Automatic tread feeding device

A technology of automatic feeding and feeding device, which is applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of inability to accurately fall to the designated position, uncontrollable falling speed, quality damage, etc., to achieve good centering effect, Improvement of efficiency and effect of bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

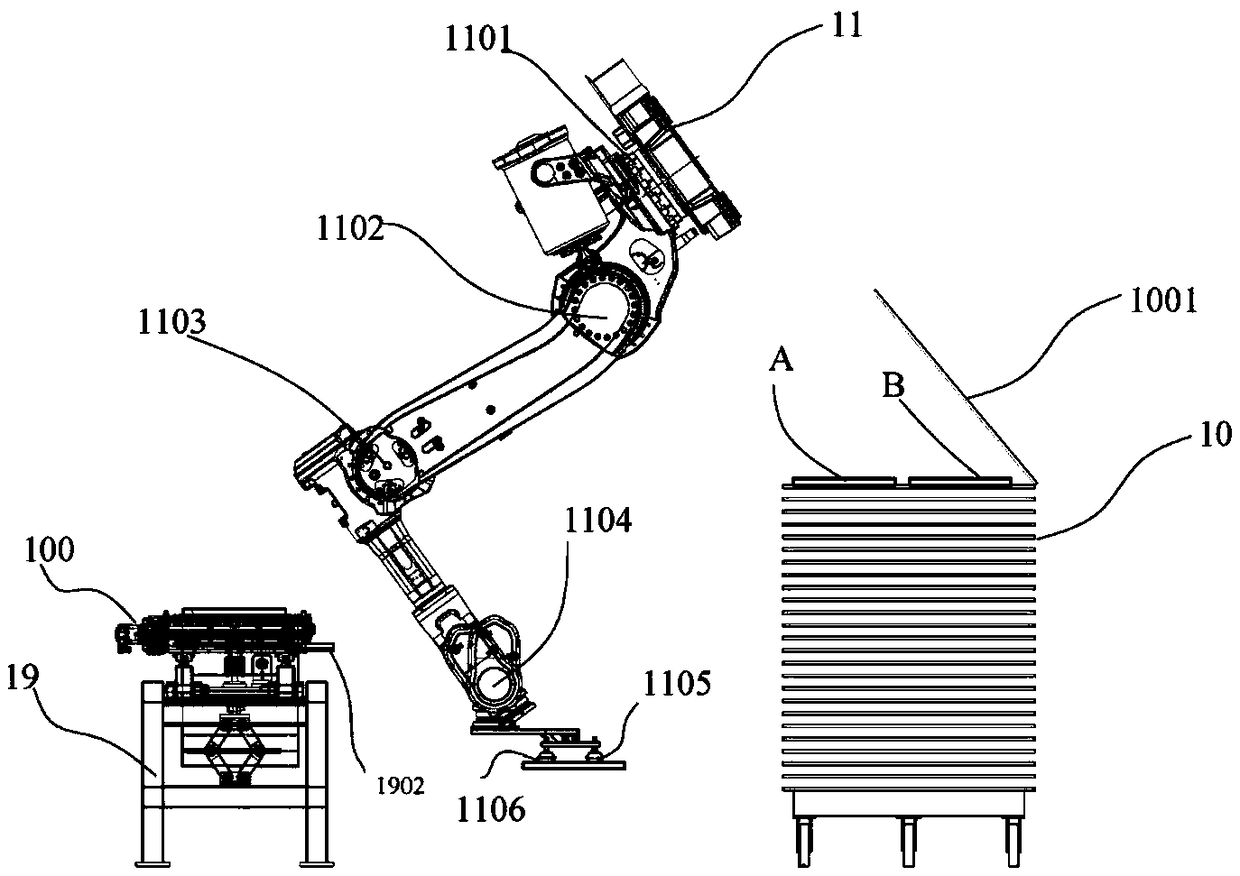

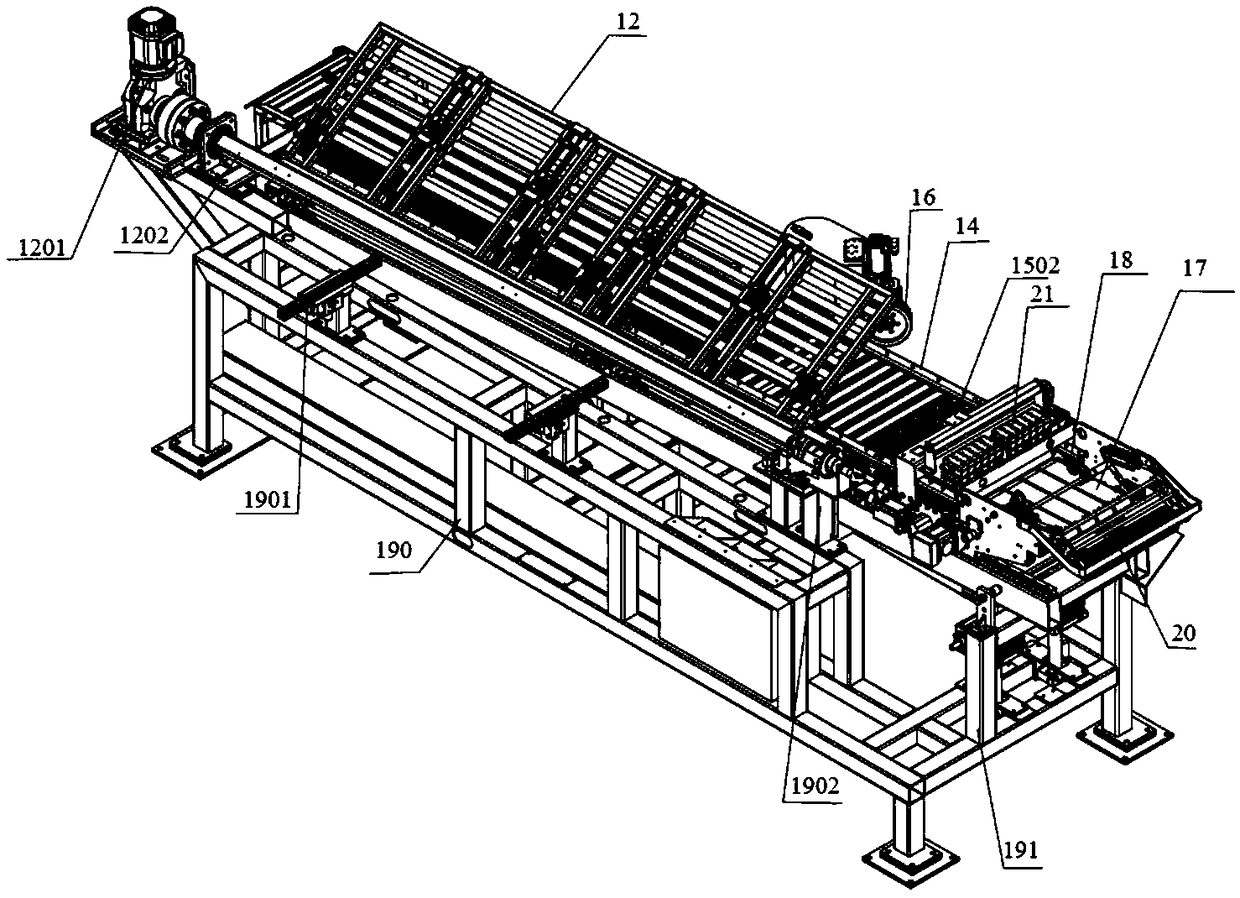

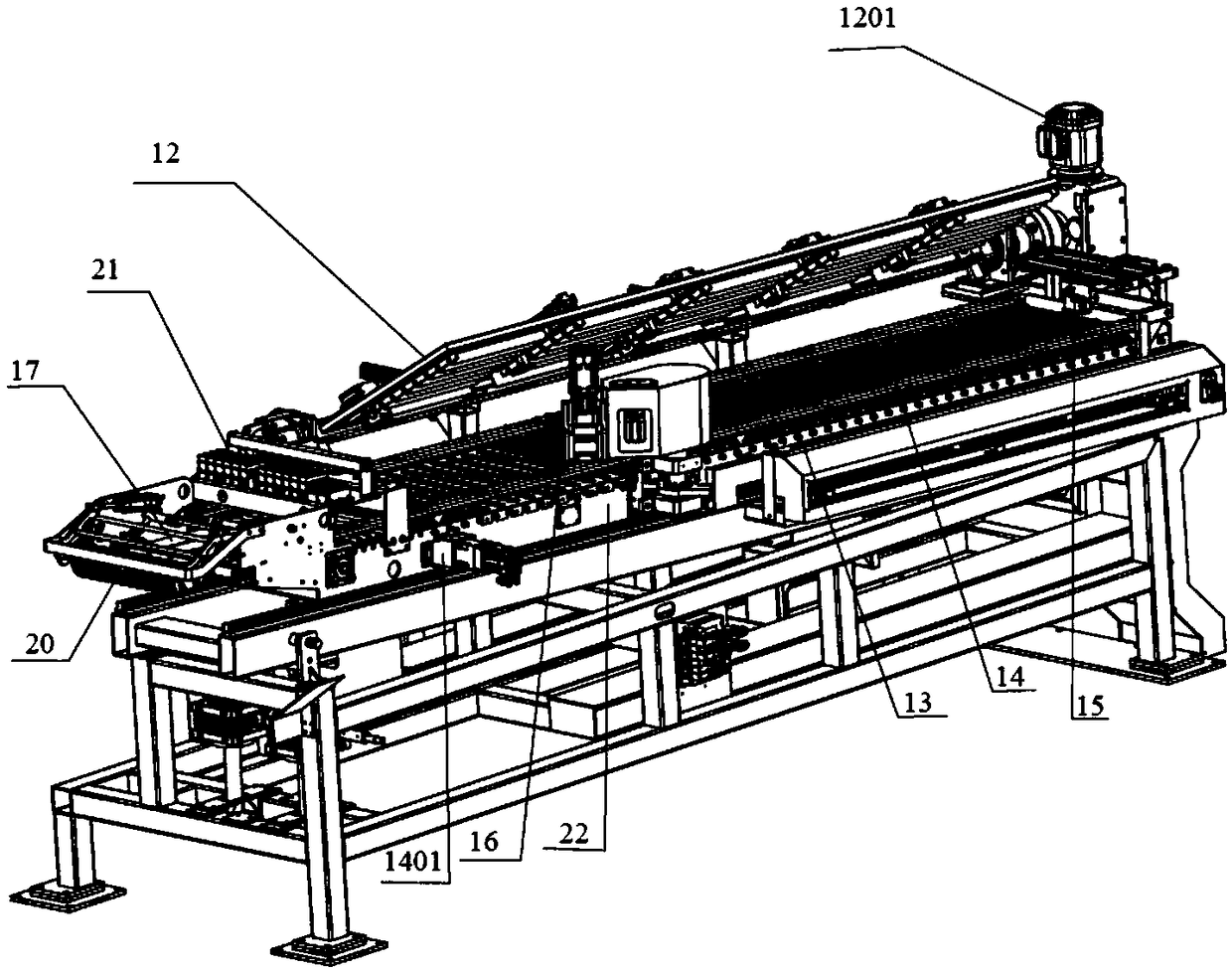

[0038] Such as figure 1 Shown, a kind of tread automatic feeding system, this feeding system comprises shutter car 10, grasping device 11, feeding device 100 and PLC controller; Grab device 11 transfers the tread on the shutter car 10 to supply The feeding device 100 is attached to the belt drum, and the tread is positioned at the rear of the feeding device (not shown in the figure); the shutter car, the grabbing device and the feeding device are all connected to the PLC controller signal;

[0039] A multi-layer hinge is formed on the shutter car 10, and a layer of tread is stored on each hinge 1101; the multi-layer tread is arranged vertically and placed on the chopped hinge respectively. The operator pushes the venetian trolley loaded with treads into the working position, and mechanisms such as cylinders and guide wheels automatically push the trolley into place and fix it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com