Anti-blocking material conveyer

A conveyor and anti-clogging technology, which is applied in packaging and other directions, can solve problems such as uneven powder packaging, shutdown, and affecting operating efficiency, and achieve the effects of accurate measurement, uniform speed in the conveying process, and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

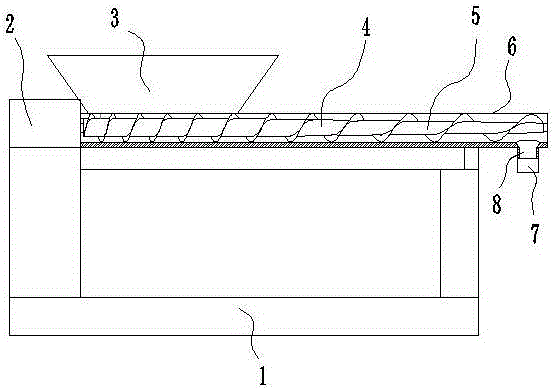

[0010] Embodiment: a kind of material conveyer that can prevent clogging, as figure 1 As shown, including a frame 1, the frame 1 is provided with a drive motor 2 and a screw 4 connected with the drive motor 2, the outside of the screw 4 is sleeved with a barrel 6, and one end of the barrel 6 is provided with a feed hopper 3, The other end of the barrel is provided with a discharge port 8, and the outer peripheral side of the screw rod 4 is provided with a spirally extending material delivery channel 5 between the feed hopper 3 and the discharge port 8, and the screw pitch of the material delivery channel 5 spirally extends from the feed From the hopper 3 to the discharge port 8, the diameter becomes linearly larger, and the diameter of the screw 4 decreases linearly from the feed hopper 3 to the discharge port 8, so that the cross-sectional area of the delivery channel 5 near the end of the feed hopper 3 is less than One end close to the discharge port 8. For the convenienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com