Built-in solar tracking azimuth driving device

A technology of sun tracking and transmission, applied in the direction of transmission, transmission parts, gear transmission, etc., to achieve the effect of improving the working environment, increasing strength and rigidity, and simplifying the truss structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

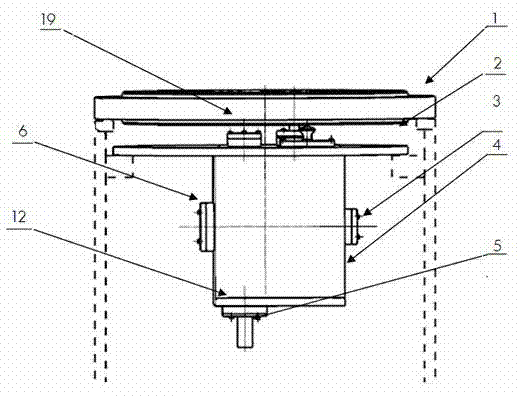

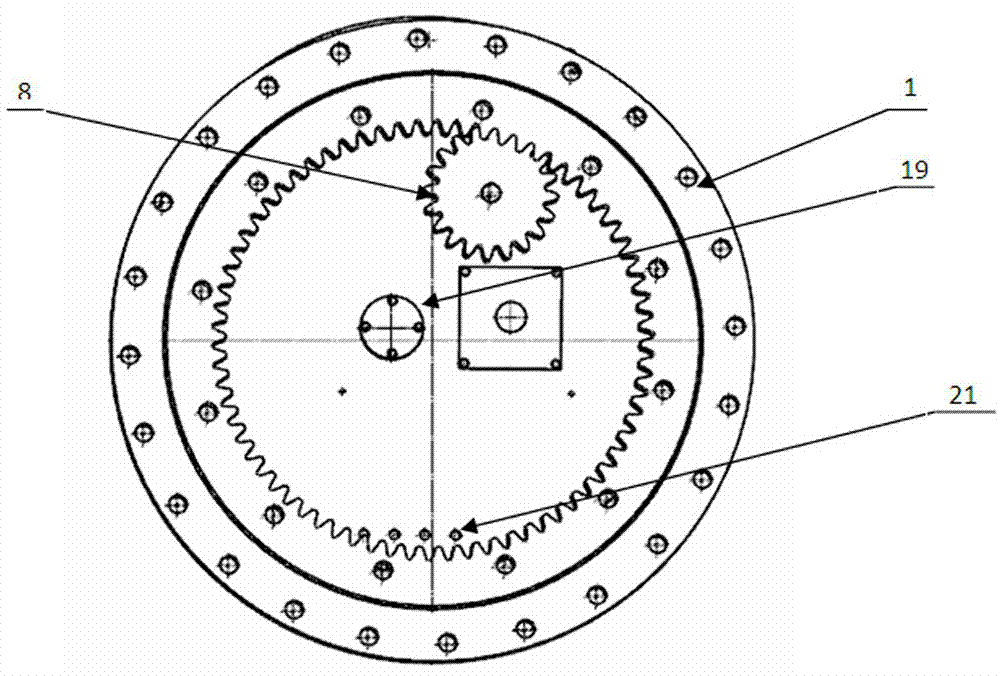

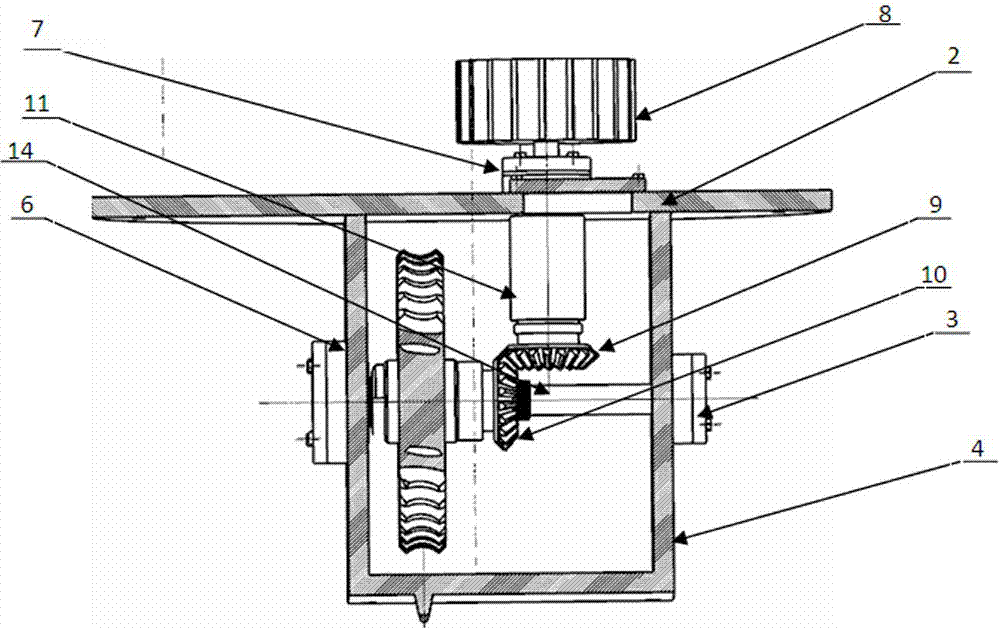

[0014] see figure 1 -5. The present invention includes a circular case cover, an internal gear four-point contact ball slewing bearing (1), a worm (5), a worm gear-bevel gear reducer assembly 4, and an output short shaft 20. The circular case cover It is fixed at the top position inside the hollow column. The reducer assembly 4 is installed on the lower part of the circular box cover. The output short shaft 20 of the reducer assembly 4 is upward, and the external gear 8 is installed on the short shaft 20. The external gear 8 and the internal gear type The four-point contact ball slewing bearing 1 meshes, the worm 5 is arranged in the reducer assembly 4, and the input end of the worm 5 is connected with the motor. The worm gear-bevel gear reducer assembly 4 includes a worm gear 13, a worm 5, a first bevel gear 9, a second bevel gear 10, a long shaft 14, and a short shaft 20. The worm 5 is toothed with the worm gear 13, and the worm gear 13 One end of the major axis 14 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com