A powder and granular body superheated steam sterilization process and system

A superheated steam, powder and granule technology, applied in the field of powder and granule superheated steam sterilization process and system, can solve the problems of difficult to achieve continuous automatic production, low sterilization energy consumption, unsatisfactory sterilization effect, etc., to save material handling and sterilization. Good effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

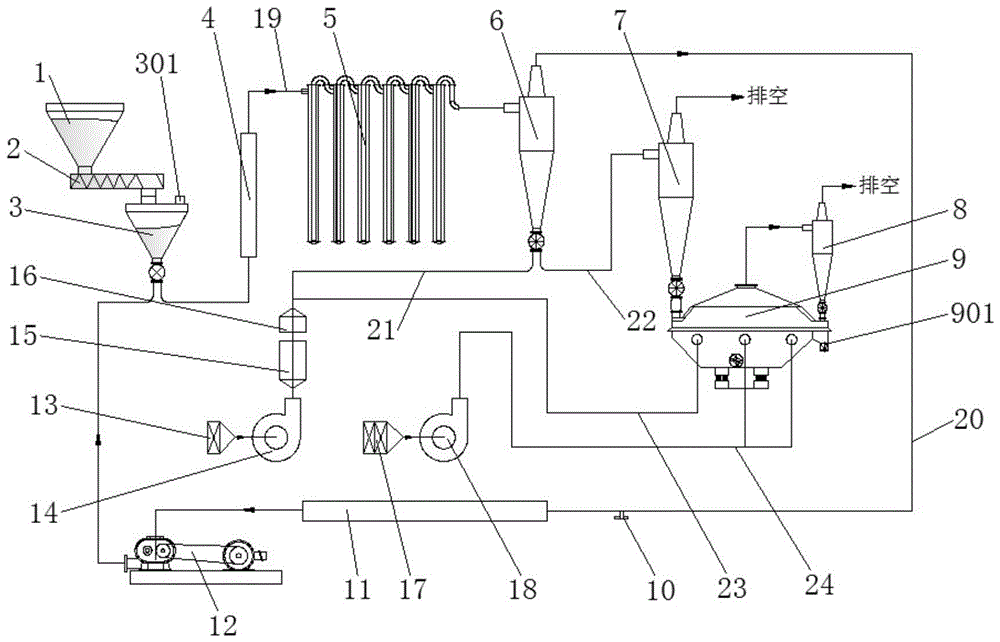

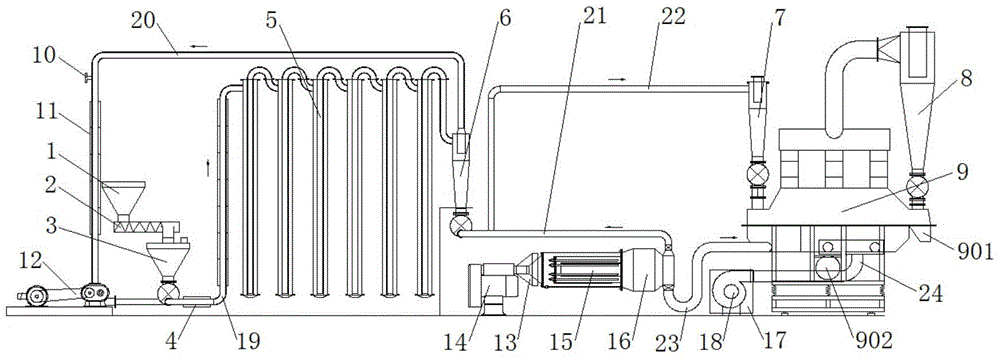

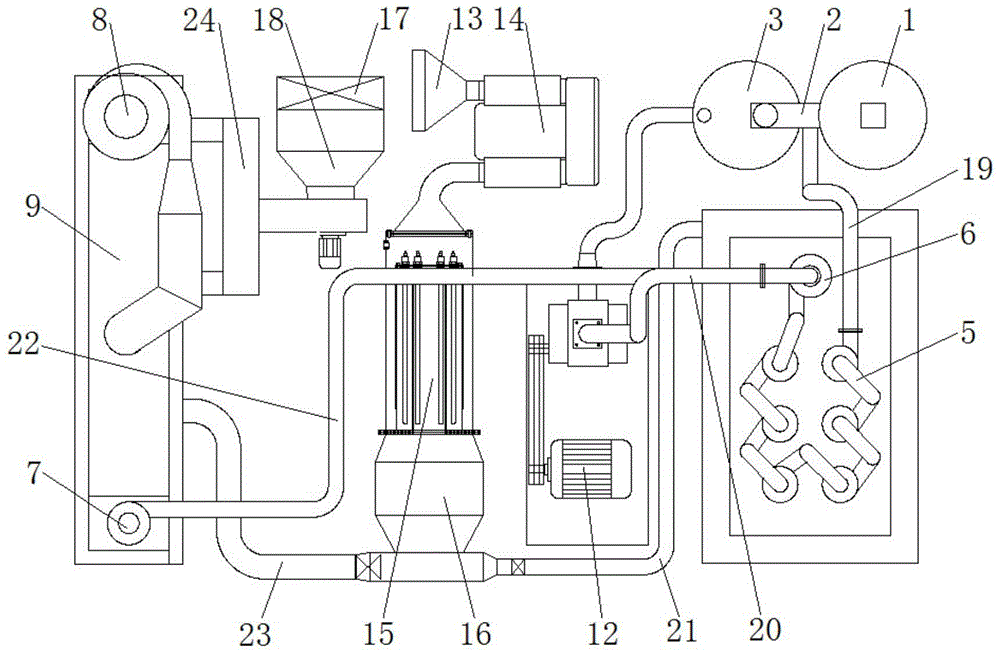

[0041] Combine figure 1 , The superheated steam sterilization process of powder and granular body of this embodiment includes the following steps:

[0042] (1) Feeding: evenly add the powder or granular material to the superheated steam flow and transport it to the sterilization process. Specifically, the powder or granular material is added to the superheated steam flow inlet of the sealed cycle at a constant rate and in the steam flow. Under the action of, the powder and granular materials are naturally transported to the next process along the flow direction of the steam flow;

[0043] (2) Sterilization: control the superheated steam flow to form a cyclone flow, so that the powder and granular materials are dispersed in the cyclone flow, use the steam heat to sterilize for 3-10 seconds, and the sterilization temperature is controlled within 120-250℃. Under the action of the cyclone flow, The powder and granular materials are loosely and uniformly dispersed in the superheated ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com