Automobile synchronizer

A synchronizer, automobile technology, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of poor synchronization, small axial force, and long synchronization time of the synchronizer, and achieve increased axial force and shift control. The effect of force reduction and synchronization time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

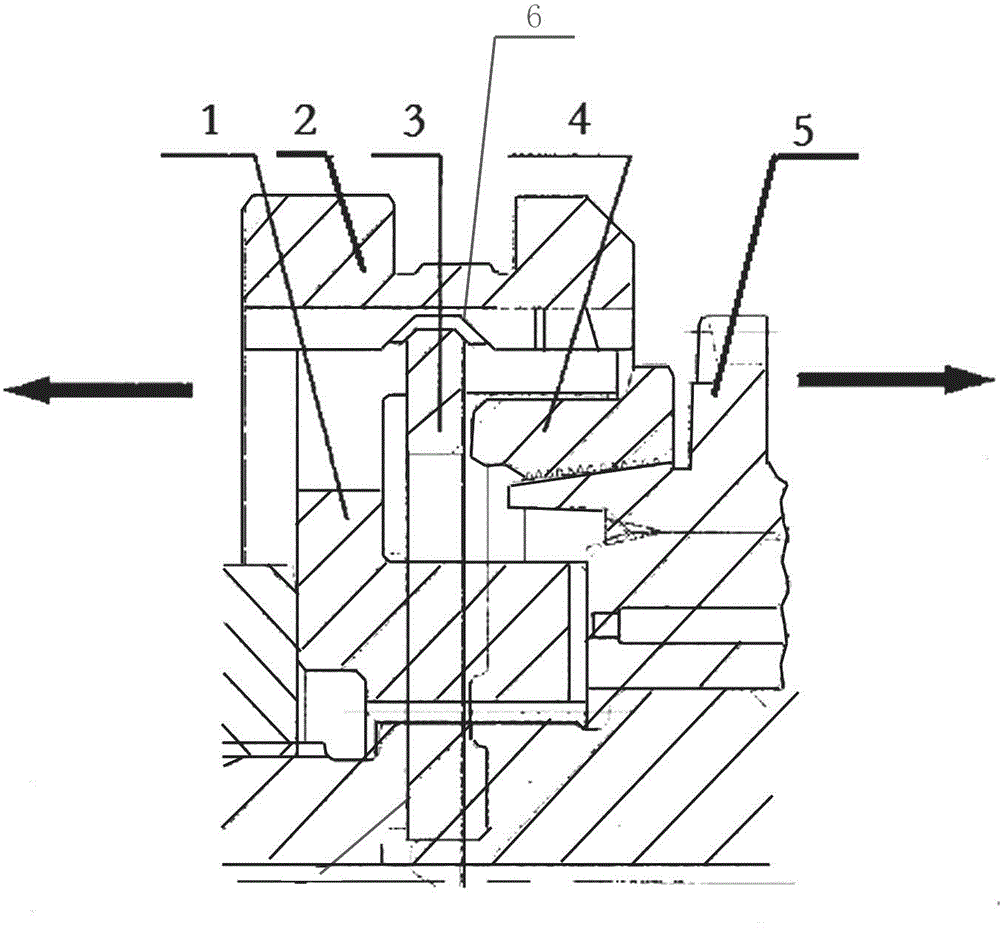

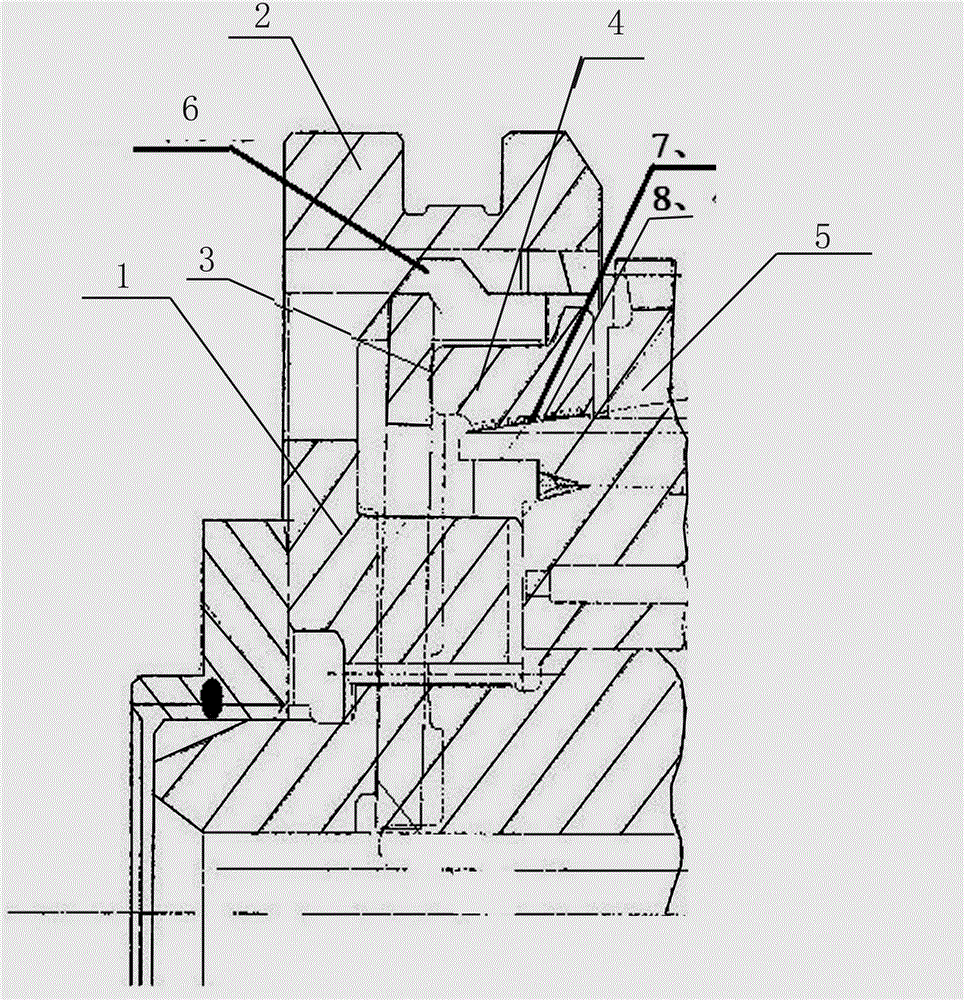

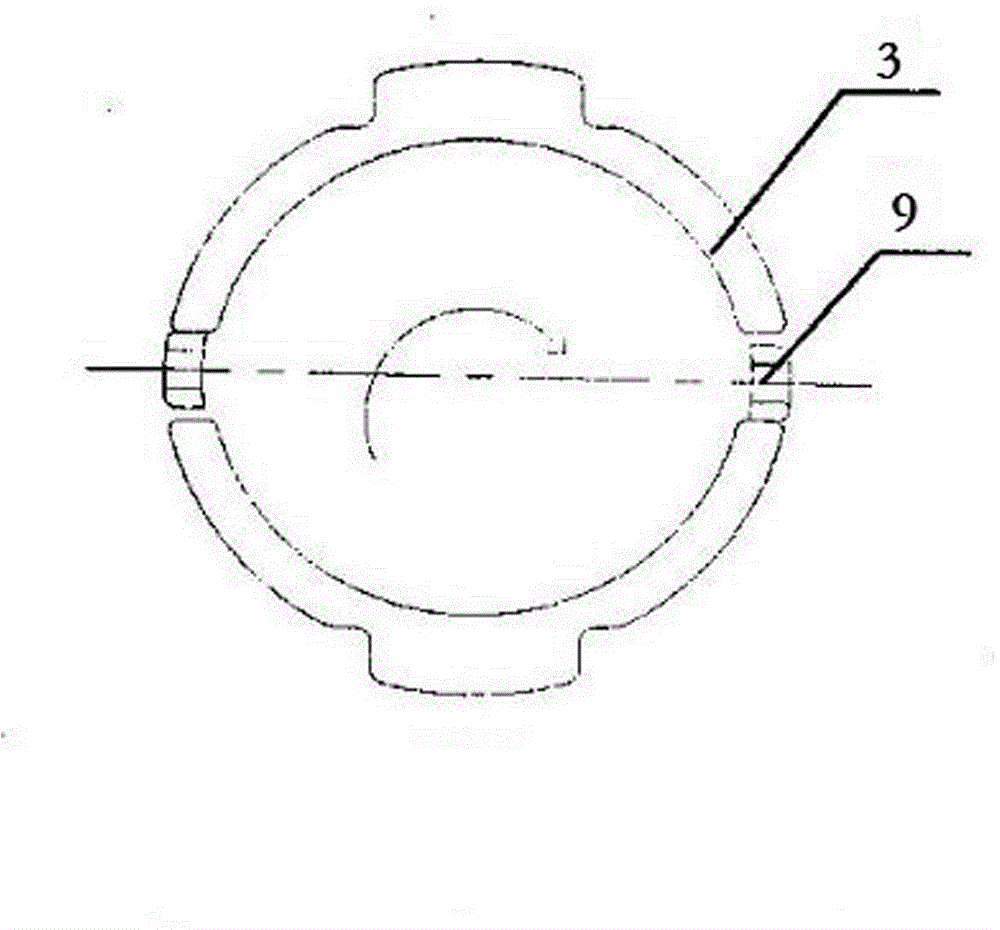

[0010] exist figure 1 , figure 2 and image 3 Among them, the present invention provides an automobile synchronizer, which includes a synchronous gear hub 1, a synchronous sliding sleeve 2, a synchronous joystick 3, a synchronous ring 4 and a synchronous cone hub 5, and the synchronous sliding sleeve 2 is sequentially The synchronous gear hub 1, the synchronous joystick 3, the synchronous ring 4 and the synchronous cone hub 5, the synchronous sliding sleeve 2 is set on the synchronous gear hub 1 and connected with the synchronous gear hub 1, and the synchronous sliding sleeve 2 and the synchronous gear hub 1 are flowers The key connection, the annular groove 6 provided on the inner wall of the synchronous sliding sleeve 2, the annular groove 6 is arranged on the inner spline provided on the inner wall of the synchronous sliding sleeve 2, the synchronous sliding sleeve 2 is set on the synchronous ring 4 and the synchronous ring 4 One side of the synchronous ring 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com