Bamboo chip carbonizing and color mixing device

A toning device, bamboo chip technology, applied in wood treatment, charcoal/burning, wood processing appliances and other directions, can solve the problems of unreasonable structural design, poor stability and safety, low production efficiency, etc. Improved operational stability, guaranteed neutrality, and less space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

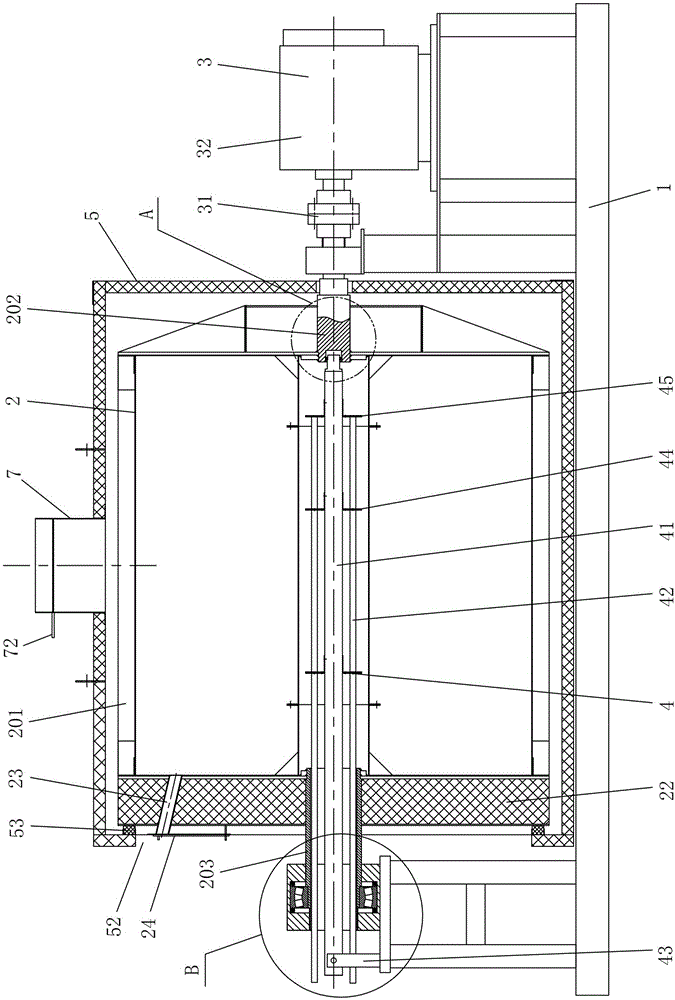

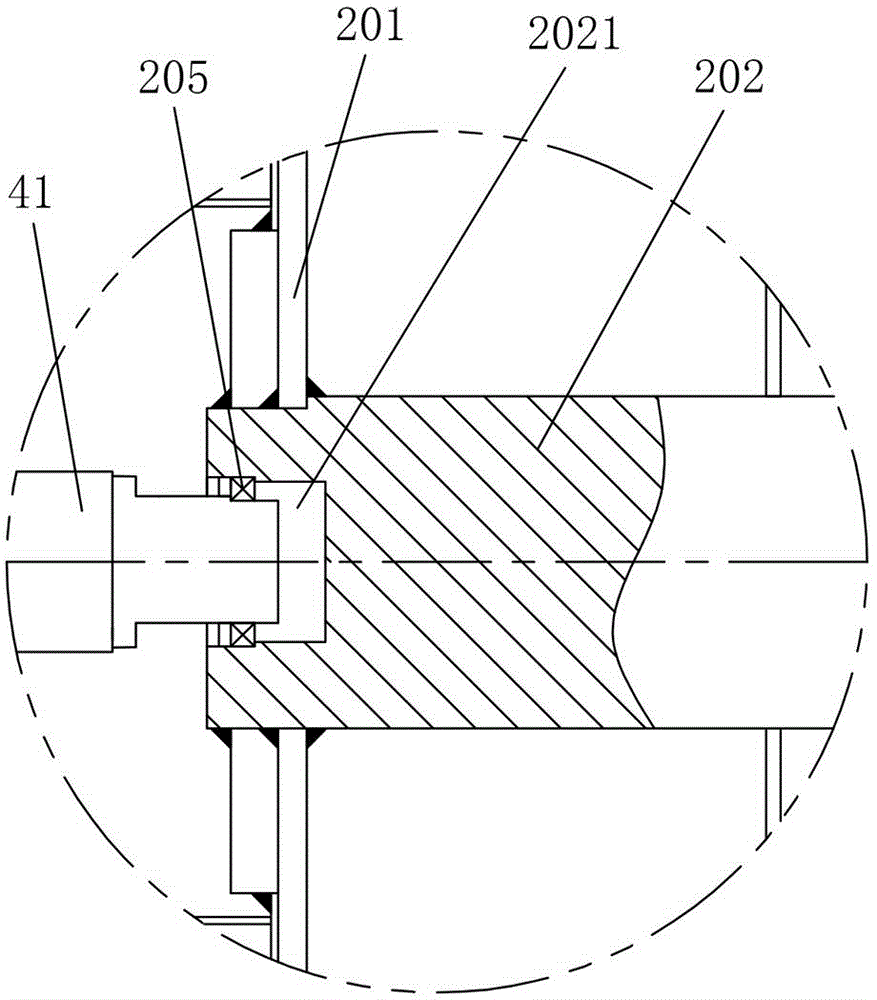

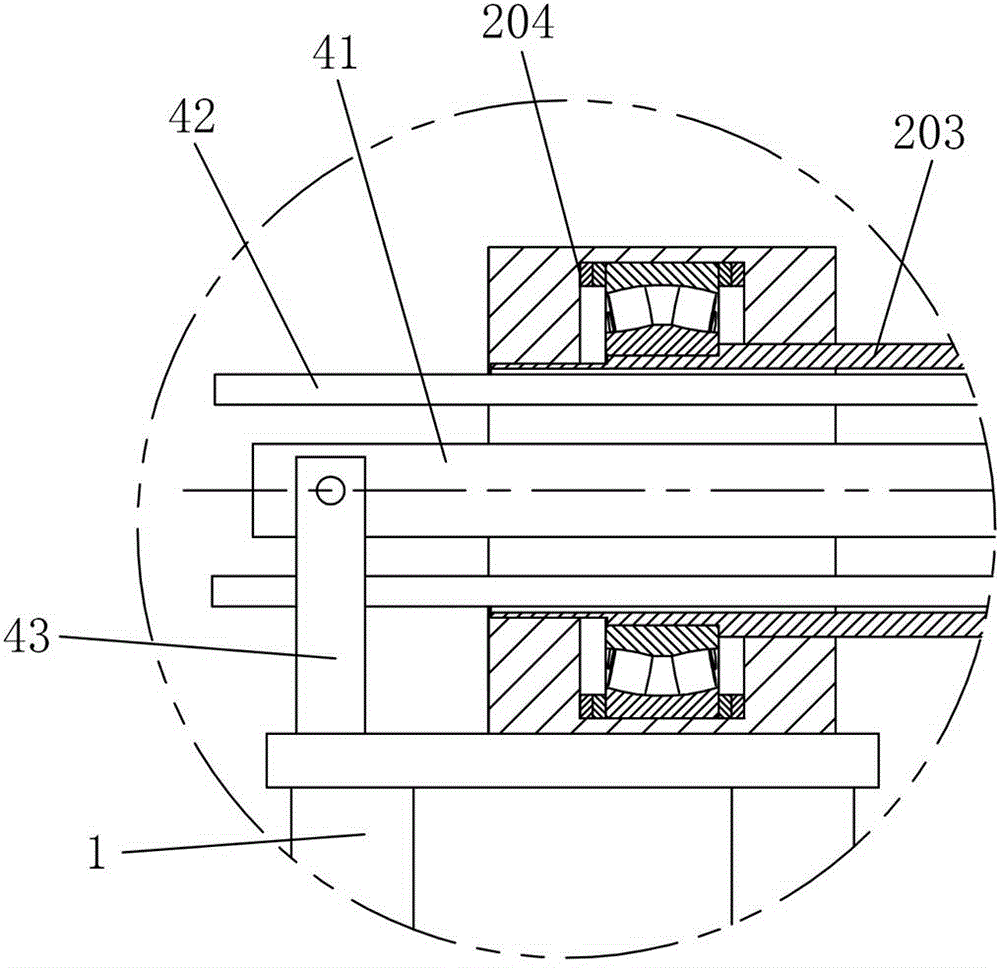

[0036] Such as Figure 1 to Figure 3 As shown, the carbonized toning device of bamboo chips of the present invention comprises a frame 1, a cylinder 2 mounted on the frame 1 and a drive mechanism 3 mounted on the frame 1 for driving the rotation of the cylinder 2, and the cylinder 2 is arranged There is a feeding and discharging mechanism for loading and unloading bamboo chips. A heating assembly 4 for heating the bamboo chips is fixedly installed in the drum 2. The heating assembly 4 includes a support shaft 41 and a plurality of electric heating tubes 42 installed on the support shaft 41. The drum 2 includes a cylinder body 201, a fixed shaft 202 fixed at one end of the cylinder body 201, and a hollow shaft 203 fixed at the other end of the cylinder body 201. The fixed shaft 202 and the hollow shaft 203 are respectively mounted on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com