Novel drilling driver

A propeller and drilling technology, which is applied in drilling equipment, driving devices for drilling in wellbore, earth-moving drilling, etc., to achieve the effects of economic drilling, reducing well site area and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

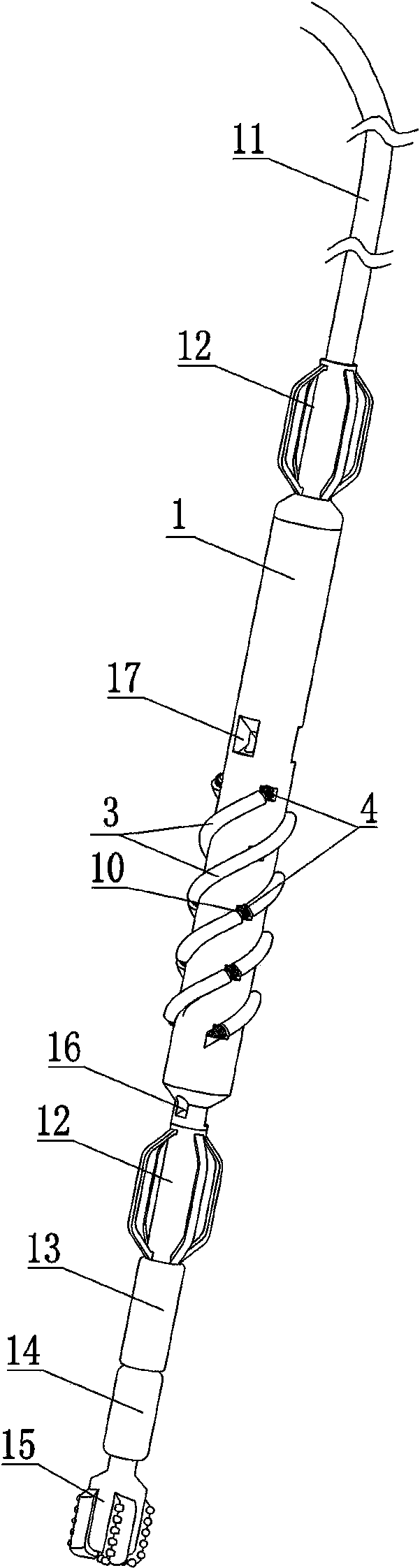

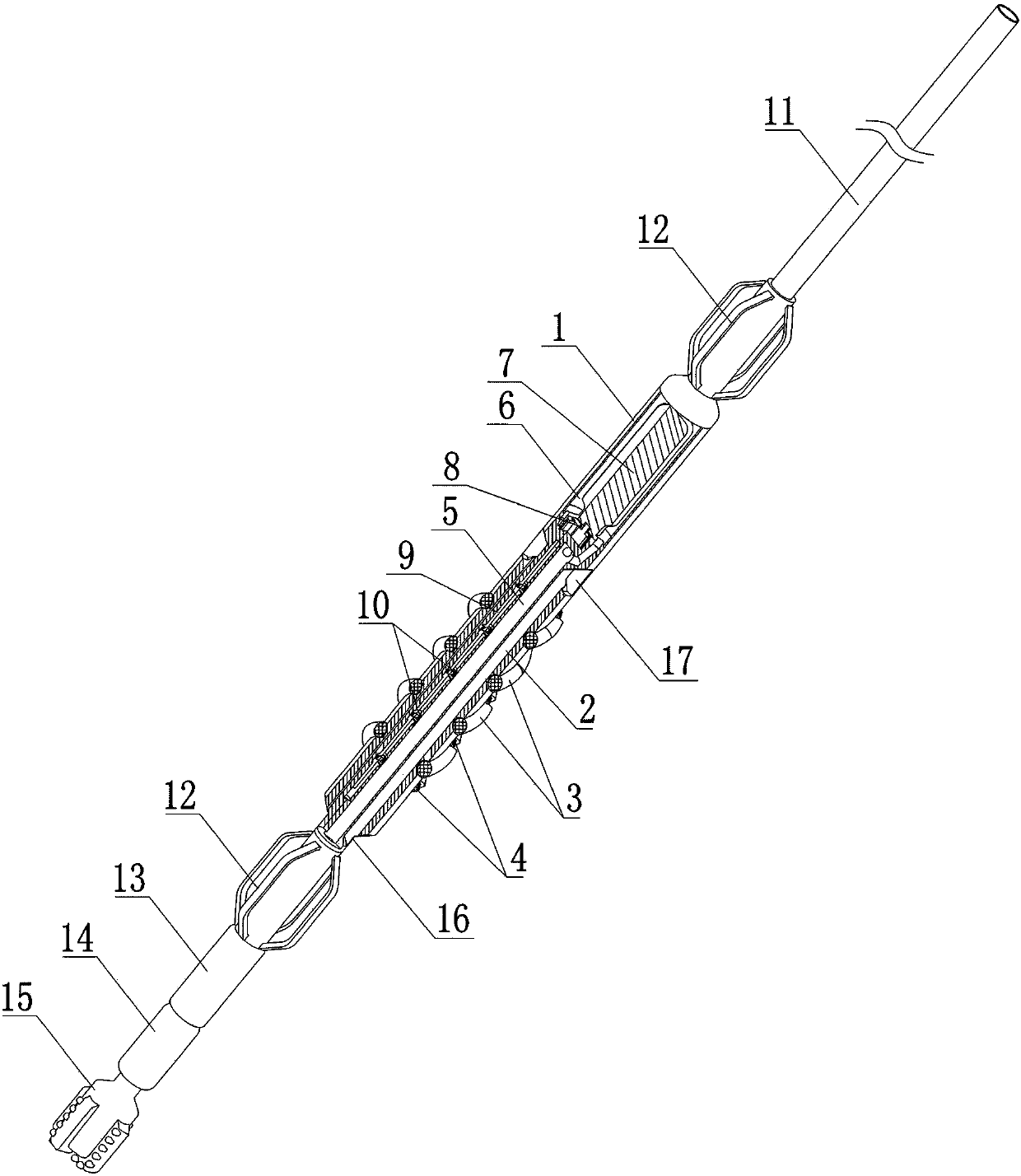

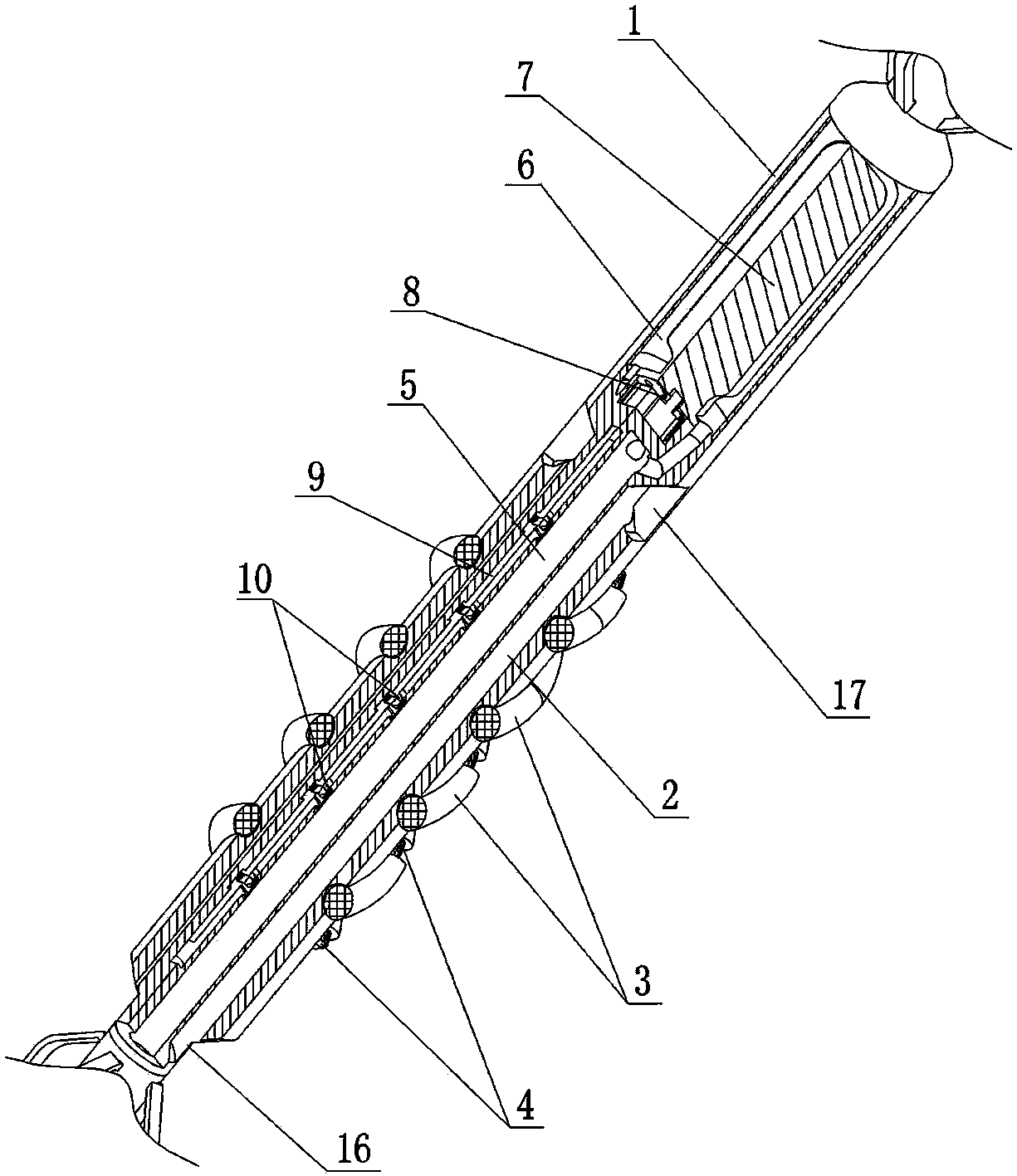

[0017] Such as figure 1 , figure 2 As shown, the new drilling thruster includes an electro-hydraulic composite pipe 11 arranged at the rear end for circulating drilling fluid and communication power supply, a driver for driving the drilling thruster forward, and a driver arranged at the front end and connected sequentially. The driving motor 13, the vibrator 14 and the drill bit 15 are connected with a centralizer 12 at the front and rear ends of the driver, and the inside of the driver and the centralizer 12 are provided with the electro-hydraulic composite pipe 11 for the drilling fluid to flow through. The flow channel, the electro-hydraulic composite pipe 11 is connected to the centralizer 12 located at the rear end of the driver, the drive motor 13 is connected to the centralizer 12 located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com