Manufacturing method and manufacturing device of electrode plate for paste-type lead storage battery

A technology for lead-acid batteries and manufacturing methods, which is applied in the direction of lead-acid battery electrodes, electrode manufacturing, lead-acid batteries, etc. It can solve problems such as skeleton deformation, exposure of skeletons in collectors, and hindrance to the filling of paste-like active materials. Liquid, easy-to-cover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

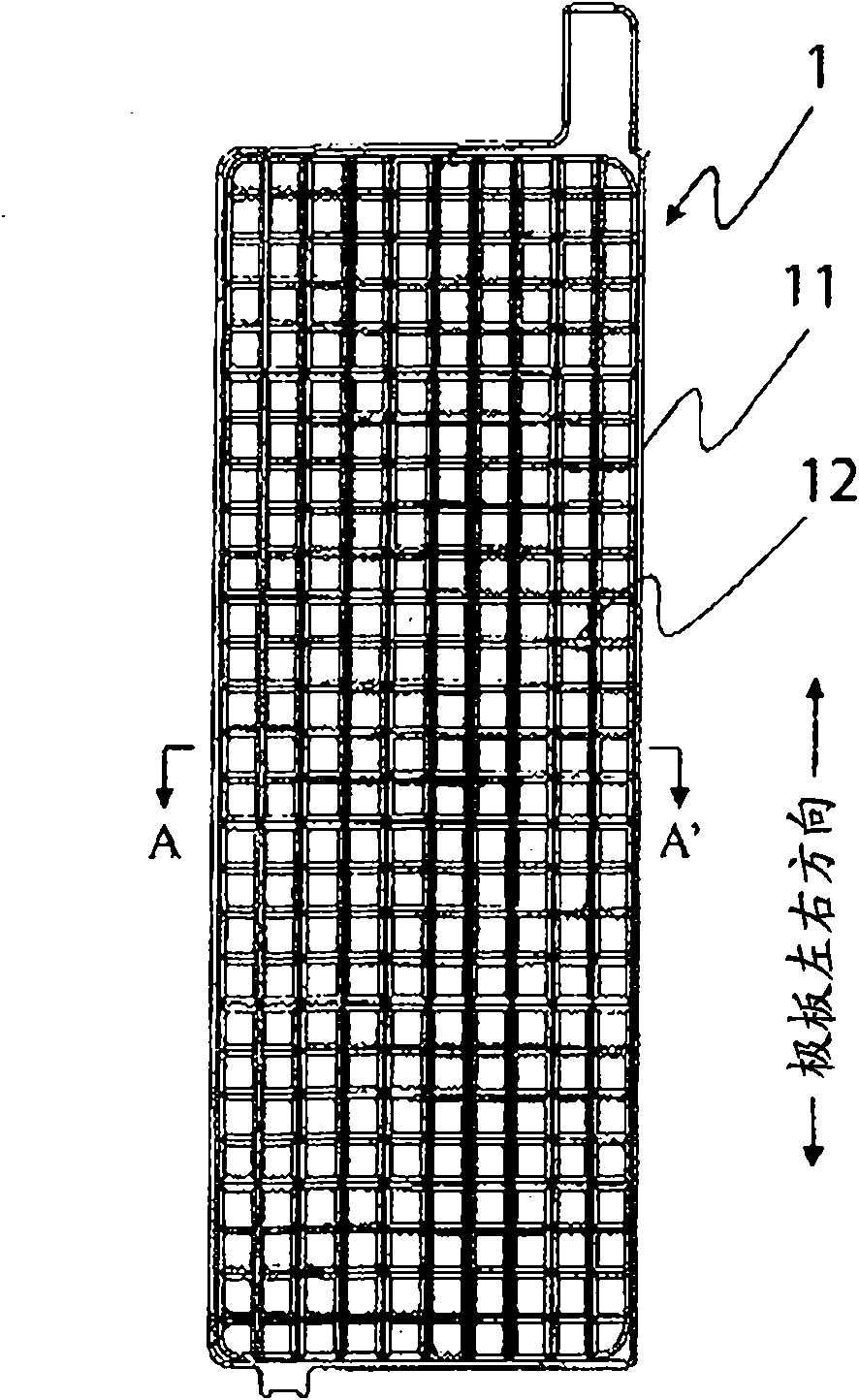

[0061] 1.6% by mass of tin and 0.08% by mass of calcium were added to lead so that the entire molten mixture was a lead alloy of 100% by mass, and a current collector for a positive electrode plate was fabricated by gravity casting. The current collector 1 as image 3 , Figure 4 As shown, a thick inner skeleton 12-1 and a thin inner skeleton 12-2 are arranged inside the frame skeleton 11. The external dimensions of the frame skeleton 11 are 385mm×140mm, the thickness is 5.8mm, and the width is 4.4mm. The cross-sectional shape of the thick inner frame 12-1 is a hexagon whose thickness is larger than the width, with a thickness of 5.4 mm and a width of 4.3 mm. In addition, the cross-sectional shape of the fine inner frame 12-2 is also hexagonal in which the thickness is larger than the width, and the thickness is 3.6 mm and the width is 2.8 mm. Such as Figure 4 As shown, the end faces on the filling surface side in the thickness direction of the thick inner frame 12-1 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com