Multi-channel flat-tube serpentine heat exchanger and heat exchange apparatus

a heat exchanger and multi-channel technology, applied in lighting and heating apparatus, tubular elements, stationary conduit assemblies, etc., can solve the problems of increasing the working hours and cost of soldering and assembly, deteriorating water-proof and dust-proof effect of the conventional heat exchanger, and reducing the number of parts and production costs. , the effect of reducing the working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The detailed description and technical contents of the present invention will become apparent with the following detailed description accompanied with related drawings. It is noteworthy to point out that the drawings is provided for the illustration purpose only, but not intended for limiting the scope of the present invention.

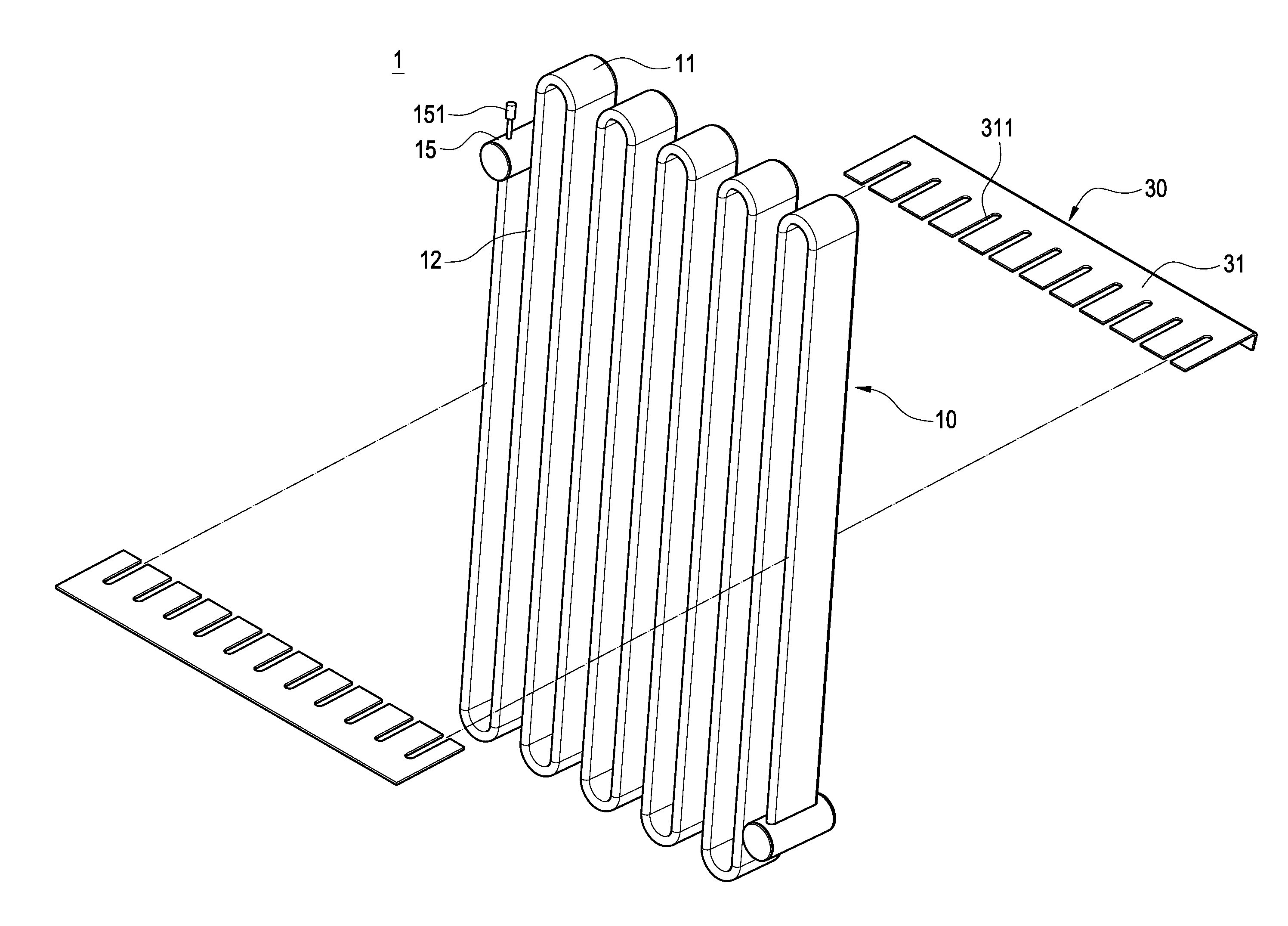

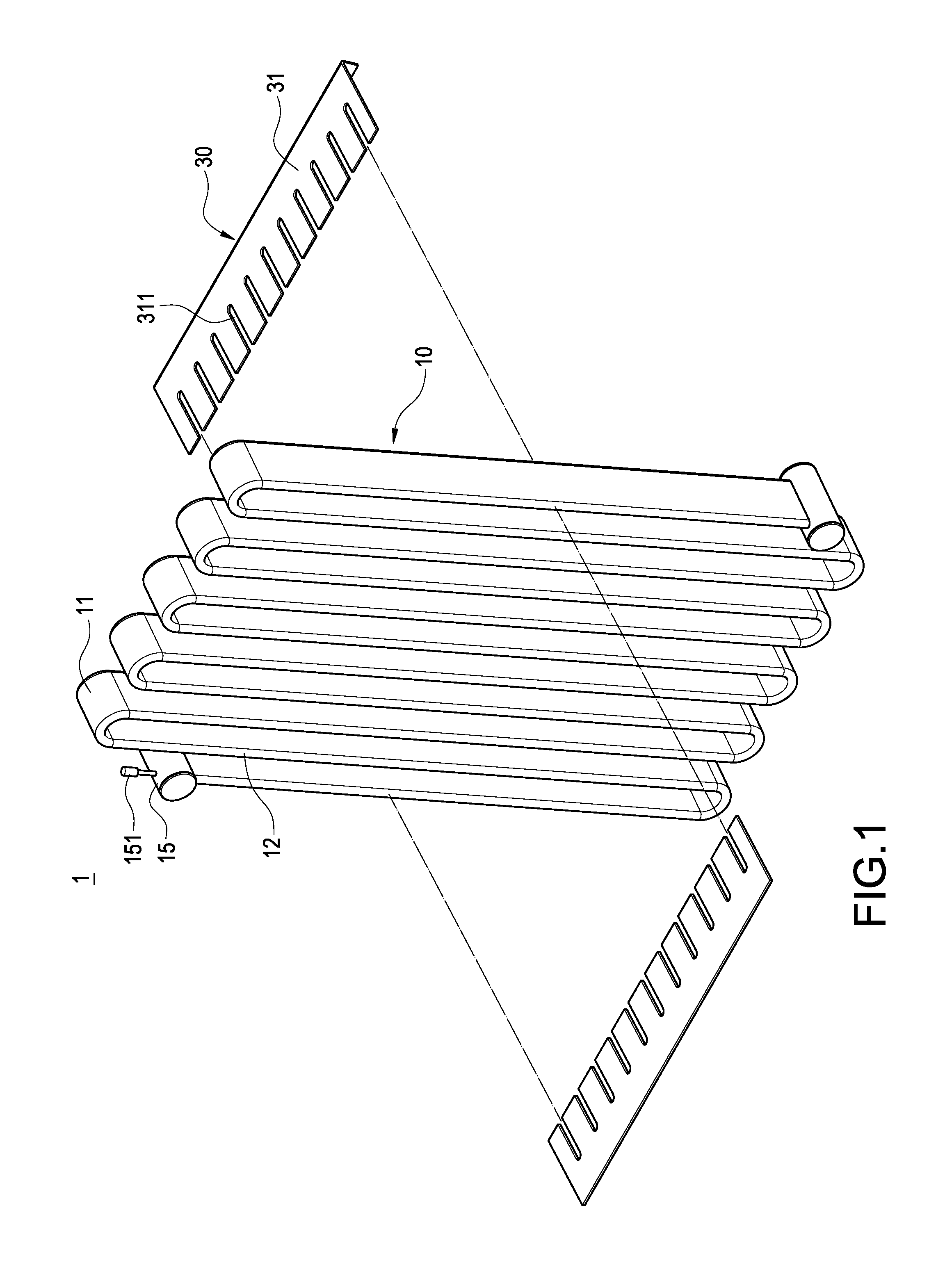

[0037]Please refer to FIGS. 1 to 4. The present invention relates to a multi-channel flat-tube serpentine heat exchanger 1, which includes a flat pipe 10, a fin set 20 and a divider assembly 30.

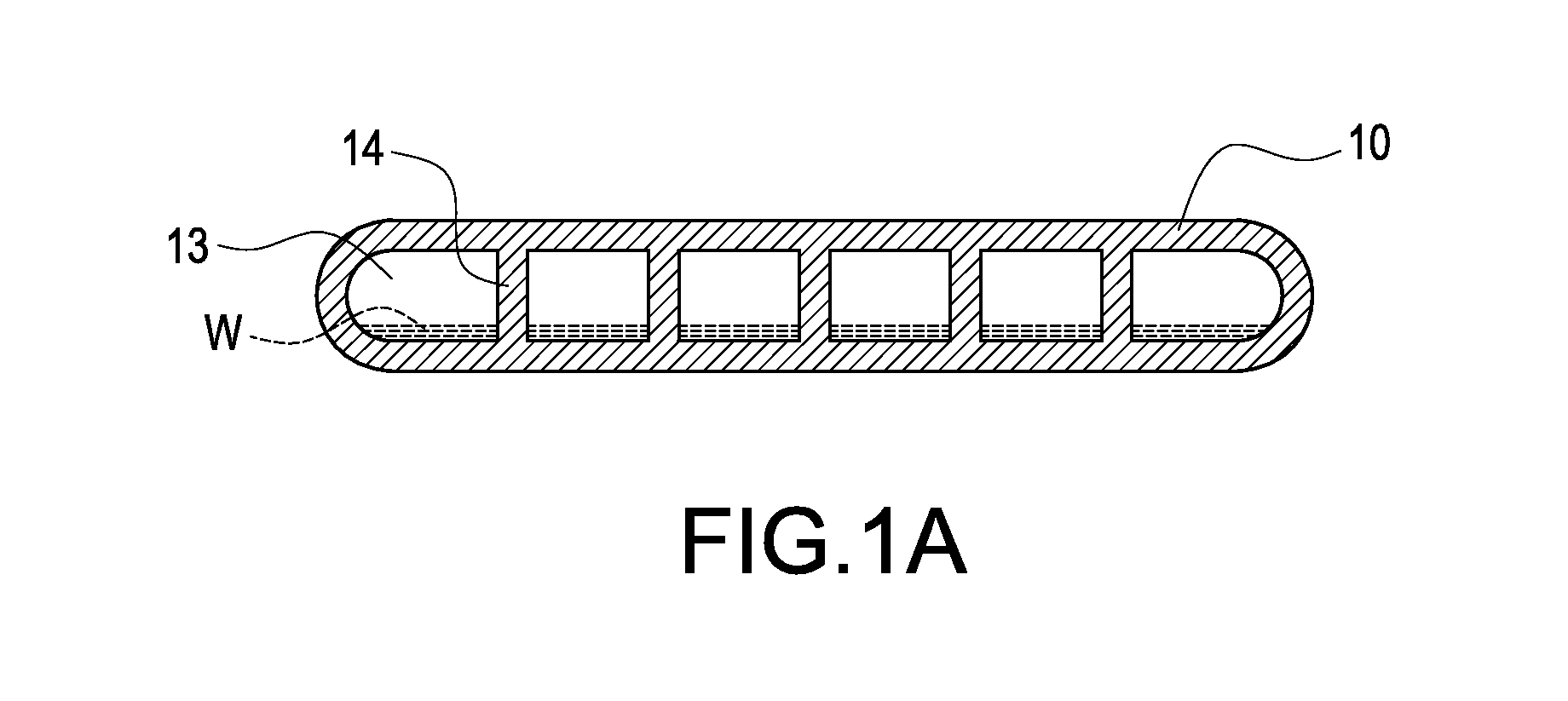

[0038]As shown in FIG. 1, the flat pipe 10 is configured to have a plurality of bending sections 11 and a plurality of connecting sections 12 each connecting adjacent two bending sections 11. As shown in FIG. 1A, the interior of the flat pipe 10 is filled with a working fluid W and provided with a plurality of channels 13 separated from each other for allowing the working fluid W to flow through. More specifically, the flat pipe 10 is made of metallic material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com