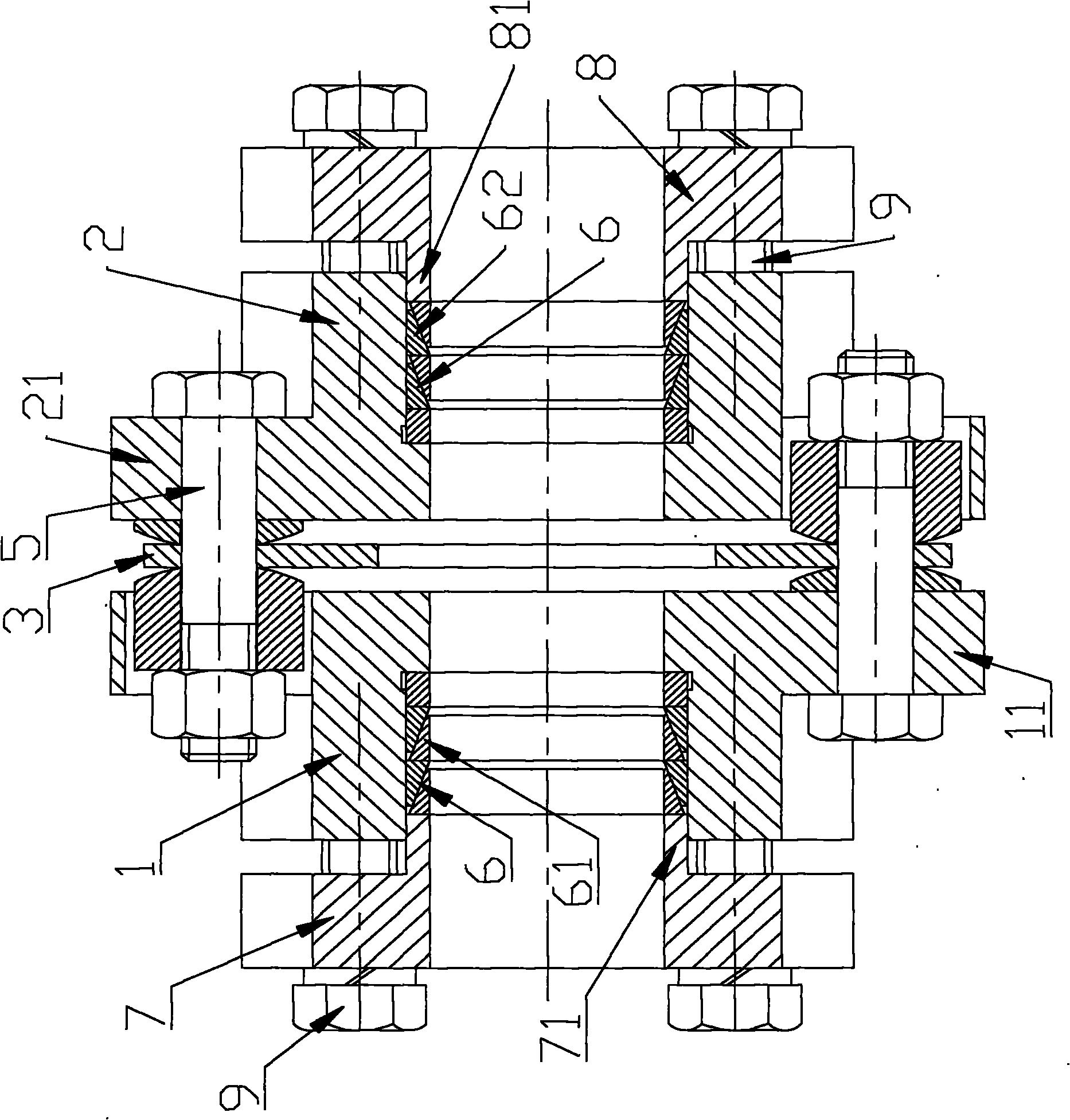

[0011] figure 1 The one-way precision diaphragm elastic coupling shown includes an input shaft 1 with a flange 11 at one end, an output shaft 2 with a flange 21 at one end, and the connection between the input shaft flange and the output shaft flange A diaphragm 3 is arranged between them; the input shaft flange, the output shaft flange and the diaphragm between them are connected by bolts 5 .

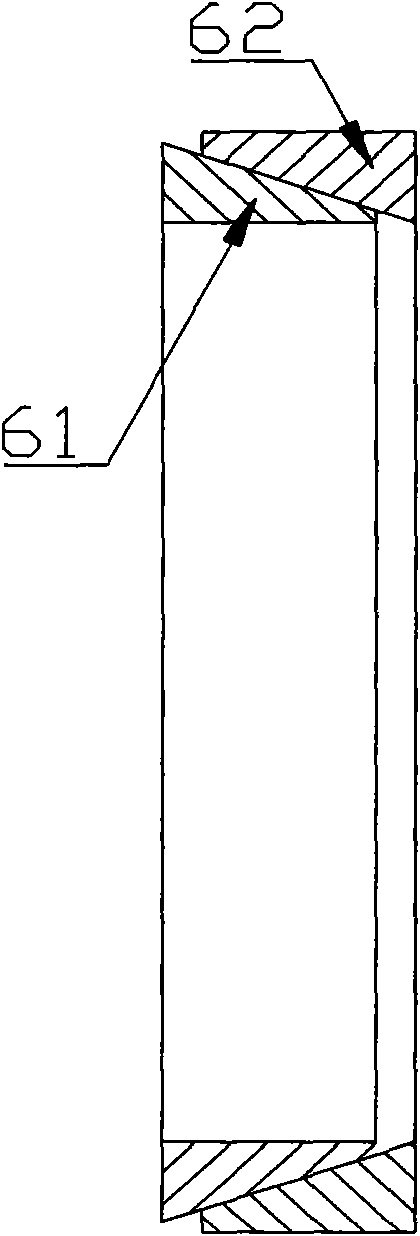

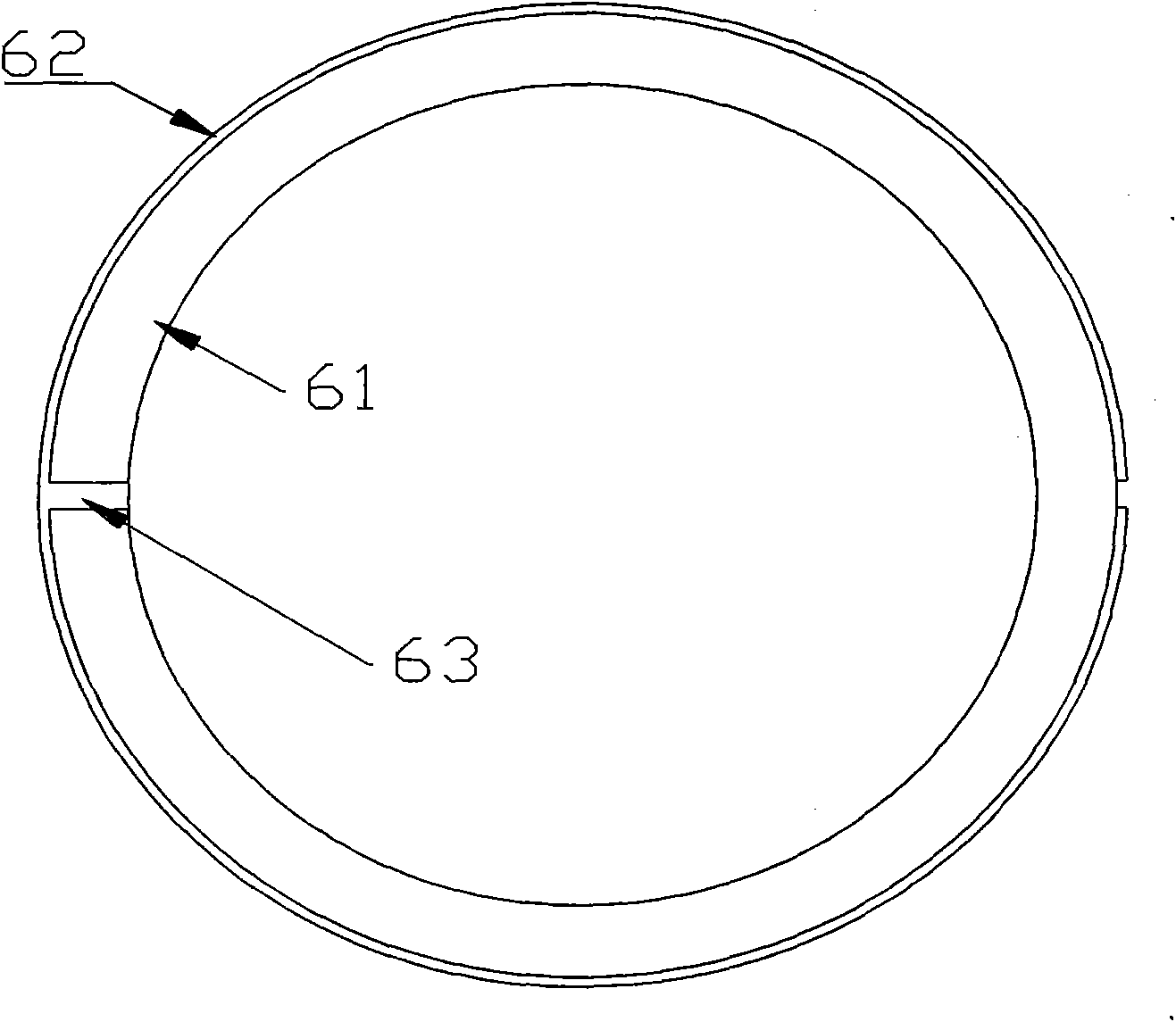

[0012] Two expansion sleeves 6 are respectively arranged in the shaft holes of the input shaft and the output shaft. The expansion sleeve includes an inner cone ring 61 and an outer cone ring 62. The inner cone ring is a circumferentially unclosed cone with radial slots 63, and the outer cone ring is a circumferentially unclosed cone with radial slots 64. . The outer peripheral surface of the inner cone ring and the inner peripheral surface of the outer cone ring are matching taper surfaces.

[0013] The two end covers 7, 8 are respectively connected to the input shaft 1 and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com