Cleaning equipment for liquid crystal glass substrates

A technology for liquid crystal glass substrates and cleaning equipment, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low ITO film effect, achieve good cleaning effect, low cost, and save labor fee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

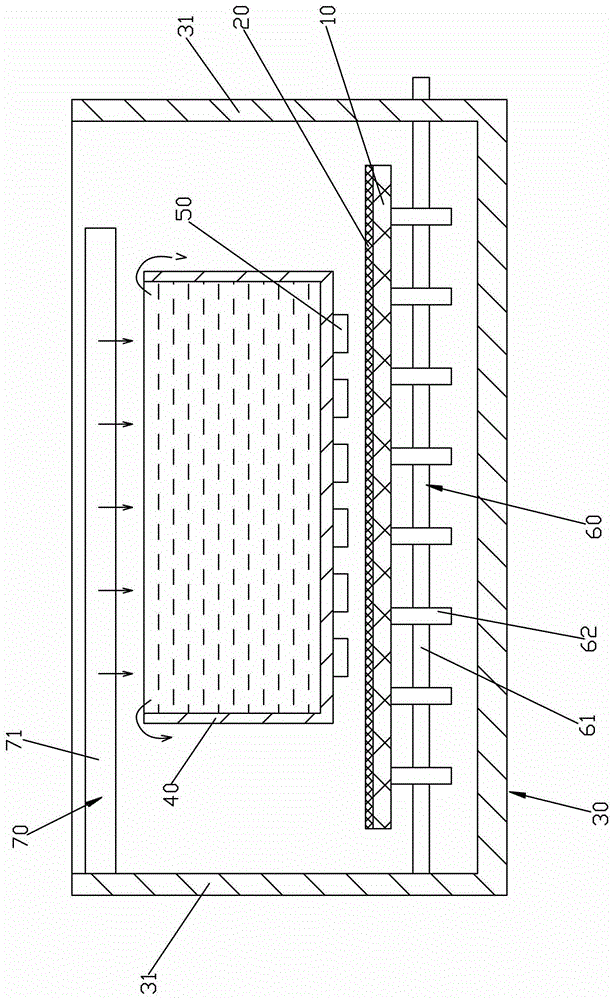

[0025] Please check figure 1 , a cleaning device for a liquid crystal glass substrate, the glass substrate 10 has a first surface and a second surface opposite to each other, and the first surface is coated with an ITO film 20 . The cleaning device includes a frame 30 , a box body 40 attached to the frame 30 , an ultrasonic generator 50 , a delivery unit 60 attached to the frame 30 , and a liquid supply unit 70 for supplying cleaning liquid.

[0026] The frame 30 includes a collection tank, the collection tank has two long side walls 31, two short side walls and a lower wall, and the two long side walls 13, two short side walls and the lower wall are fixedly connected to form the above-mentioned collection with the opening facing upward. groove. If required, a cover plate can be provided to cover the opening of the receiving sump.

[0027] The box body 40 has a bottom wall and a peripheral wall extending upward from the peripheral edge of the bottom wall, and an opening is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com