Adjustable shaft part drilling jig

An adjustable technology for shaft parts, applied in the direction of the drilling jig used for workpieces, etc., can solve problems such as prone to skew, unsatisfactory shape and position tolerances, single special parts, etc., to achieve reliable installation and compression, ensure the center position, good centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

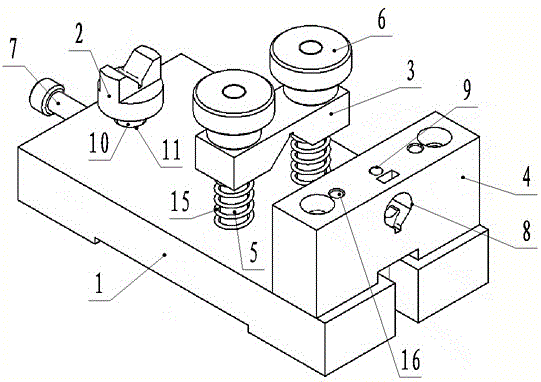

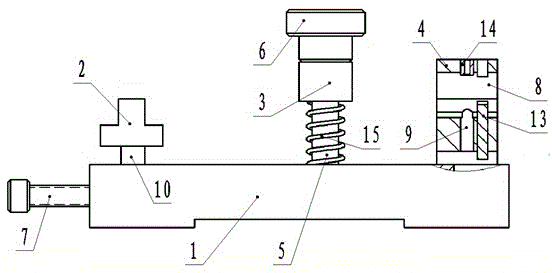

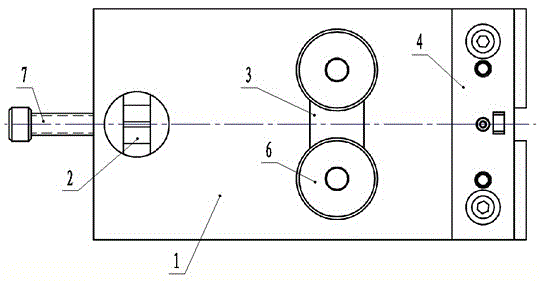

[0021] like Figure 1 to Figure 4 As shown, an adjustable shaft part drilling template includes a bottom plate 1, a floating V-shaped block 2, a compressed V-shaped block 3 and a drilling template 4, and the floating V-shaped block 2 and the drilling template 4 are respectively installed on the bottom plate 1 At the left and right ends close to each other, the floating V-shaped block 2 can float up and down and be locked by the fastening screw 7 arranged at the end of the bottom plate 1, and the pressing V-shaped block 2 is installed upside down in the middle of the base 1 On the column 5, a compression nut 6 is arranged above the compression V-shaped block 2, and the compression nut 6 is screwed on the upper end of the column 5, and a support hole 8 for supporting the workpiece to be processed is provided on the drilling template 4. The top of the drilling template 4 is provided with a drilling template hole 9 that runs through the support hole 8 downwards, and a drill sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com