Reciprocating hydraulic diaphragm pump

A hydraulic diaphragm pump, reciprocating technology, applied in the field of reciprocating pumps, can solve the problems of large structure, many failure points, heavy weight, etc., and achieve the effect of obvious structural advantages, improved plunger stroke, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

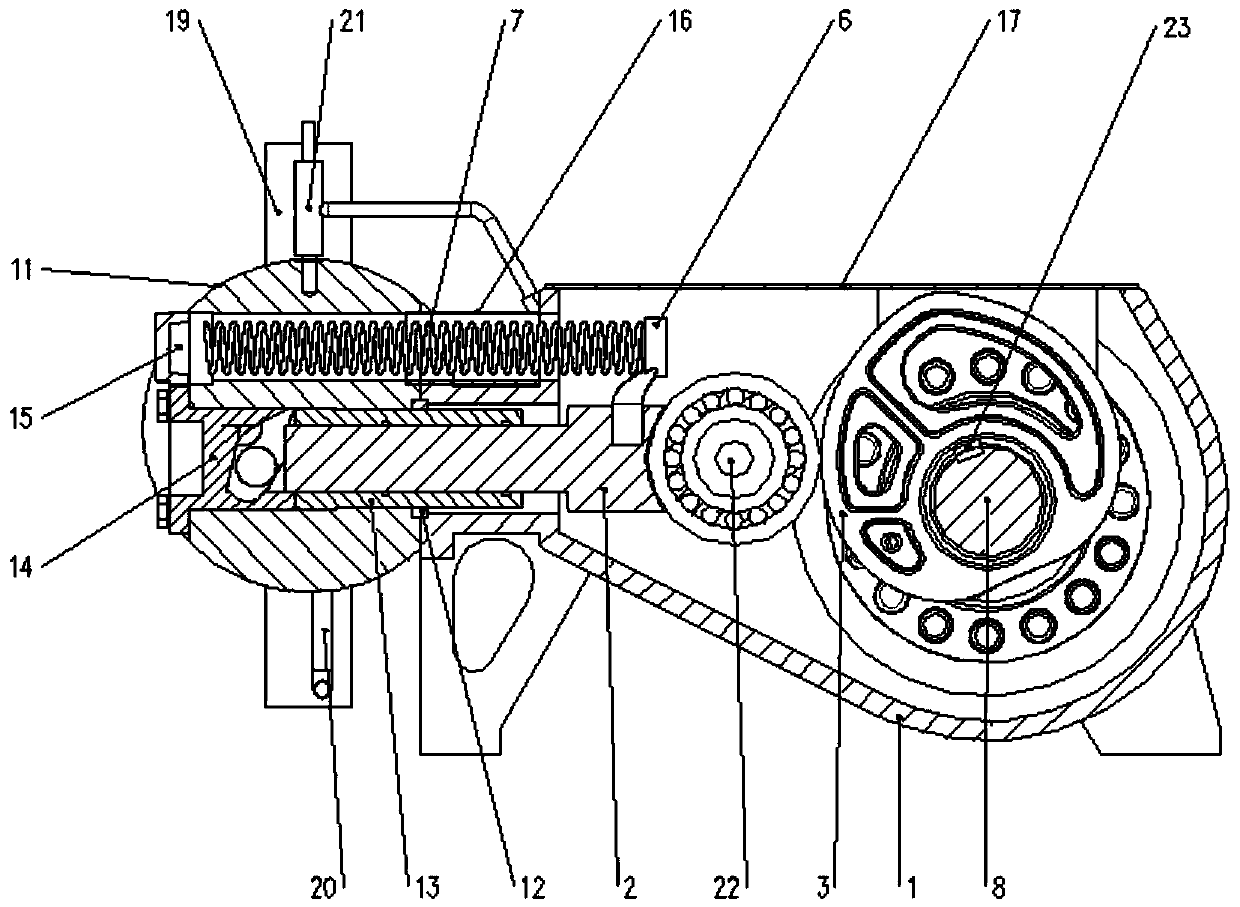

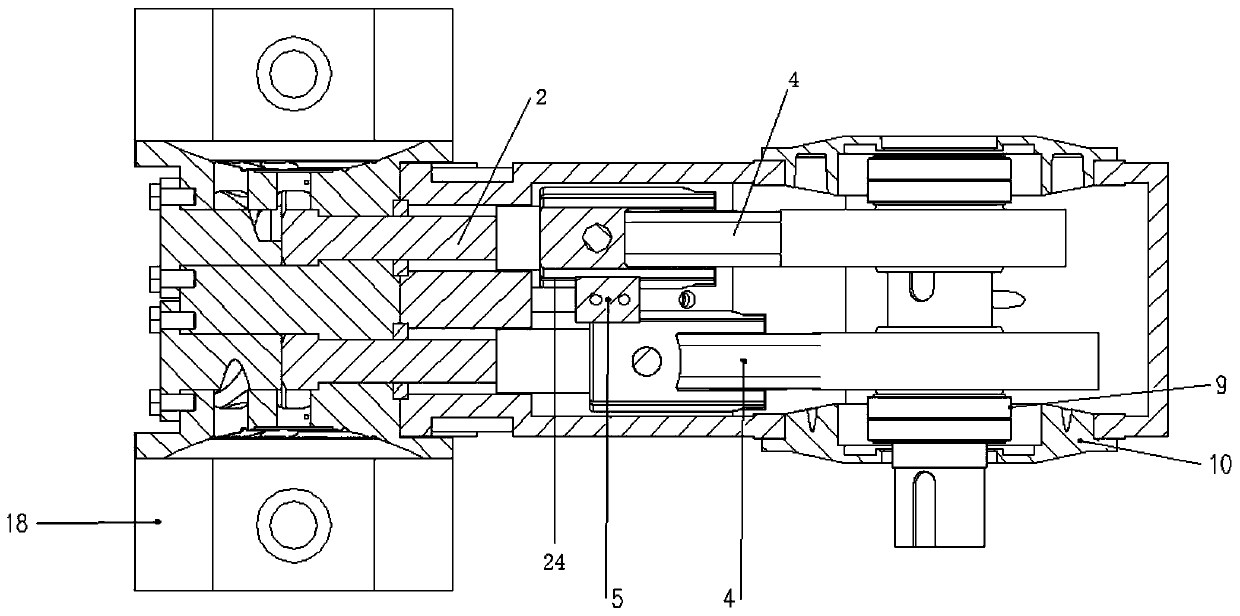

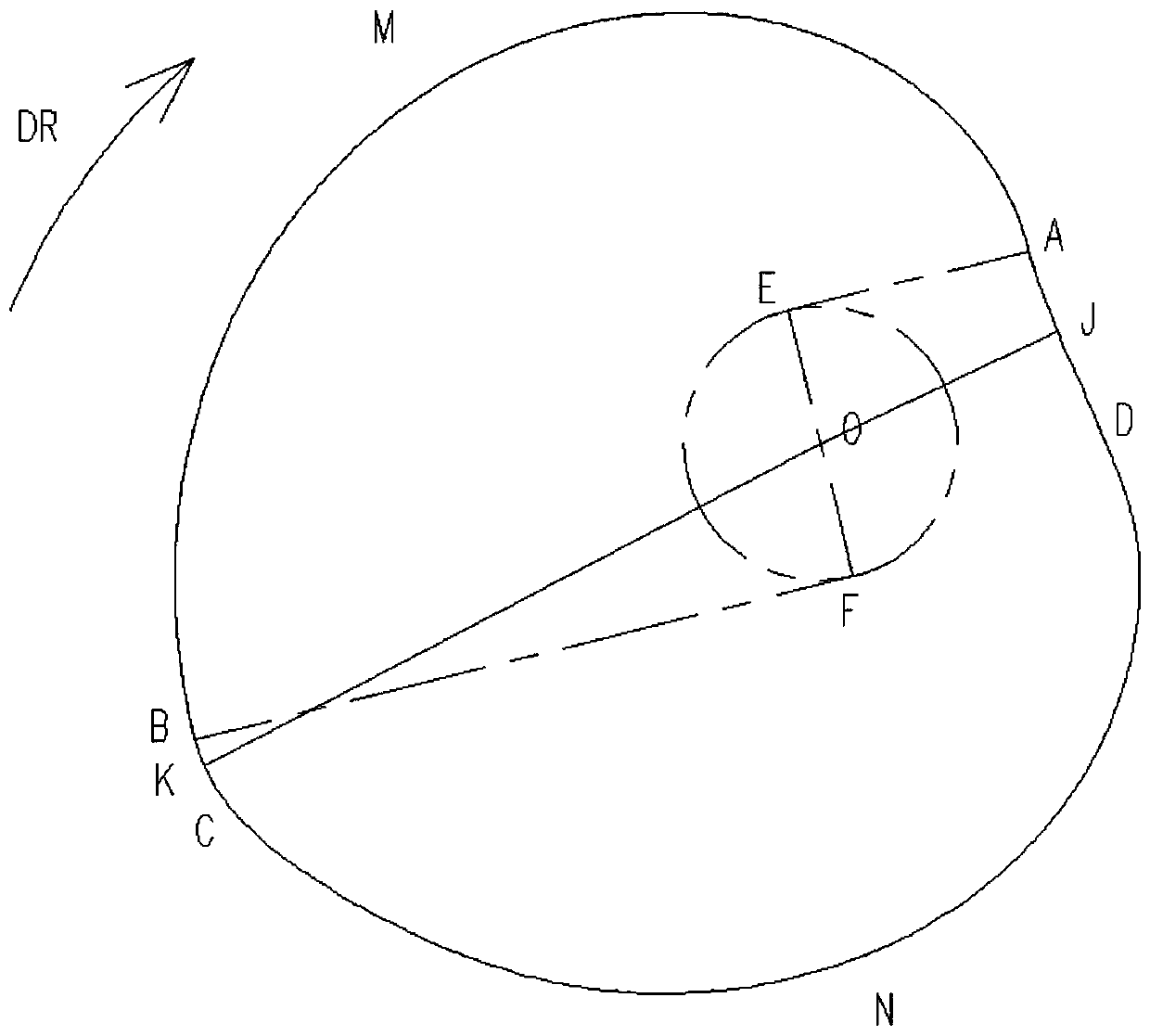

[0023] Such as figure 1 and figure 2 As shown, a reciprocating hydraulic diaphragm pump consists of a transmission case 1, a plunger 2, an involute cam 3, a plunger bearing 4, a guide frame 5, a retaining column 6, a return spring 7, a mandrel 8, and a bearing 9. Bearing gland 10, hydraulic chamber assembly 11, positioning sleeve 12, cylinder liner 13, front plug 14, spring gland 15, spring sheath 16, cover plate 17, diaphragm head assembly 18, valve group 19, oil supply line 20. Oil return pipeline 21, bearing pin 22, key 23 and other main components.

[0024] The hydraulic chamber assembly 11 is positioned in cooperation with the transmission case 1 through the positioning sleeve 12, the hydraulic chamber assembly 11 is filled with hydraulic oil, and the diaphragm head assembly 18 is arranged on both sides of the hydraulic chamber assembly 11, arranged back to back. A cylinder liner 13 is installed in the hydraulic chamber assembly 11, and the cylinder liner 13 is compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com