Test paper bag sealing label pressing device

A technology of a pressing device and a test paper bag, which is applied in the field of printing and packaging, can solve the problems of damaged test paper bags and less development of test paper printing technologies, and achieves the effects of low cost, simple structure and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

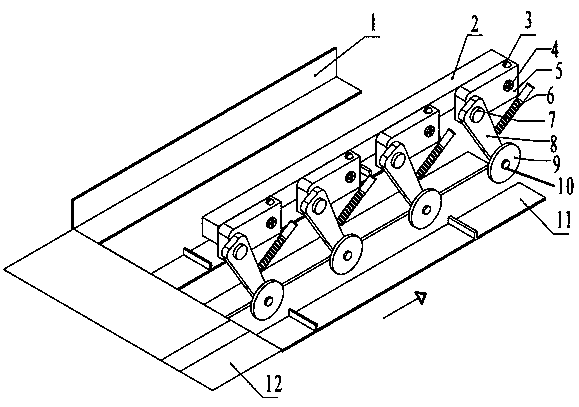

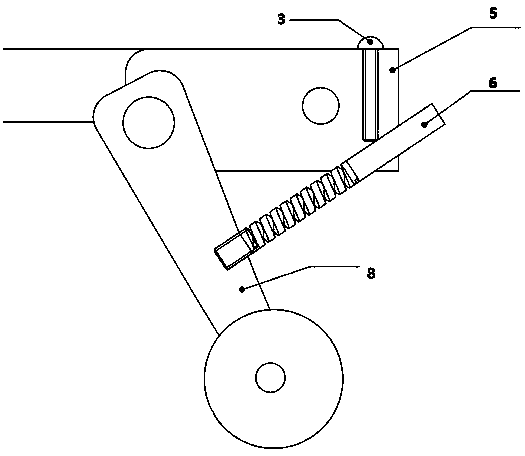

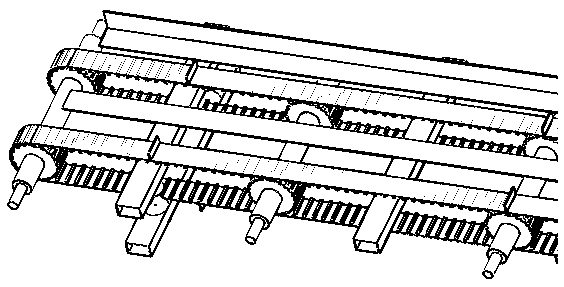

[0012] Embodiment 1: as Figure 1-3 As shown, a test paper bag sealing sign pressing device includes an L-shaped baffle 1, a support tube 2, an adjustment screw 3, an anti-compression spring mounting plate 5, an anti-compression spring 6, an installation shaft 7, a bearing mounting plate 8, and a deep Groove ball rolling bearing 9, bearing axially fixed shaft 10, conveyor belt 11; wherein L-shaped rib 1 is located on the upper side of the conveying direction of conveyor belt 11, the horizontal baffle plate of L-shaped rib 1 is located on the same plane as conveyor belt 11, and L-shaped rib 1 The vertical baffle plate of 1 is located on the side away from the conveyor belt 11 and is perpendicular to the baffle plate on the conveyor belt 11. The baffle plate on the conveyor belt 11 is perpendicular to the moving direction of the conveyor belt 11. The sealing sign on the top surface of the test paper bag 12 passes directly below the deep groove ball rolling bearing 9, and the dee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com