Spraying type washing machine

A spray washing machine and hand washing technology, which is applied to other washing machines, washing machine appliances, washing machines with containers, etc., can solve the problems of not being able to completely remove stains on clothes, improve washing efficiency, improve the effect, and save washing water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout.

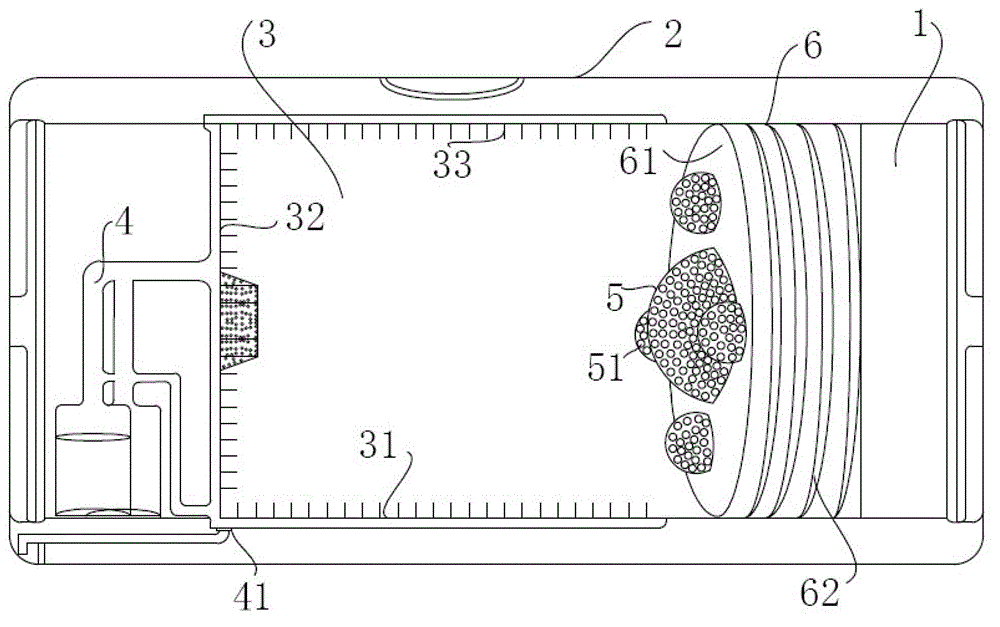

[0018] An embodiment of the present invention provides a spray washing machine, figure 1 Shown is a schematic diagram of the overall structure of the present invention. The spray washing machine of this embodiment includes: a motor 1, a water tub 2, a drum 3 placed in the water tub 2, and an air intake and drainage system 4 arranged on the drum, and a washing machine in the same direction as the central axis of the tub. Hand 5, wherein the washing hand is connected with a telescopic device 6, and the water intake and drainage, air system adopts the water intake mode of high-pressure ultra-fine water jet. The present invention will be described in detail below through the use process of the spray washing machine.

[0019] The water inlet and drainage and air system 4 include water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com