Fluid line for connection with a coupling

a technology of coupling and pipe, which is applied in the direction of hose connection, coupling, battery, etc., can solve the problem of not holding true for the outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

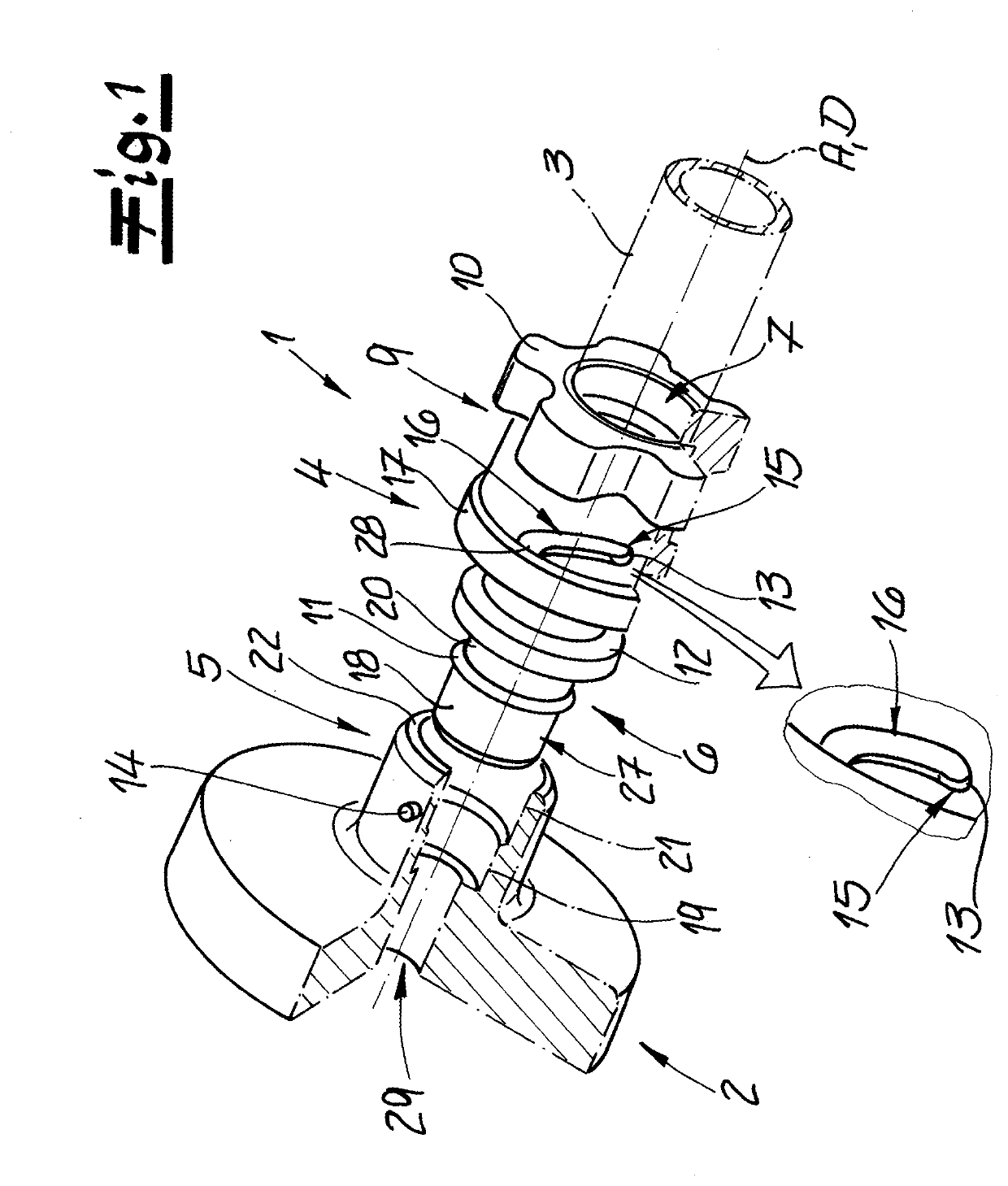

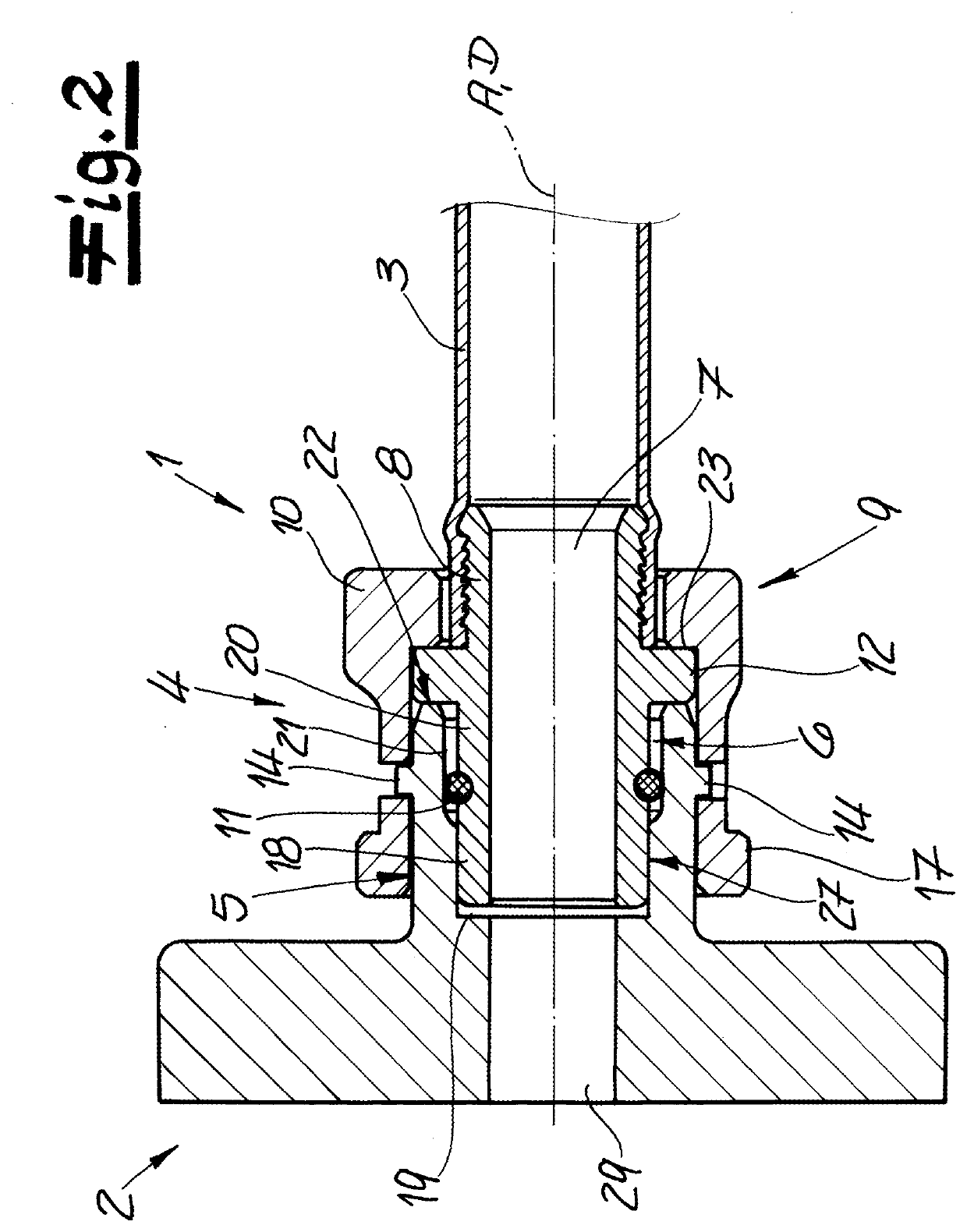

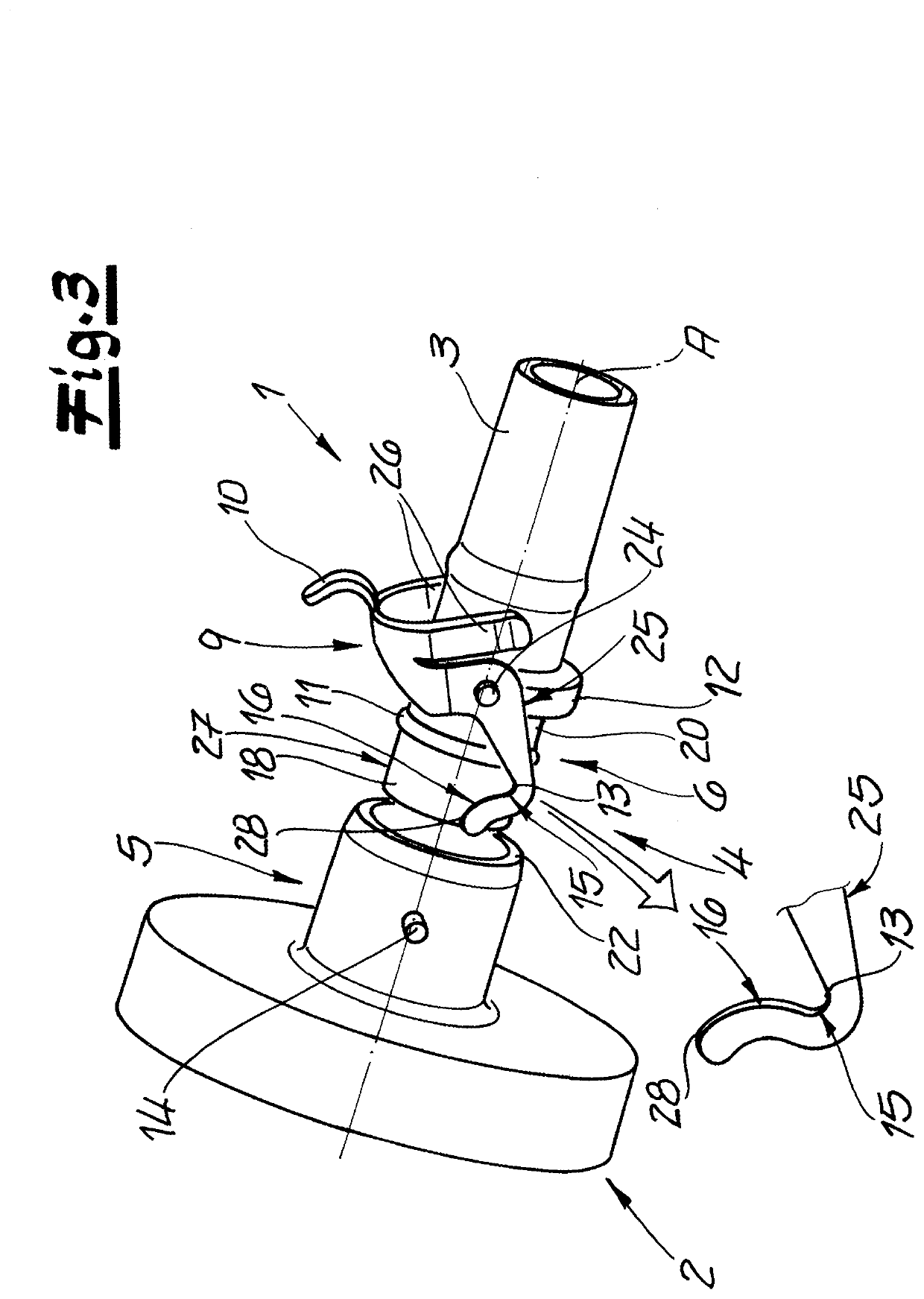

[0044]Shown on FIG. 1 is a first exemplary embodiment of a connector 4 according to the disclosure. The connector 4 comprises a main body 6 as well as a locking element 9, which in this exemplary embodiment is bayonetlike in design. The main body 6 and locking element 9 are preferably separately designed elements. The main body 6 and / or locking element 9 is / are (each) preferably one-piece or integral in design. The connector 4 is a component part of a fluid line 1, which apart from the connector 4 in particular has a tube 3 as well. The tube 3 is connected with the connector 4, as will be illustrated in somewhat more detail later. The connector 4 or main body 6 has a preferably cylindrically designed fluid channel 7. The fluid channel 7 or main body 6 defines an axis A, which preferably is a rotational axis or a longitudinal axis of the main body 6. It is expedient that the fluid channel 7 connect a first end of the connector 4 or main body 6 facing the coupling 5 with a second end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com