A guide plate coil material fixed-length feeding device

A feeding device and coil material technology, which is applied in the field of guide plate coil material fixed-length feeding device, can solve the problems of difficult synchronization of punching machines, lower product quality, and low work efficiency, so as to improve fluency, safety and stability, improve safety, and realize The effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

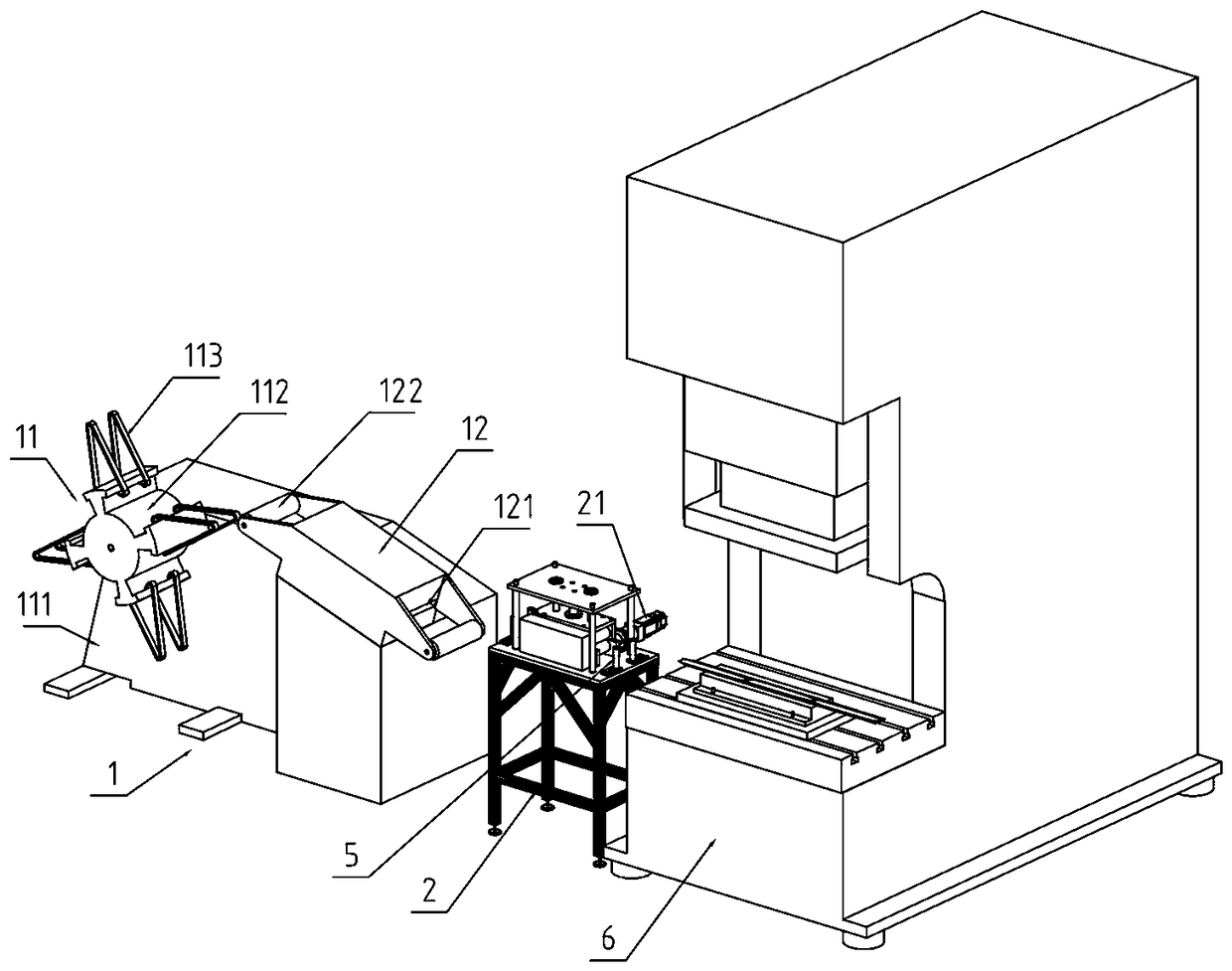

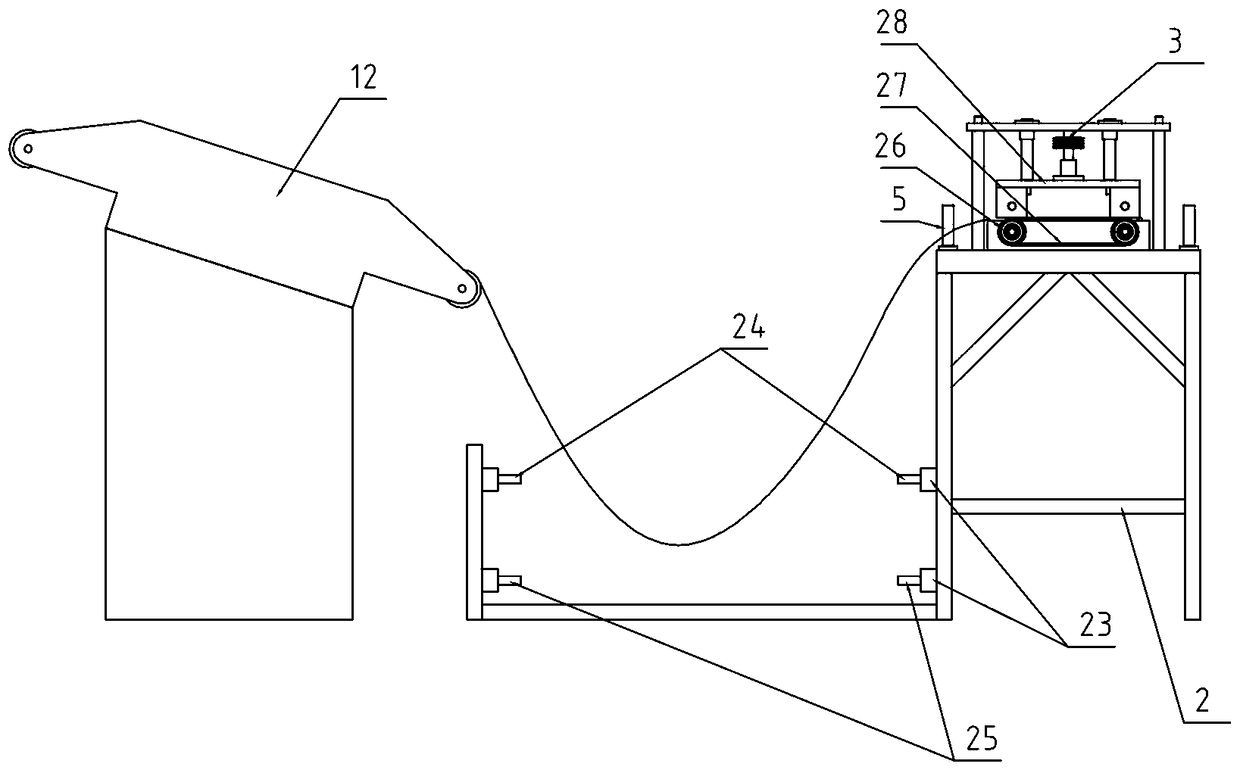

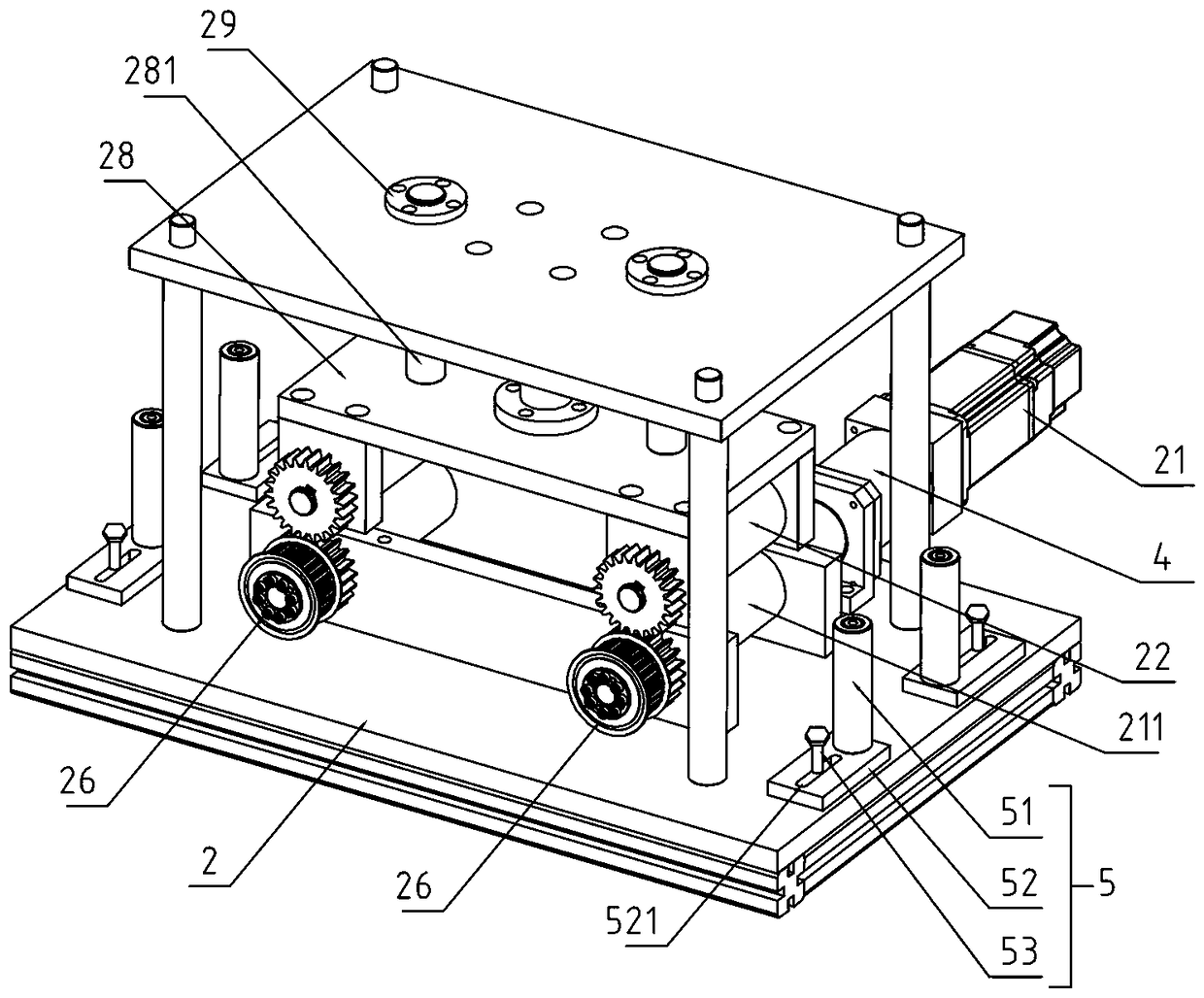

[0025] refer to Figure 1-8As shown, a guide coil material fixed-length feeding device includes a discharging mechanism 1, a feeding bracket 2, and a punch press 6 arranged in sequence, and also includes a controller, which can be a programmable controller, and the discharging mechanism 1 It includes a raw material rack 11 for placing sheet coils, and a straightening machine 12 for leveling the sheet. The straightening machine 12 includes a straighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com