Cable arranging device

A cable arrangement and linear bearing technology, which is applied in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of cable surface damage, large axial force, and impact on cable life. To achieve the effect of axial guidance, large radial force, and avoiding overlapping each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

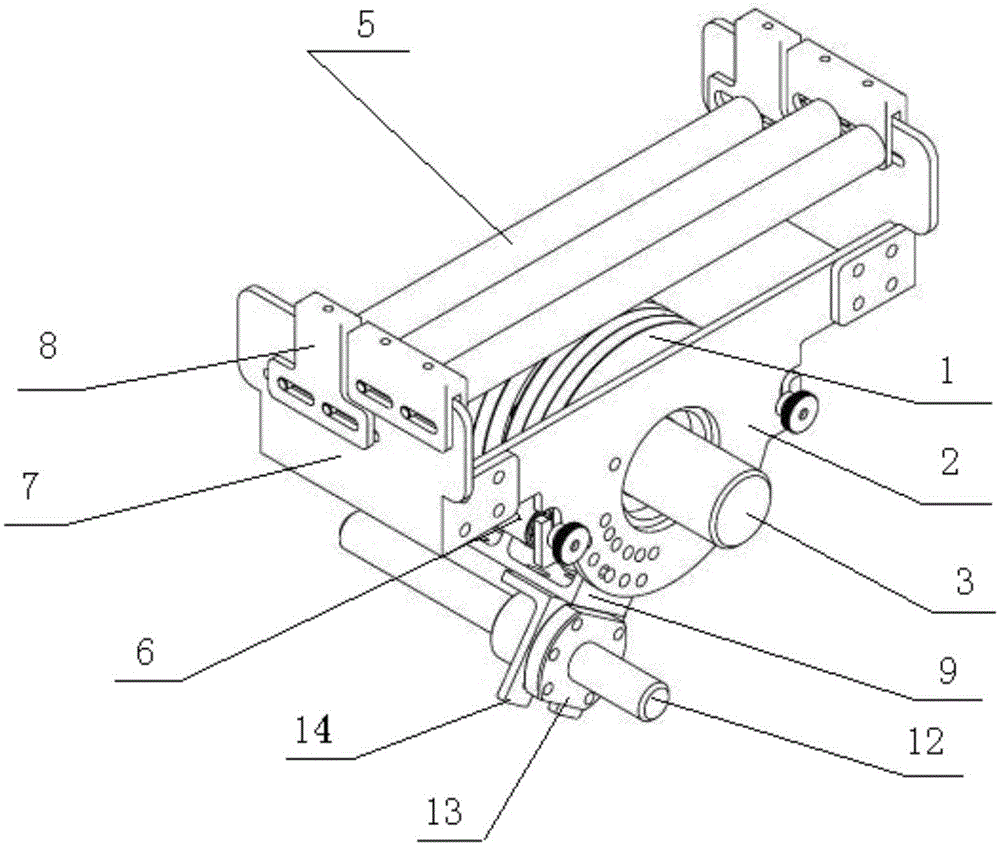

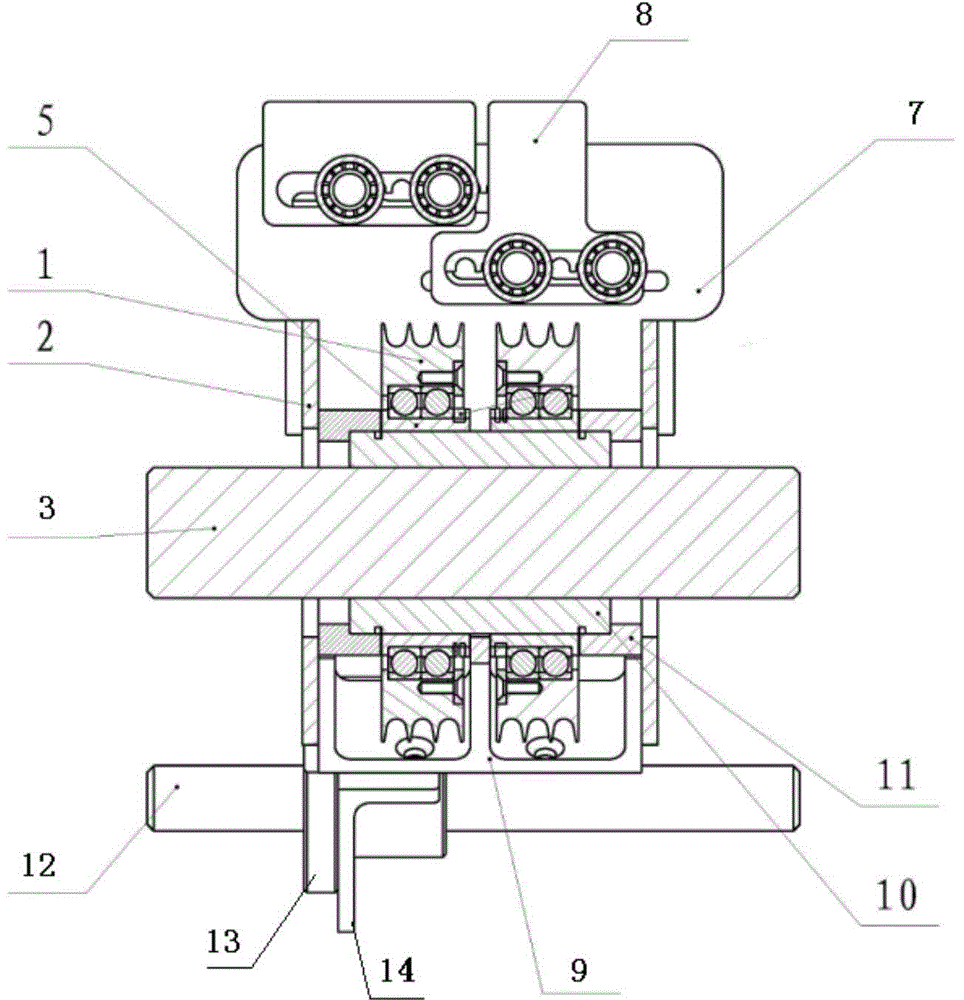

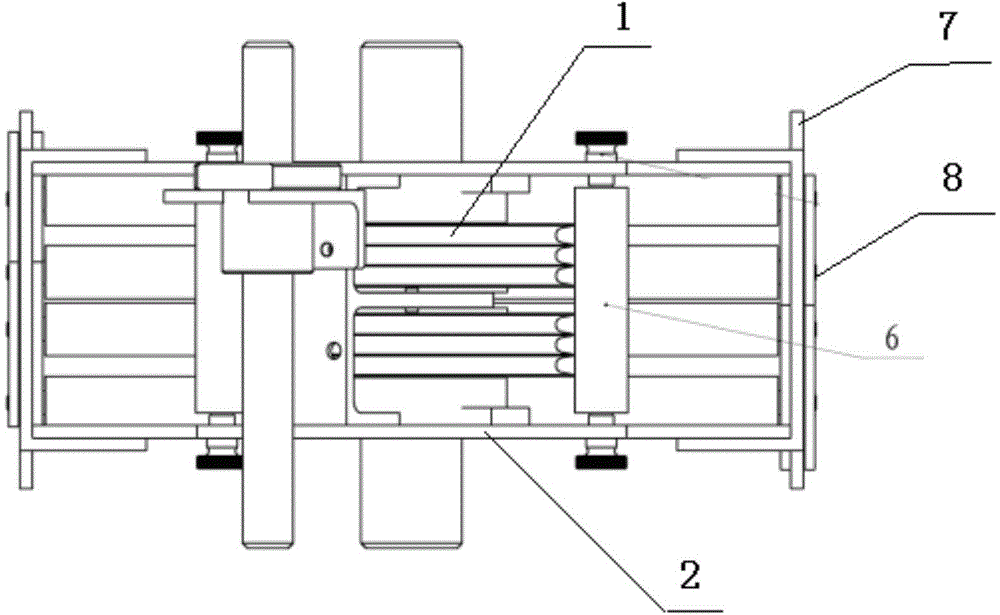

[0022] like Figure 1-4 As shown, a cable straightener includes: a pulley 1, a connecting plate 2, a polished rod 3, a sleeve 4, a guide rod 5, a pressing rod 6, a guide rod fixing frame 7, a guide rod pressing frame 8, and a shift fork 9 , linear bearing 10, linear bearing seat 11, screw rod 12, nut 13, nut connecting plate 14;

[0023] The surface of the pulley 1 is provided with a wiring groove, and the pulley 1 is more than one group. The pulley 1 is set on the sleeve 4 with a rib at one end, and the other end is locked by a lock nut. The sleeve 4 is set on the linear bearing. 10, the linear bearing seat 11 is set on the linear bearing 10 and fixes one end of the sleeve 4, side plates are arranged on both sides of the shift fork 9, and a semicircular bracket is arranged in the middle, and the other end of the sleeve 4 passes through the semicircle in the middle of the shift fork 9 The bracket is fixed; the linear bearing 10 is set on the polished rod 3, and can rotate aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com