Adjustable sanding system for gravure solvent ink

A solvent and ink technology, which is applied in the field of adjustable sanding system for gravure solvent ink, can solve the problems of tediousness, affecting the ink production process, pumping out of the pump, etc., and achieve the effects of convenient switching, uniform transportation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

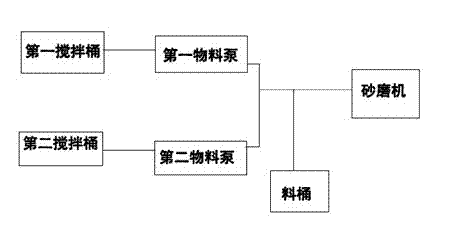

[0011] An adjustable sanding system for gravure solvent inks, such as figure 1 As shown, it includes a sand mill, the feed end of the sand mill is connected with the first and second material pumps arranged in parallel, and the feed ends of the first and second material pumps are respectively connected with first , The discharge end of the second mixing barrel. The first and second material pumps are respectively low-viscosity material pumps and high-viscosity material pumps, and correspondingly the first mixing tank and the second mixing tank contain low-viscosity materials and high-viscosity materials respectively. When in use, just switch the corresponding pump valve to realize the universal grinding of high and low viscosity materials.

[0012] In order to switch the use of the material pump, the material in the sand mill will not be affected by the viscosity, and a material barrel is also arranged between the sand mill and the material pump. That is, if at the beginning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com