Patents

Literature

229results about How to "Production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

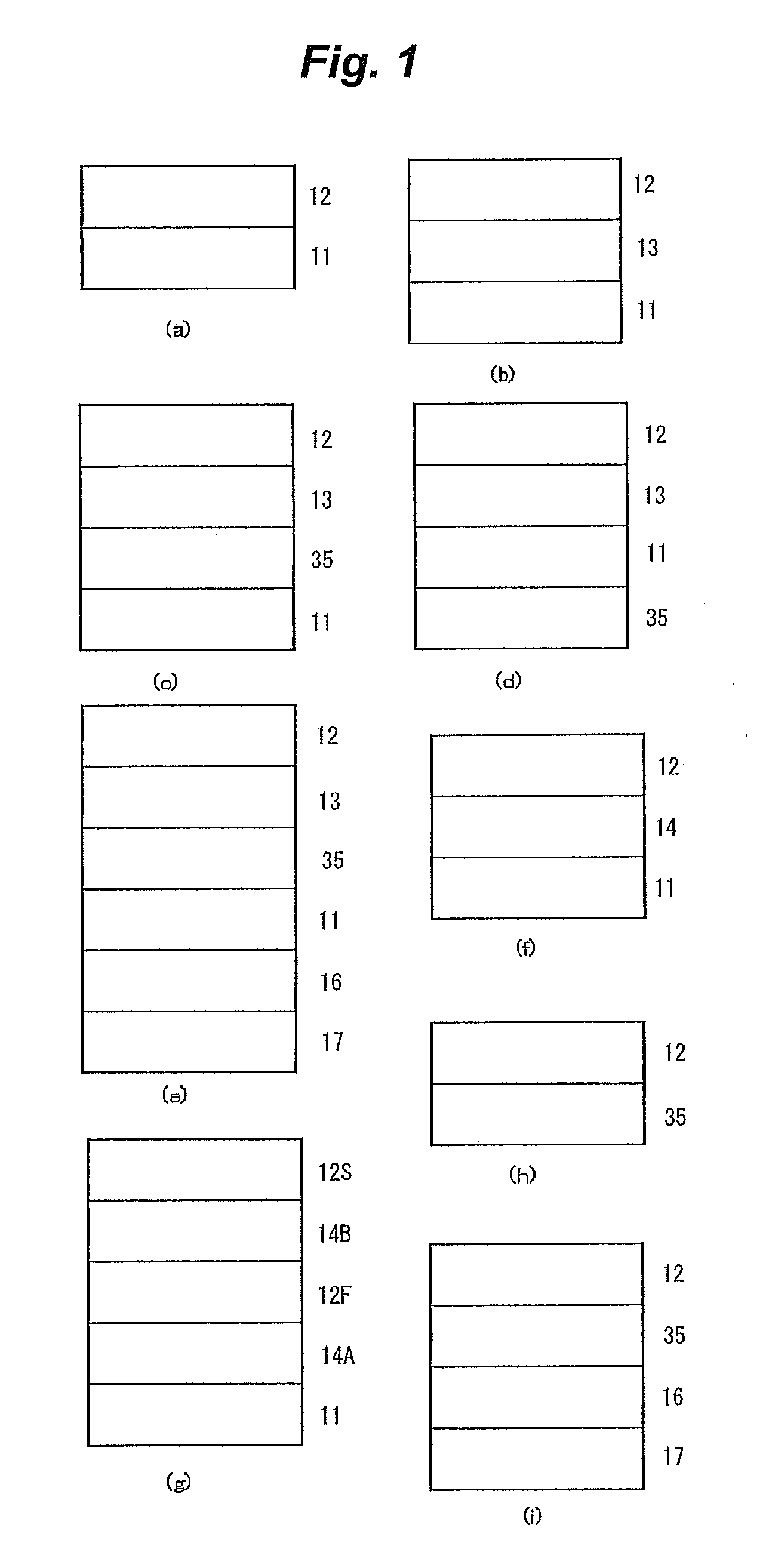

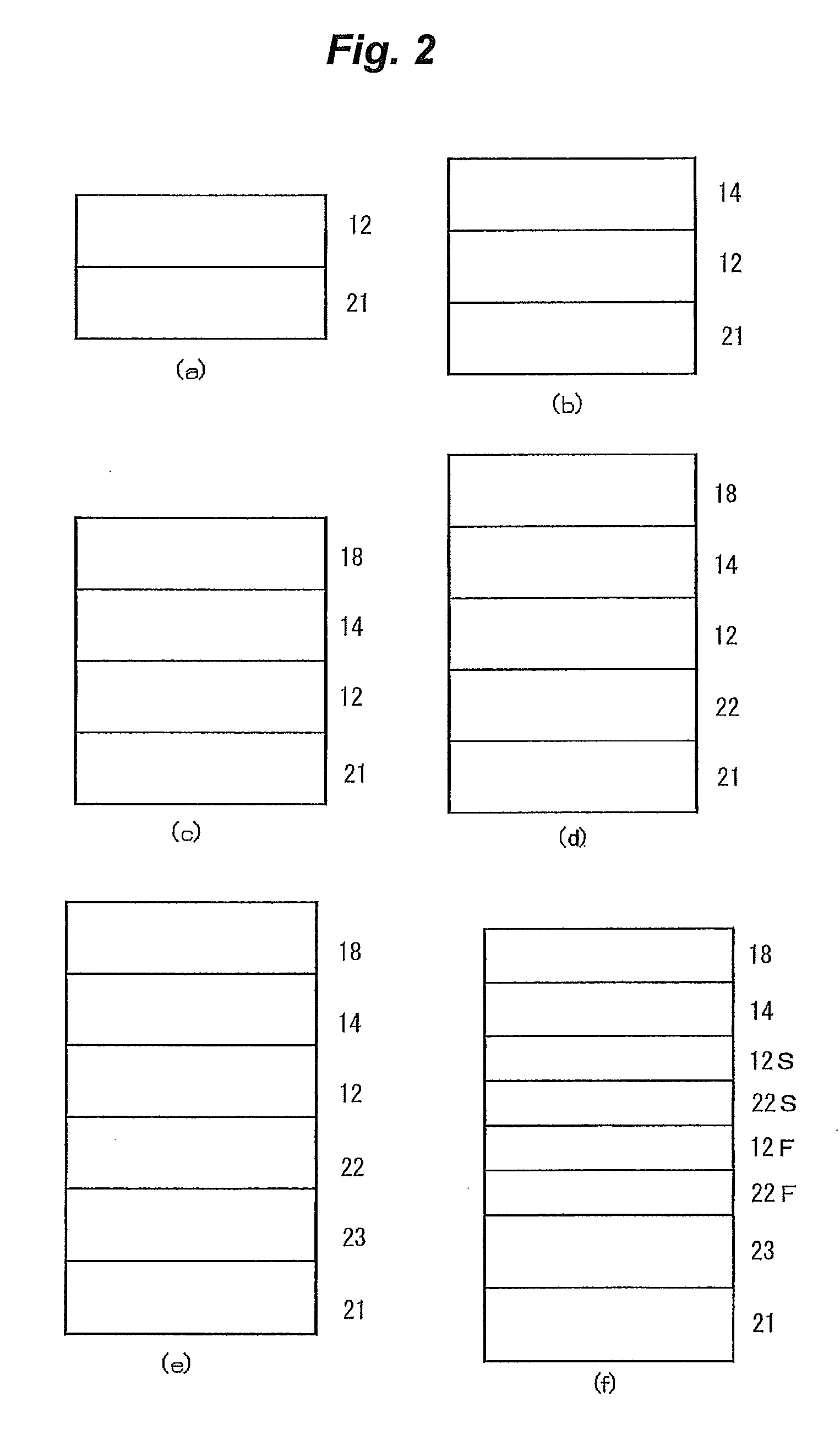

Process for production of semiconductor substrate

InactiveUS7148119B1Improve productivityLow costSemiconductor/solid-state device detailsSolid-state devicesPorous layerSemiconductor

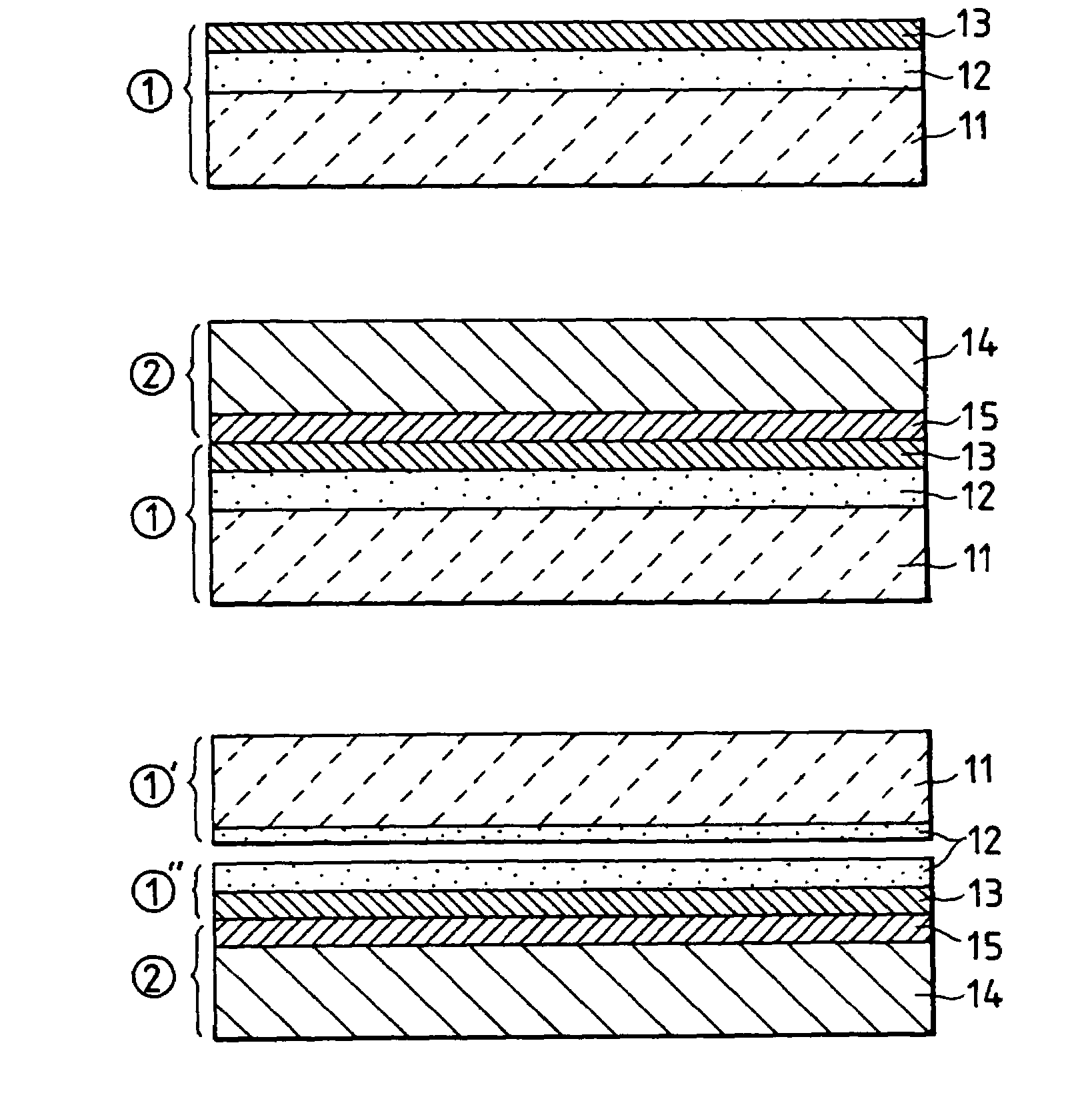

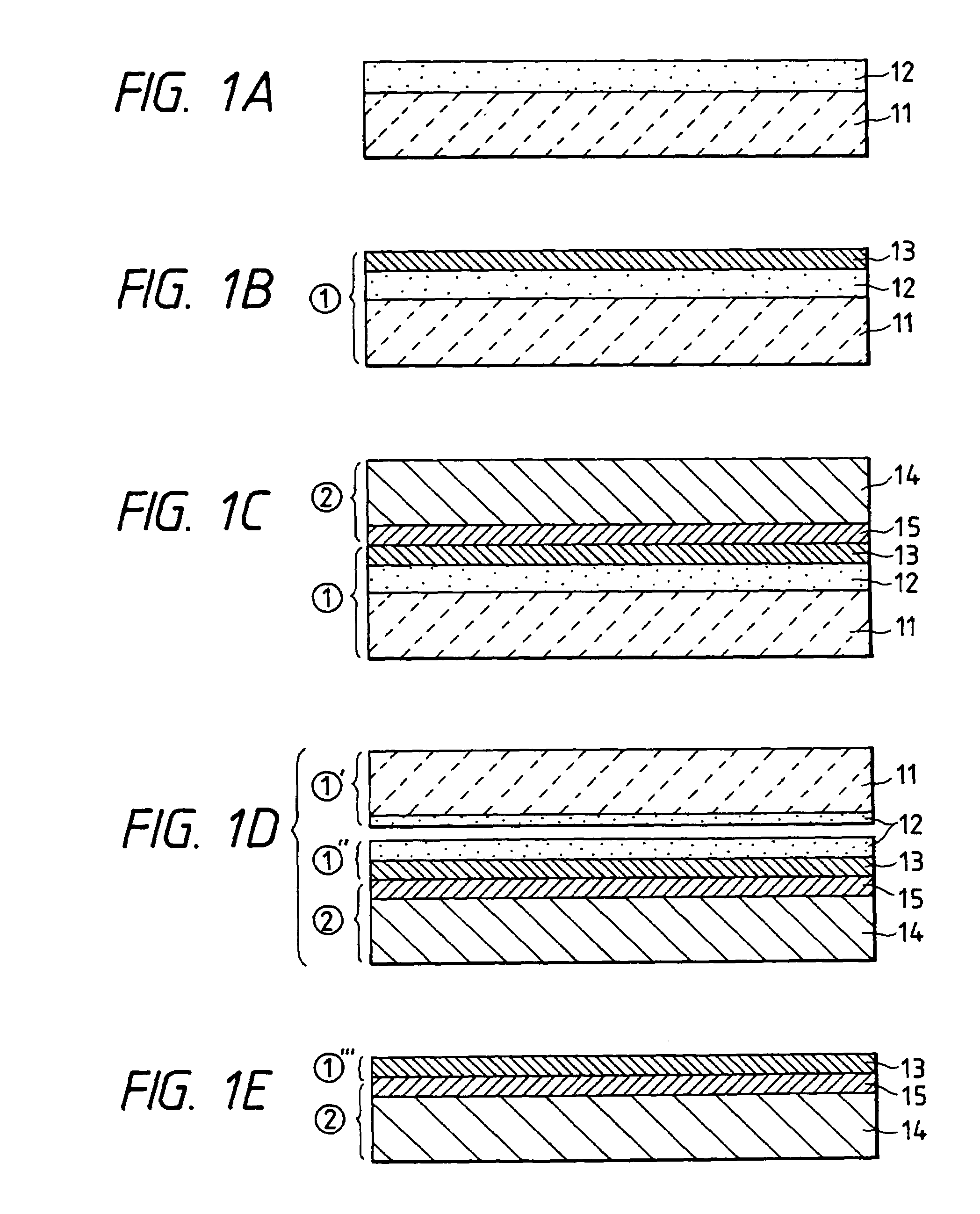

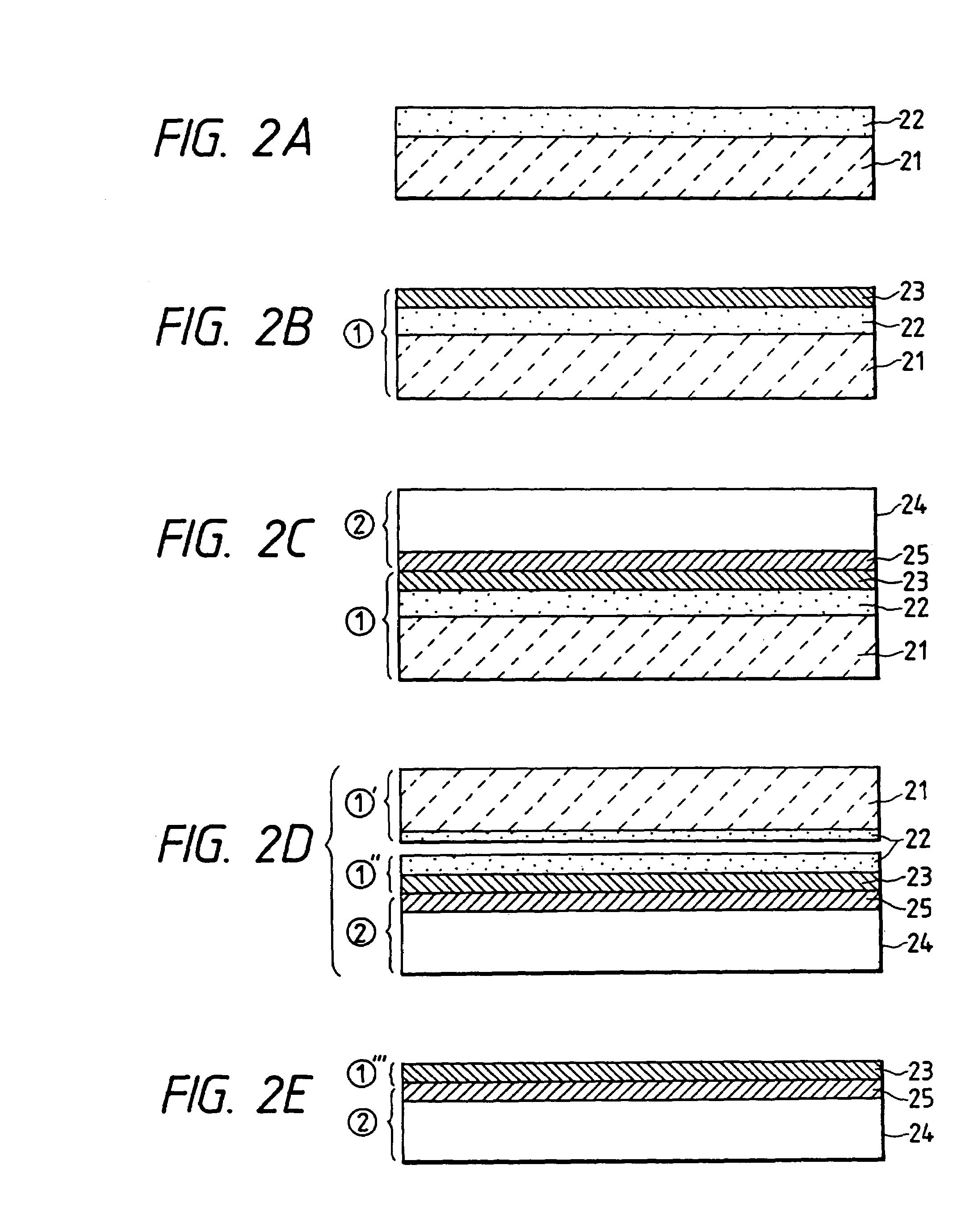

A process for producing a semiconductor substrate is provided which comprises steps of forming a porous layer on a first substrate, forming a nonporous monocrystalline semiconductor layer on the porous layer of the first substrate, bonding the nonporous monocrystalline layer onto a second substrate, separating the bonded substrates at the porous layer, removing the porous layer on the second substrate, and removing the porous layer constituting the first substrate.

Owner:CANON KK

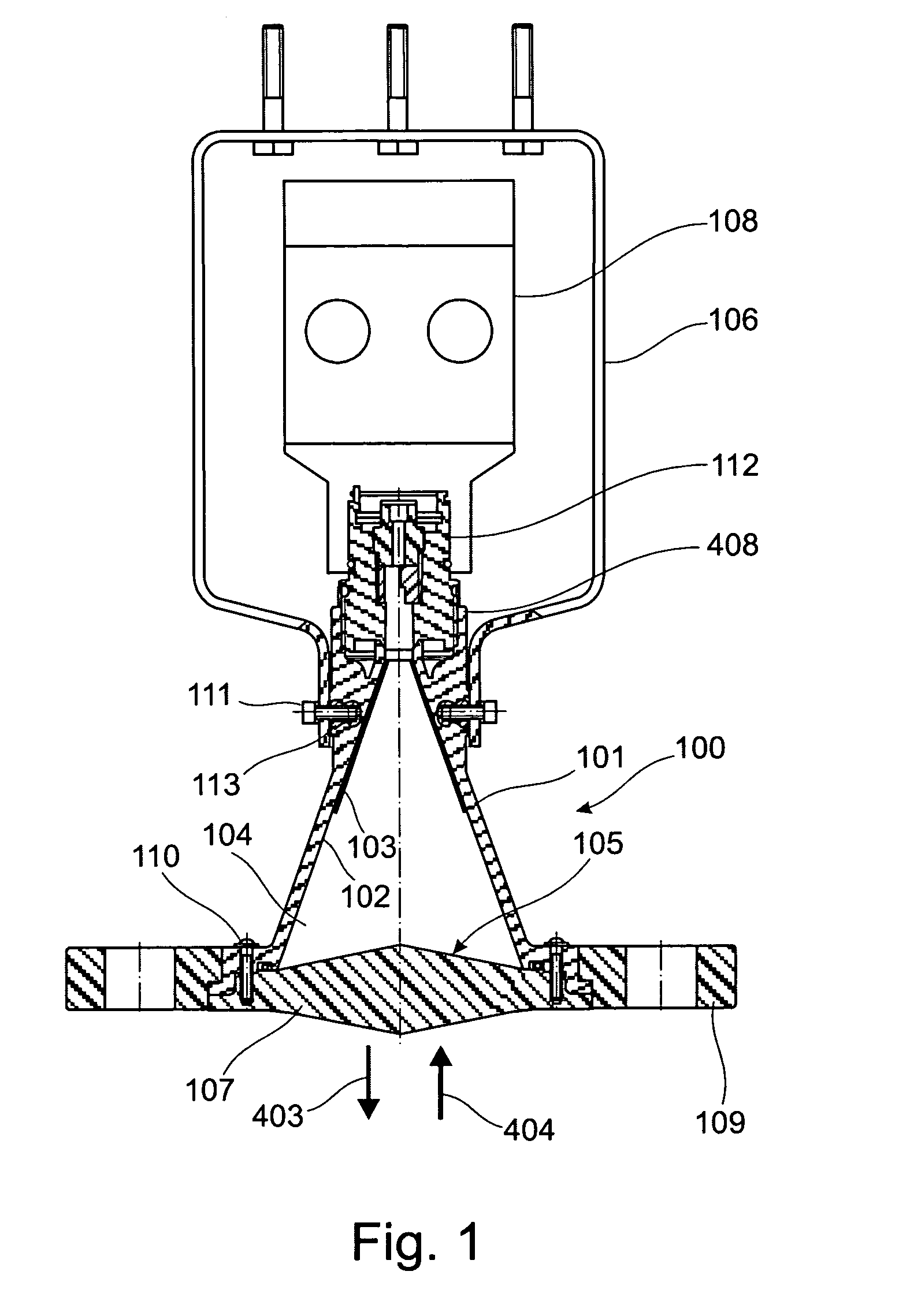

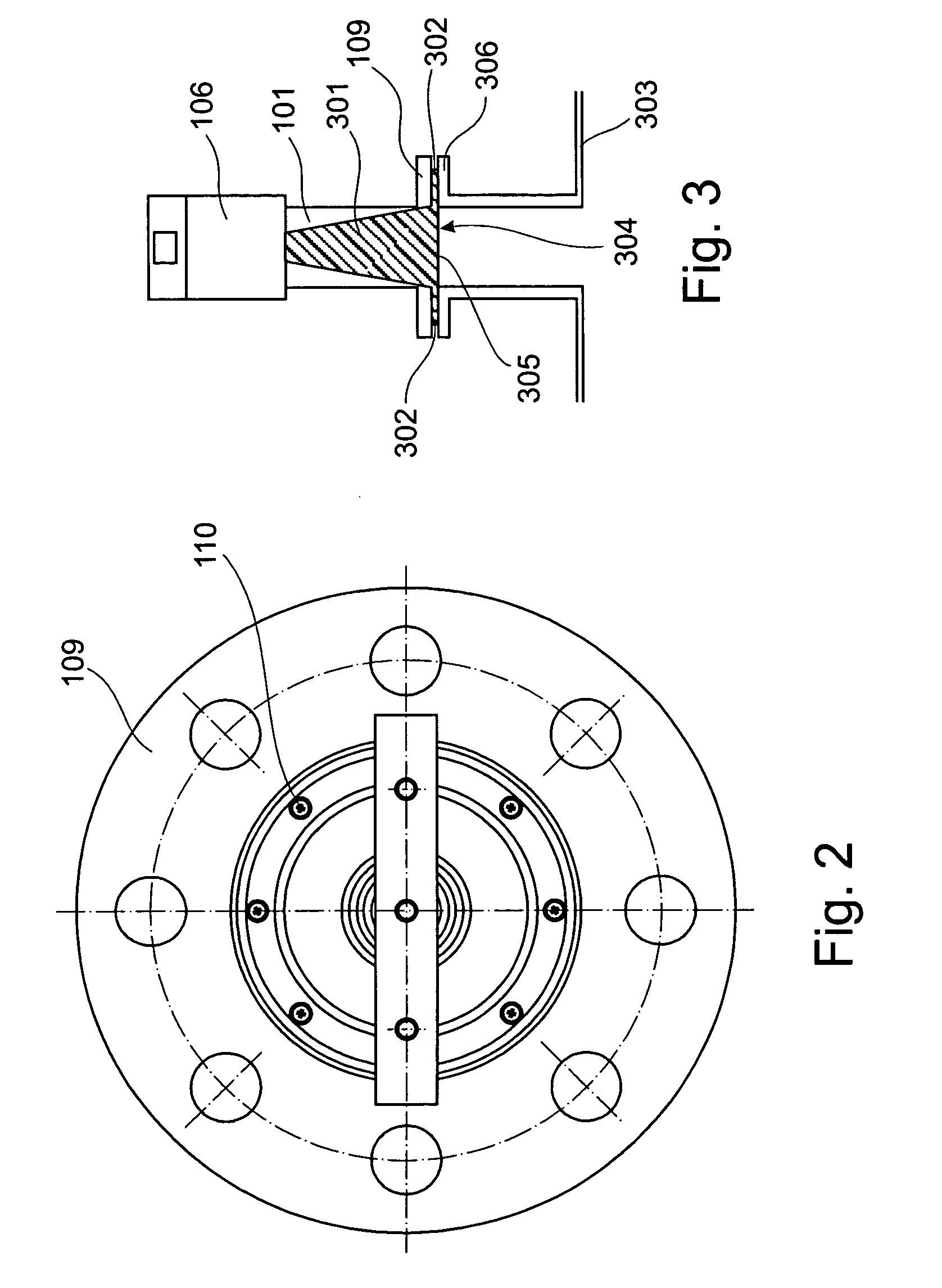

Metallised plastic antenna funnel for a fill level radar

A metalized plastic antenna includes a plastic antenna body with metallization on the inside. In this arrangement metallization is used for conducting electromagnetic waves. Furthermore, metallization may be implemented as a protective coating so that chemical resistance of the plastic antenna may be ensured even in the case of corrosive environmental conditions.

Owner:VEGA GRIESHABER GMBH & CO

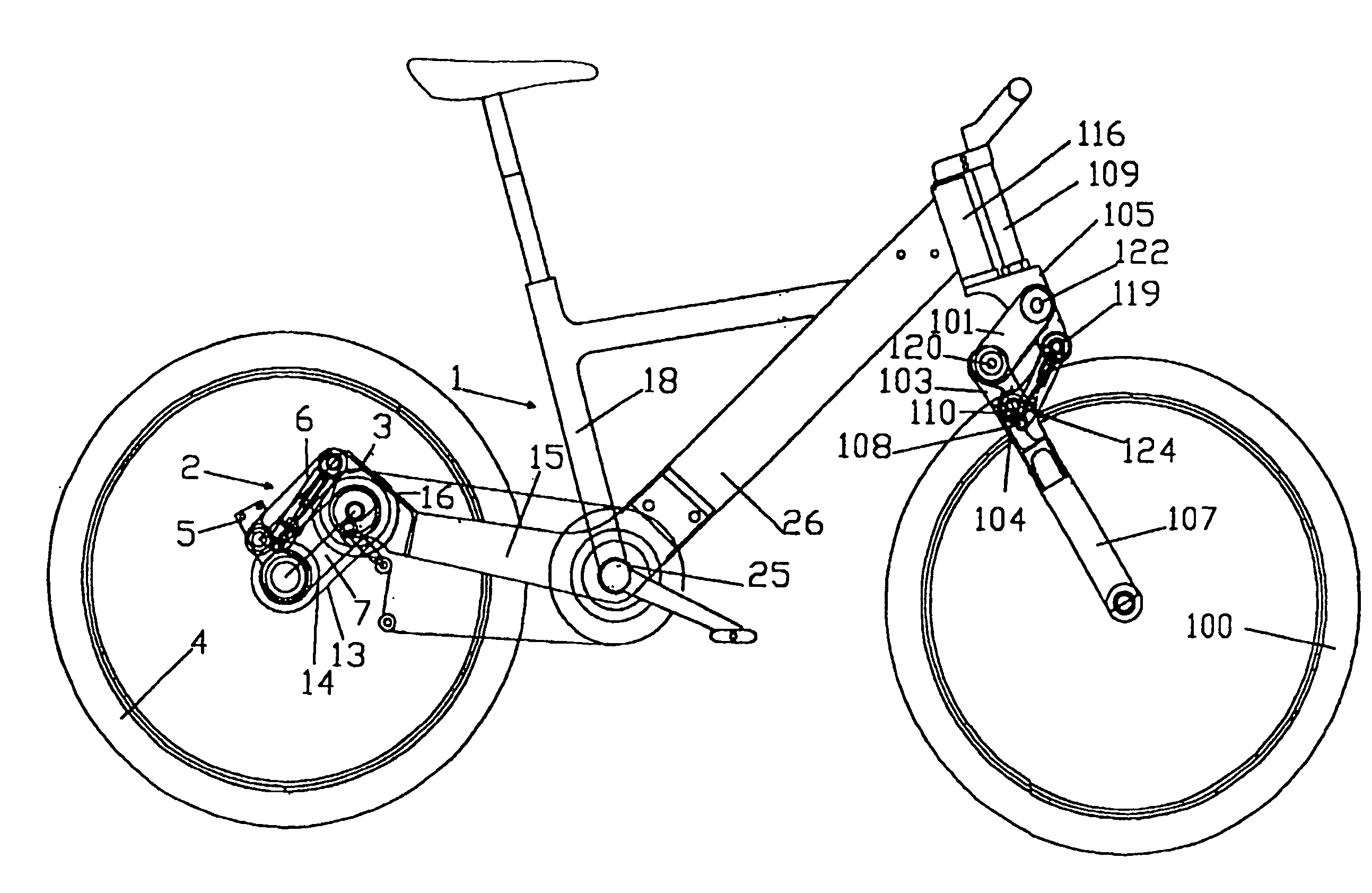

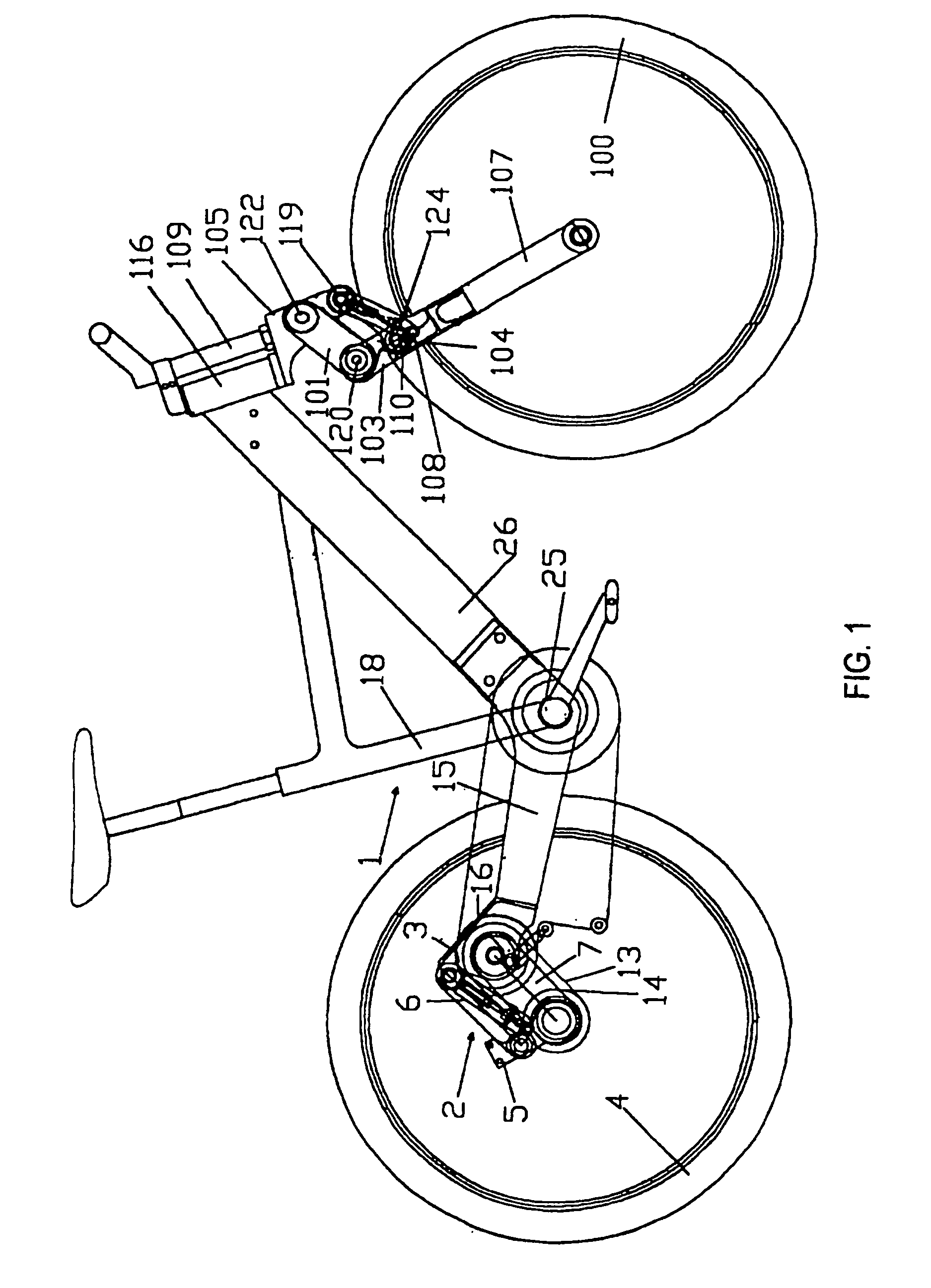

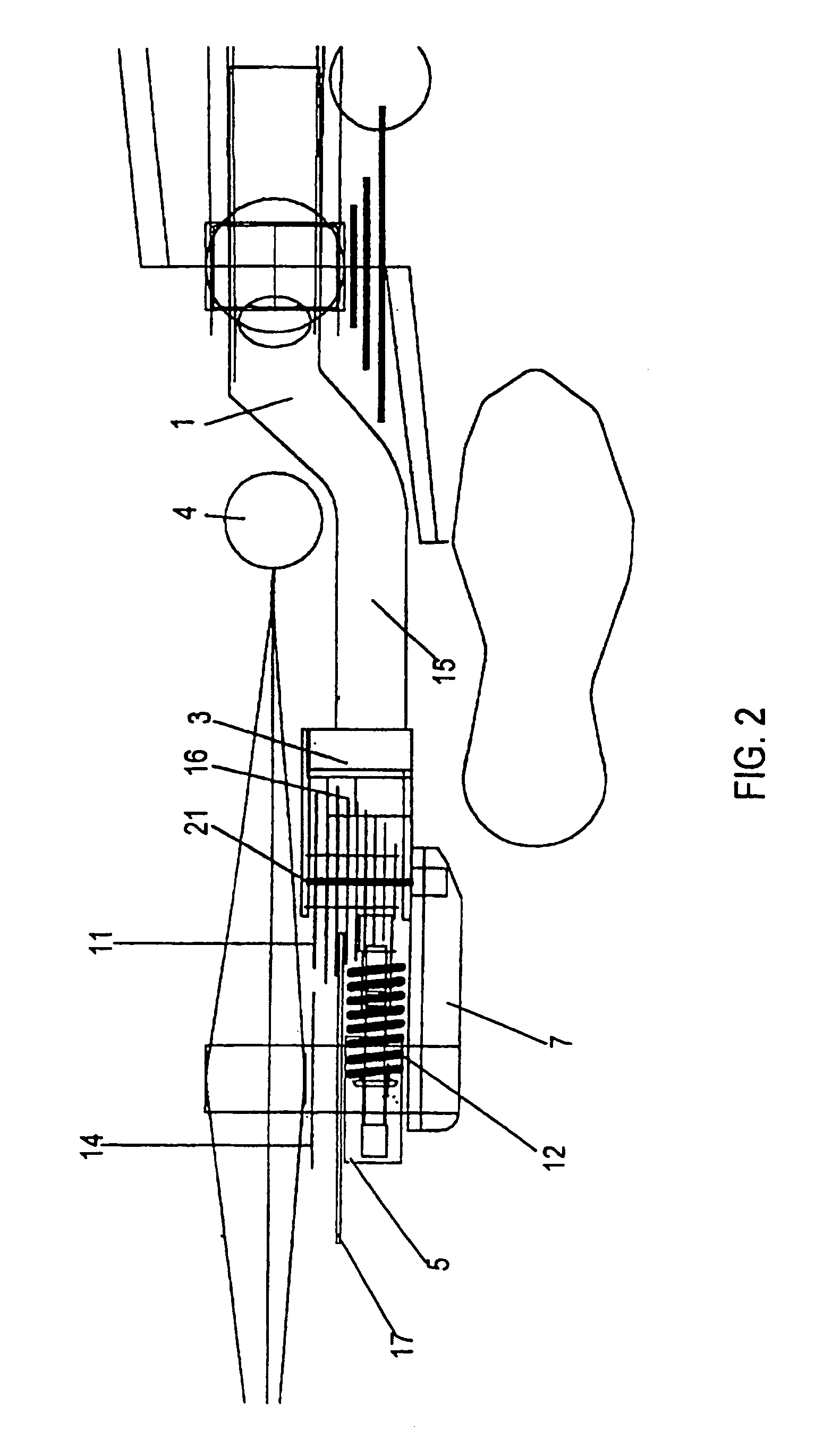

All-suspension bicycle frame with isolated drive gear

InactiveUS6910702B1Dampen undesirable rocking movementReduce frictionPassenger cyclesChildren cyclesVehicle frameGear wheel

A frame assembly for a two-wheel vehicle includes a front wheel fork and chainstays. Between the front wheel fork and the chainstays, the frame assembly further includes a saddle tube, a crank housing, and a lower tube connecting the crank housing to a steering tube. A parallelogram-shaped suspension assembly is attached to a rear end of the chainstays.

Owner:HALS CATO

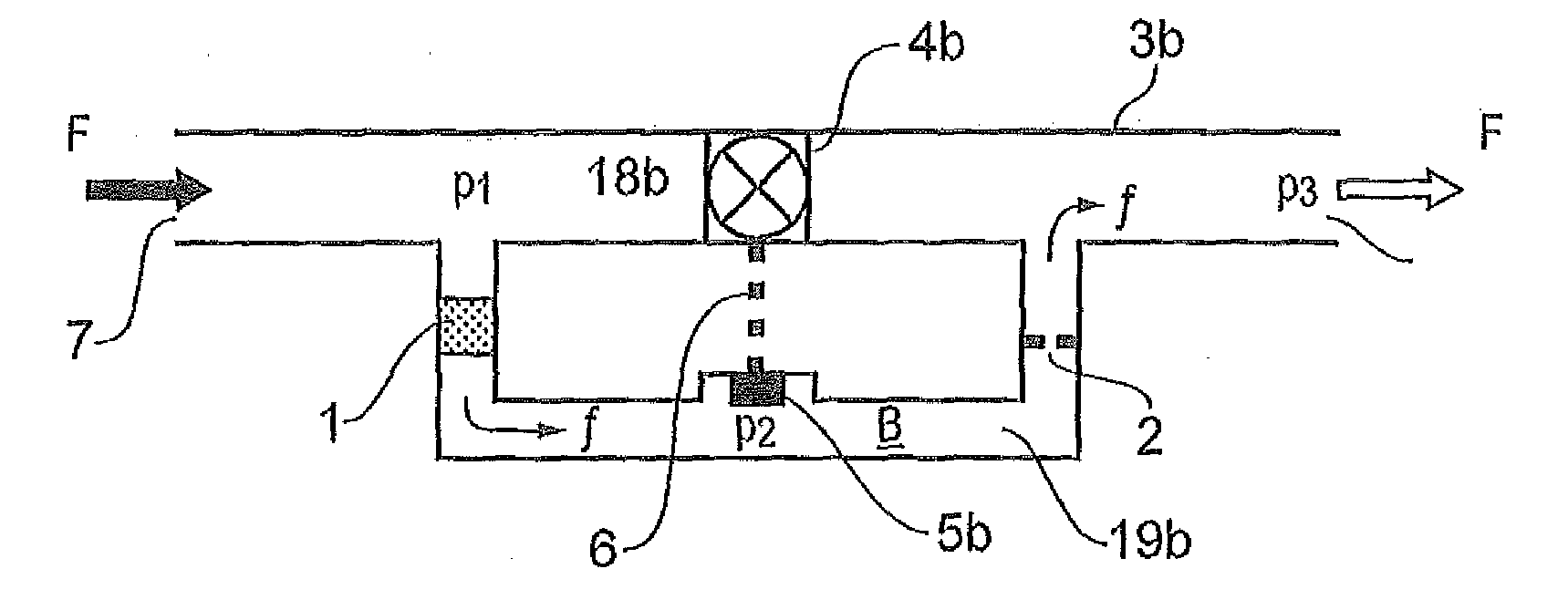

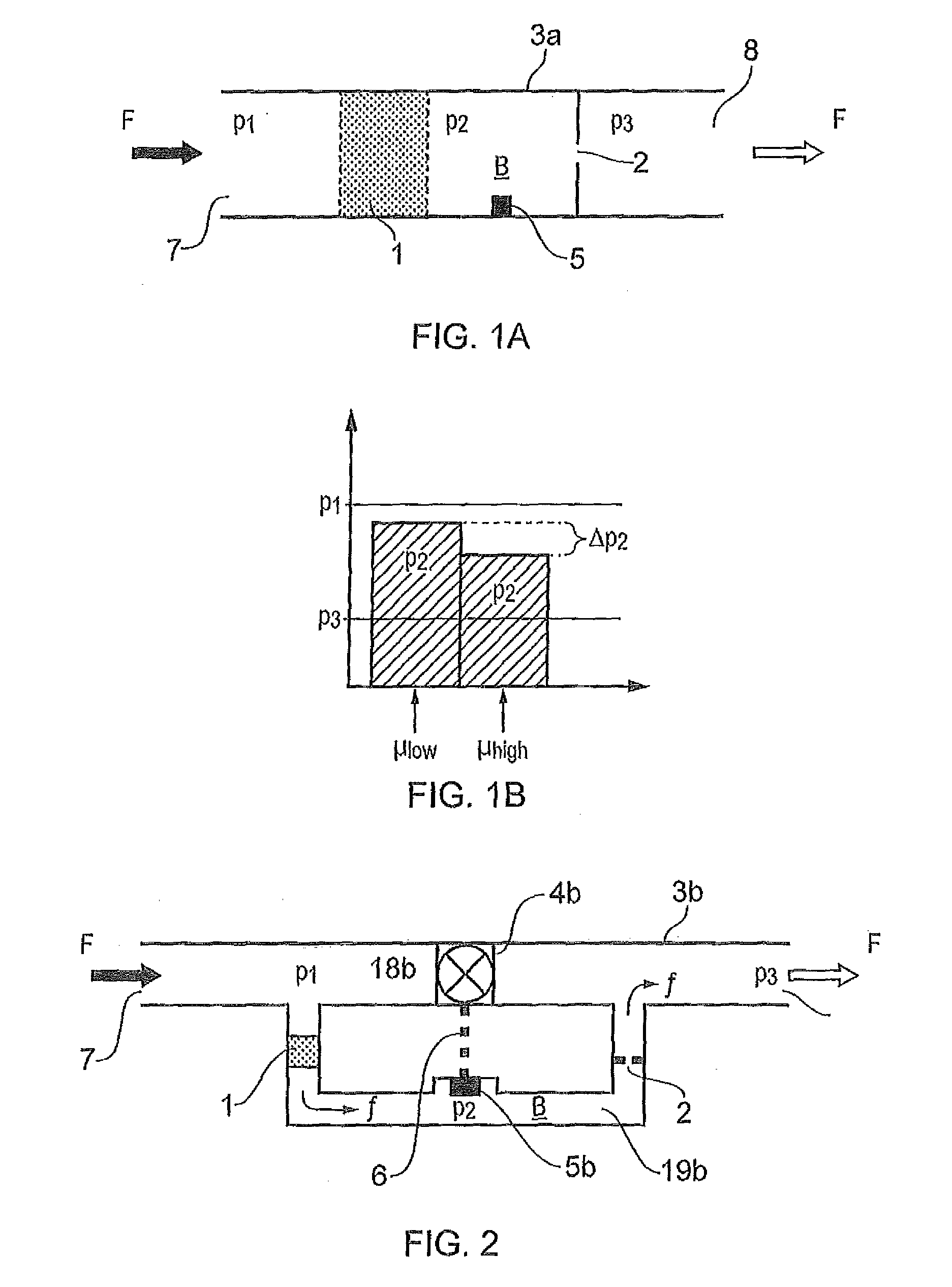

Flow control device and method

ActiveUS20150040990A1Avoid suffocationHigh degreeOperating means/releasing devices for valvesFluid removalEngineeringFluid pressure

A fluid flow control device includes a housing having a fluid inlet (7) and at least one fluid outlet (8). A first fluid flow restrictor (1) serves as an inflow port to a chamber (B) in the housing, and a second fluid flow restrictor (2) serves as an outflow port from the chamber (B). The first fluid flow restrictor and the second fluid flow restrictor are configured to generate different fluid flow characteristics; and the chamber (B) includes an actuating device (5a-1) that is responsive to fluid pressure changes (ΔP2) in the chamber. The first fluid flow restrictor (1) and the second fluid flow restrictor (2) are configured to impose respective different fluid flow characteristics based on different fluid properties.

Owner:INFLOWCONTROL

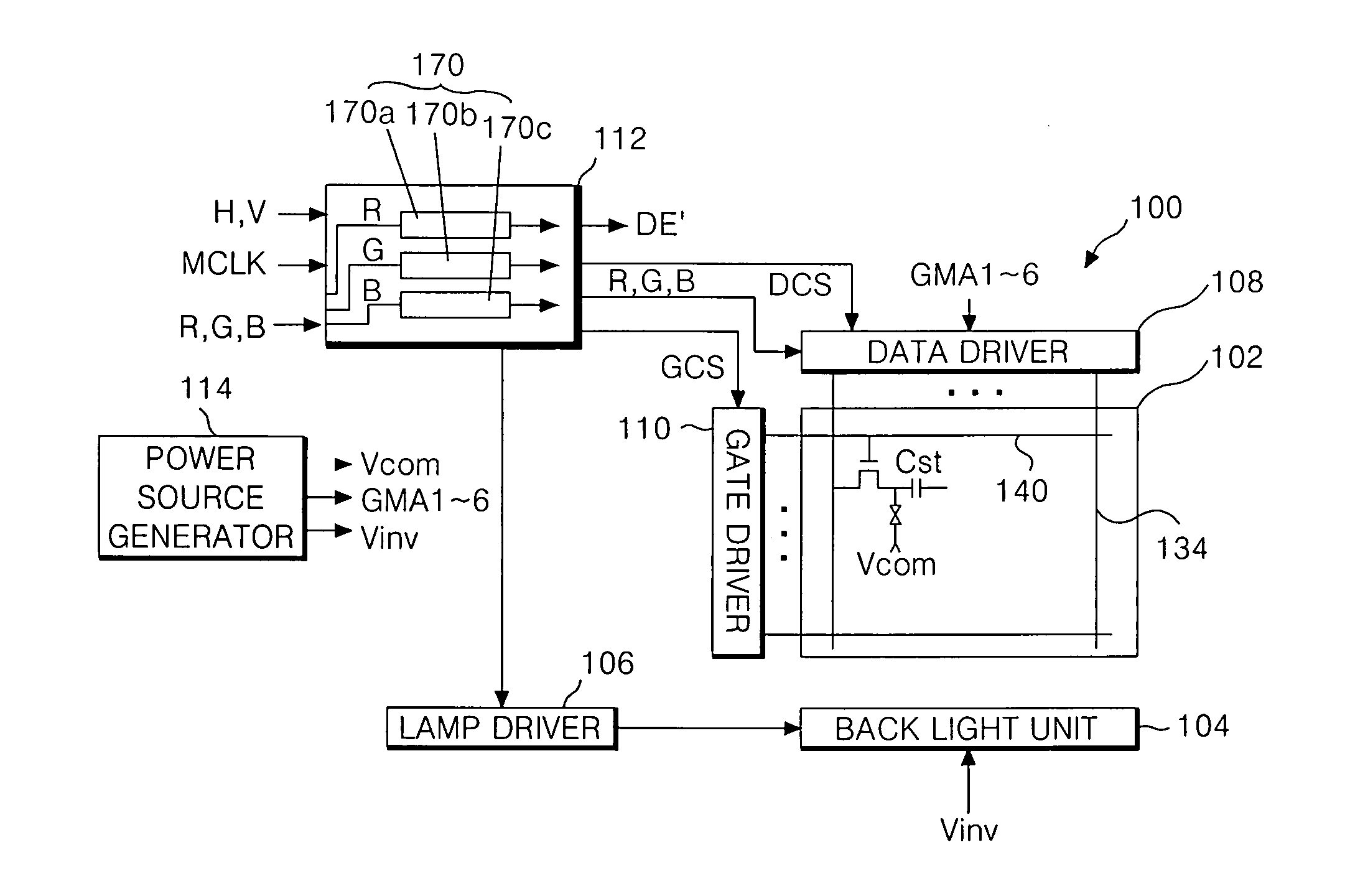

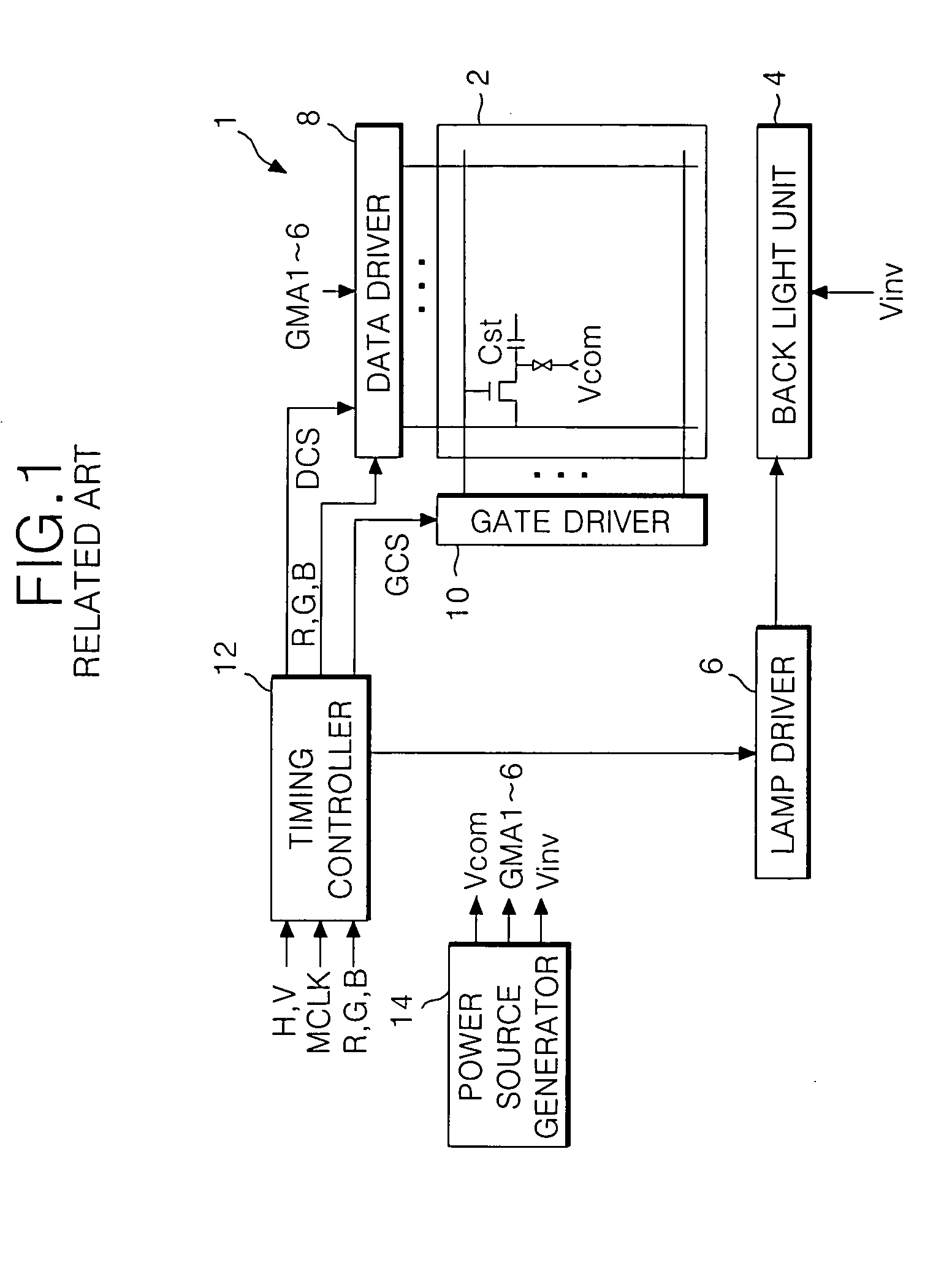

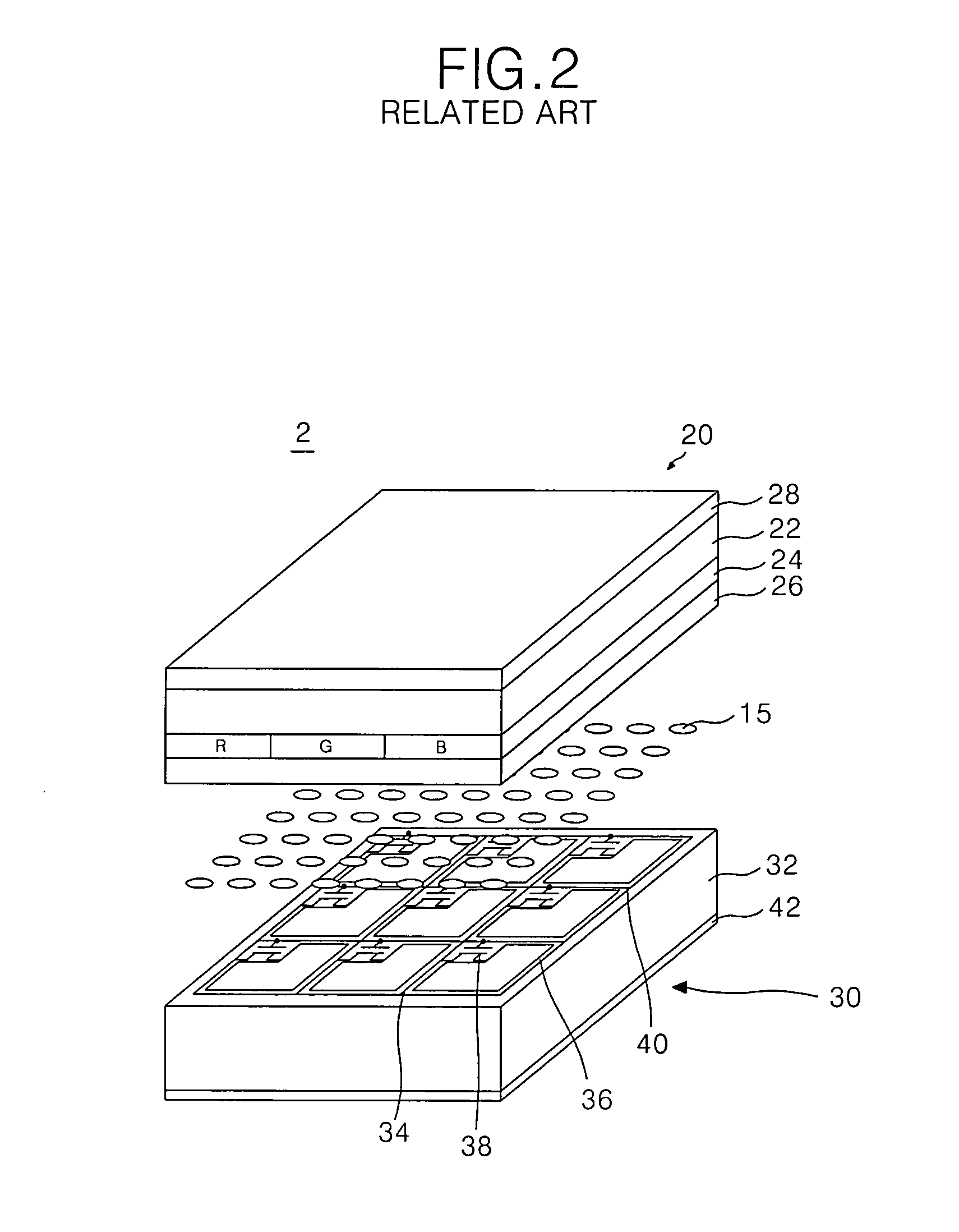

Liquid crystal display apparatus and driving method thereof

InactiveUS20050041006A1Reduce power consumptionLow production costCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display apparatus and a method of driving the same capable of lowering a power consumption as well as a production cost. A liquid crystal display apparatus according to the present invention comprises: pixels including red, green and blue color pixels arranged in a direction along a data line; gate line groups, each gate line group having a set of two gate lines electrically connected each other, and each gate line crossing the data line; a data driver that drives the data line; a gate driver that drives the gate line groups; and a timing controller that controls the data driver and the gate driver, the timing controller having at least one line memory that temporarily stores data supplied to the data driver.

Owner:LG DISPLAY CO LTD

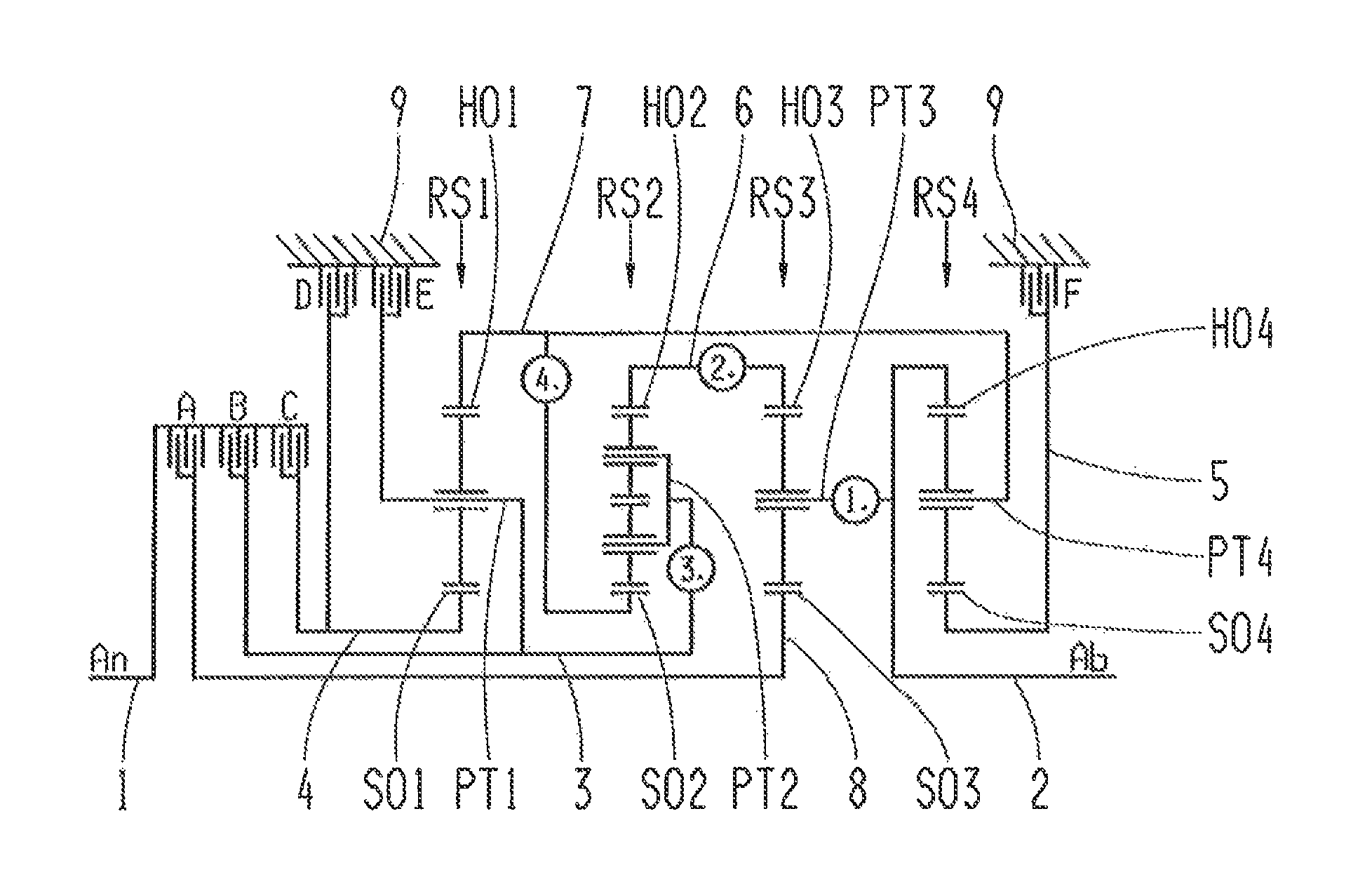

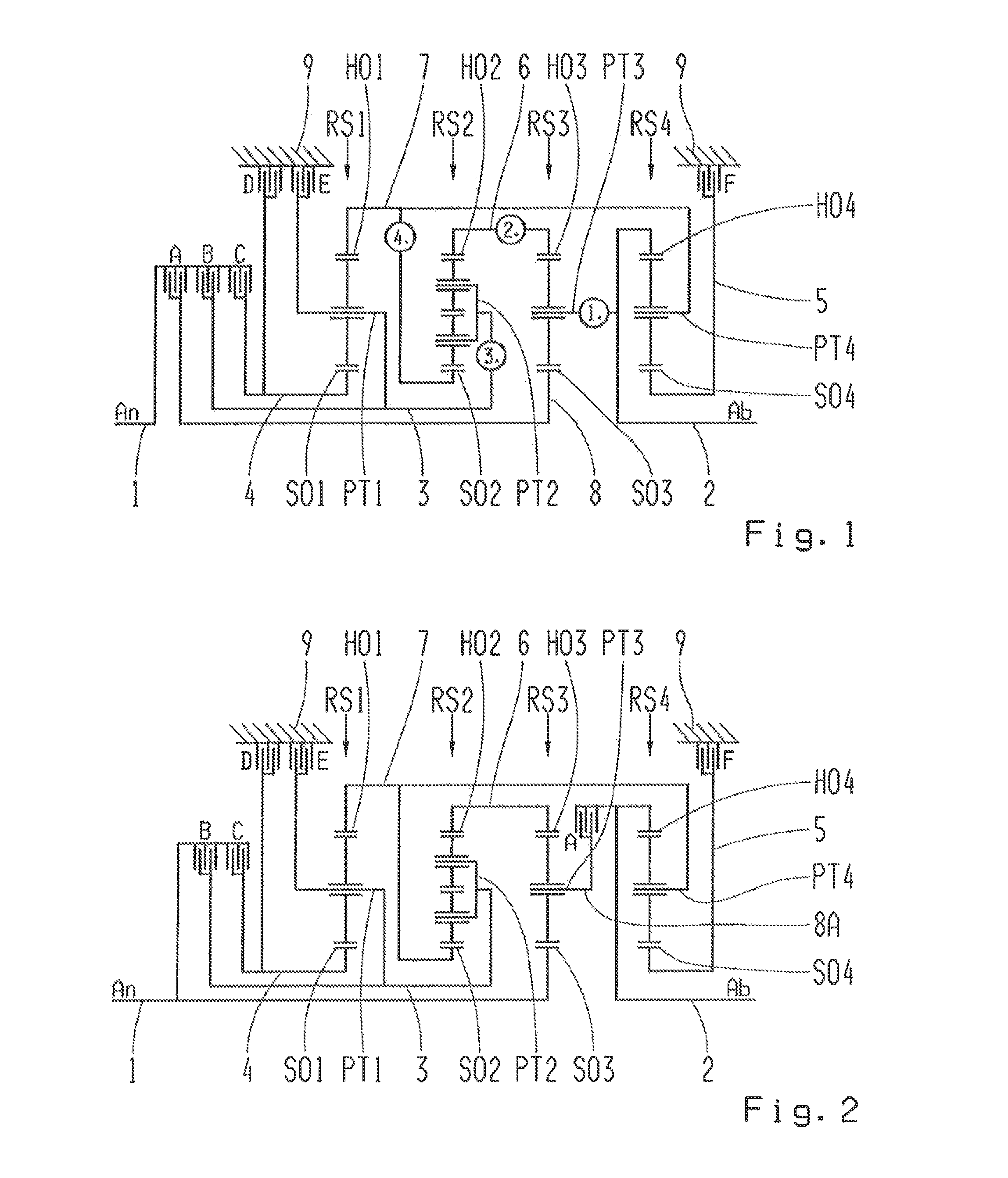

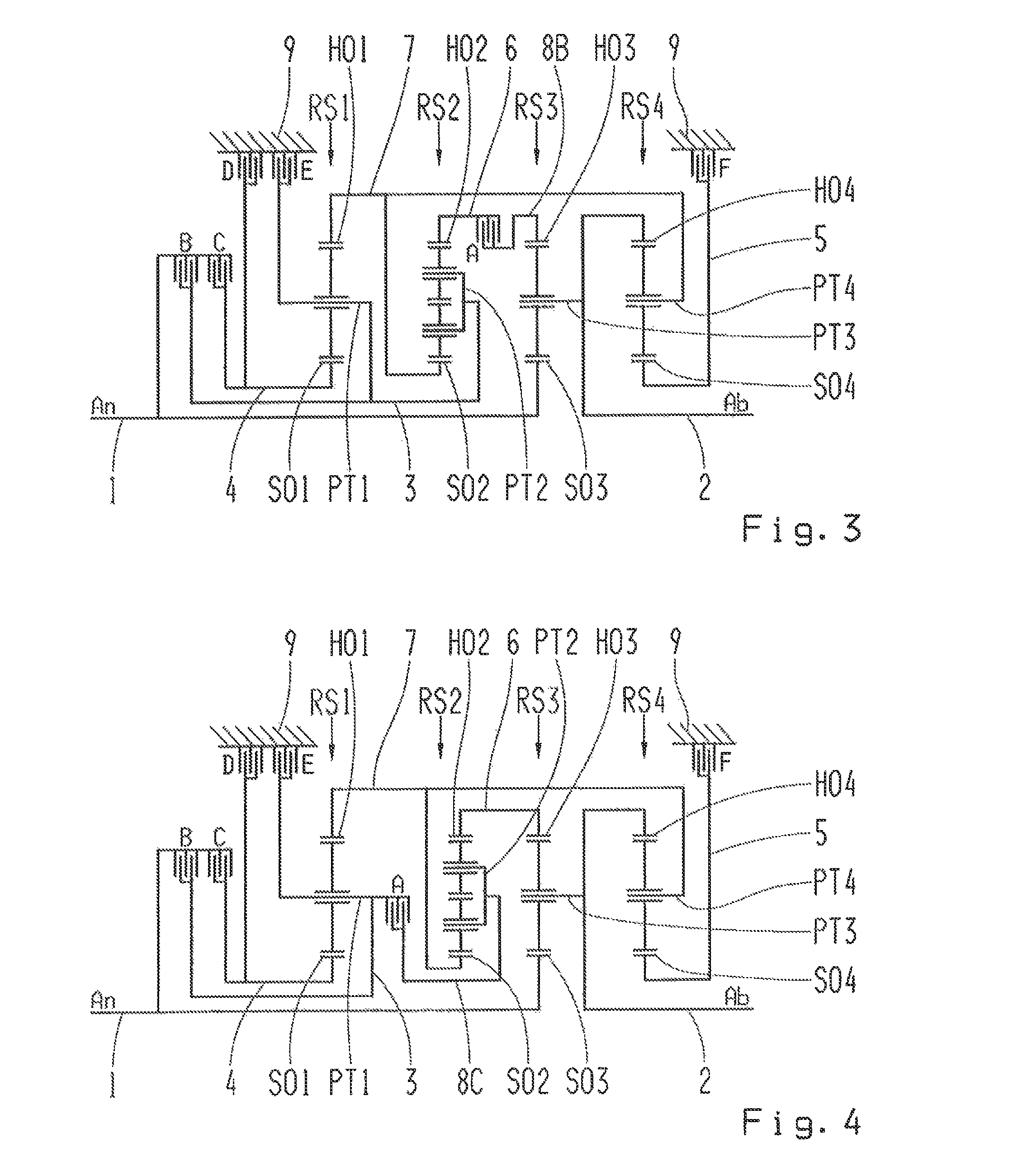

Multi-stage planetary vehicle transmission

InactiveUS8992373B2Improve efficiencyLittle structural complexityToothed gearingsTransmission elementsEngineeringGear transmission

A multi-gear transmission of a vehicle having a housing in which four planetary gearsets and a plurality of shafts and shifting elements are arranged. The drive input shaft can couple the sun gears of gearsets (RS1, RS3) and the carrier of gearset (RS1) and can be connected indirectly to the carrier of gearset (RS2). The drive output shaft couples the ring gear of gearset (RS4) and is connected directly or can be indirectly connected to the carrier of gearset (RS3), the sun gear and carrier of gearset (RS1) and the sun gear of gearset (RS4) can be connected to the housing. The ring gear of gearset (RS1) couples the carrier of gearset (RS4) and can be or is connected to the sun gear of gearset (RS2), and the ring gear of gearset (RS2) and the ring gear of gearset (RS3) are, or can be, connected to one another.

Owner:ZF FRIEDRICHSHAFEN AG

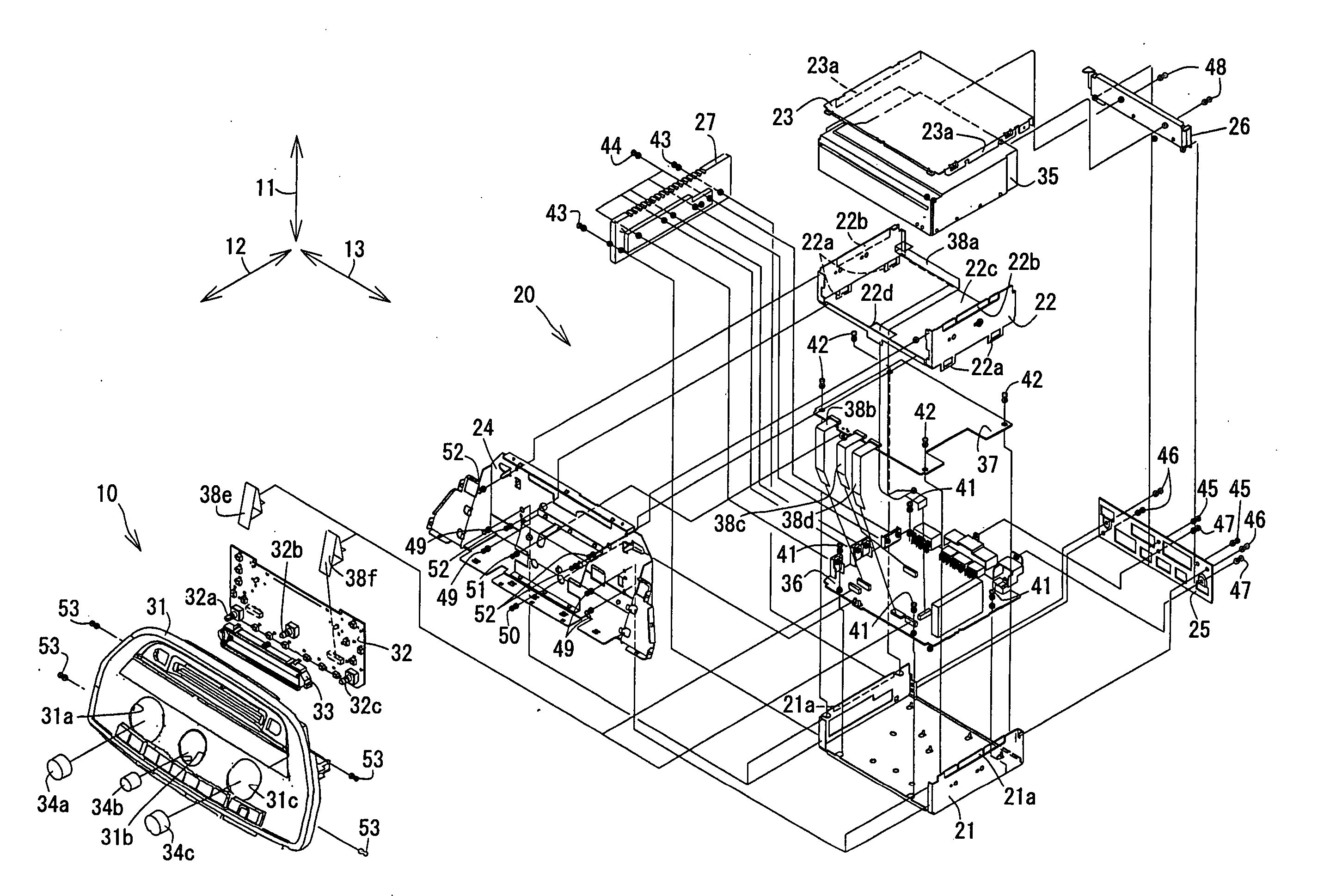

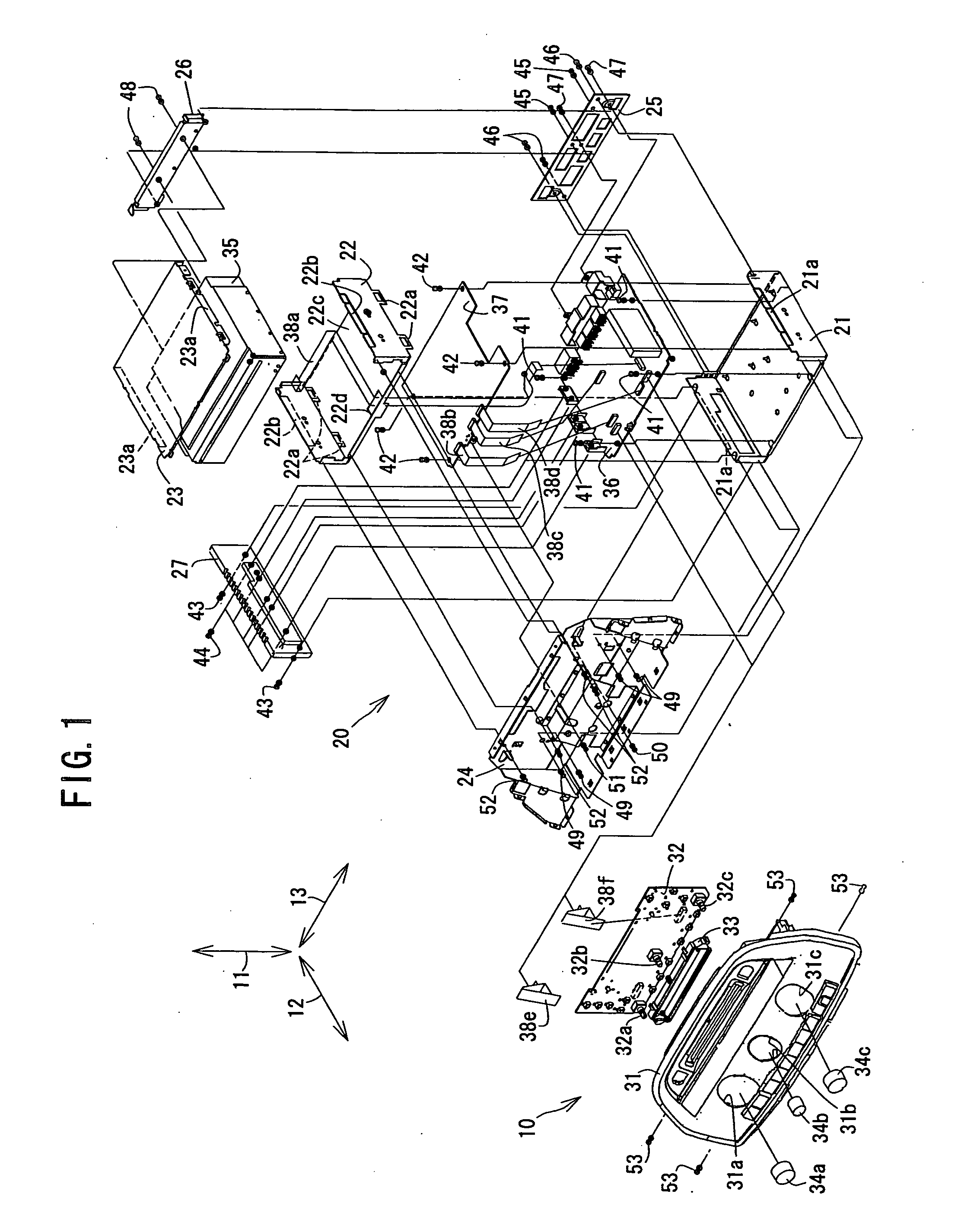

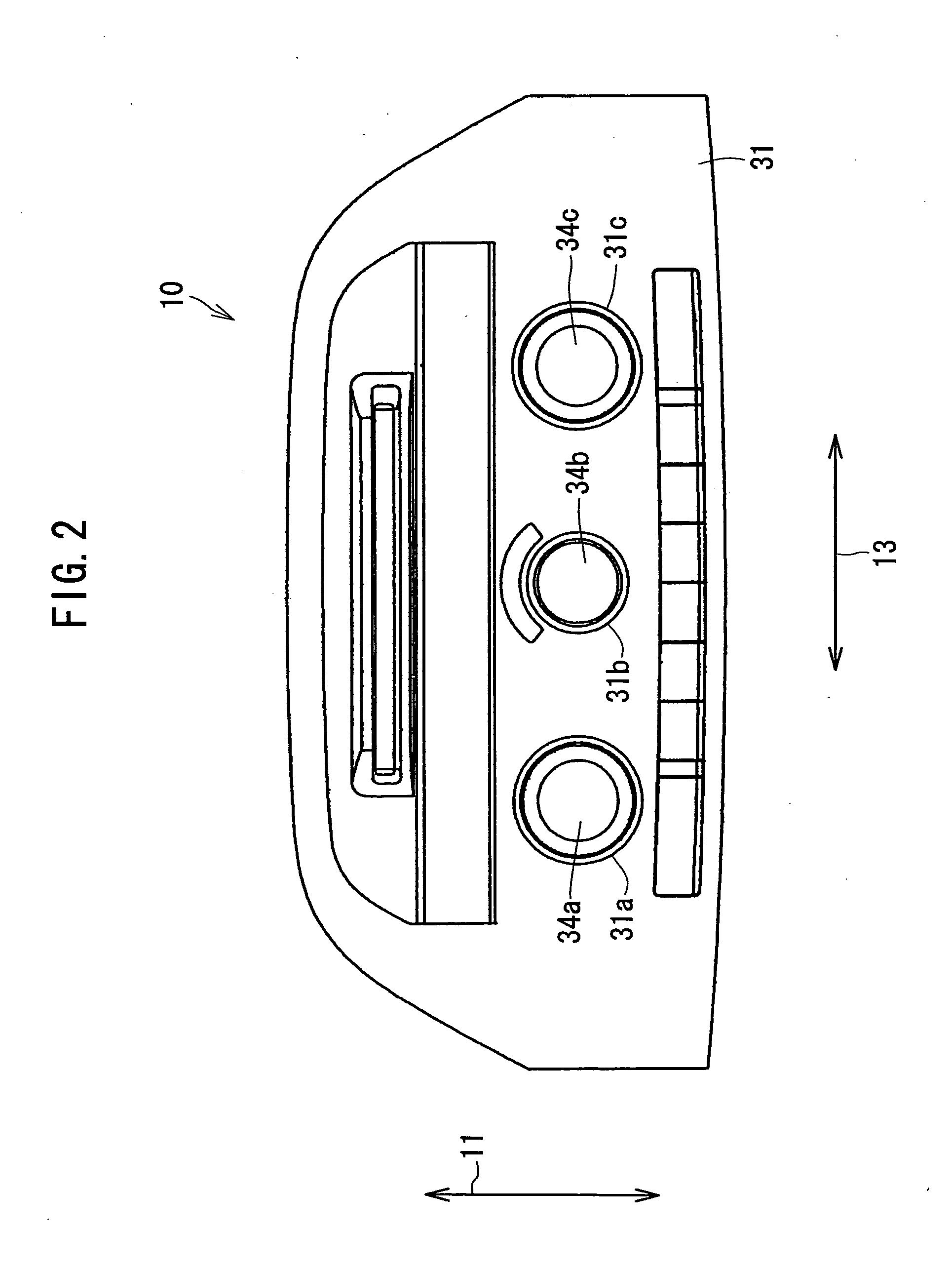

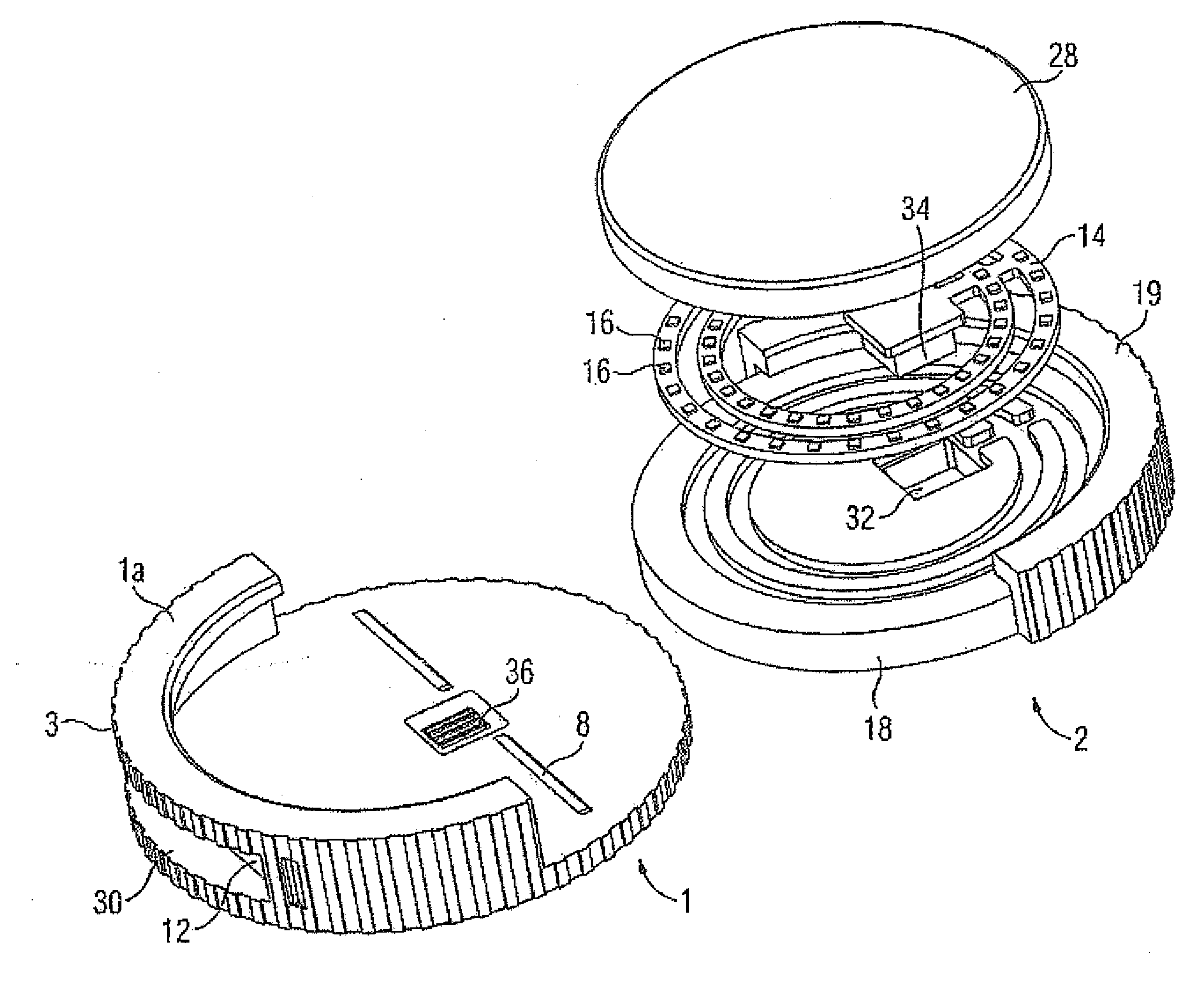

Electronic equipment

InactiveUS20060126274A1Reduce stepsProduction costSubstation/switching arrangement detailsMagnetic/electric field screeningEngineeringElectronic equipment

Electronic equipment according to the present invention comprises a case having an overall length substantially twice as long as a predetermined standard length in a predetermined direction shown by an arrow. The case includes a bottom cover case shorter in overall length in the predetermined direction than the standard length and available for a part of a standard length case having in the predetermined direction an overall length identical to the standard length, and an intermediate cover case longer in overall length in the predetermined direction than the standard length case and disposed on a predetermined side of the bottom cover case. The bottom cover case has an engaging portion held in engagement with the intermediate cover case, and the intermediate cover case has an engaging portion held in engagement with the engaging portion of the bottom cover case.

Owner:PANASONIC CORP

LED Lighting Device

InactiveUS20130010473A1Reduce maintenance costsProduction costPoint-like light sourceLighting support devicesEffect lightEngineering

Owner:OSRAM GMBH

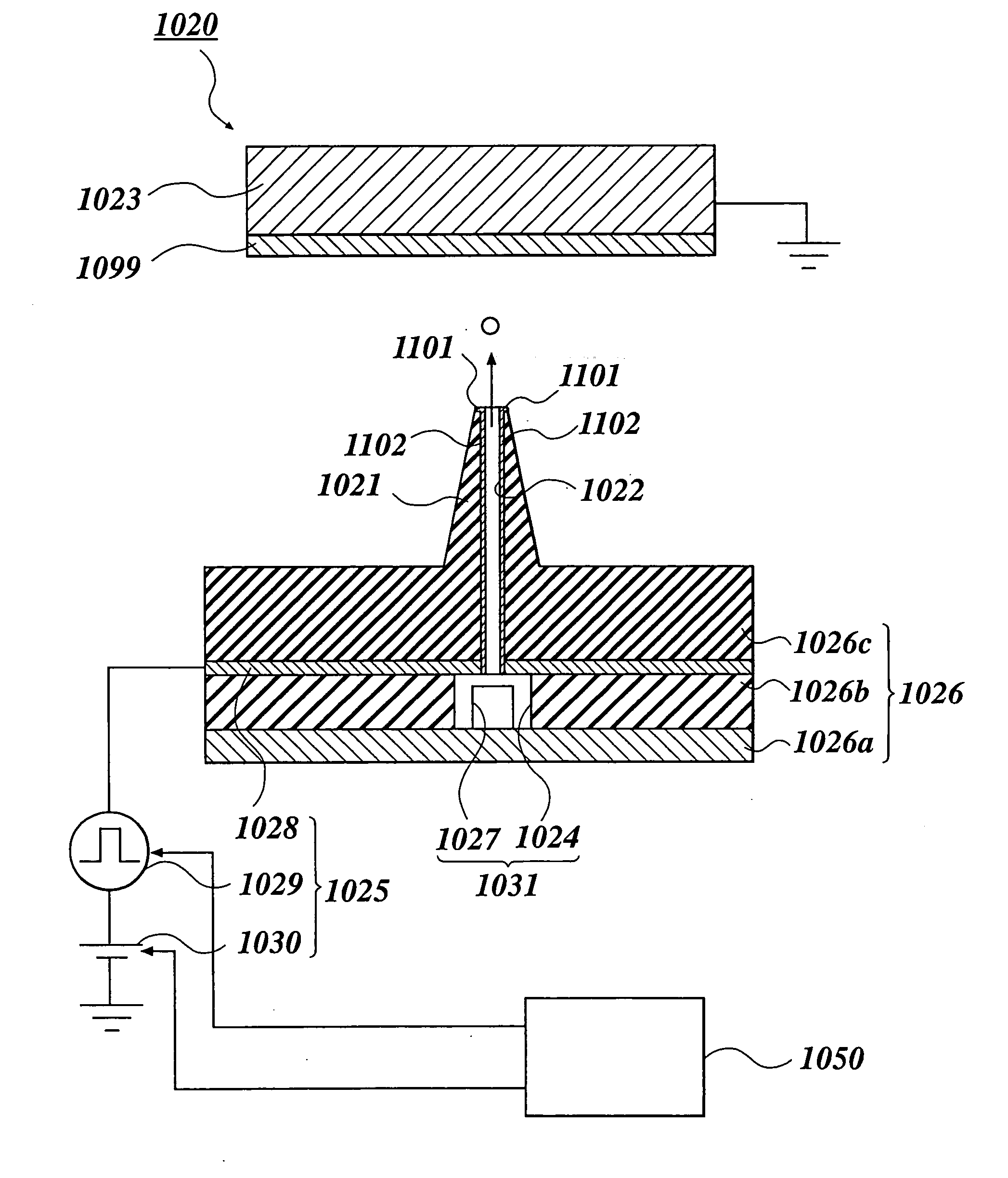

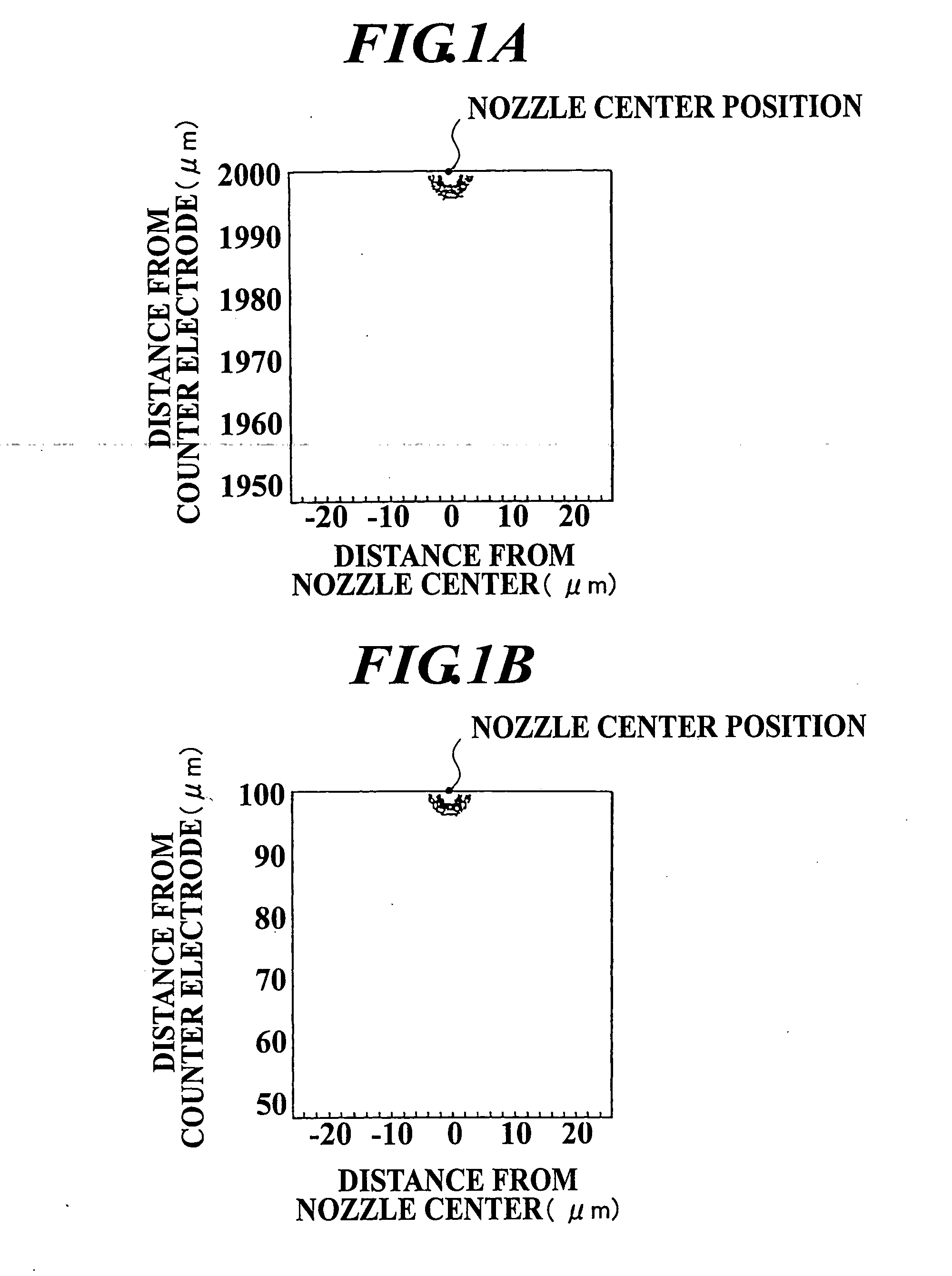

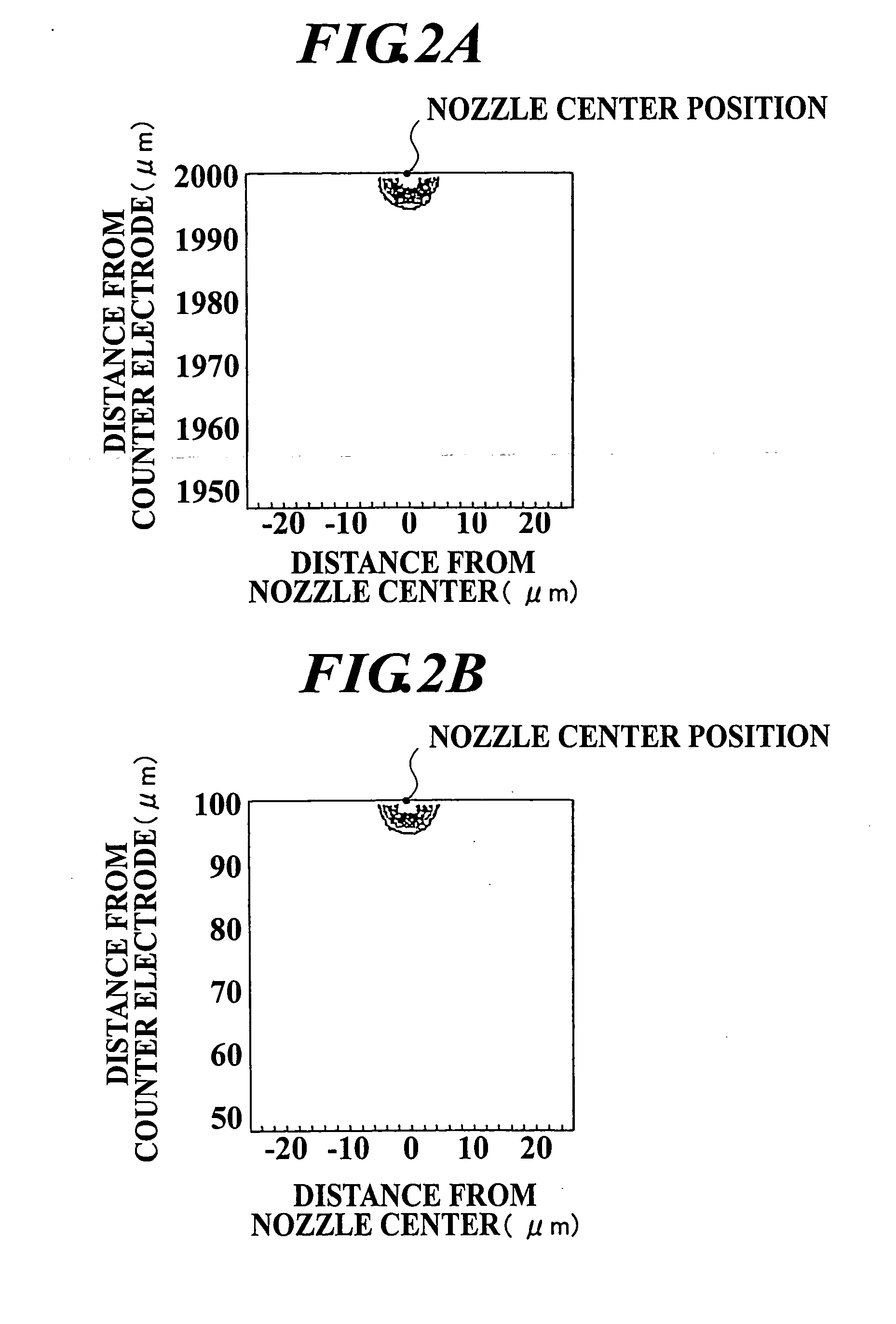

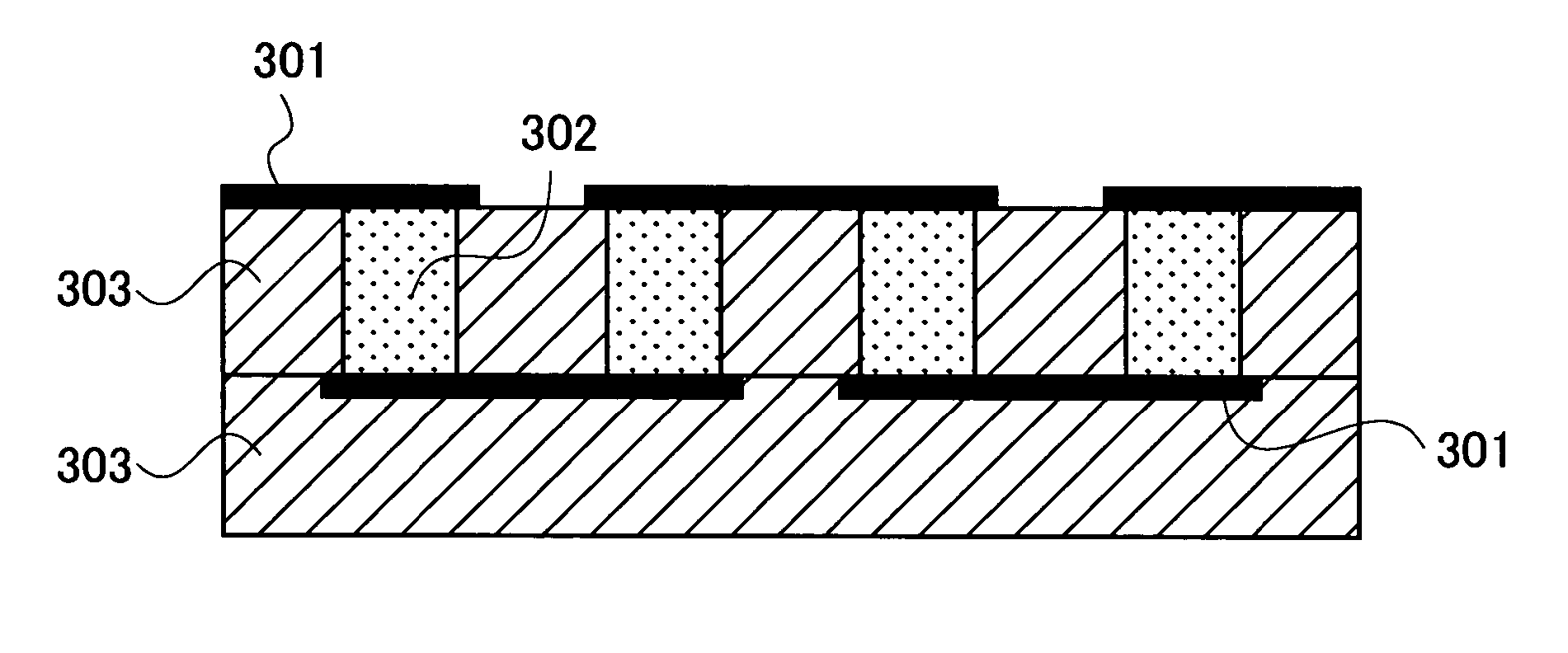

Method for manufacturing electrostatic attraction type liquid discharge head, method for manufacturing nozzle plate, method for driving electrostatic attraction type liquid discharge head, electrostatic attraction type liquid discharging apparatus, and liquid discharging apparatus

InactiveUS20060017782A1Easily improve reliabilityEasy to controlPhotomechanical apparatusLiquid spraying apparatusResistSpray nozzle

First, through a coating step, a photolithography step and an etching step, a plurality of electrodes 142, 142, . . . are formed on a base plate 141. Next, a resist layer 143b is formed on the base plate 141 so as to cover all of the electrodes 142, 142, . . . , and by exposing and developing the resist layer 143b, a nozzle 103 having a super minute diameter is formed to stand with respect to the base plate 141 so as to make the resist layer 143b correspond to each electrode 142, and an in-nozzle passage is formed in each nozzle 103.

Owner:NAT INST OF ADVANCED IND SCI & TECH

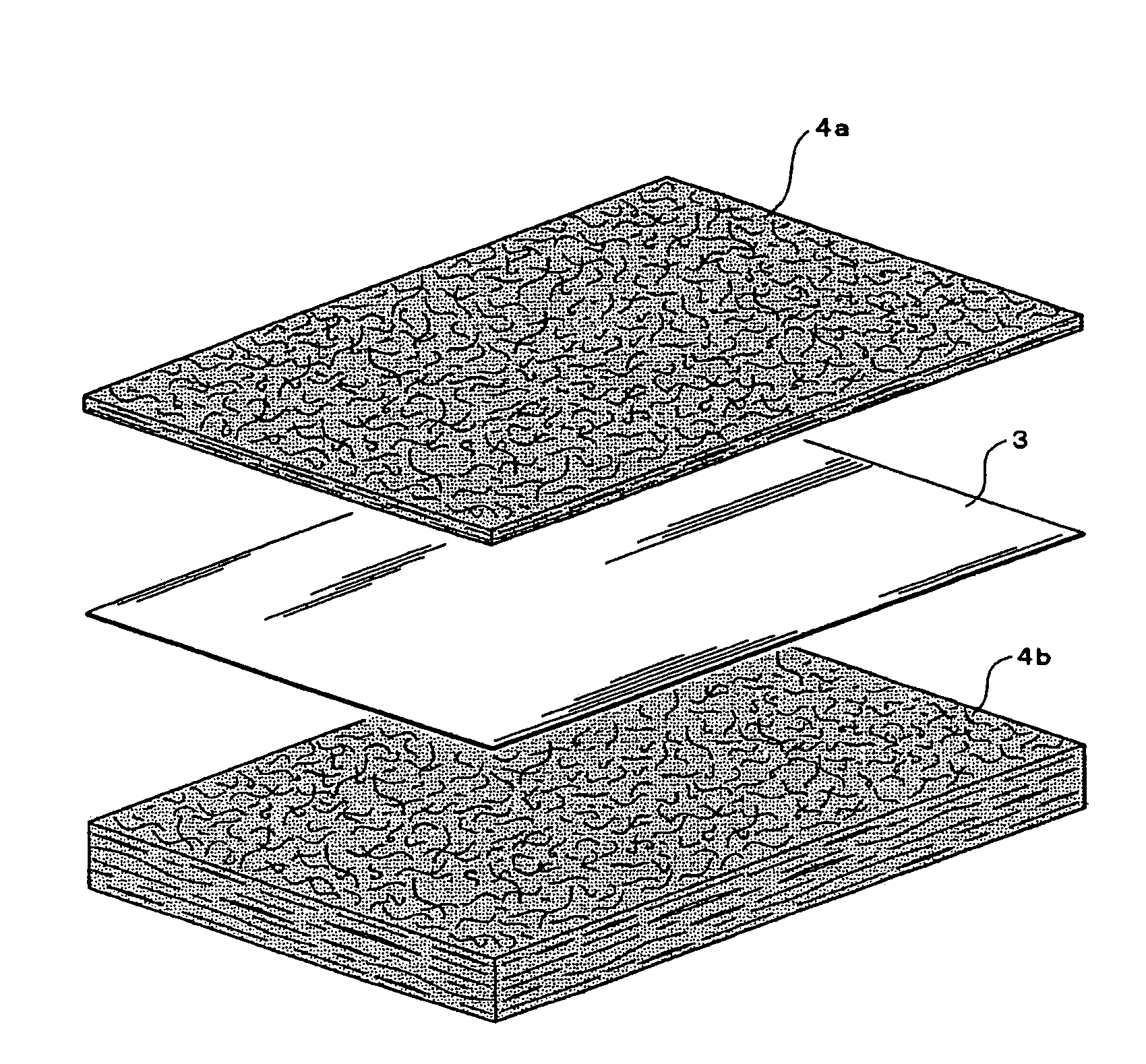

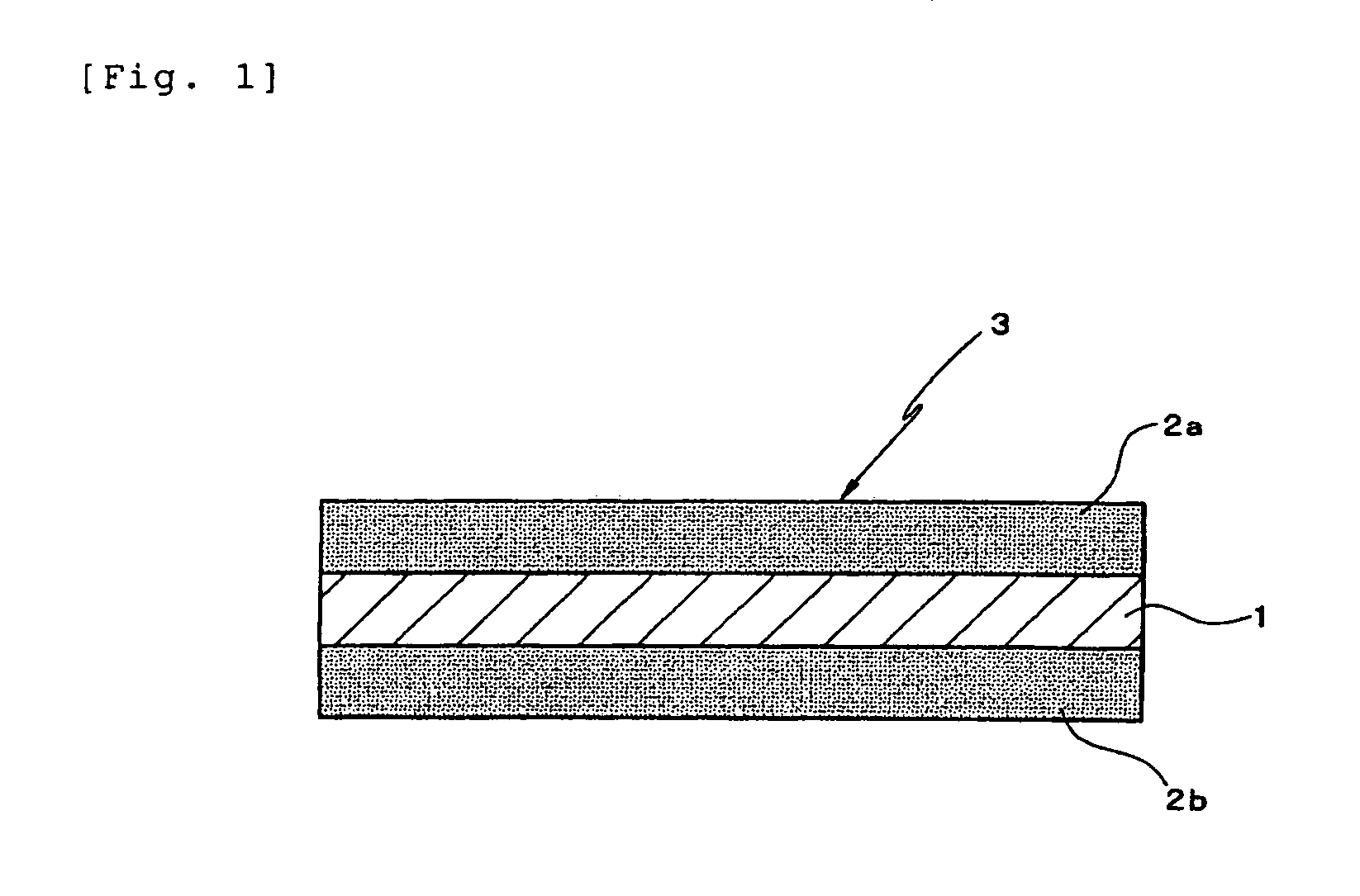

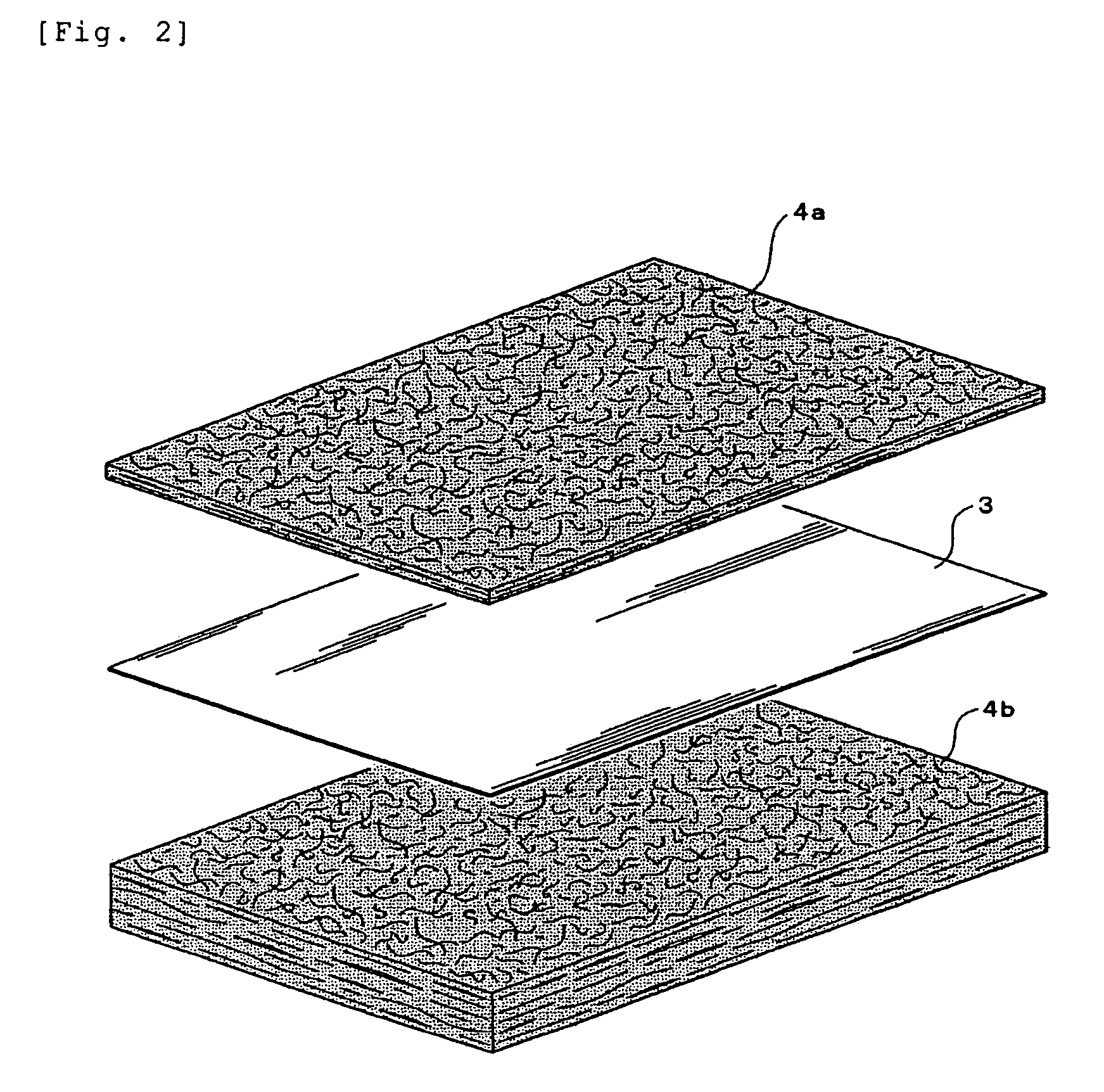

Formation method of metal layer on resin layer, printed wiring board, and production method thereof

InactiveUS20050106370A1Improve electrical performanceDispersion suppressionSurface layering apparatusThin material handlingElectrical conductorSurface roughness

A printed wiring board having a conductor circuit comprising a copper layer adjacent to an insulating layer and an electroless gold plating, wherein the insulating layer has ten-point mean surface roughness (Rz) of 2.0 μm or less is provided. According to the present invention, there is no such a defect that gold plating is deposited on a resin, and fine wiring formation with accuracy is realized.

Owner:HITACHI CHEM CO LTD

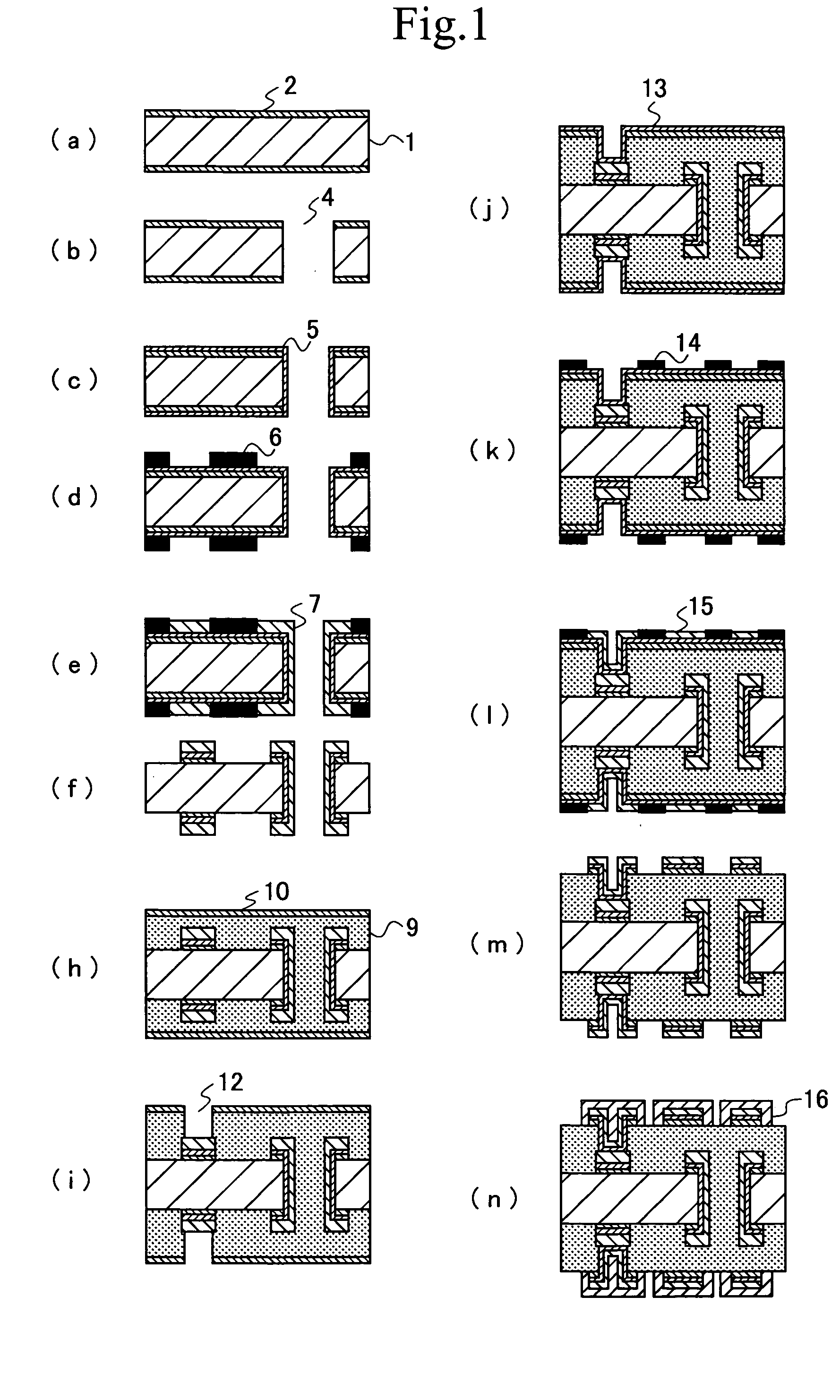

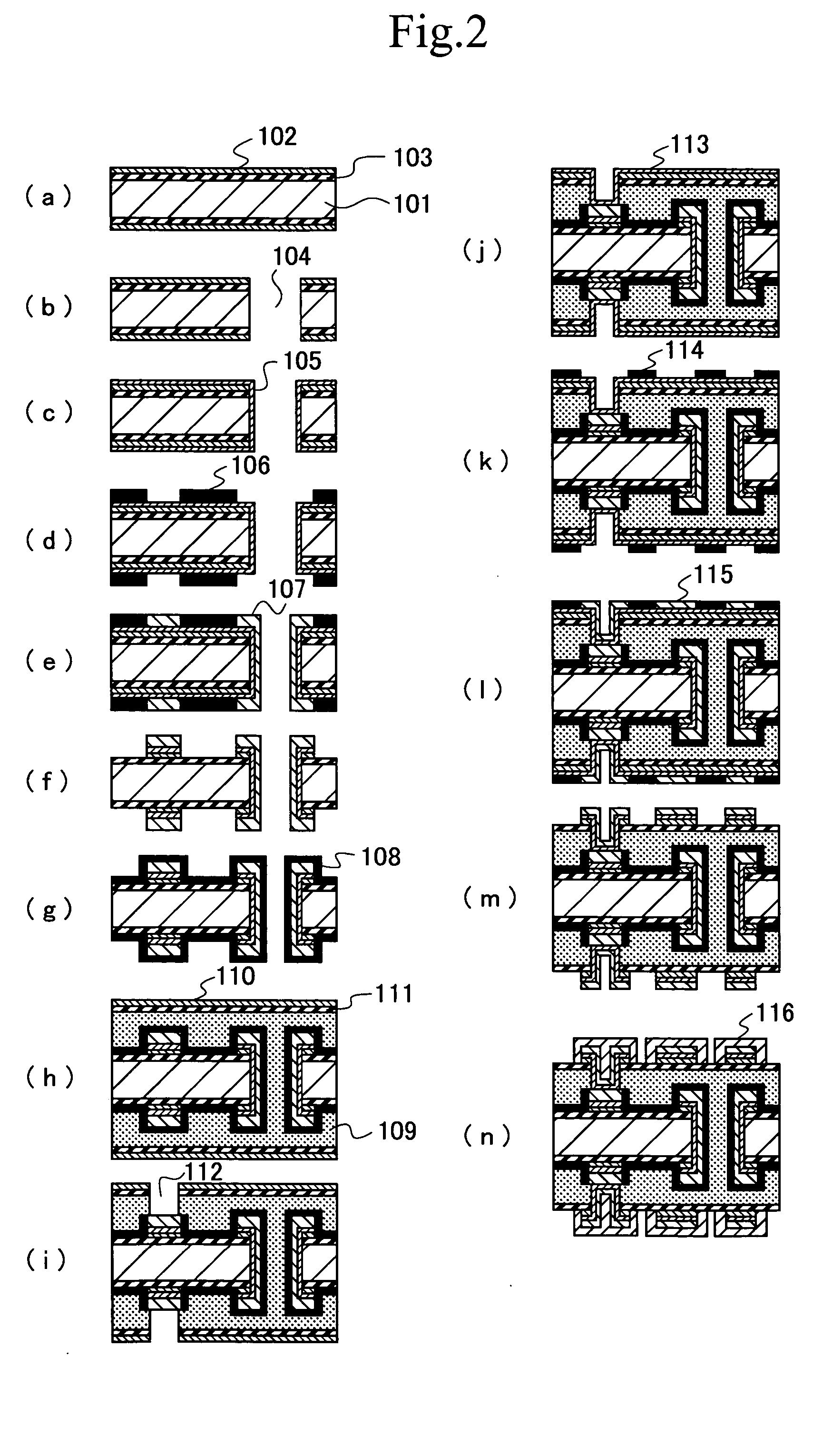

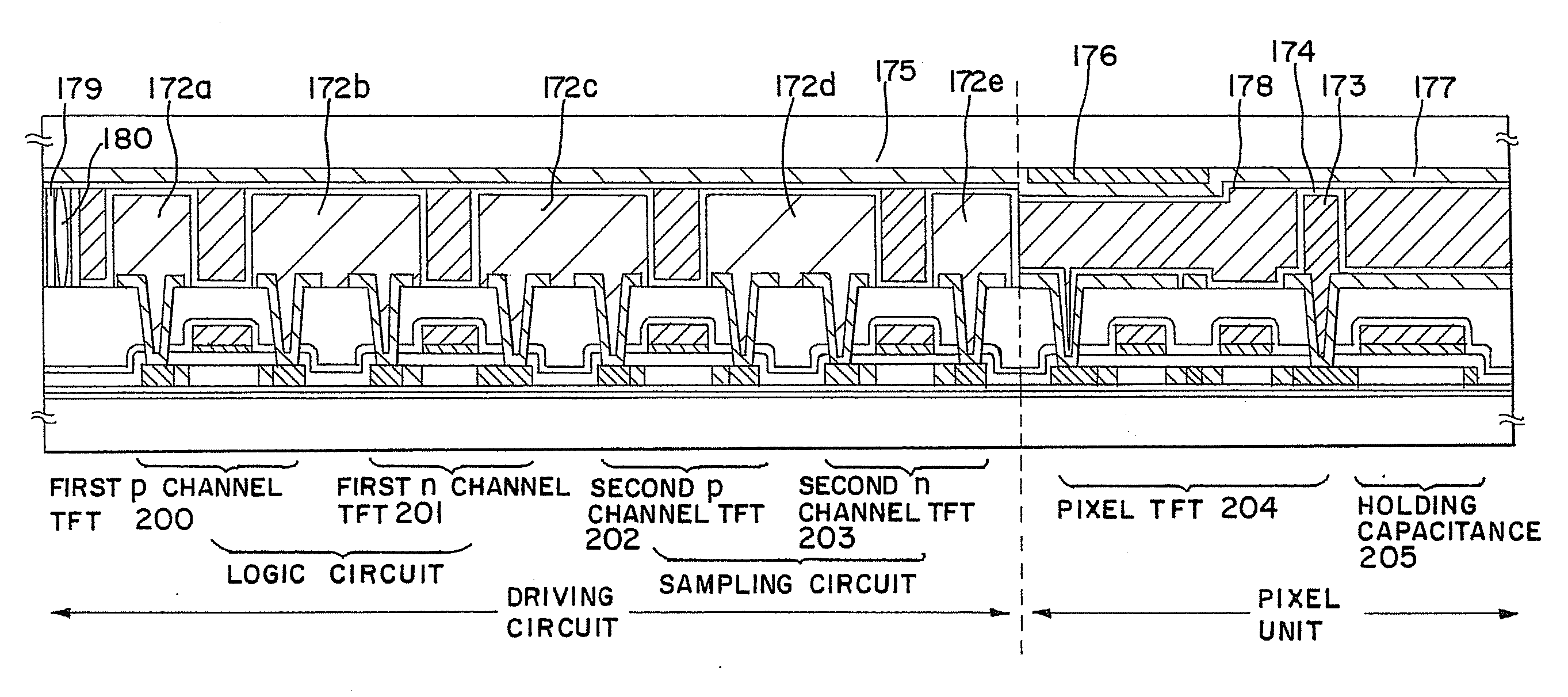

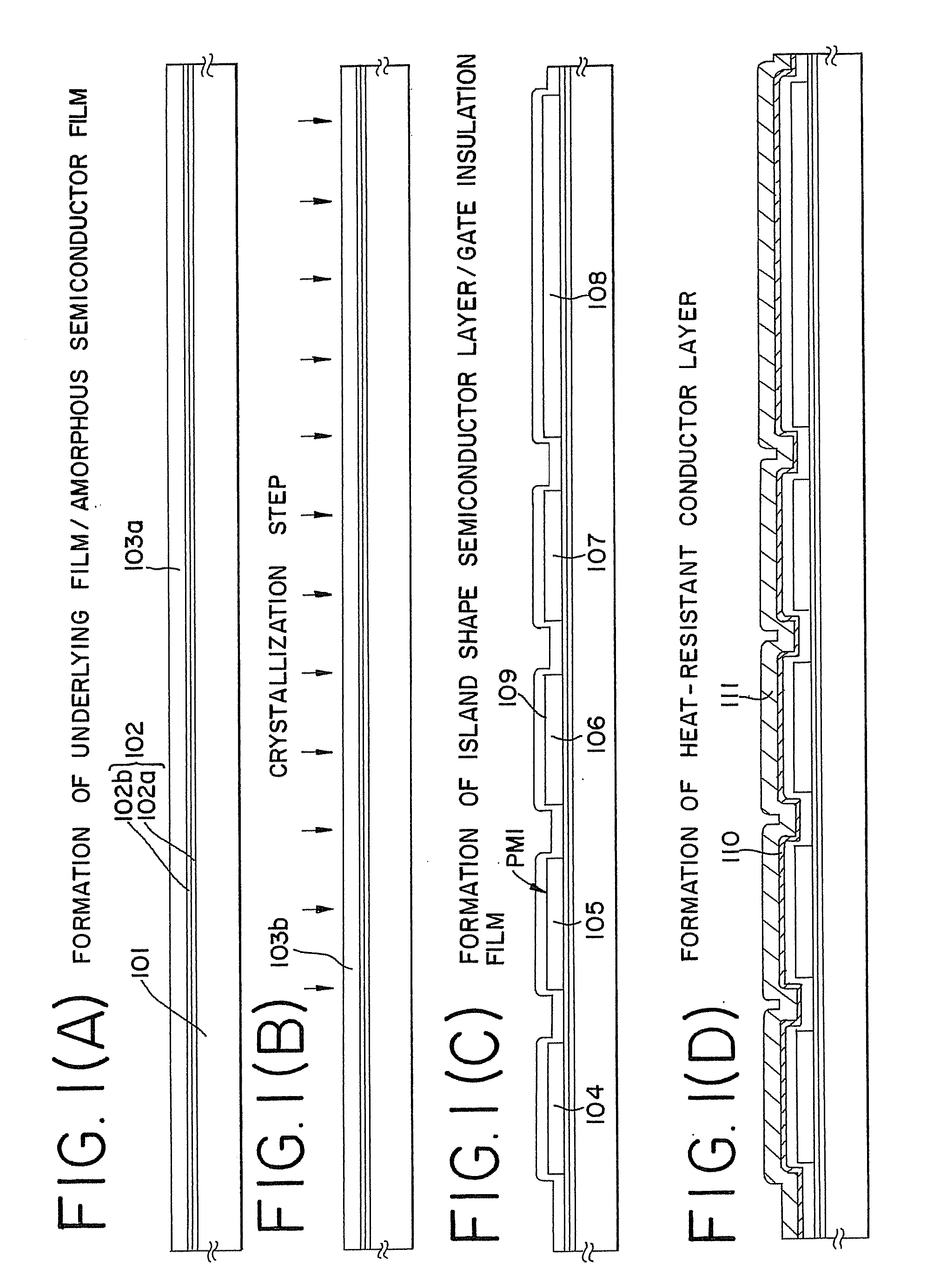

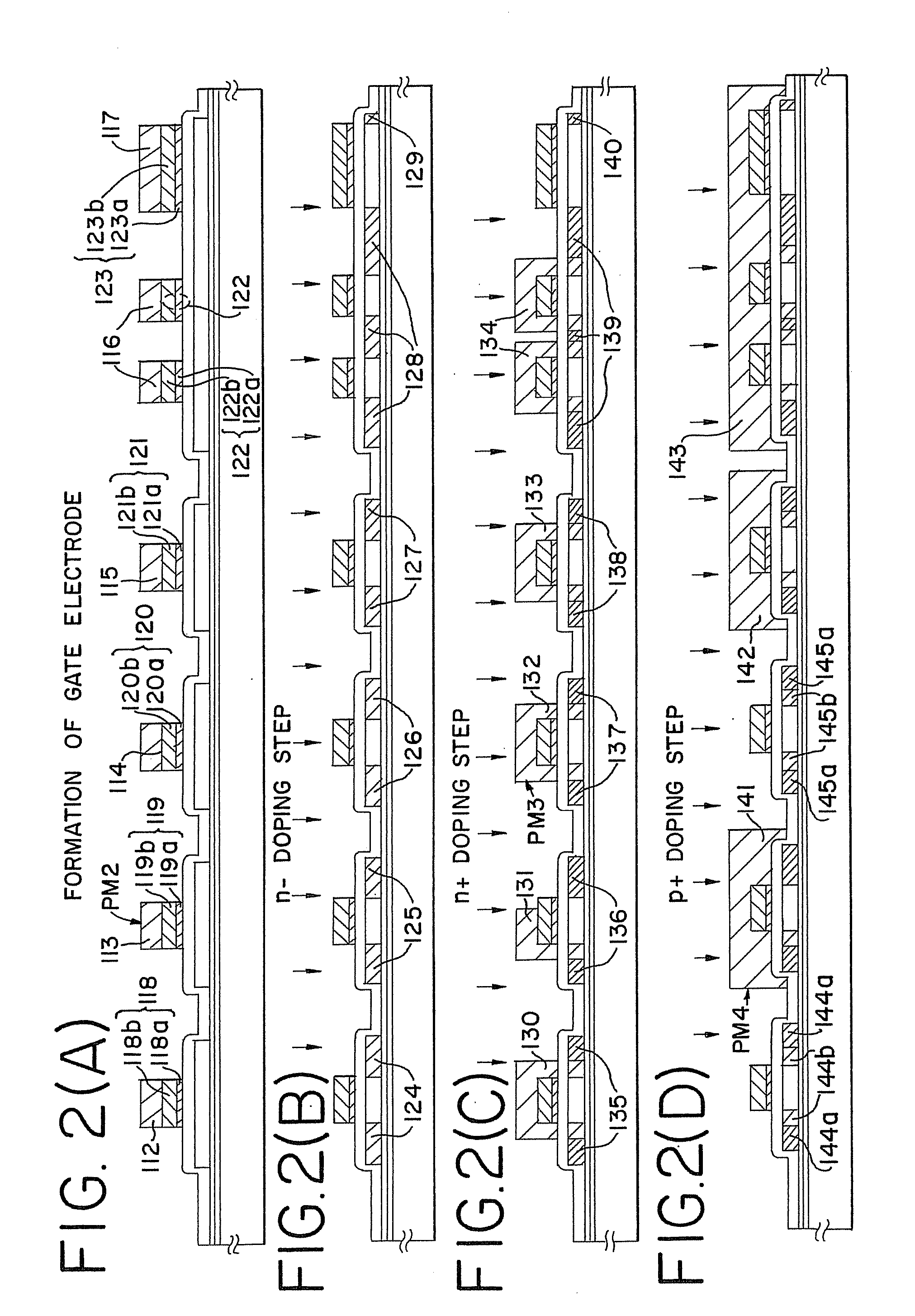

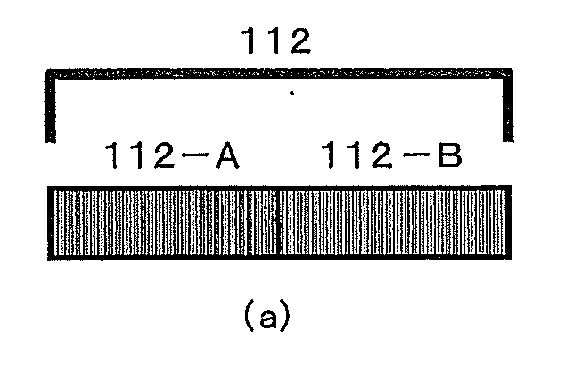

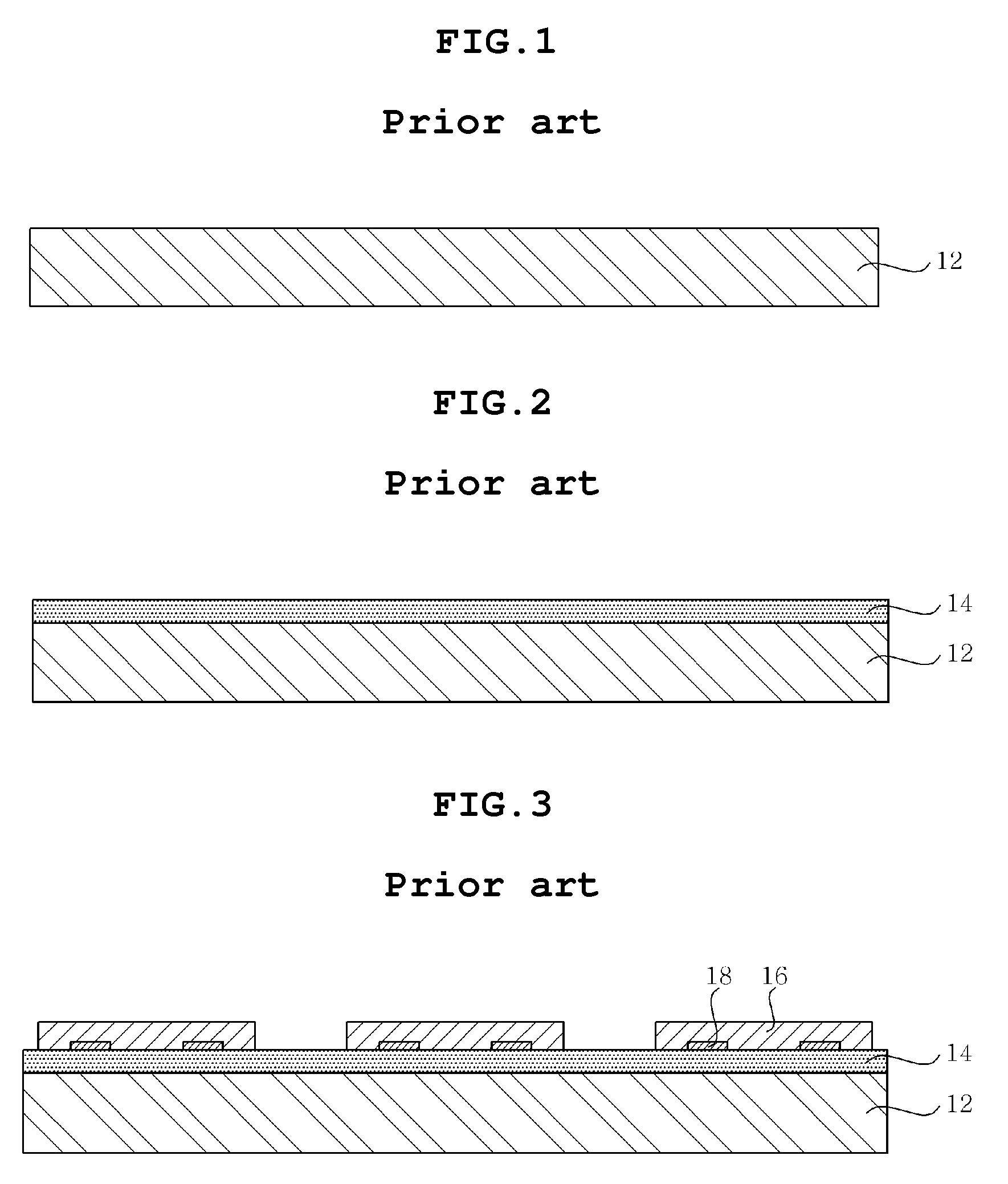

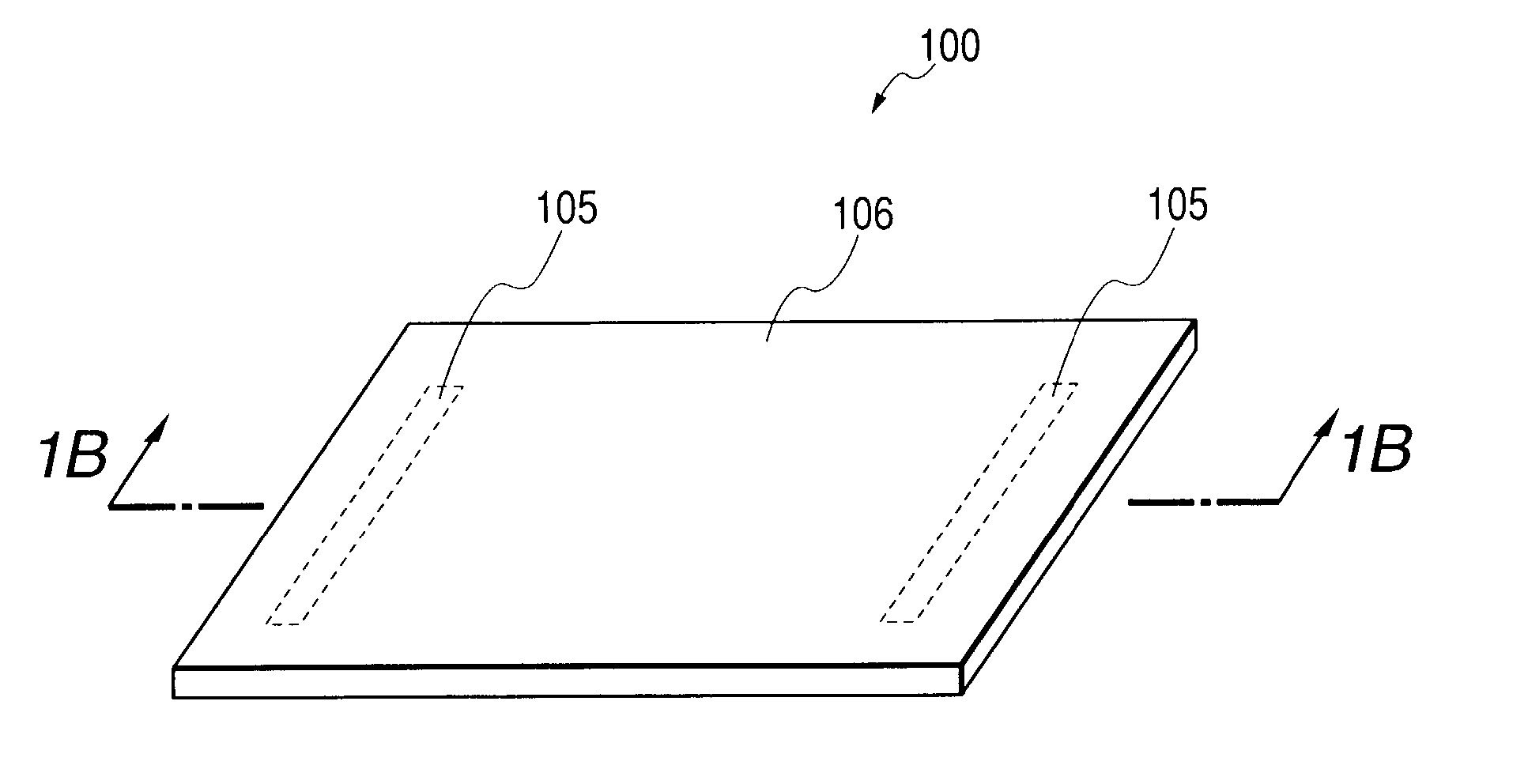

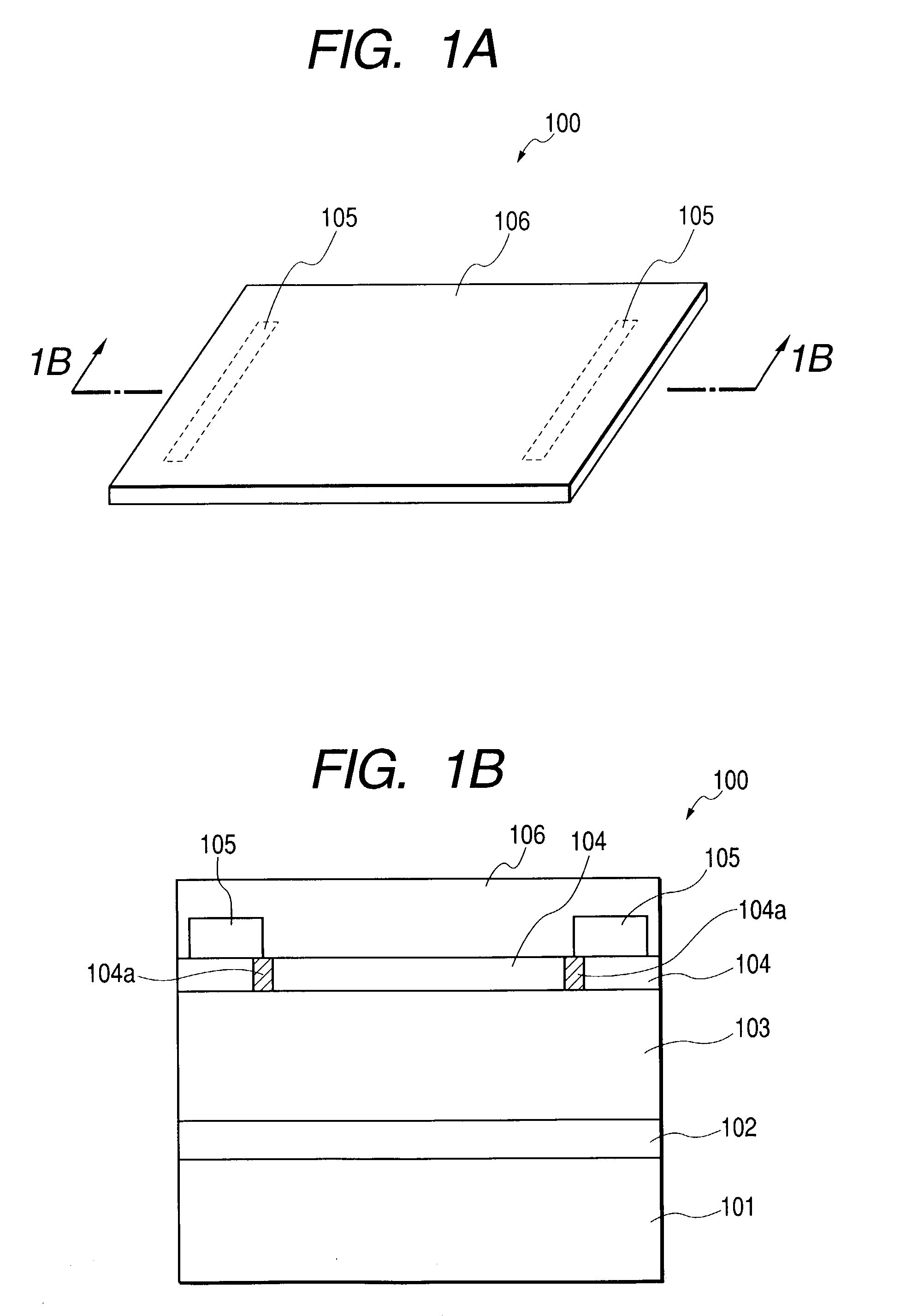

Semiconductor Device and Fabrication Method Thereof

InactiveUS20090290082A1Excellent characteristicsImprove reliabilityTransistorSolid-state devicesInter layerEngineering

A p channel TFT of a driving circuit has a single drain structure and its n channel TFT, an LDD structure. A pixel TFT has the LDD structure. A pixel electrode disposed in a pixel unit is connected to the pixel TFT through a hole bored in at least a protective insulation film formed of an inorganic insulating material and formed above a gate electrode of the pixel TFT, and in an inter-layer insulation film disposed on the insulation film in close contact therewith. These process steps use 6 to 8 photo-masks.

Owner:SEMICON ENERGY LAB CO LTD

Method of producing a patterned birefringent product

ActiveUS20110043911A1High resolutionReadily pattern-identifiableLight effect designsPhotographic printingPolymerOptical anisotropy

A method of producing a patterned birefringent product, containing at least steps (I) to (III) in this order:(I) providing a birefringent pattern builder having an optically anisotropic layer containing a polymer;(II) subjecting two or more regions of the birefringent pattern builder to exposure to light under exposure conditions different from each other; and(III) heating a laminated structure obtained after the step (II) at 50° C. or higher and 400° C. or lower.

Owner:FUJIFILM CORP

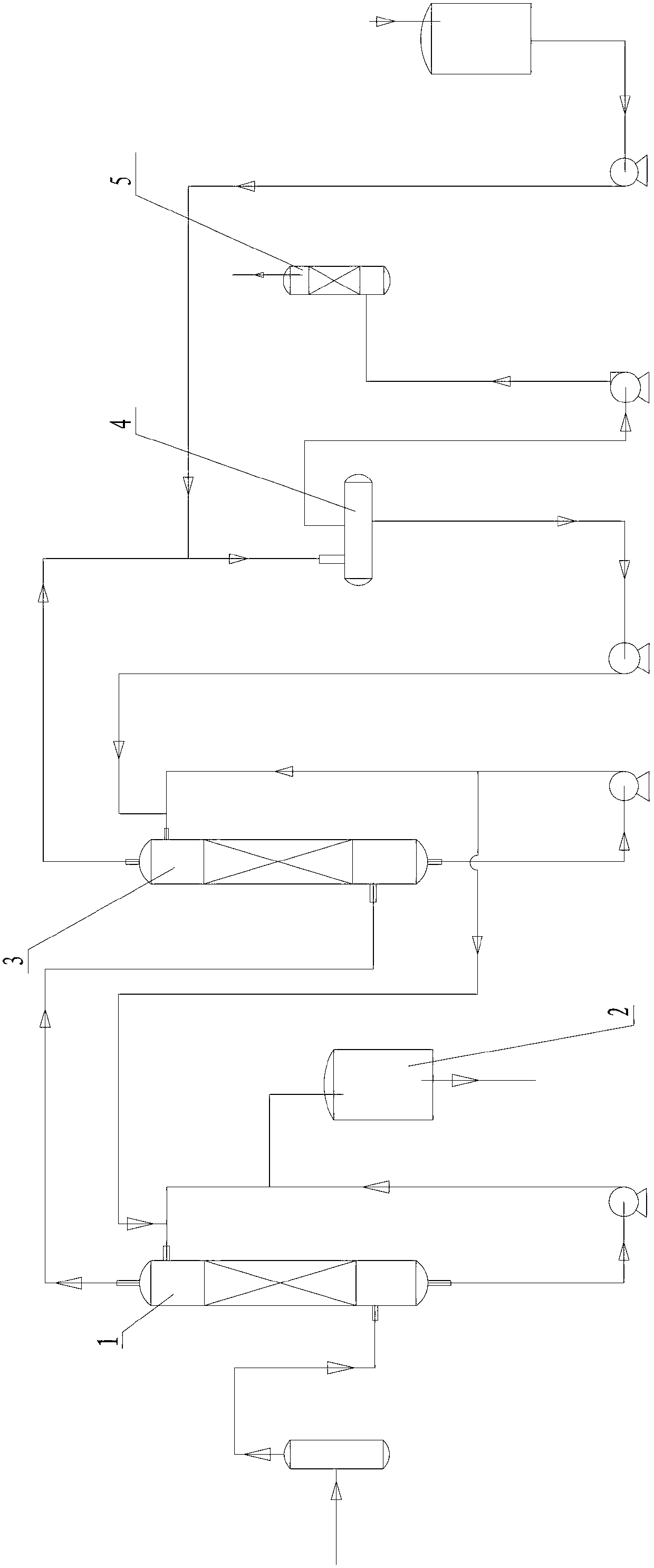

Technique method for producing sodium bisulfide

InactiveCN102765700AReduce power consumptionProduction costSulfur compoundsSodium bisulfideSodium hydrosulfide

The invention discloses a technique method for producing sodium bisulfide and belongs to the technical field of the chemical engineering production technology. The technique method for producing sodium bisulfide is low in production cost and can control product quality easily during production. The technique method includes: feeding buffered hydrogen sulfide and process absorption liquid with sodium sulphide as the main ingredient into an absorption tower respectively from the lower portion and the upper portion of the absorption tower, absorbing the hydrogen sulfide and the process absorption liquid on the surface of packing in the absorption tower to generate solution with the sodium bisulfide as the main ingredient, enabling the solution to flow to the bottom of the absorption tower, and discharging the unabsorbed hydrogen sulfide tail gas from the top of the absorption tower; pumping the solution at the bottom of the absorption tower out, returning most of the solution back to the absorption tower for recycling, feeding the small amount of solution to a sodium bisulfide production solution storing tank, and simultaneously adding the process absorption liquid in the absorption tower from the upper portion of the absorption tower during the absorption circulating process; and finally performing evaporation, concentration and dehydration on the solution, cooling the solution for molding, packaging and finishing the production of the sodium bisulfide.

Owner:CHENGDU DEMEI ENG TECH

Soundproofing material for vehicle

Owner:HOWA MASCH LTD

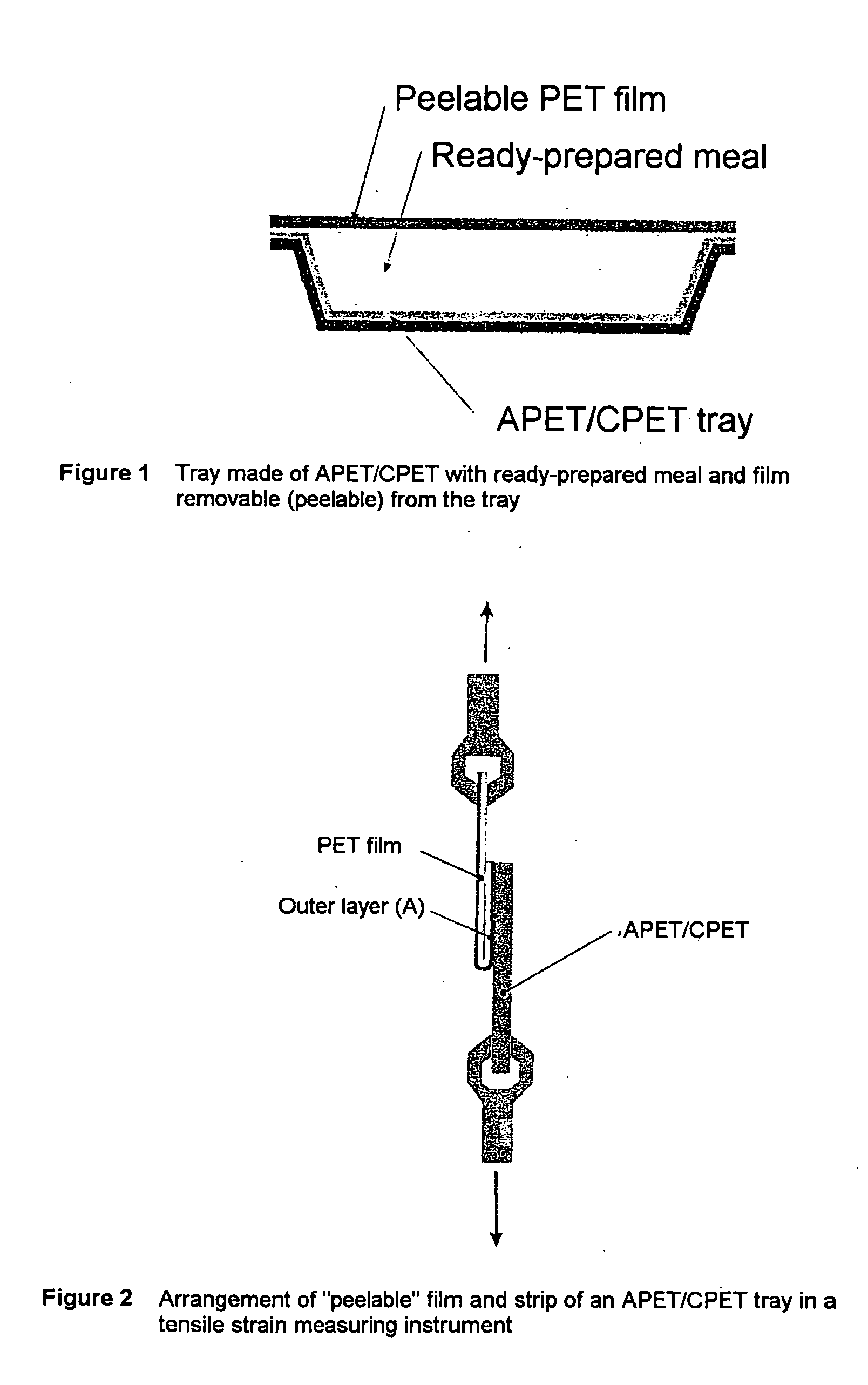

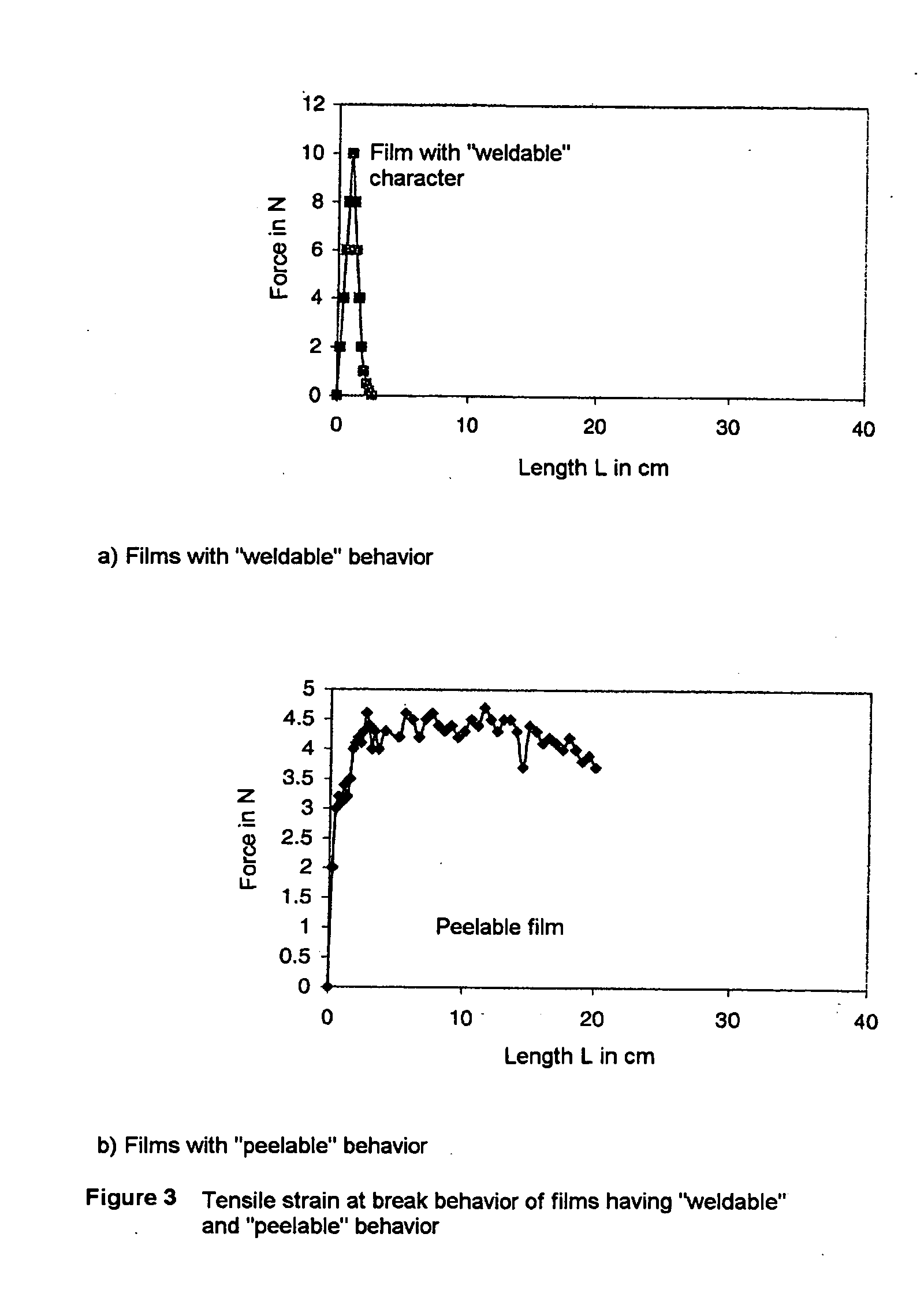

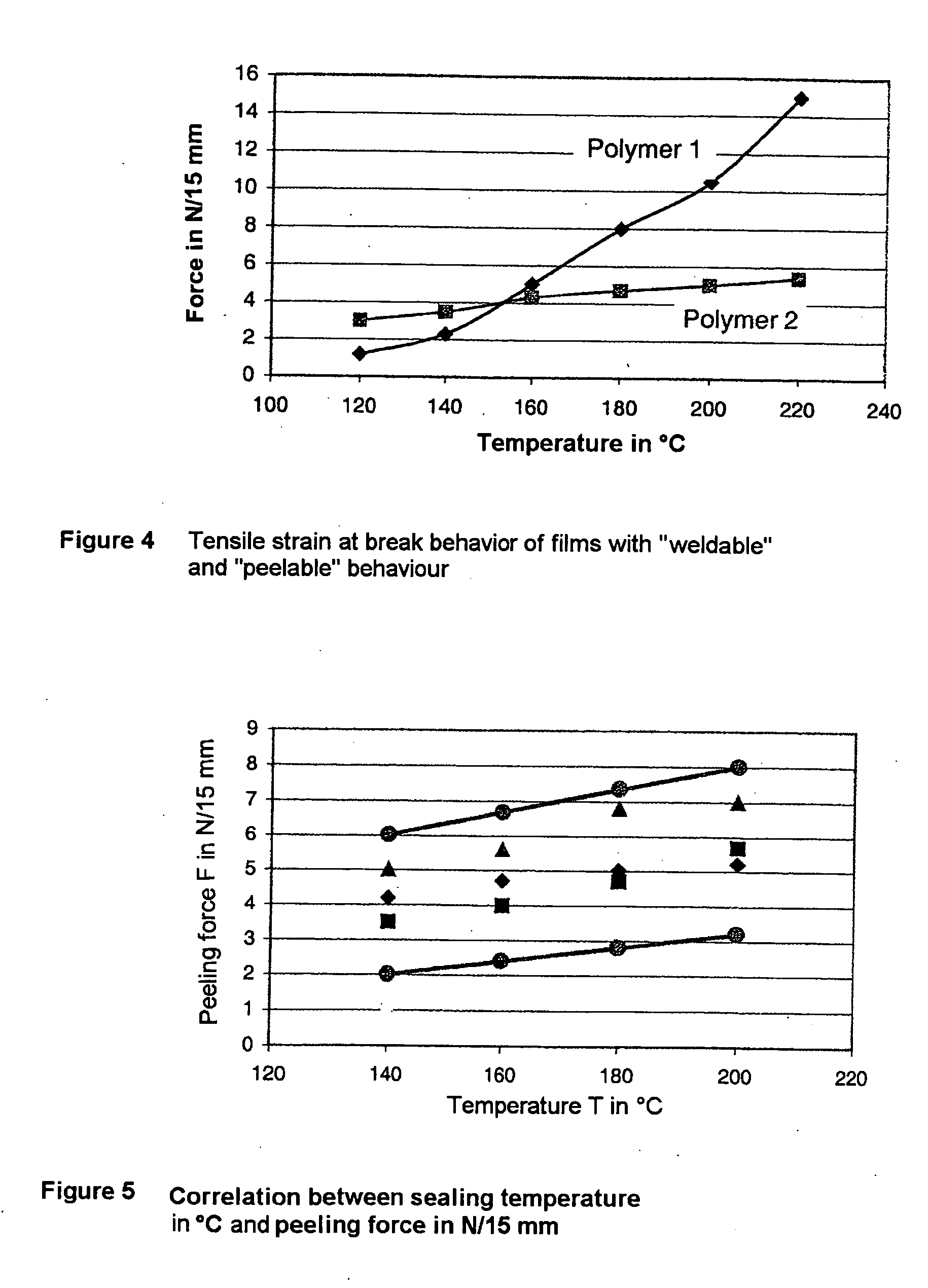

Process for producing a heatsealable and peelable polyester film

InactiveUS20050173050A1Production cost is notProduction costSynthetic resin layered productsLaminationPolyesterCarboxylic acid

A process for producing a biaxially oriented polyester film which has a base layer (B) and has a heatsealable outer layer (A) that can be peeled from polyester, where the outer layer (A) includes from 60 to 99% by weight of polyester which is composed of from 12 to 89 mol % of units derived from an aromatic dicarboxylic acid and of from 11 to 88 mol % of units derived from at least one aliphatic dicarboxylic acid, where the total of the molar percentages is 100, encompassing the steps of a) extruding of at least the base layer (B) to give an unoriented film; b) stretching this film in a first direction; c) stretching this film in a second direction perpendicular to the first d) heat-setting the stretched film, and e) producing the outer layer (A) on the base layer (B) by using lamination to apply the outer layer film (A) produced in a separate process, where the lamination step e) takes place prior to step b) or between steps b) and c).

Owner:MITSUBISHI POLYESTER FILM

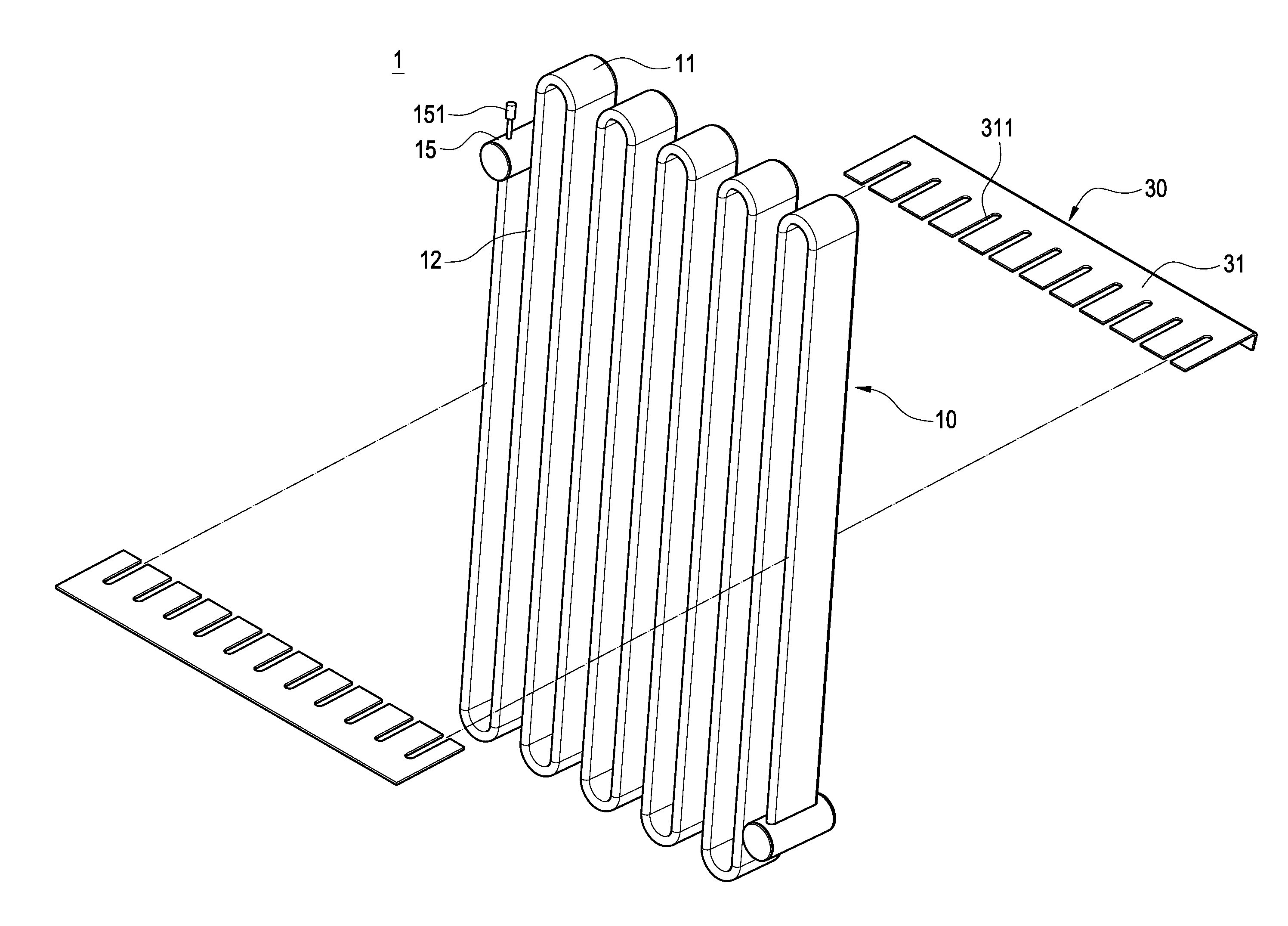

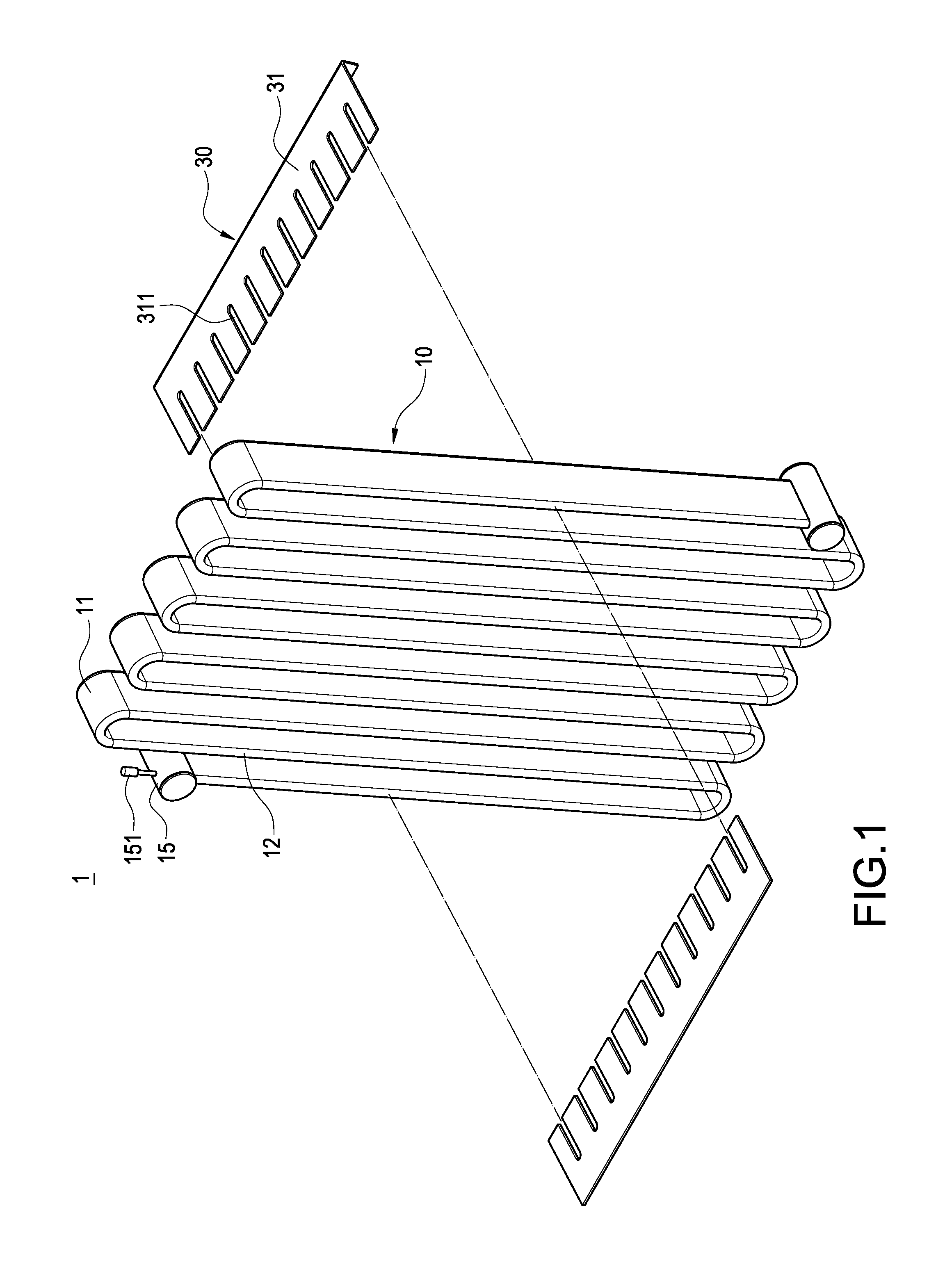

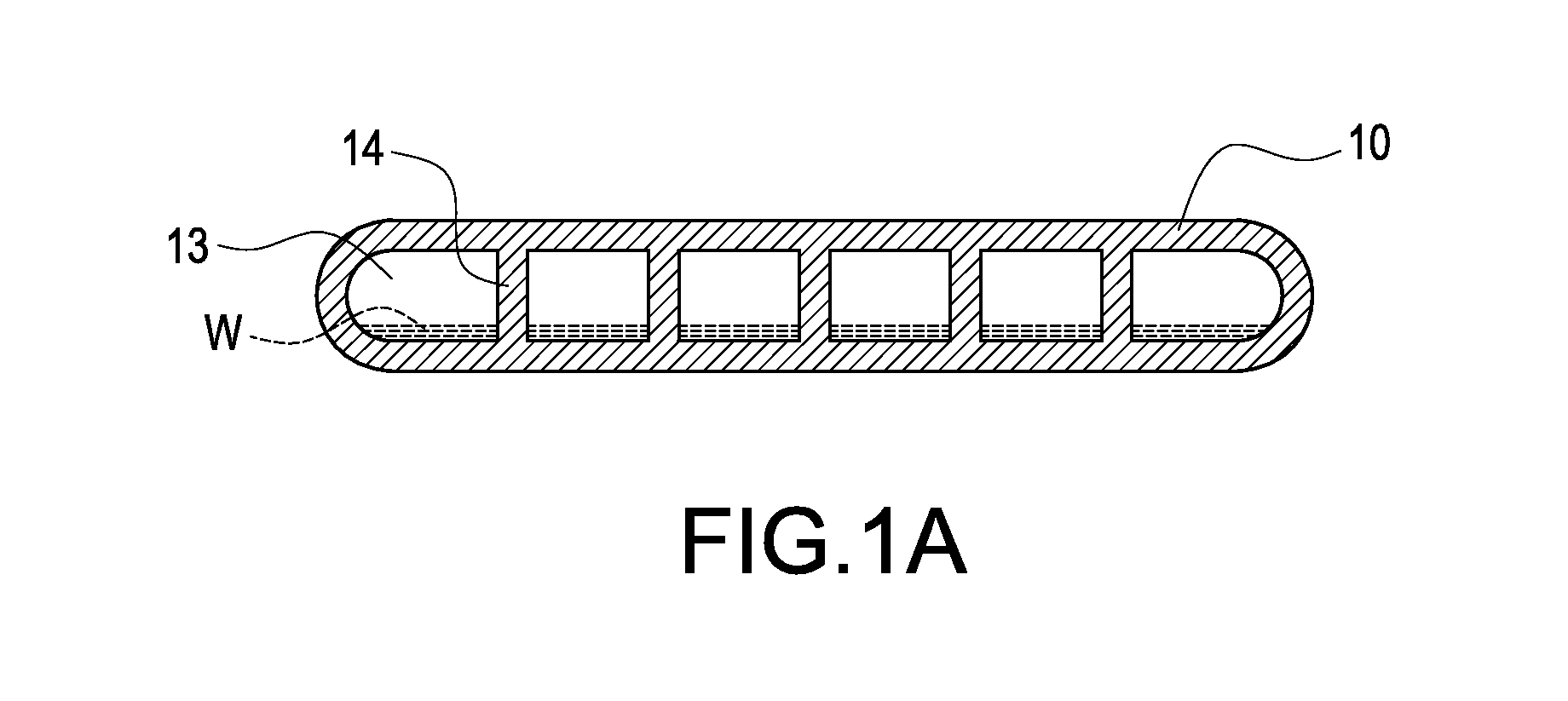

Multi-channel flat-tube serpentine heat exchanger and heat exchange apparatus

InactiveUS20120267088A1Work lessImprove yield rateStationary conduit assembliesHeat exchanger casingsWorking fluidEngineering

The present invention relates to a multi-channel flat-tube serpentine heat exchanger and a heat exchange apparatus. The heat exchanger includes a flat pipe, a fin set and a divider assembly. The flat pipe has bending sections and connecting sections. The flat pipe is filled with a working fluid and has channels. The fin set is connected between the connecting sections to increase heat-exchange area of the flat pipe. The divider assembly is connected to the flat pipe to divide the flat pipe into a heat-absorbing region and a heat-releasing region. The working fluid in the heat-absorbing region absorbs heat to evaporate and then flows into the heat-releasing region along the channels. The evaporated working fluid condenses in the heat-releasing region to flow back to the heat-absorbing region along the channels by means of gravity. Therefore, the present invention has a reduced production cost and an increased heat-exchange efficiency.

Owner:COOLING HOUSE

Thermally conductive resin composition

ActiveUS8324313B2Reduce hardnessImprove thermal conductivitySpecial tyresSilane compoundsPolymer science

The thermally conductive resin composition of the present invention contains (a) a matrix component, (b) a larger-diameter thermally conductive inorganic powder, (c) a smaller-diameter thermally conductive inorganic powder, and (d) a vulcanizing agent and / or curing agent. The surface of the smaller-diameter thermally conductive inorganic powder is selectively treated with a silane compound represented by R(CH3)aSi(OR′)3-a (wherein R is an unsubstituted or substituted organic group having 6 to 20 carbon atoms, R′ is an alkyl group having 1 to 4 carbon atoms, and a is 0 or 1) or a partially hydrolyzed product thereof, and the amount thereof is smaller than the amount necessary to coat the entire surface area of the smaller-diameter thermally conductive inorganic powder. Accordingly, a thermally conductive resin composition that has a low hardness and a high thermal conductivity and that undergoes little outgassing and has storage stability is provided even when large amounts of thermally conductive inorganic powder is loaded into the resin component.

Owner:FUJI POLYMER INDUSTRIES CO LTD

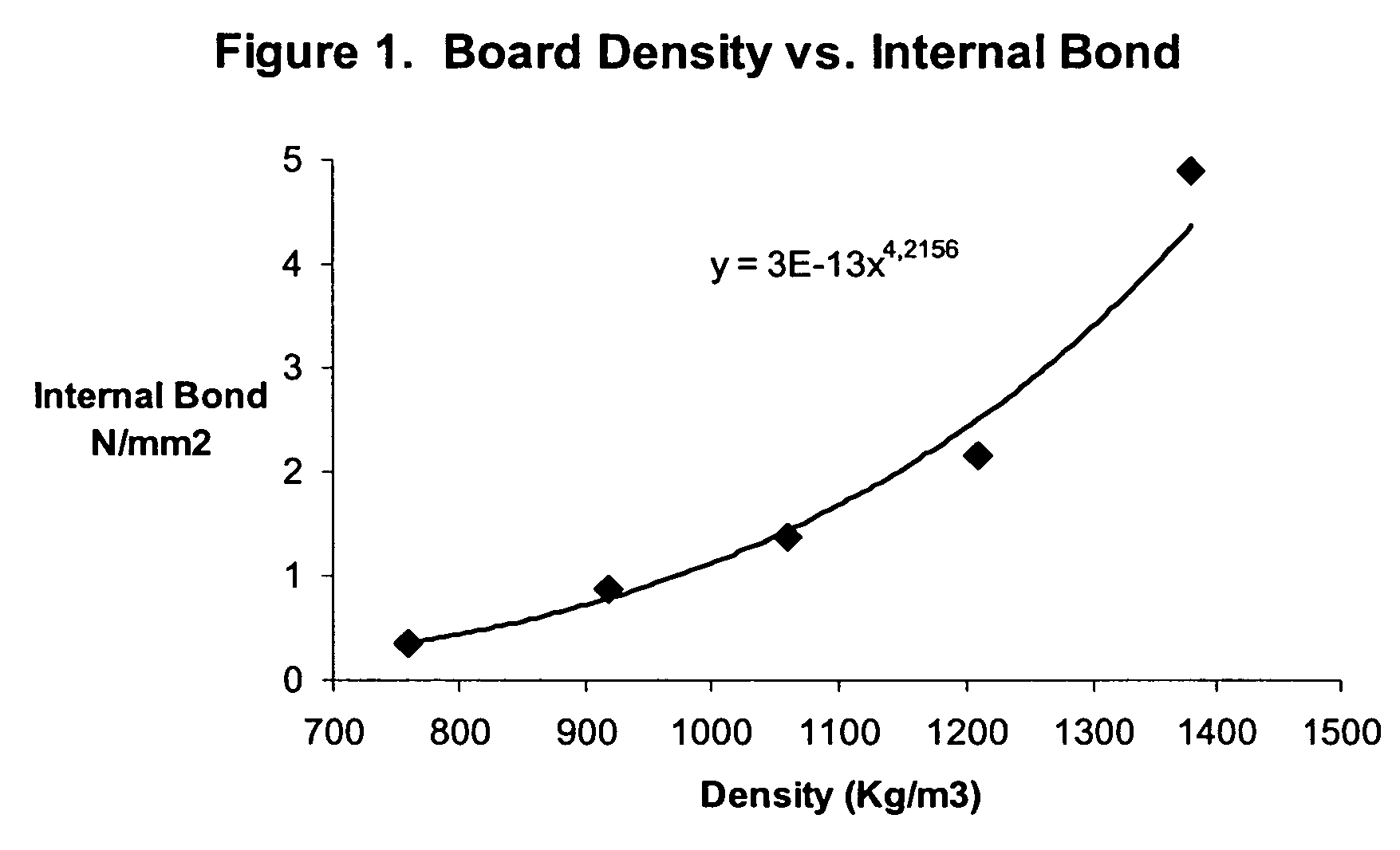

Method for making dimensionally stable composite products from lignocelluloses

InactiveUS7183339B2Good physical propertiesImprove water resistanceCeramic shaping apparatusCork mechanical workingPolymer scienceHigh density

This invention relates to a process for making dimensionally stable reconstituted composite products from lignocellulosic material. By treating lignocellulose with high pressure steam to decompose and hydrolyze the hemicellulose, cellulose and lignin fractions of the lignocellulose and using those decomposition products as both a bonding and bulking agent, it converts, under heat and pressure in a molding operation, the treated lignocellulose into molded composite products such as panel boards and molded articles. The composite products thus produced possess good physical and mechanical properties. Specifically, the dimensional stability in terms of the thickness swelling and linear expansion of panel boards such as fiberboards and particleboard, can be minimized to very low levels when the panel boards are made in high density. The adhesive bond developed from thermosetting of the decomposition products of hemicellulose, cellulose and lignin is strong and stable, and resistant to boiling water and acid hydrolysis, and is free of formaldehyde emissions. Thus, the reconstituted panel boards and molded products are suitable for exterior and particularly for indoor applications. The absence of free formaldehyde emissions makes the product very suitable for interior applications. The manufacturing cost for the reconstituted products is significantly lower in comparison to the conventional process because expensive synthetic resin is not used.

Owner:SHEN KUO C +1

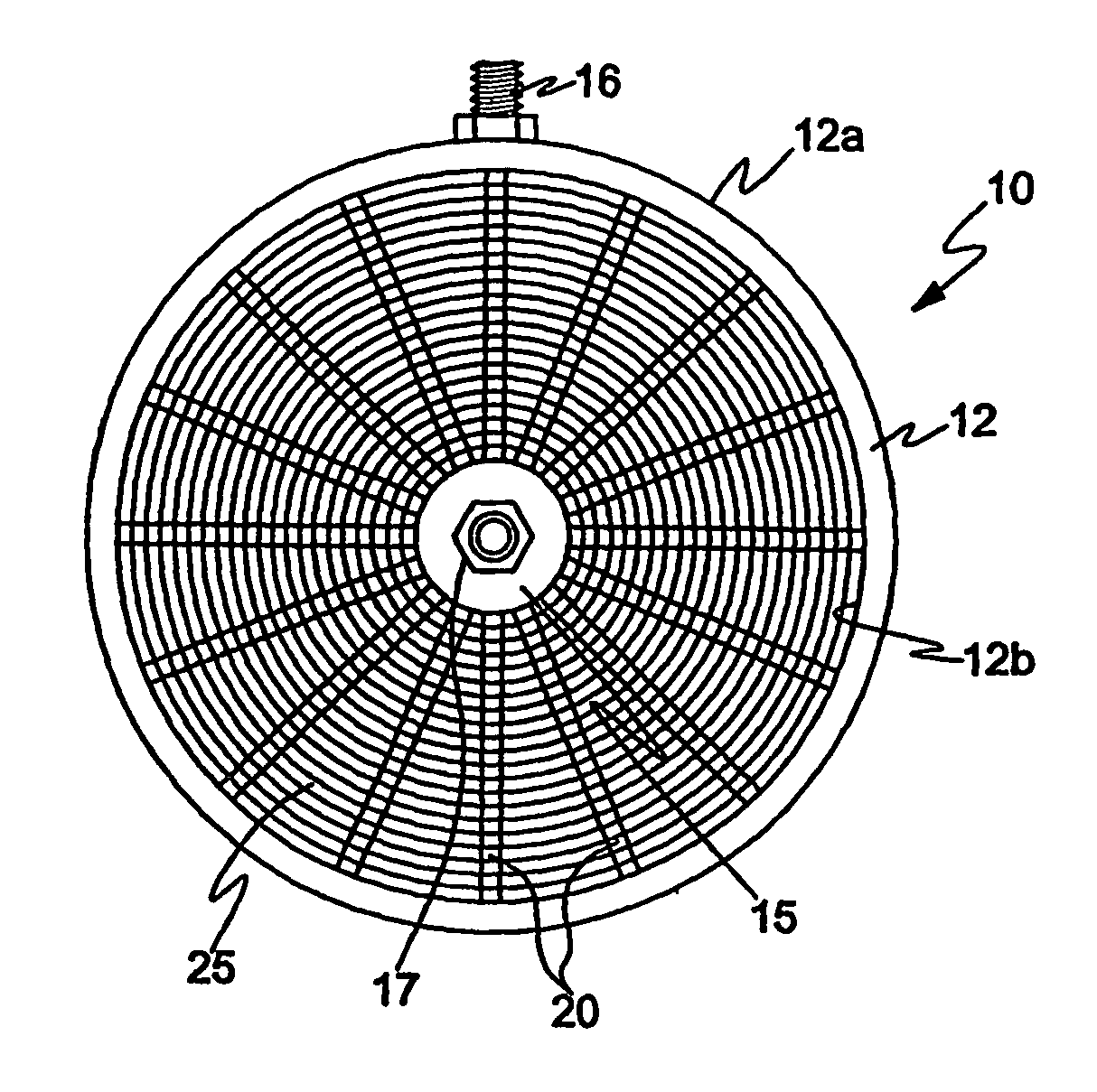

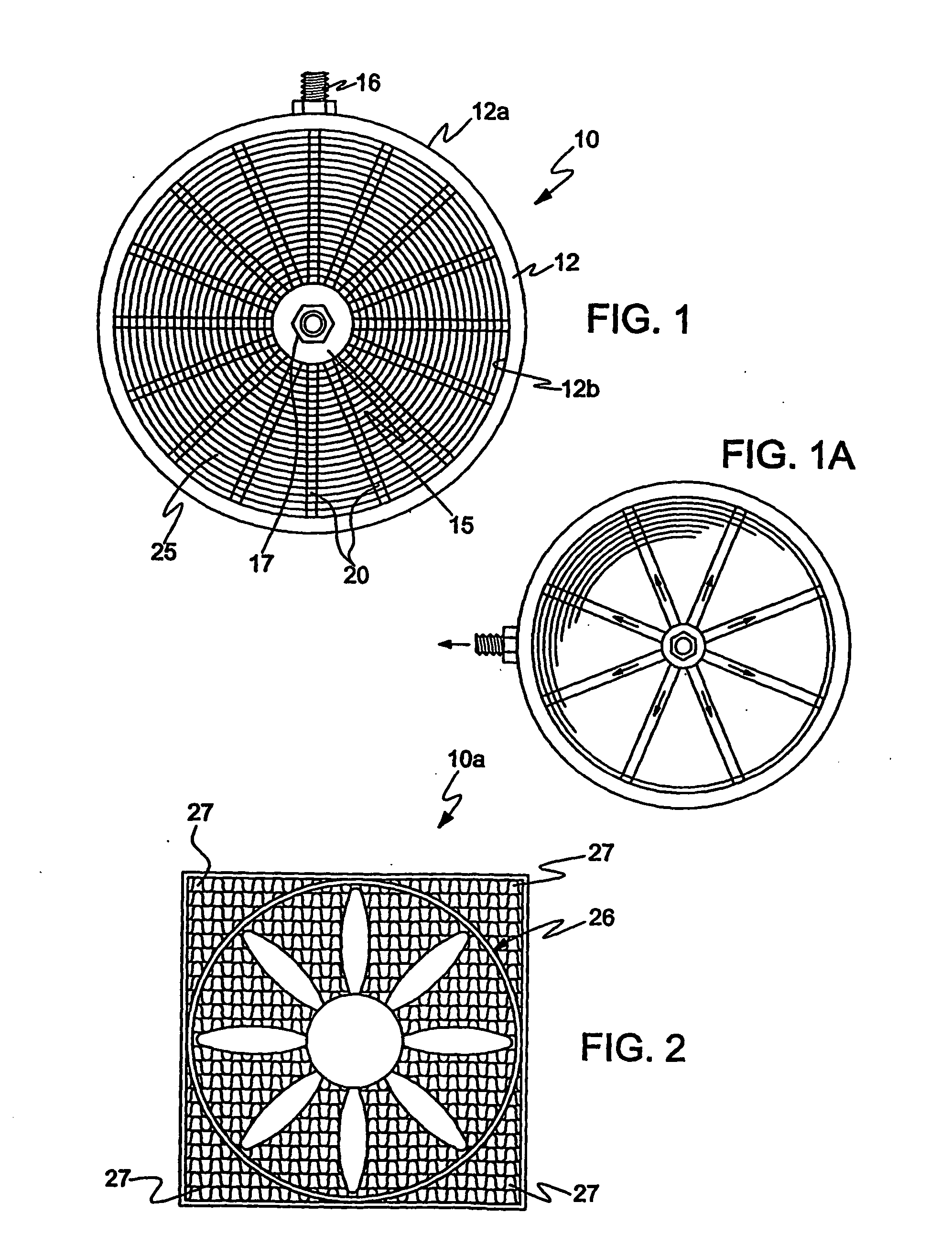

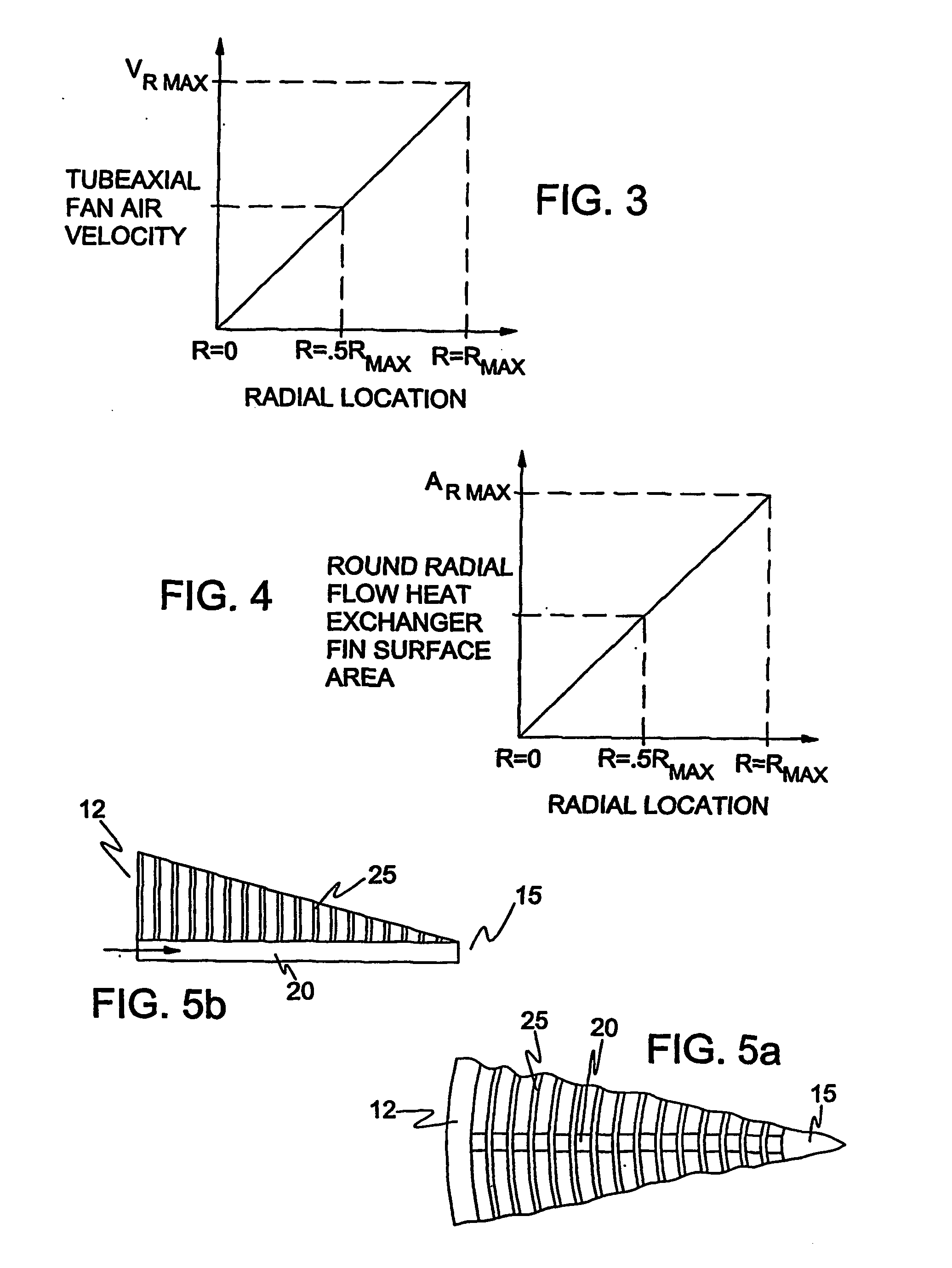

Radial flow heat exchanger

InactiveUS20050056408A1Improve heat transfer performanceEfficient heat transferStationary conduit assembliesHeat exchanger casingsHeat conductingBiomedical engineering

A radial flow heat exchanger for heating or cooling a fluid includes a sealed fluid manifold for passage of fluid. A sealed fluid receiving hub is spaced interiorly of the interior peripheral portion of the manifold and includes a passageway for passage of fluid into or out of the heat exchanger. A plurality of separate and spaced fluid flow tubes are disposed between the manifold and the hub. Each of the tubes are in sealed fluid communication with the manifold at one end and the other end is in sealed fluid communication with the hub. A fin assembly is positioned between the manifold and the hub and includes a heat conducting material arranged at spaced intervals between the manifold and the hub, the heat conducting material including a plurality of spaced apertures through which tubes pass. The heat conducting material is in intimate heat conducting contact with the tubes whereby fluid flowing between the manifold and the hub flows into each of the tubes in a radial direction between the manifold and the hub and wherein the heat conducting material of the fin assembly operates to give up or pick up heat from the fluid through the wall of the tubes.

Owner:GREGORY CHRISTIAN T

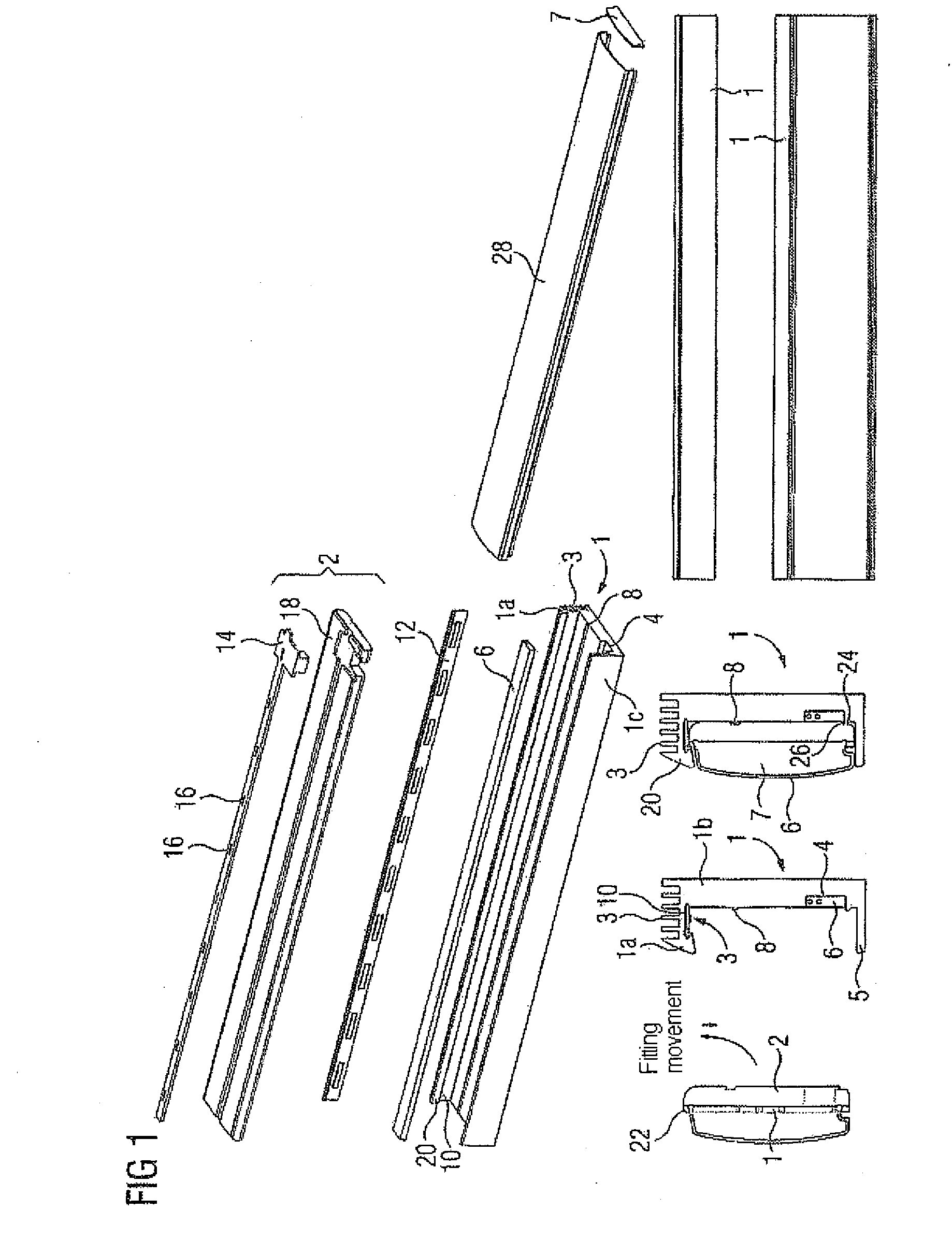

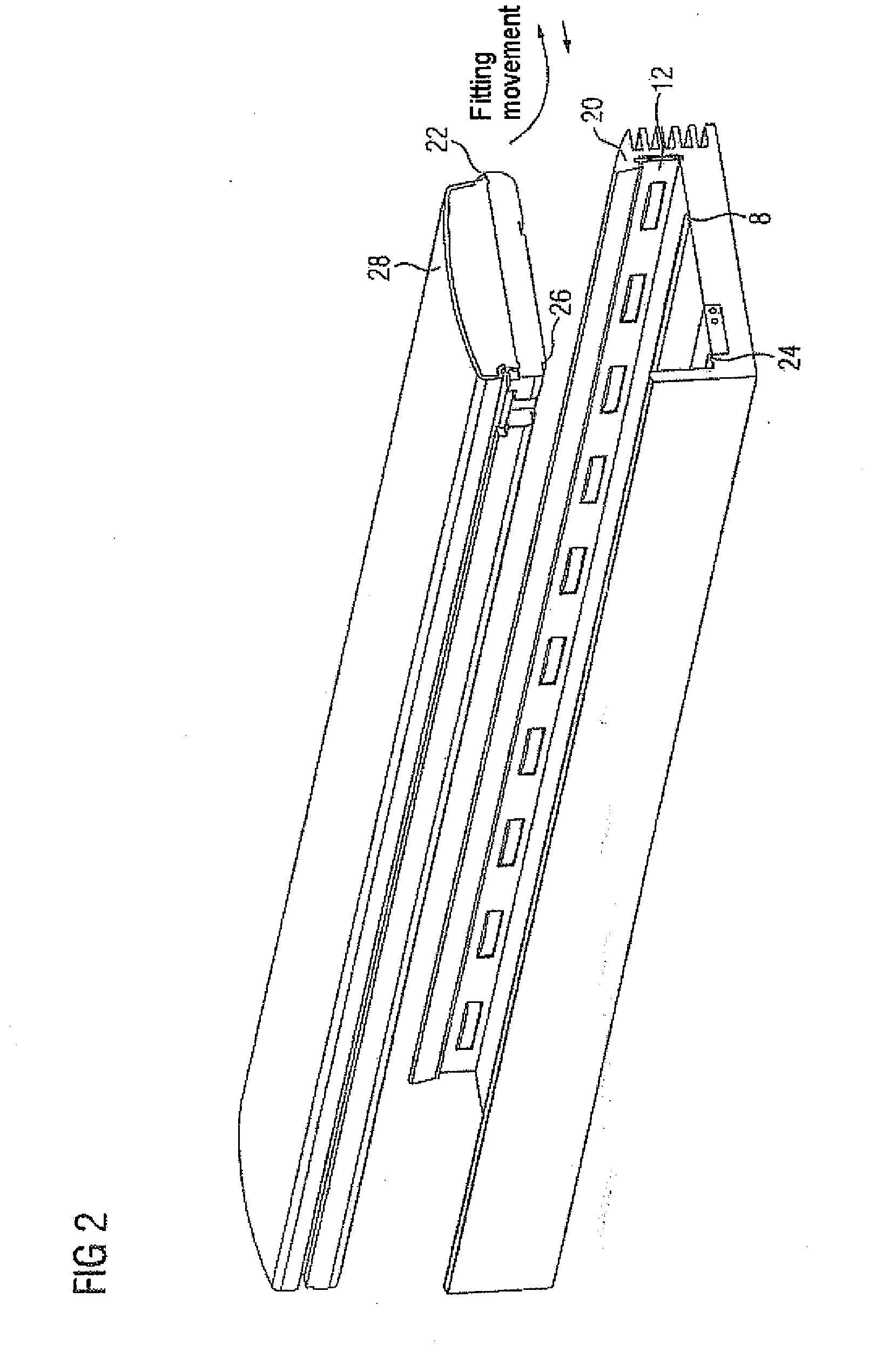

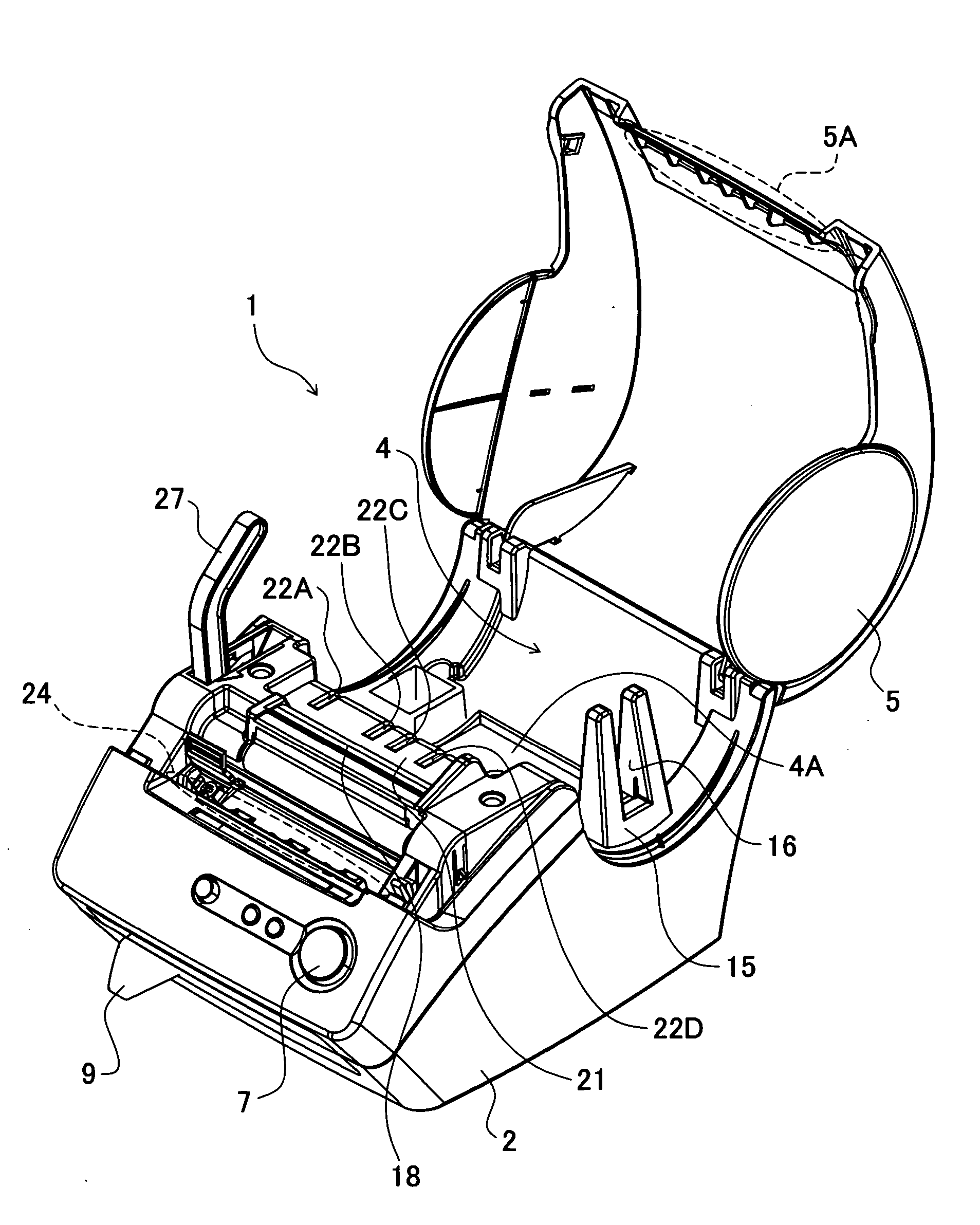

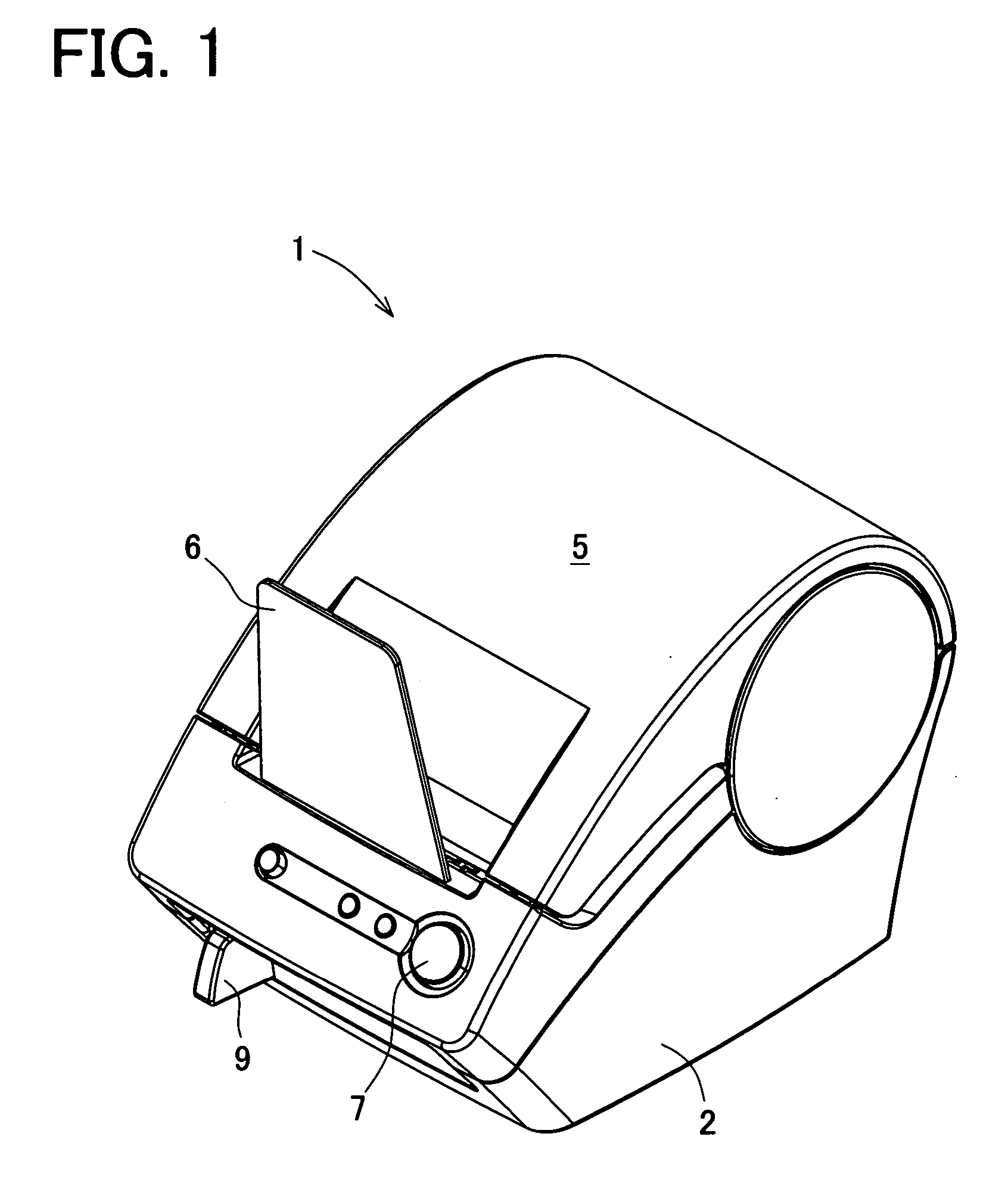

Printer

ActiveUS20060008312A1Improve accuracySimple designOther printing apparatusArticle deliveryRolling paperComputer printing

A top cover and a guide member form a discharge port. A plurality of guide ribs is provided on an edge portion of the top cover. A plurality of projecting pieces is provided on a guide member at positions not to face to the guide ribs. These guide ribs and projecting pieces are used for guiding a roll sheet to a discharge port. At least one of the guide ribs is provided with an extended portion extending upstream in a feeding direction to prevent the roll sheet 3A from curving in a direction vertical to the feeding direction. Thus, the inability to discharge the roll sheet can be avoided.

Owner:BROTHER KOGYO KK

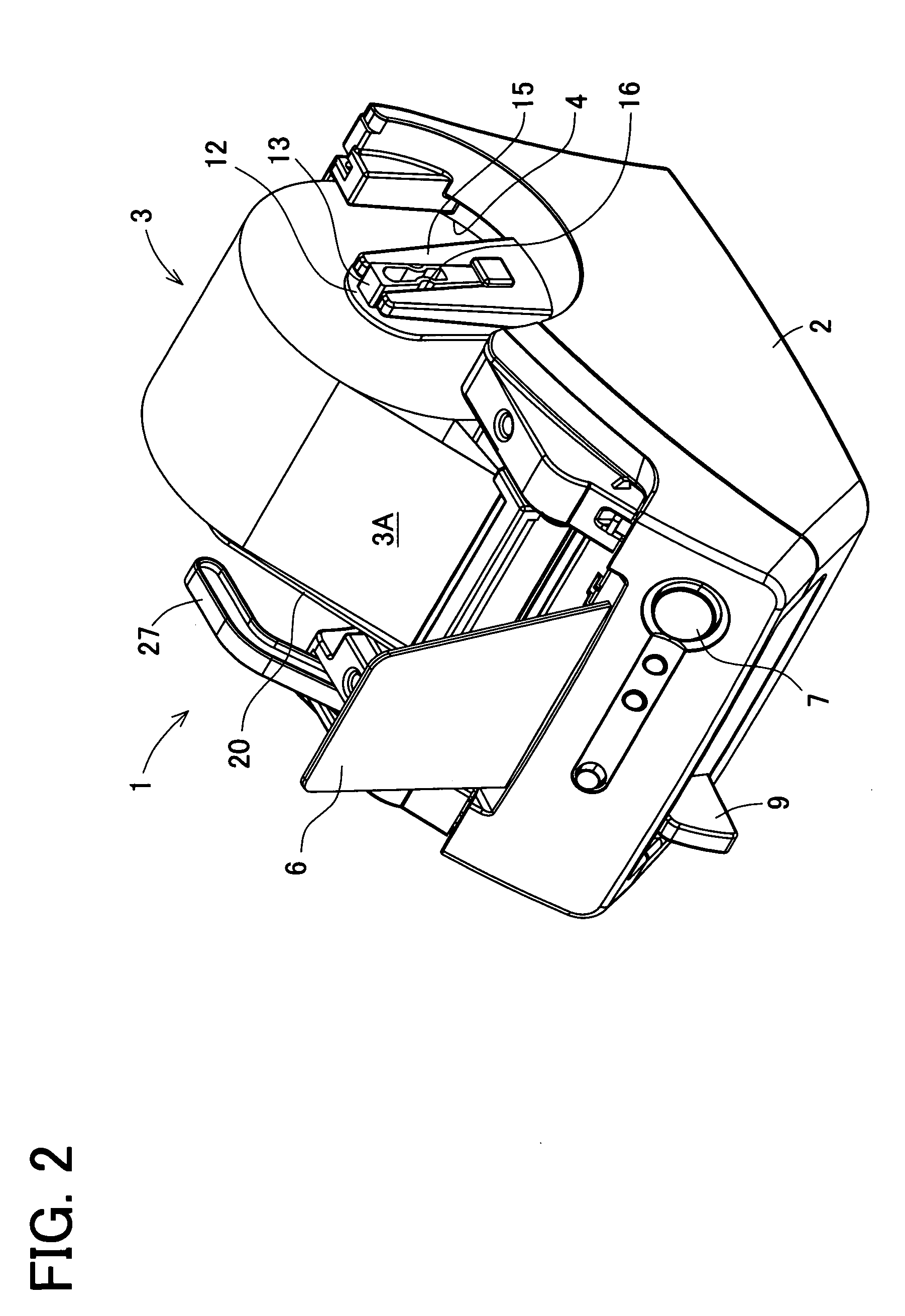

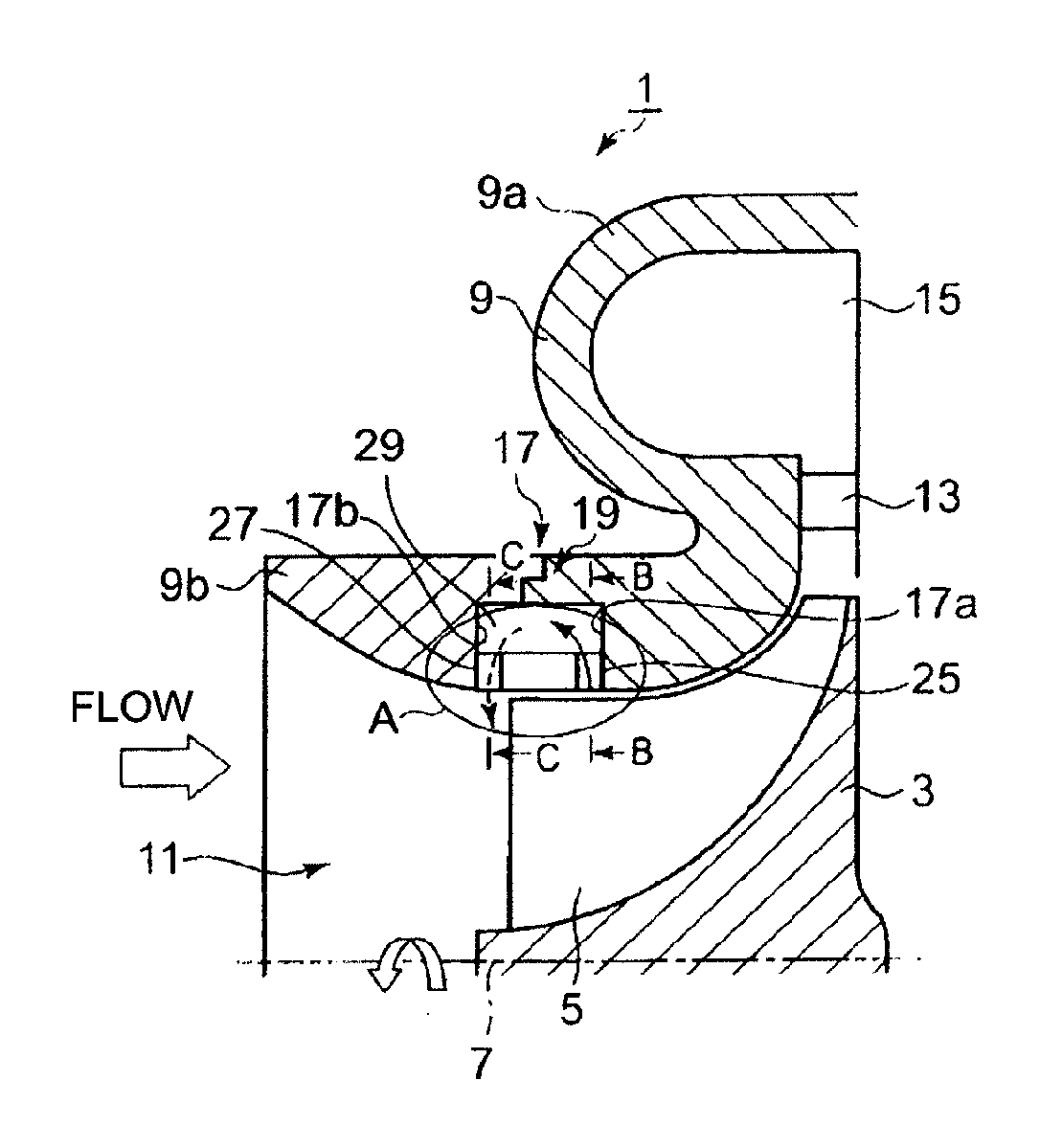

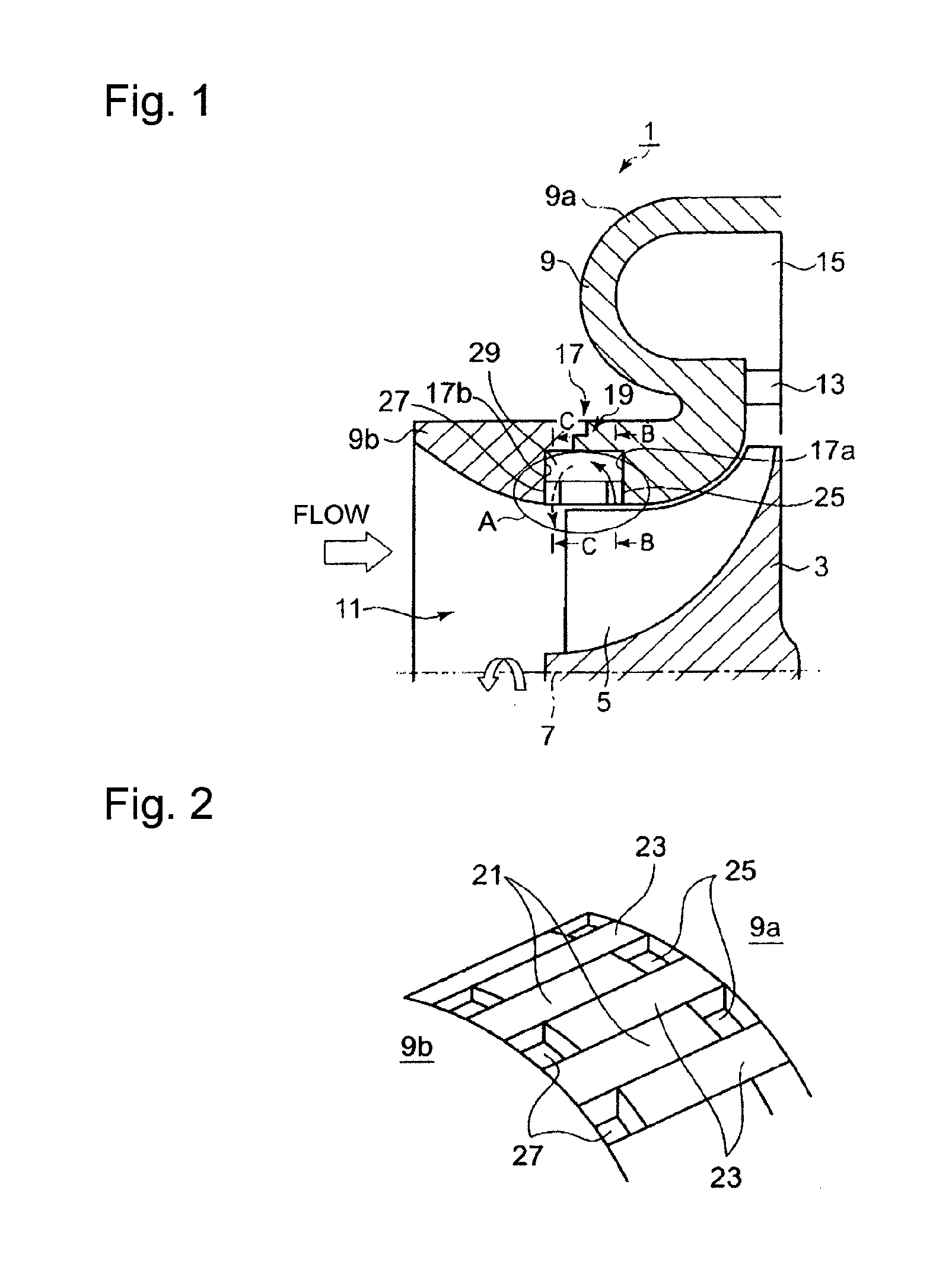

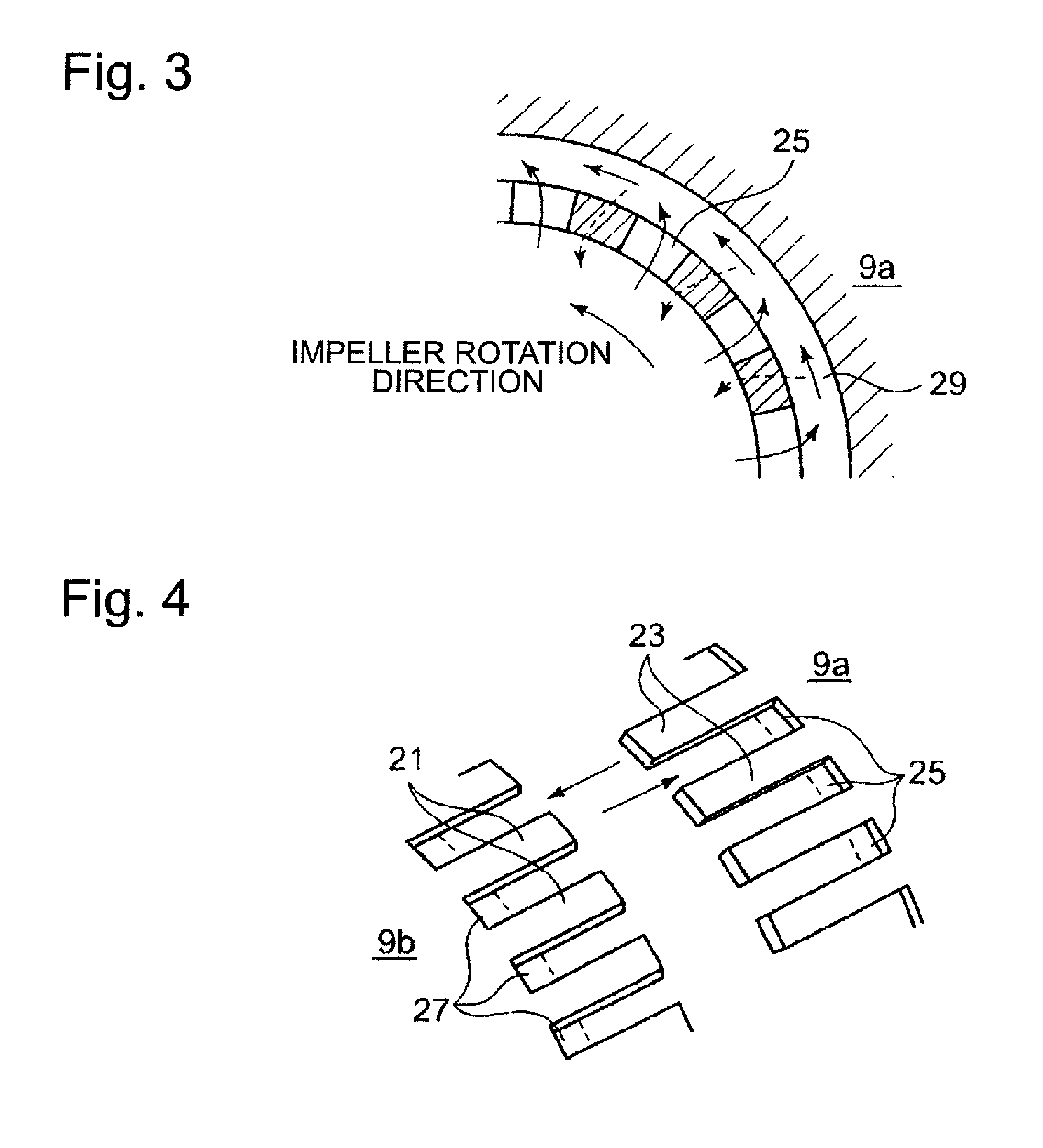

Compressor of exhaust gas turbocharger

ActiveUS20120121400A1Shorten production hoursProduction costPump componentsStatorsImpellerTurbocharger

A compressor of an exhaust gas turbocharger has an inlet slit, an outlet slit and the recirculation passage can formed at the same time when the compressor housing assembled. Ease of assembly and the reduction of the production cost is achieved. The structure of the inlet slit, the outlet slit and the recirculation passage can be compact and can be easily adjusted. Noises generated in the compressor impeller can be reduced without providing a noise insulation cover.

Owner:MITSUBISHI HEAVY IND LTD

Method for producing sintered ferrit magnet, and sintered ferrite magnet

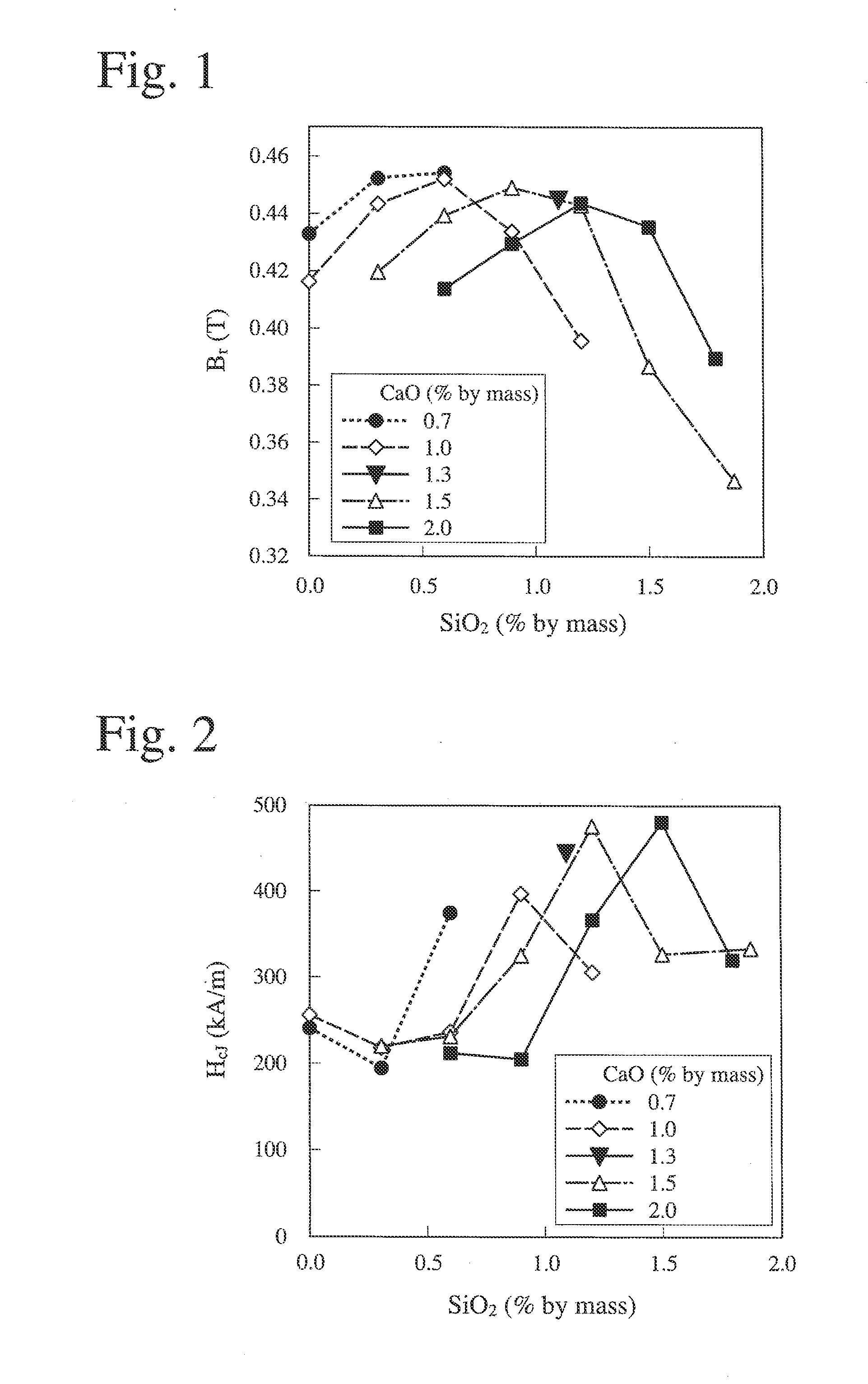

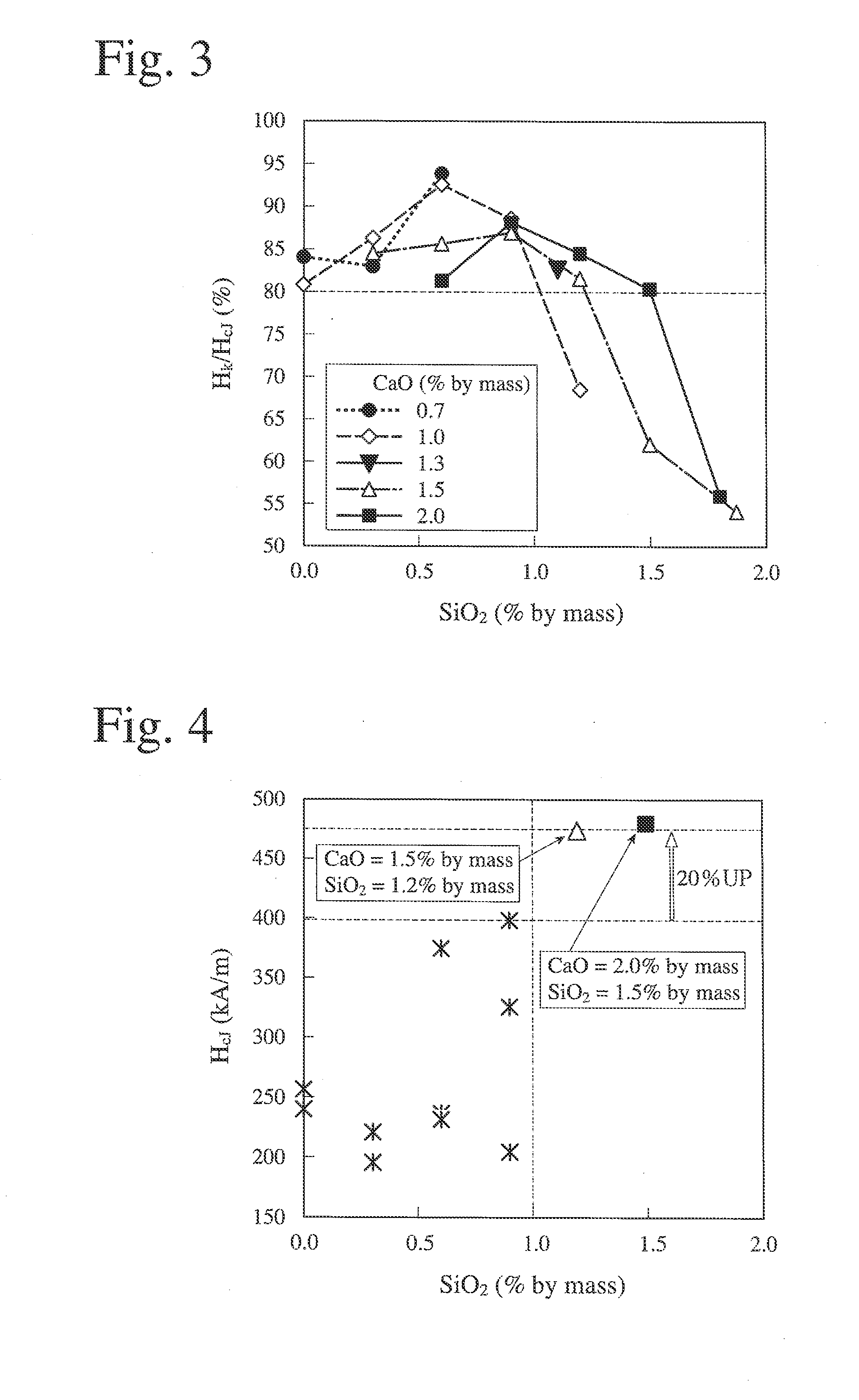

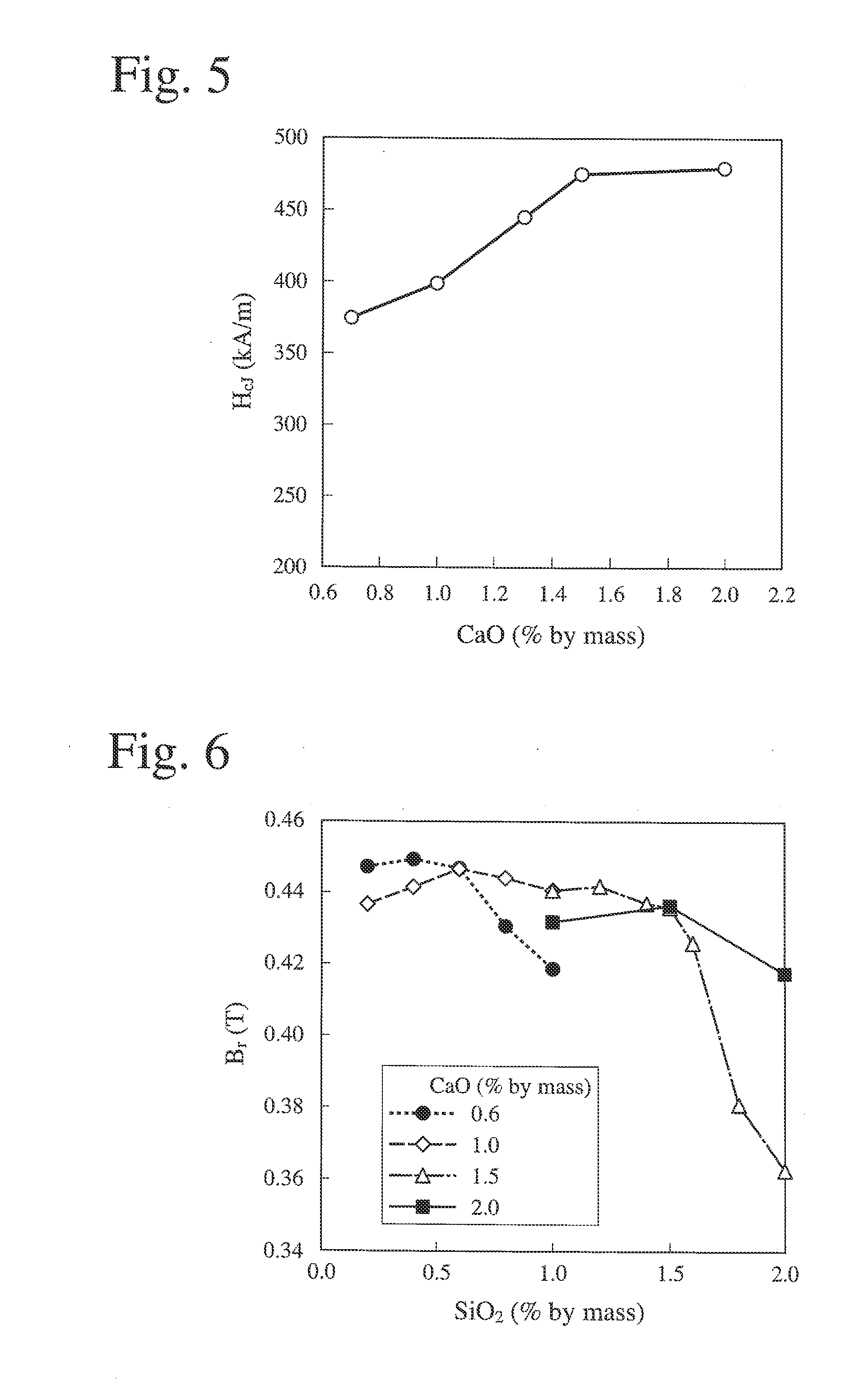

ActiveUS20120105185A1Improve HcjLow costPermanent magnetsInorganic material magnetismRare-earth elementFerrite (magnet)

A sintered ferrite magnet comprising (a) a ferrite phase having a hexagonal M-type magnetoplumbite structure comprising Ca, an element R which is at least one of rare earth elements and indispensably includes La, an element A which is Ba and / or Sr, Fe, and Co as indispensable elements, the composition of metal elements of Ca, R, A, Fe and Co being represented by the general formula of Ca1-x-yRxAyFe2n-zCoz, wherein the atomic ratios (1-x-y), x, y and z of these elements and the molar ratio n meet the relations of 0.3≦(1-x-y)≦0.65, 0.2≦x≦0.65, 0≦y≦0.2, 0.03≦z≦0.65, and 4≦n≦7, and (b) a grain boundary phase indispensably containing Si, the amount of Si being more than 1% by mass and 1.8% or less by mass (calculated as SiO2) based on the entire sintered ferrite magnet, and its production method.

Owner:HITACHI METALS LTD

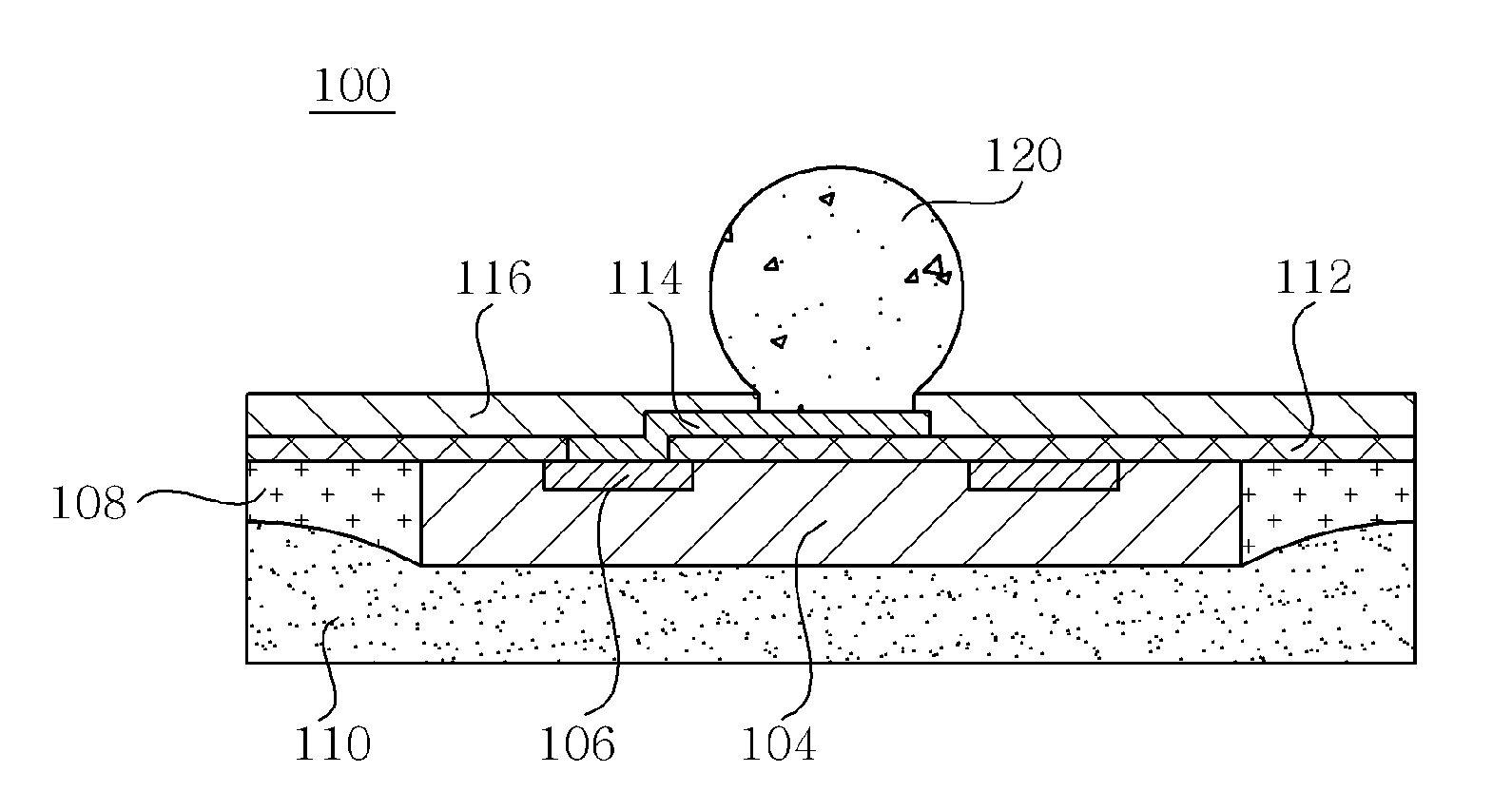

Die package including encapsulated die and method of manufacturing the same

InactiveUS20100320624A1Improve reliabilityMinimize occurrenceSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerThermal expansion

Disclosed herein is a die package including an encapsulated die, including: a die including pads on one side thereof; an encapsulation layer covering lateral sides of the die; a support layer covering the encapsulation layer and one side of the die; a passivation layer formed on the other side of the die such that the pads are exposed therethrough; and a redistribution layer formed on the passivation layer such that one part thereof is connected with the pad. Here, since one side of the die is supported by the support layer and the encapsulation layer is formed on only the lateral side of the die, the warpage of the die package due to the difference in thermal expansion coefficient can be minimized.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

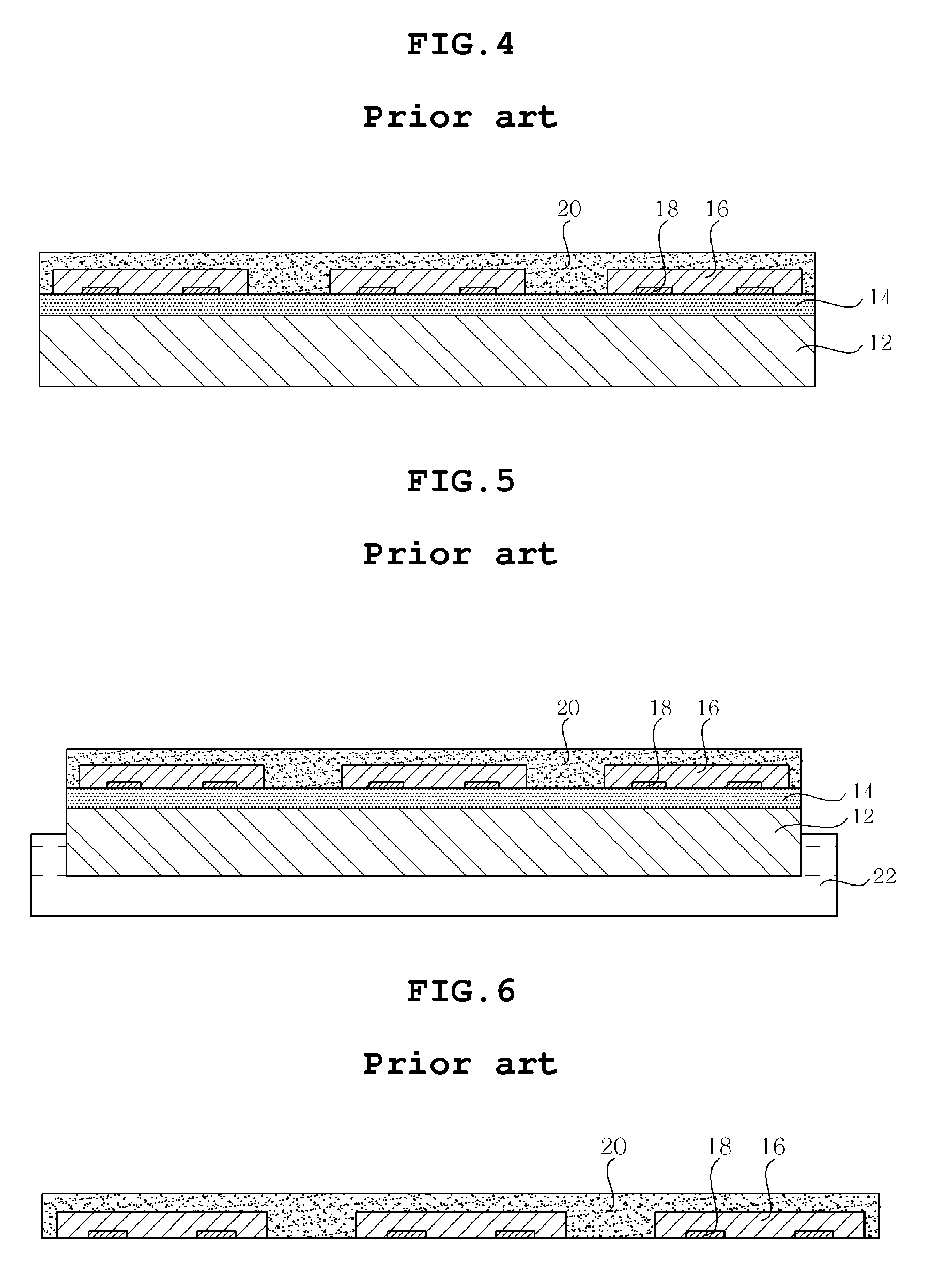

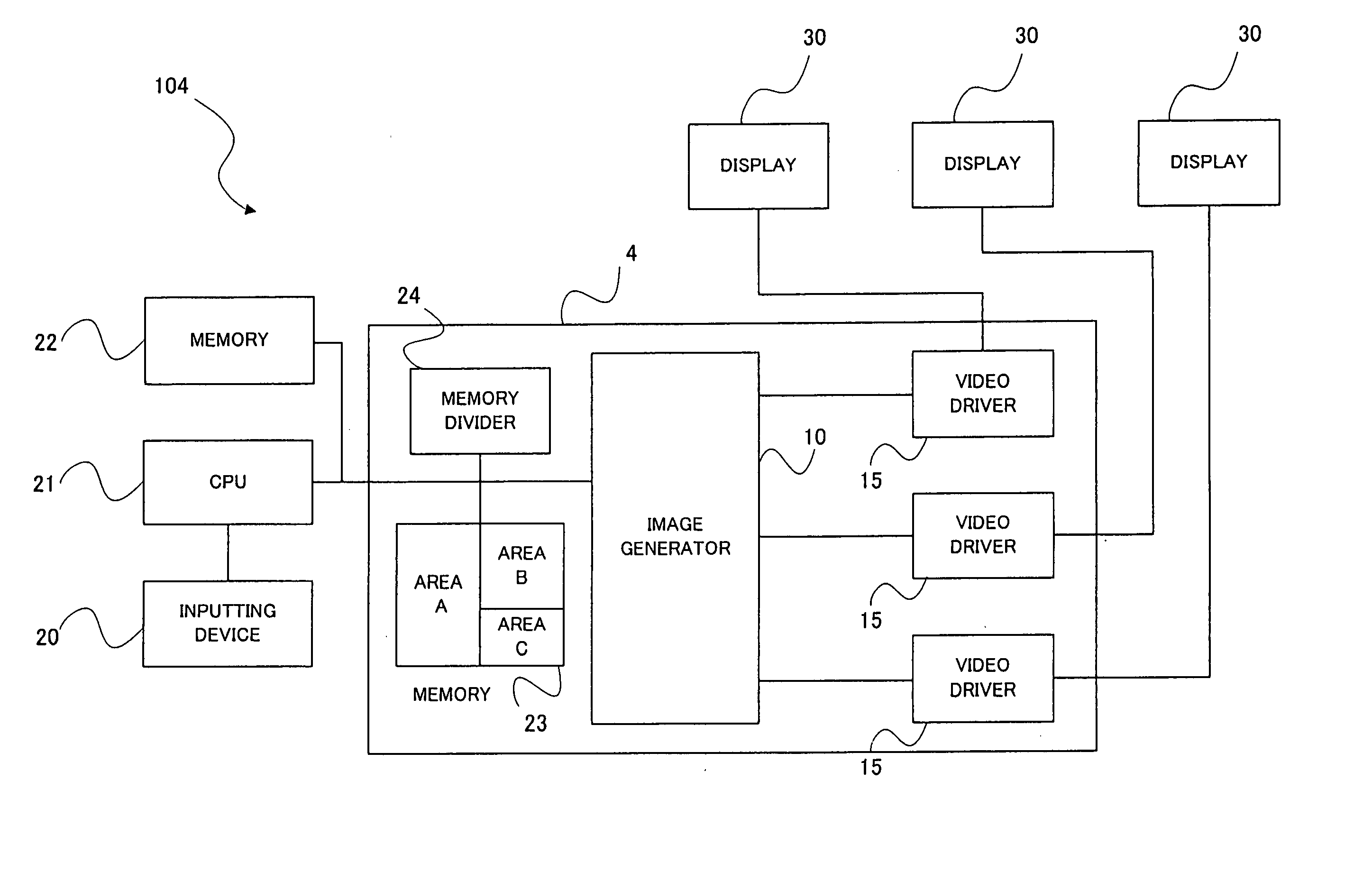

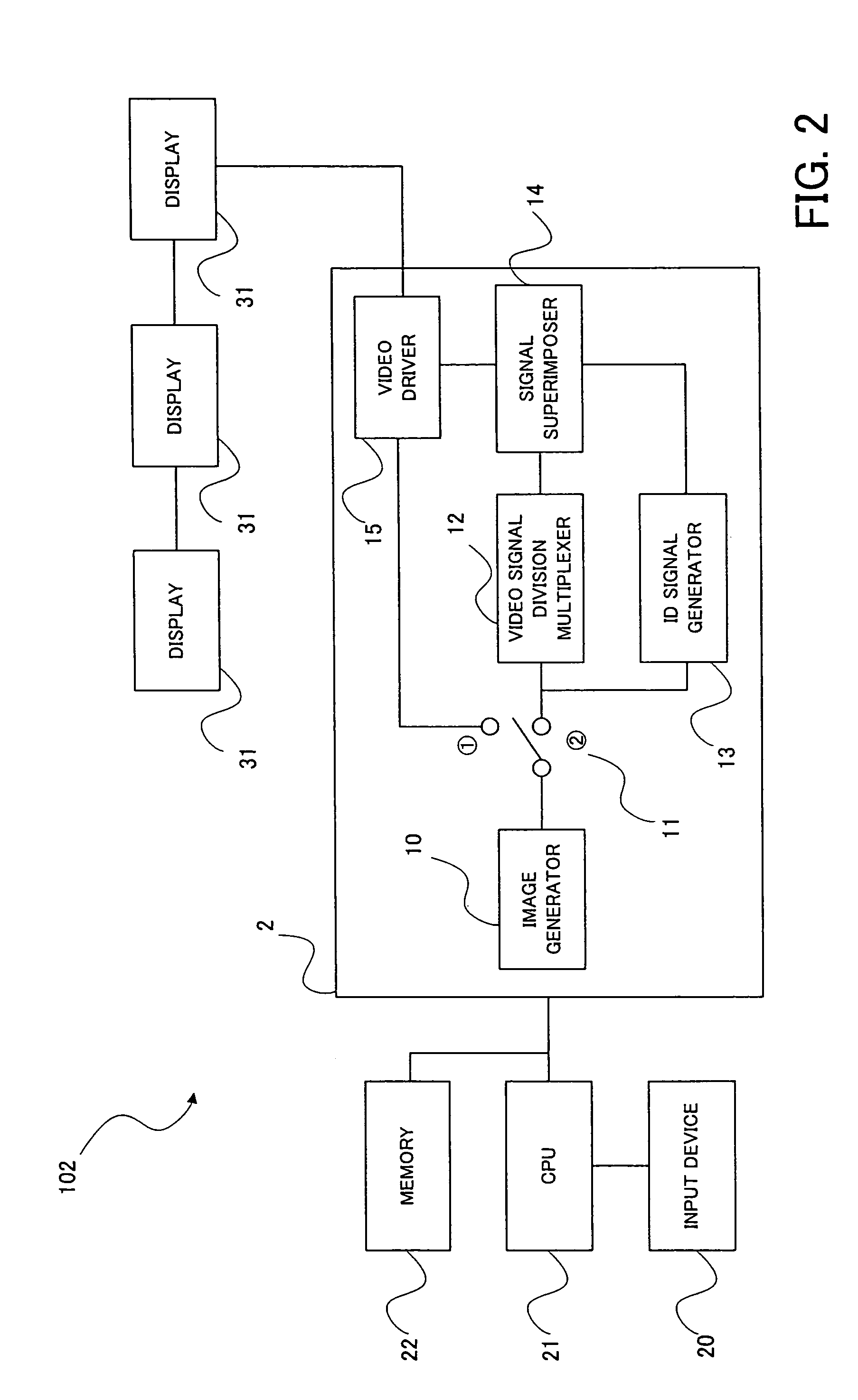

Drawing apparatus and method, computer program product, and drawing display system

InactiveUS20050140567A1Easily embodiedReduce areaTelevision system detailsColor television detailsComputer graphics (images)Display device

A drawing apparatus for displaying video images on a plurality of display devices respectively, the apparatus is provided with: a video signal generating device for generating a plurality of different video signals; and a signal transmitting device for transmitting each of the plurality of different video signals to the plurality of display devices corresponding to each of the different video signals.

Owner:PIONEER CORP

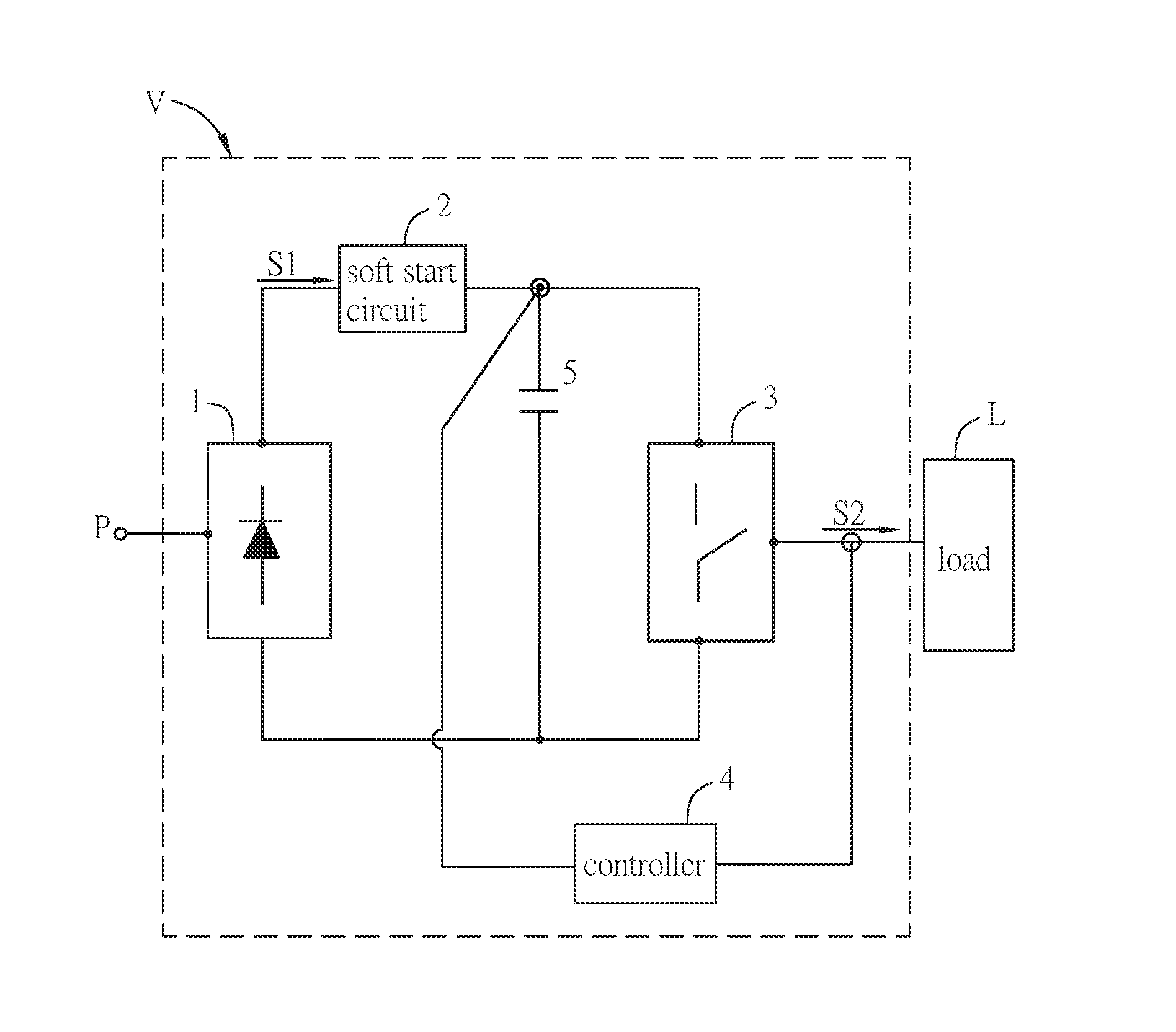

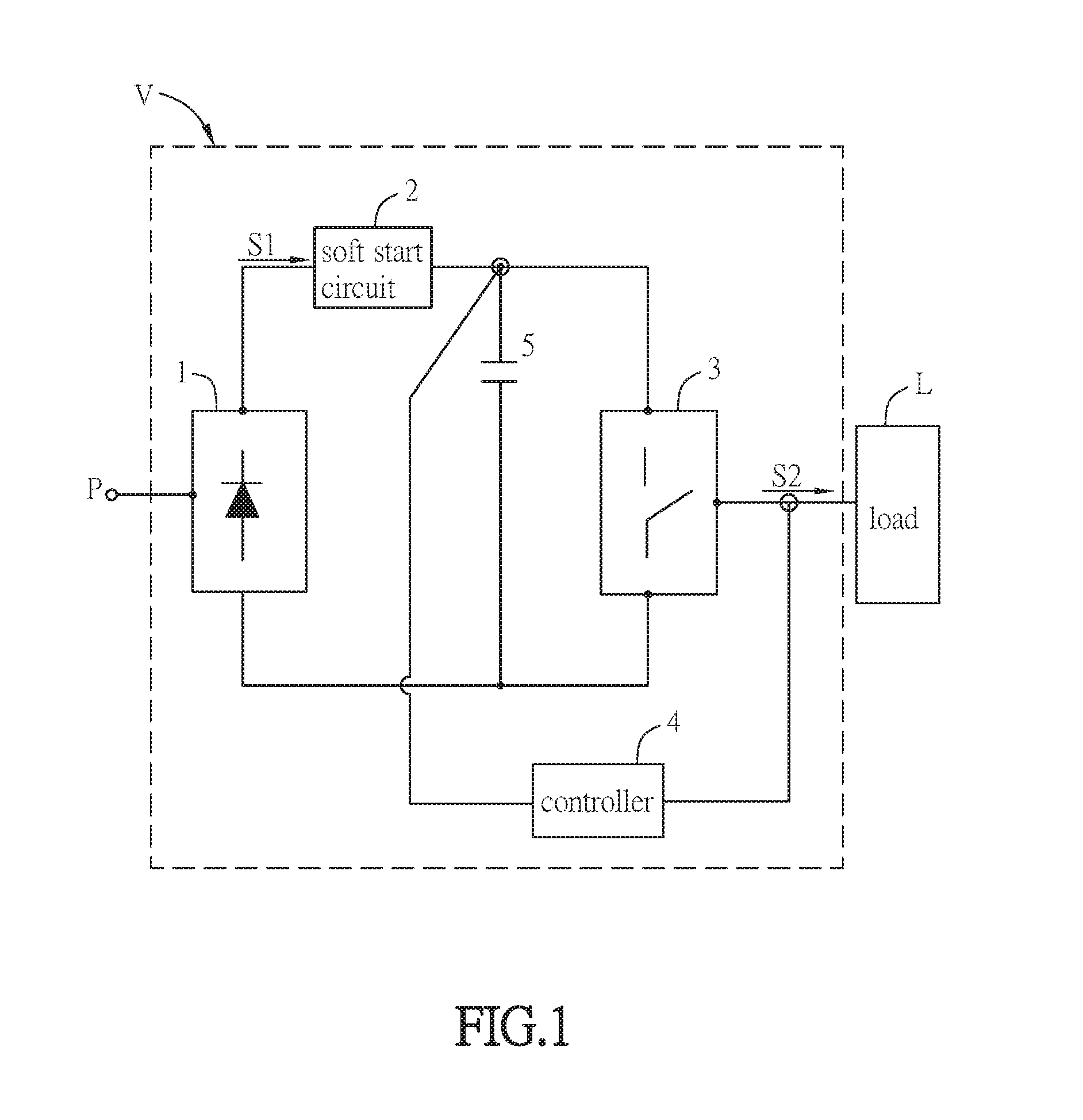

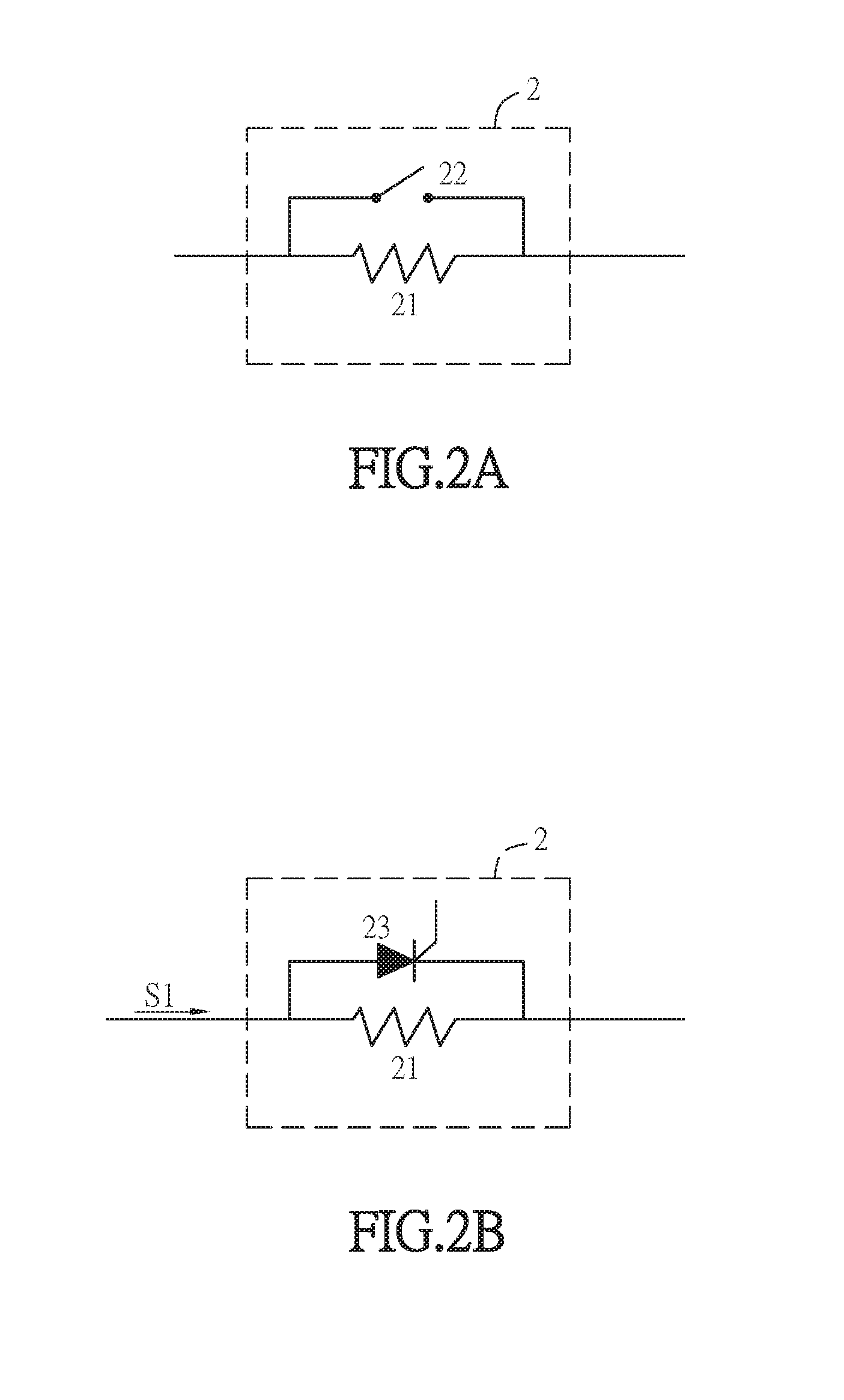

Method for detecting failure of soft start and variable frequency device

ActiveUS20160359422A1Prevent burnoutProduction costConversion with intermediate conversion to dcEmergency protective arrangements for automatic disconnectionPeak valueVoltage reference

A method for detecting failure of soft start includes: connecting a variable frequency device to a load; detecting an energy storage unit at a first voltage level; generating an output current to the load; detecting the energy storage unit changed from the first voltage level into a second voltage level; generating a reference voltage value according to the output current and determining whether a voltage difference value between the first voltage level and the second voltage level is larger than the reference voltage value; determining whether a voltage peak-to-peak value of the energy storage unit is smaller than a set value by the controller if the voltage difference value is larger than the reference voltage value; and controlling the inverter circuit to stop outputting the output current to the load if the voltage peak-to-peak value is smaller than the set value.

Owner:DELTA ELECTRONICS INC

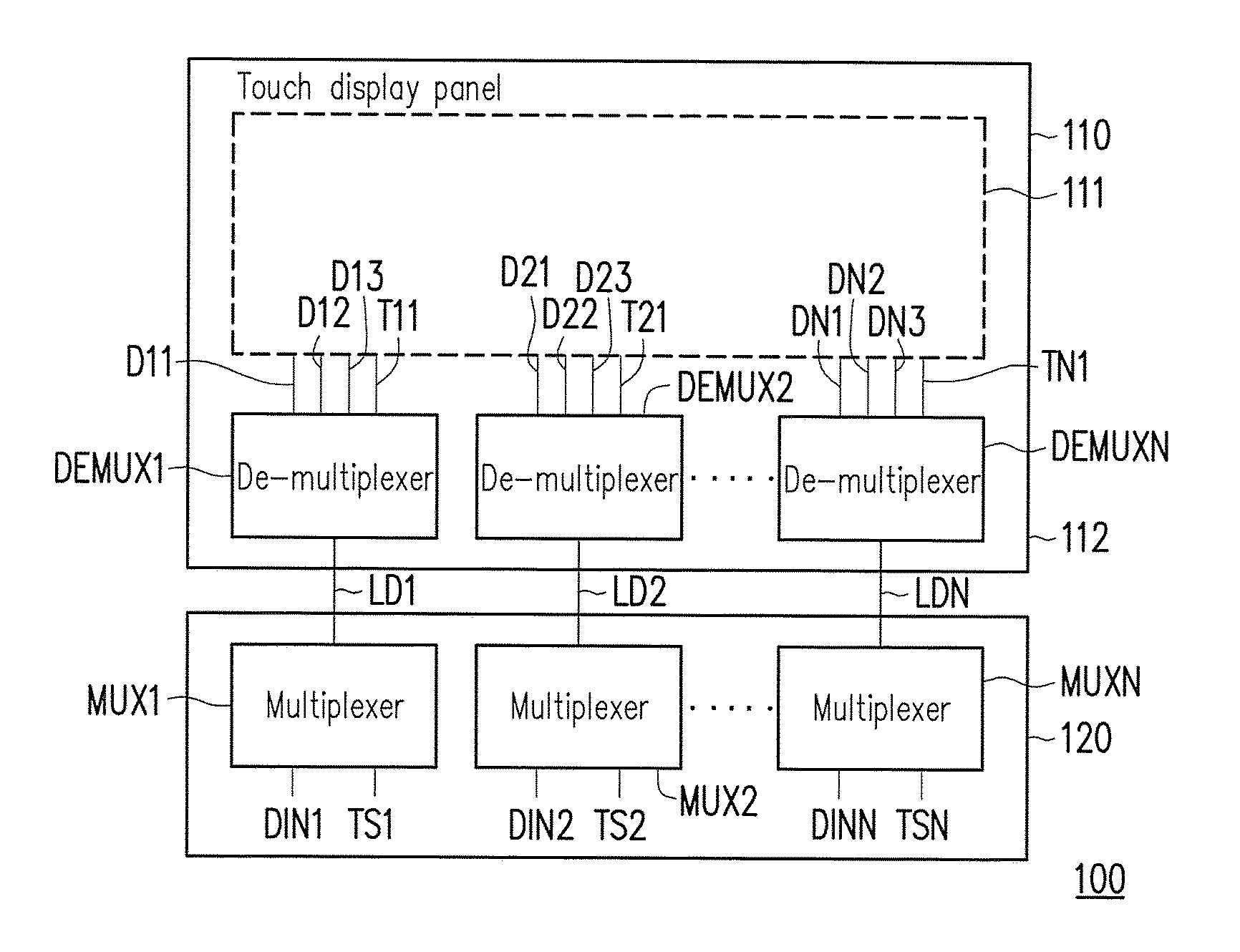

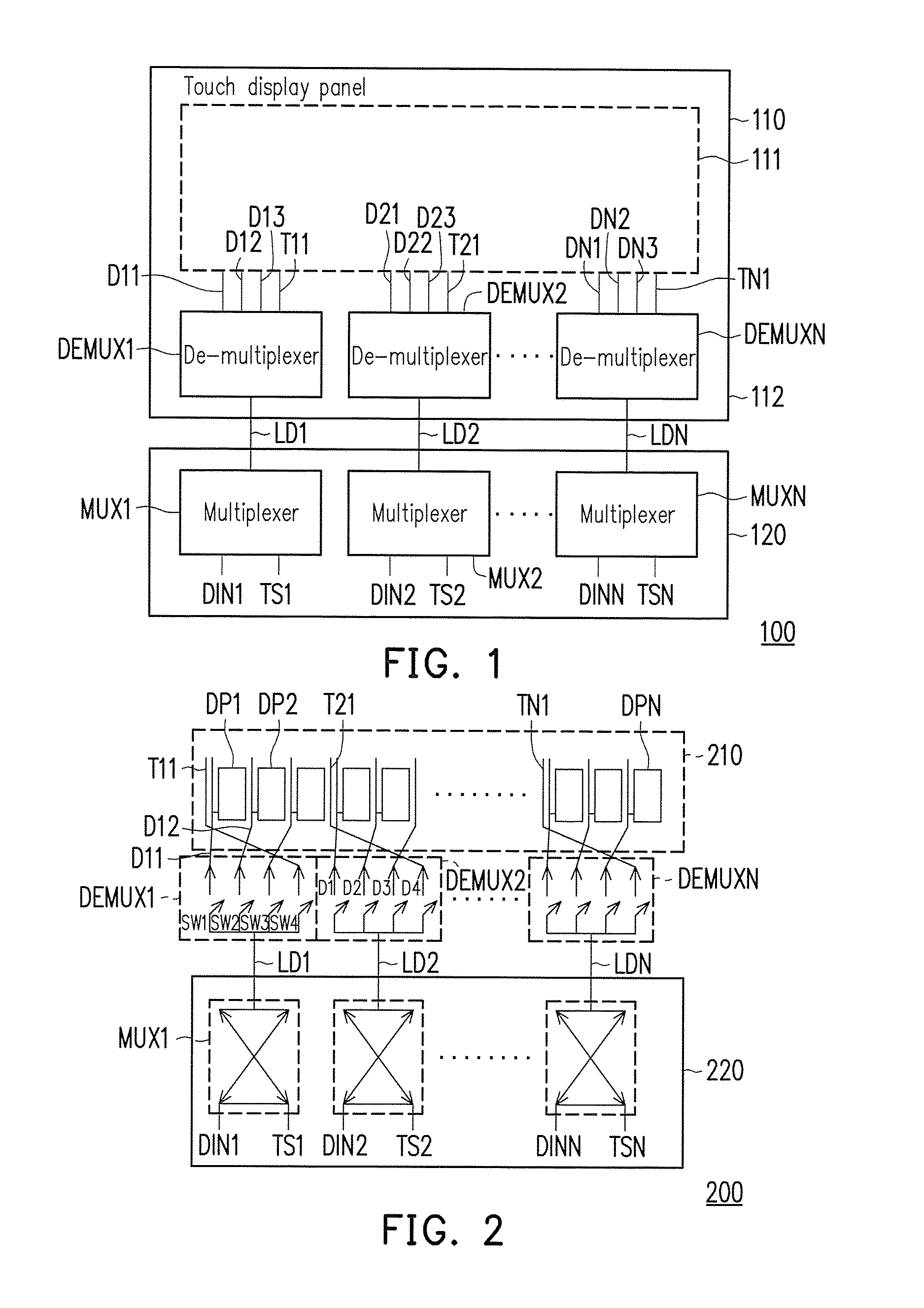

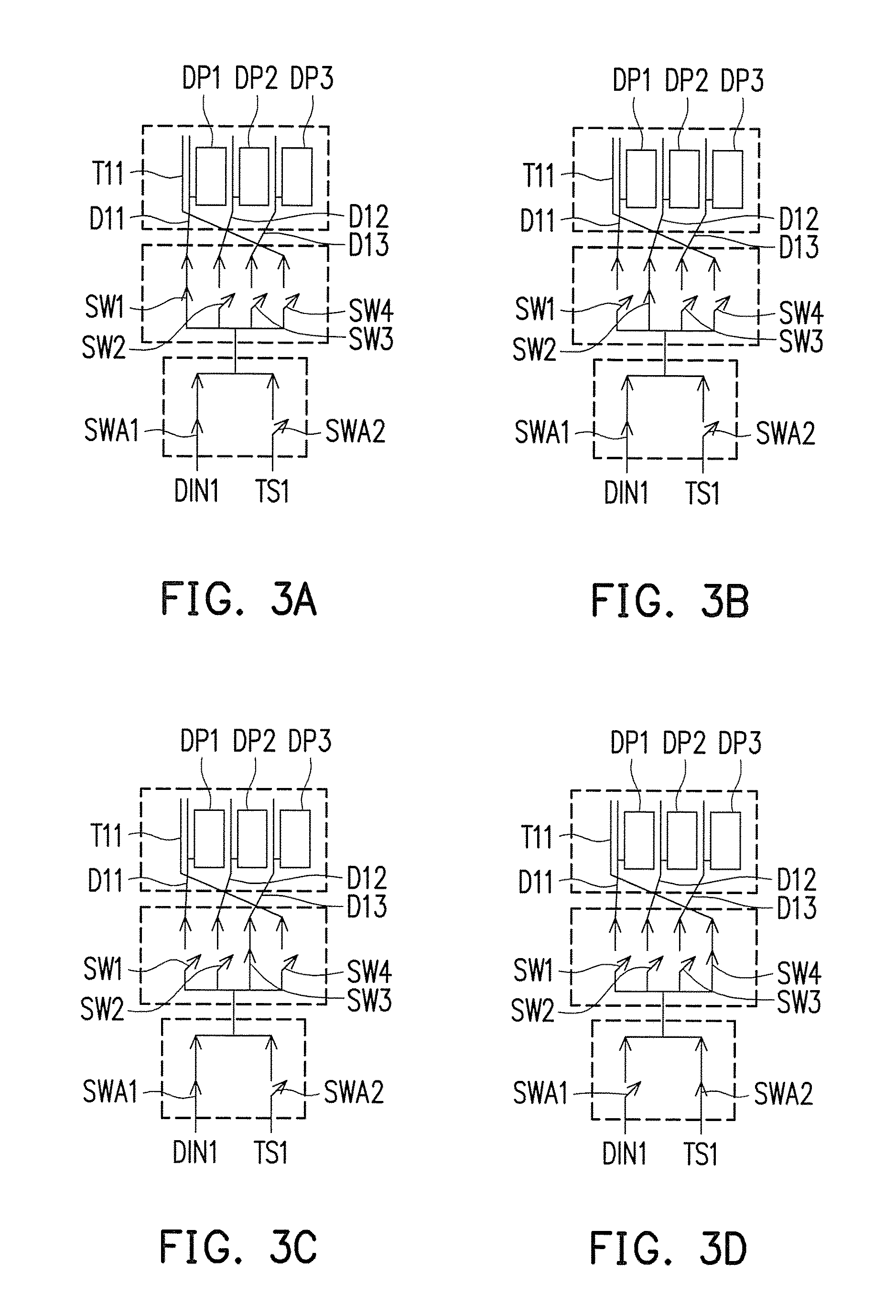

Touch display device

InactiveUS20170017325A1Small sizeReduce in quantityStatic indicating devicesInput/output processes for data processingMultiplexerDisplay device

A touch display device comprising a touch display panel, a first de-multiplexer and a driving integrated circuit (IC) is provided. The touch display panel includes a plurality of first display data transmitting wires and a touch data transmitting wire. The first de-multiplexer includes a plurality of first output terminals and a first input terminal. The driving IC includes a multiplexer including a second output terminal. The first output terminals of the first de-multiplexer are electrically connected to the first display data transmitting wires and the touch data transmitting wire, respectively. The second output terminal of the multiplexer is electrically connected to the first input terminal of the first de-multiplexer through a first lead.

Owner:INNOLUX CORP

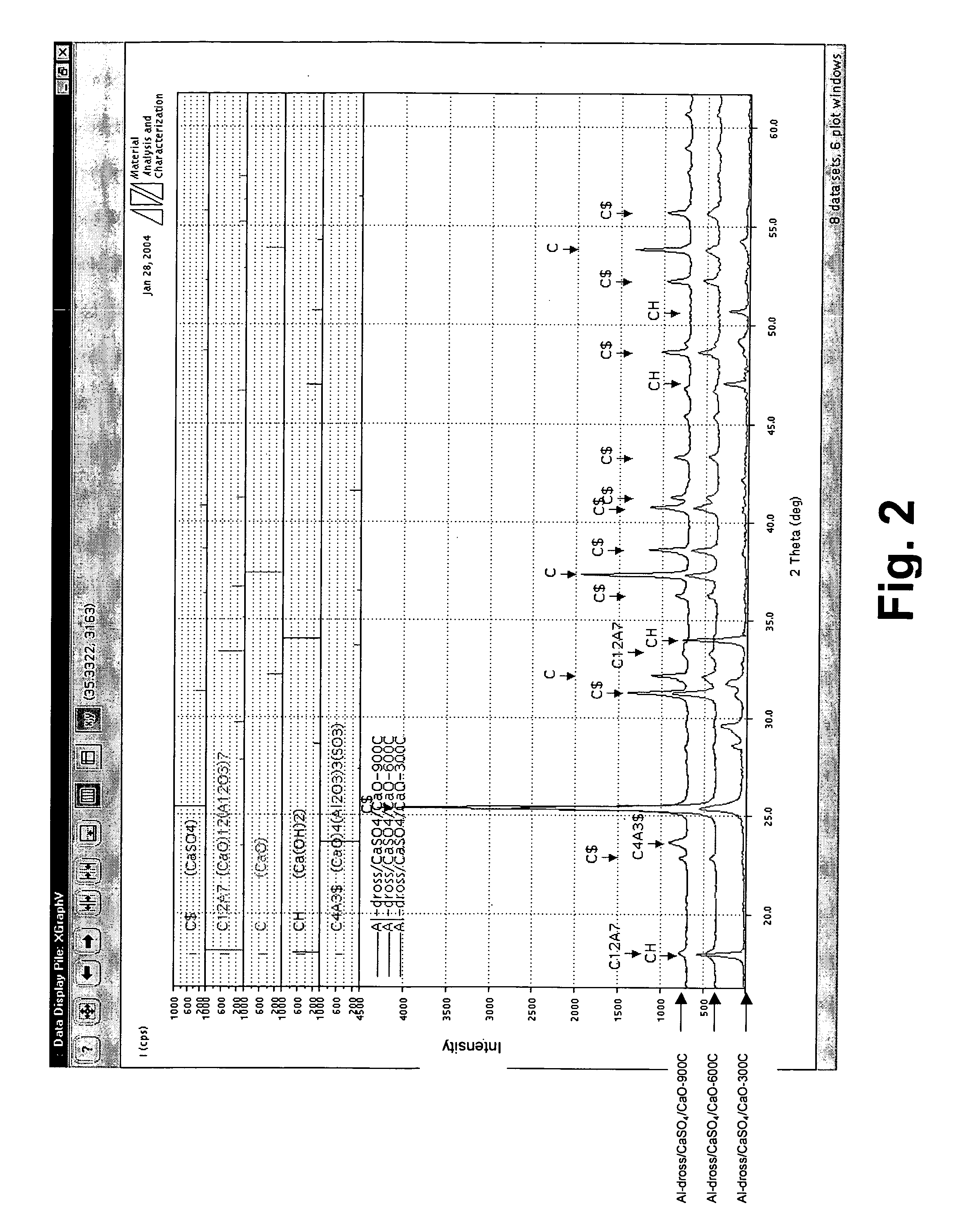

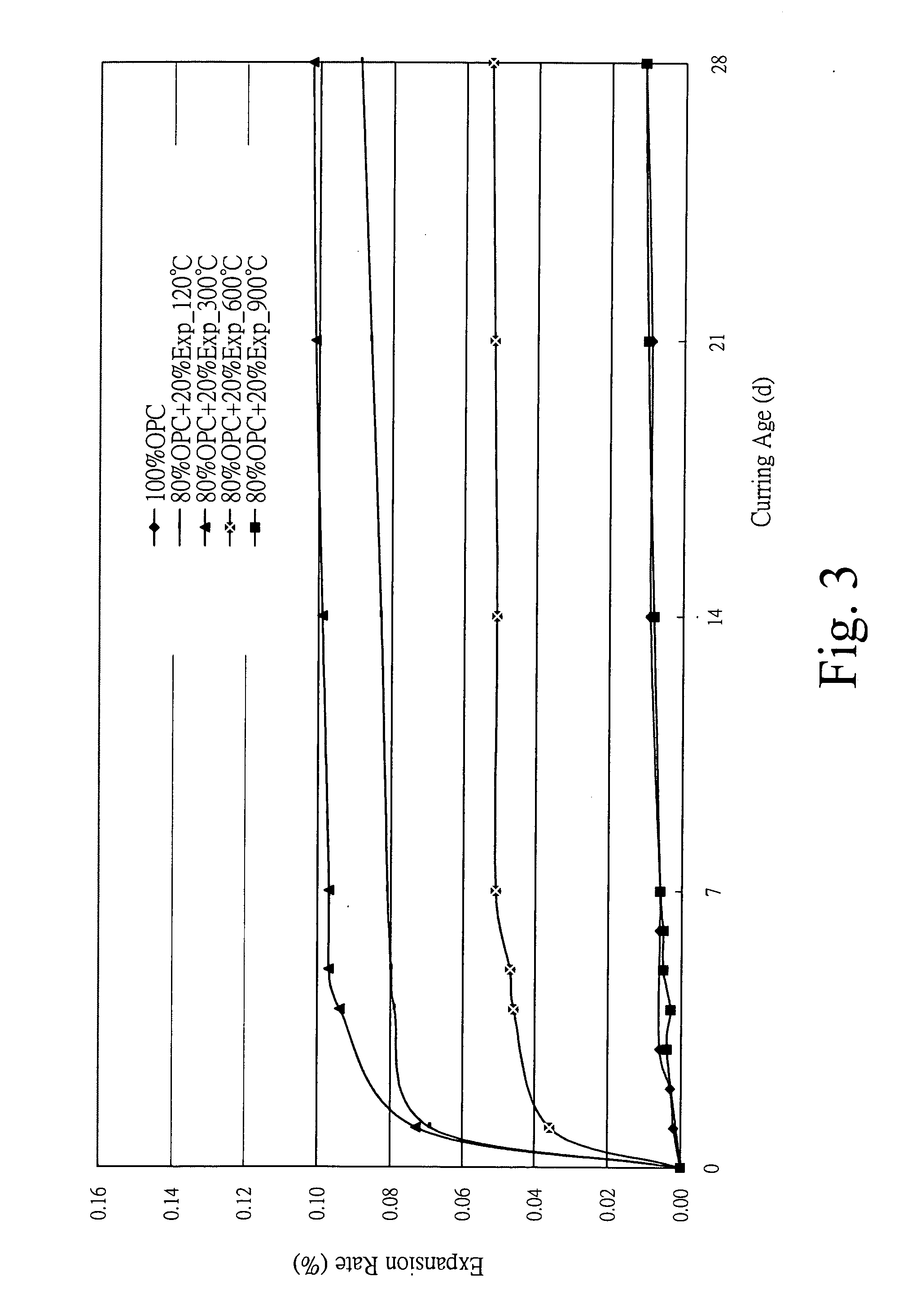

Process and composition for the manufacture of cement expansion additive

The present invention is related to the process and composition for the manufacture of cement expansion additive. The process comprises a blending step, a reaction step, and a calcination step. The blending step is to incorporate soluble calcium sulfate, soluble calcium oxide, and soluble aluminum compounds such as aluminum dross. The addition of water with the above incorporated materials to from ettringite is so-called reaction step. The calcination step is to calcine the products which are produced from reaction step at a temperature range between 60° C. and 900° C. by transforming ettringite from amorphous to calcium sulfoaluminate respectively. After calcinations, the final products can be used as expansive additives for cement or concrete. Further, this manufacturing method can effectively decrease raw material cost and production cost due to the raw material coming from recycling and no need to calcine at high temperature than other relative arts.

Owner:CHINA HI MENT CORP

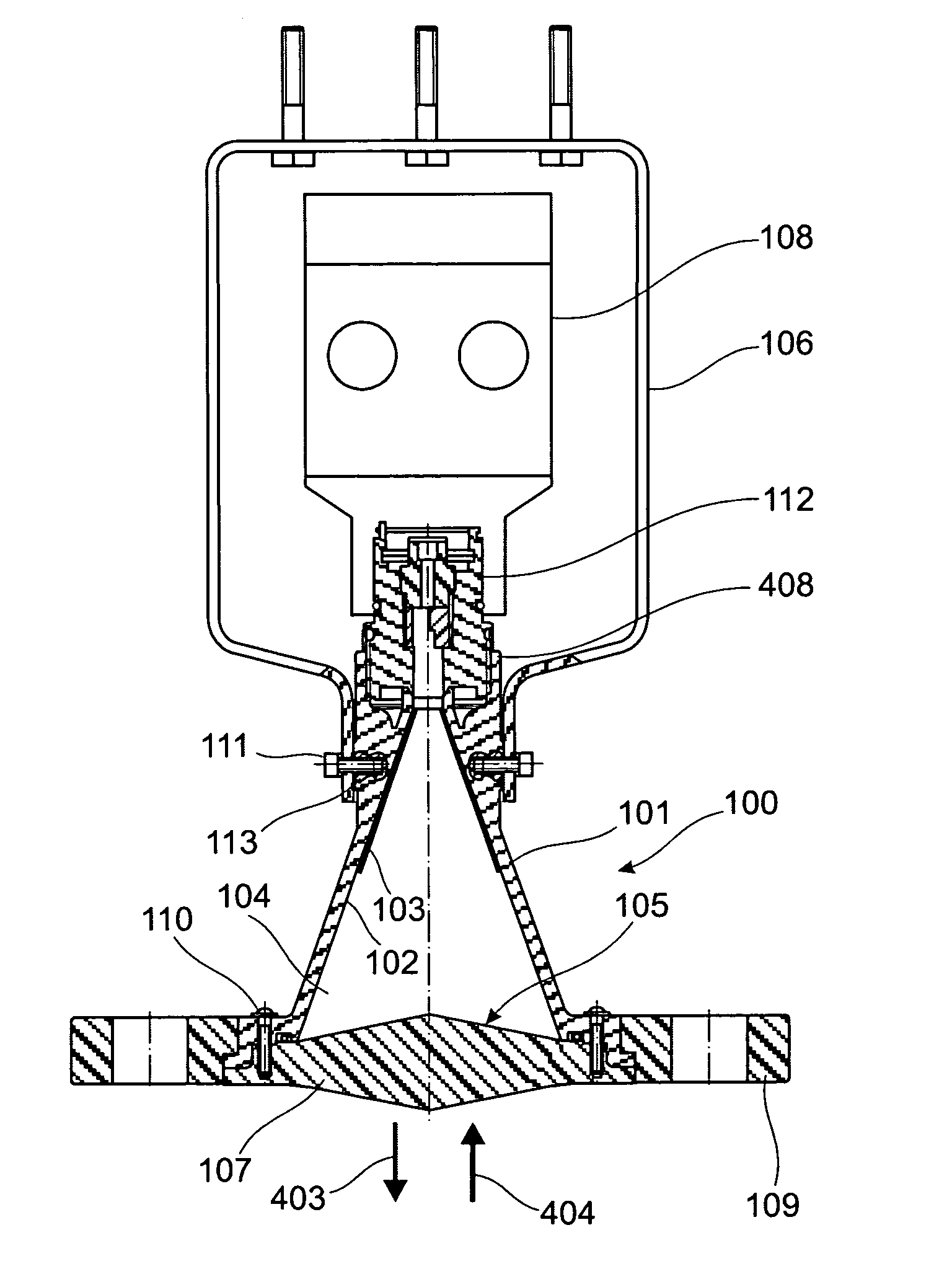

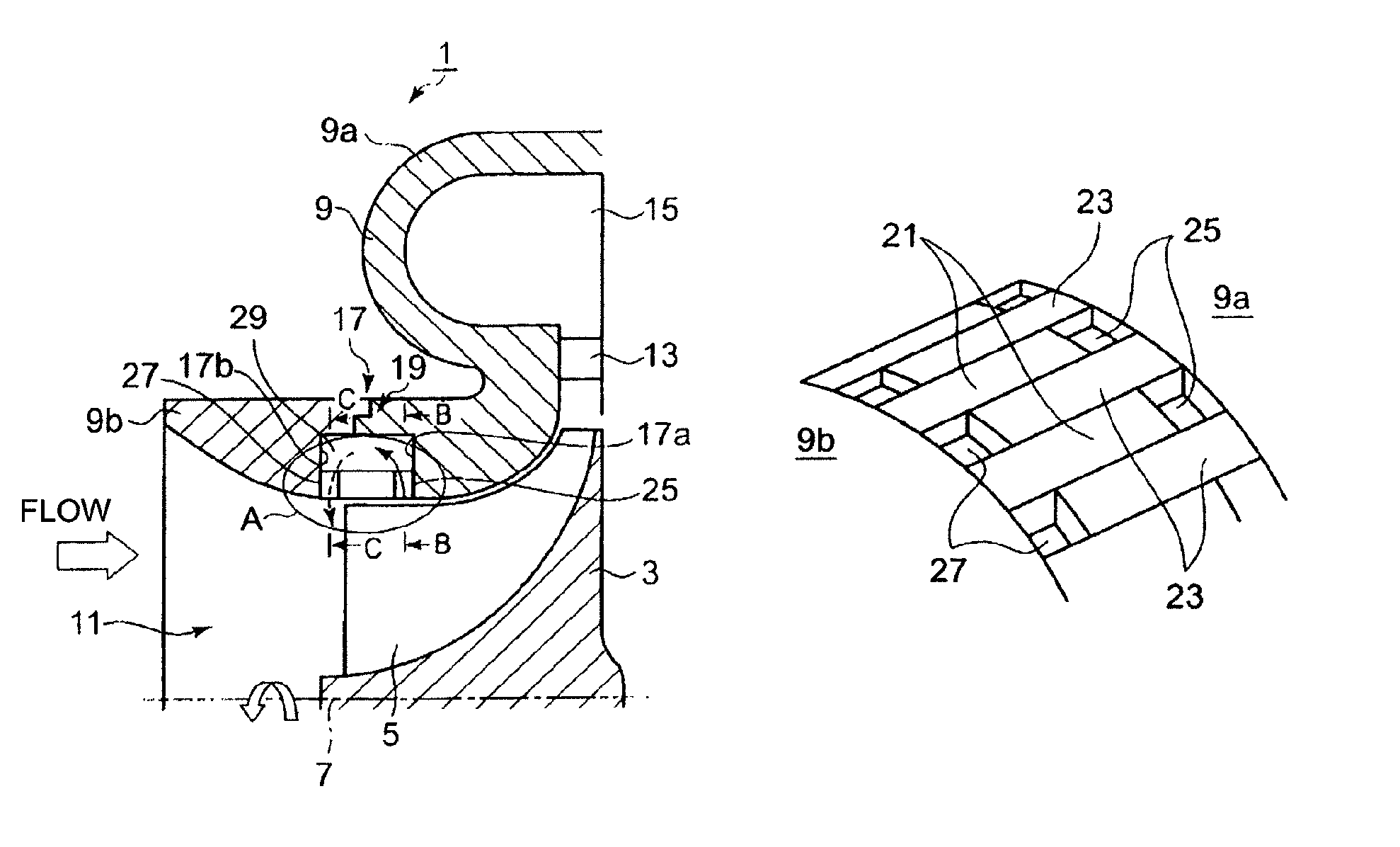

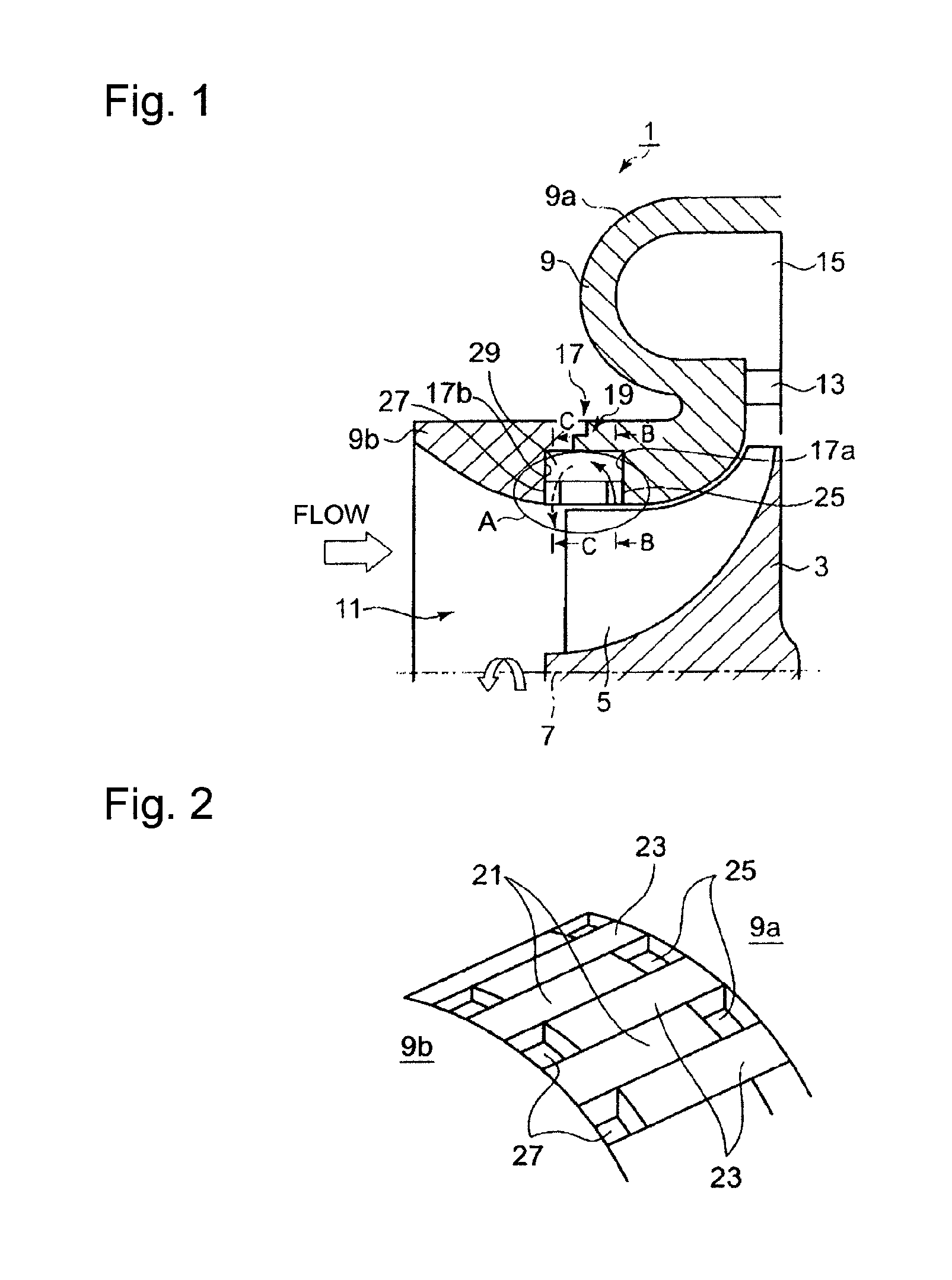

Compressor of exhaust gas turbocharger

A compressor of an exhaust gas turbocharger has a compressor housing of a divided type that forms an inlet slit, an outlet slit and a recirculation passage at the same time when the compressor housing is assembled. In the compressor of the exhaust gas turbocharger, mating surfaces of compressor housing members 9a and 9b are formed in the neighborhood of the inlet part of the impeller 5 in the compressor housing 9 that is divided into the compressor housing members 9a and 9b in the direction of the rotation axis of the impeller; and, a space forming the recirculation passage 29, an inlet slit 25 and an outlet slit 27 are formed between the mating compressor housing members 9a and 9b.

Owner:MITSUBISHI HEAVY IND LTD

Coating material and photovoltaic element

InactiveUS20020185170A1Suitable for useProduction costPV power plantsSynthetic resin layered productsPolymer scienceEnergy conversion efficiency

The present invention provides a coating material which resin-coats a light-receiving plane side of a photovoltaic element, and which can increase a conversion efficiency by effectively using light incident on the photovoltaic element and is excellent in weatherability since the coating material comprises a resin which is a polymer blend containing at least a first polymeric material, and a second polymeric material made by bonding a polymer component (A) and a polymer component (B), wherein the polymer component (A) includes a functional group with comparatively high compatibility with the first polymeric material, and a polymer component (B) includes a functional group with compatibility with the first polymeric material which is lower than the compatibility of the functional group of the polymer component (A), and wherein the polymer component (B) forms an aggregate.

Owner:CANON KK

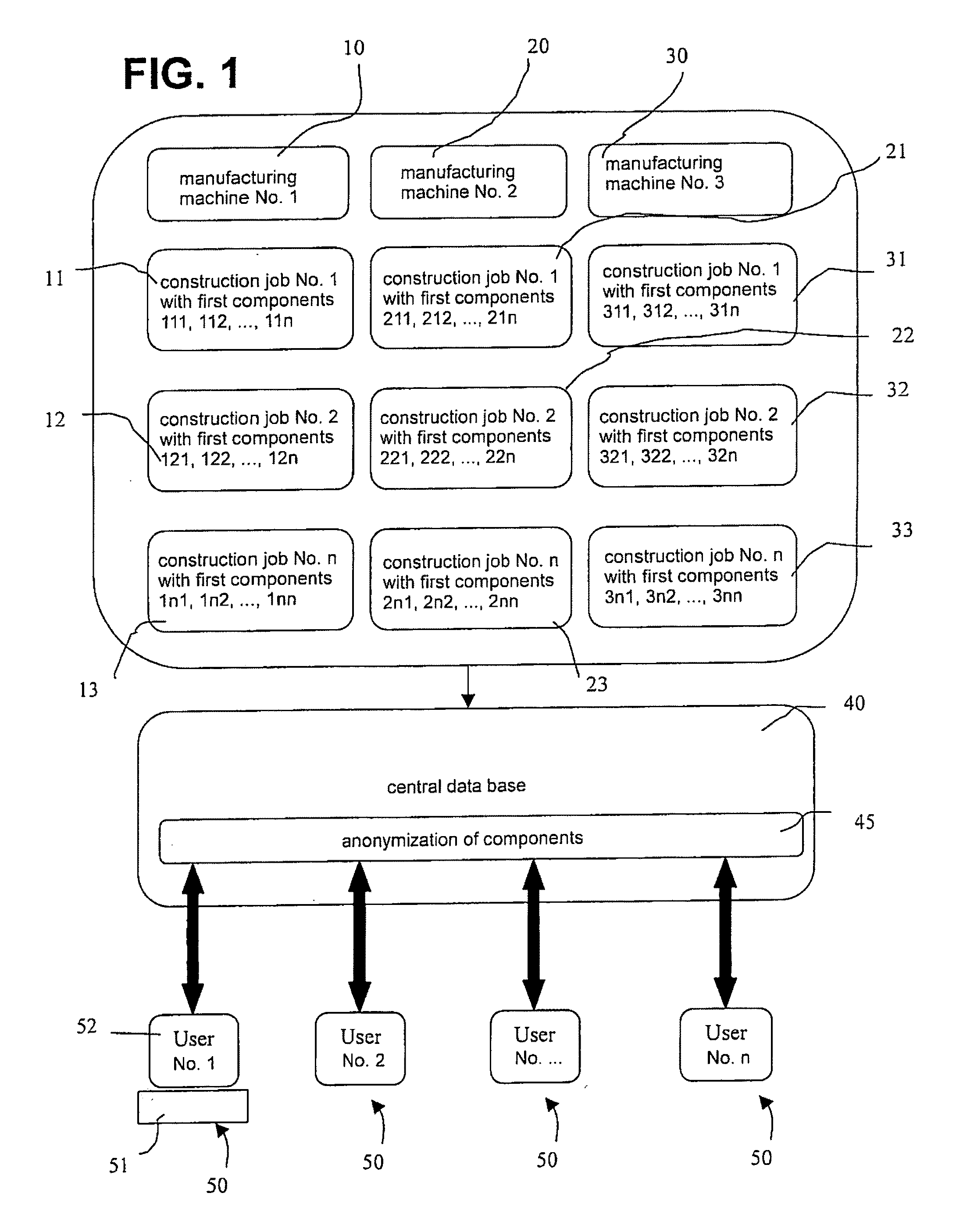

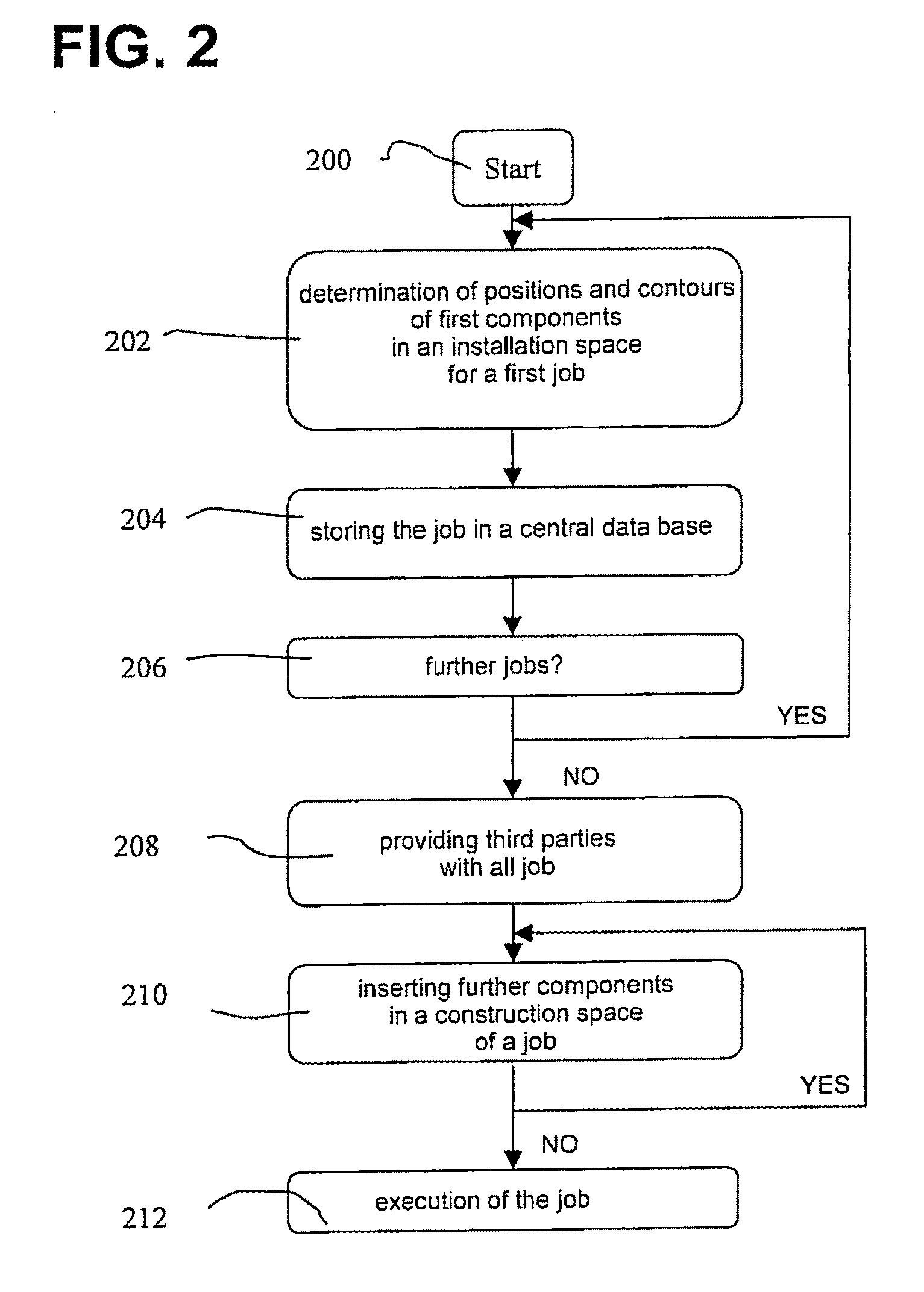

Methods and manufacturing systems for manufacturing parts, utilizing geometrical free spaces of manufacturing machines

InactiveUS20090139078A1Reduce part costReduce free spaceProgramme controlTotal factory controlDigitizationManufacturing systems

A method for manufacturing a first part and a further part in a manufacturing machine including a construction space for manufacturing parts, the method including the steps of providing position and contours of the first part positioned in the construction space as digital first part data, providing digital construction space data representing the construction space, providing the digital first part data and the digital construction space data to a potential ordering party for displaying the first part in the construction space, receiving digital second part data representing the further part and its position in the construction space, virtual positioning of at least one other part which was not yet commissioned in the displayed construction space, and manufacturing the at least one first part and the at least one further part in the manufacturing machine.

Owner:FIT FRUTH INNOVATIVE TECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com