A drawing frame cleaning device

A technology of cleaning device and drawing frame, applied in spinning machine, textile and paper making, drafting equipment, etc. The effect of uniform conveying, avoiding clutter and knotting, and improving the centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

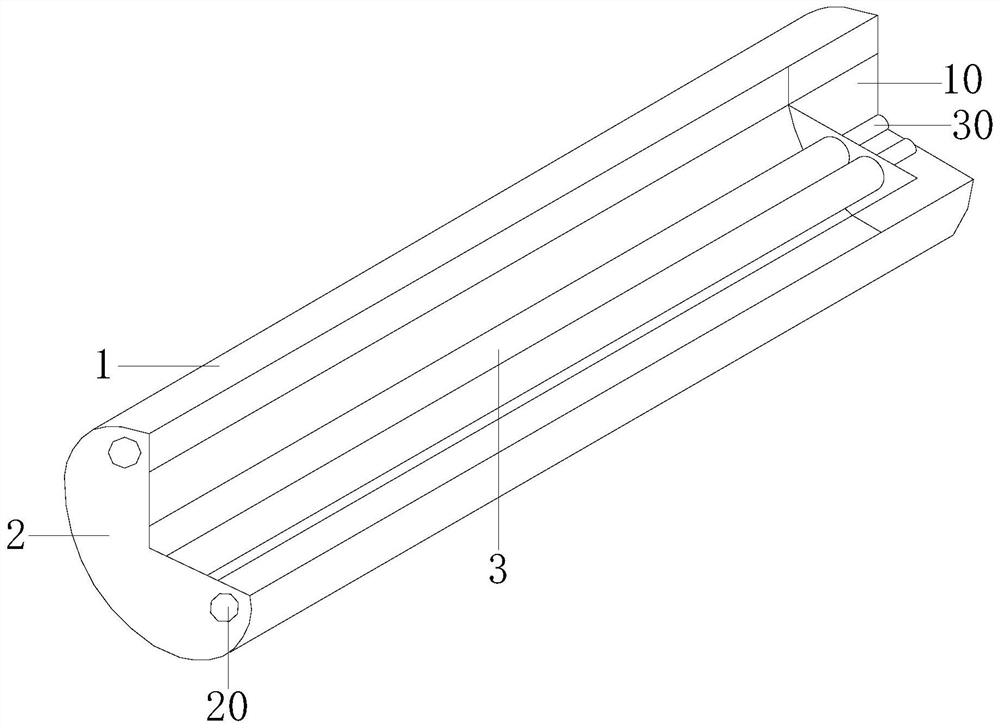

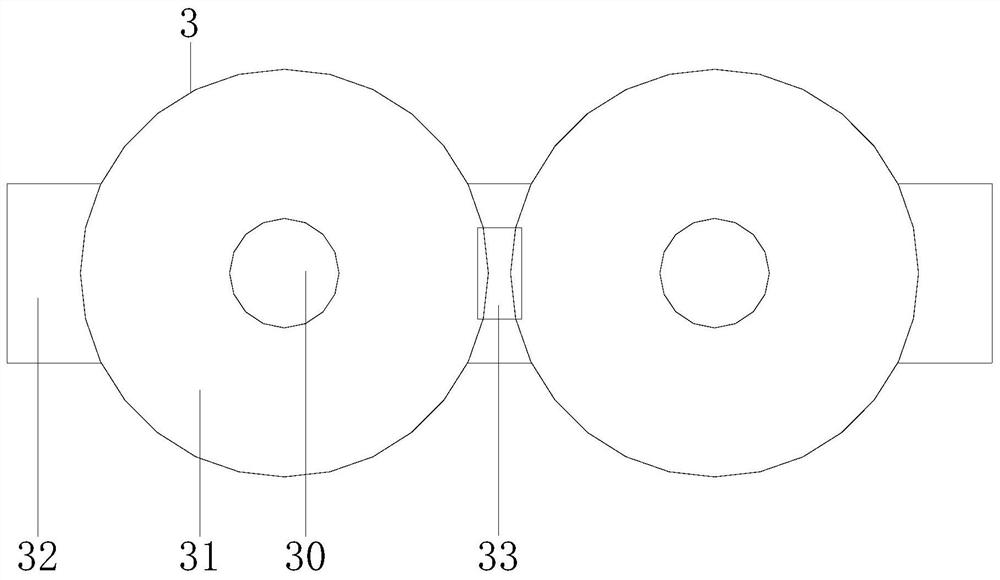

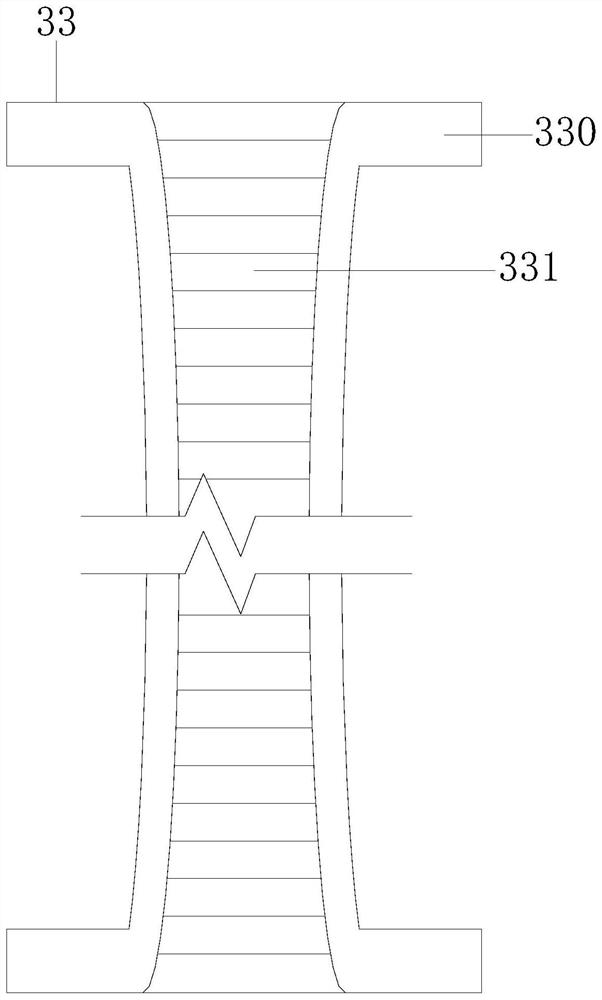

[0026] Example 1 see Figure 1-4 , the present invention provides a technical solution for a drawing frame cleaning device: its structure includes a dust collecting frame 1, a side mounting plate 2, and a conveying double roller 3, the dust collecting frame 1 is installed and connected to the side mounting plate 2, and the conveying double The roller 3 is installed on the dust collection frame 1 and the side mounting plate 2, the dust collecting frame 1 is equipped with a thickened side plate 10, the side mounting plate 2 is provided with a locking shaft 20, the thickened side plate 10, The locking shaft 20 is located at the left and right ends of the conveying double rollers 3. The conveying double rollers 3 include a rod shaft 30, a transmission line double roller 31, a mounting plate 32, and a middle device 33. The rod shaft 30 and the transmission line double rollers 31 Shaft connection, the double rollers 31 of the transmission line are attached to the middle device 33, t...

Embodiment 2

[0028] Example 2 see Figure 5-7 , the present invention provides a technical solution for a drawing frame cleaning device: the structure of the end center line device 50 includes a spring cover frame 500, a center line end spring 501, a center line side end plate 502, and a wire storage plate 503, and the end center line The device 50 plays the role of controlling the conveying speed of the sliver. The spring cover frame 500 is welded with the midline end spring 501, and the spring cover frame 500 is installed and connected with the midline side end plate 502. The plate 503 is installed and connected, and the elastic force of the center line end spring 501 plays a role in supporting the line storage plate 503 so that it fits with the sliver. The middle line device 51 includes an end plate 510 and a main delivery plate 511. The end plate 510 is assembled and connected with the main feeding board 511, and the main feeding board 511 includes the side board 5110, the middle board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com