Paint detection sampling device

A sampling device and coating technology, applied in the direction of sampling devices, measuring devices, sampling, etc., can solve the problems of inconvenient cleaning, inconvenient placement of sampling bottles, inconvenient sampling bottles, etc., and achieve the effect of easy cleaning, convenient detection and sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

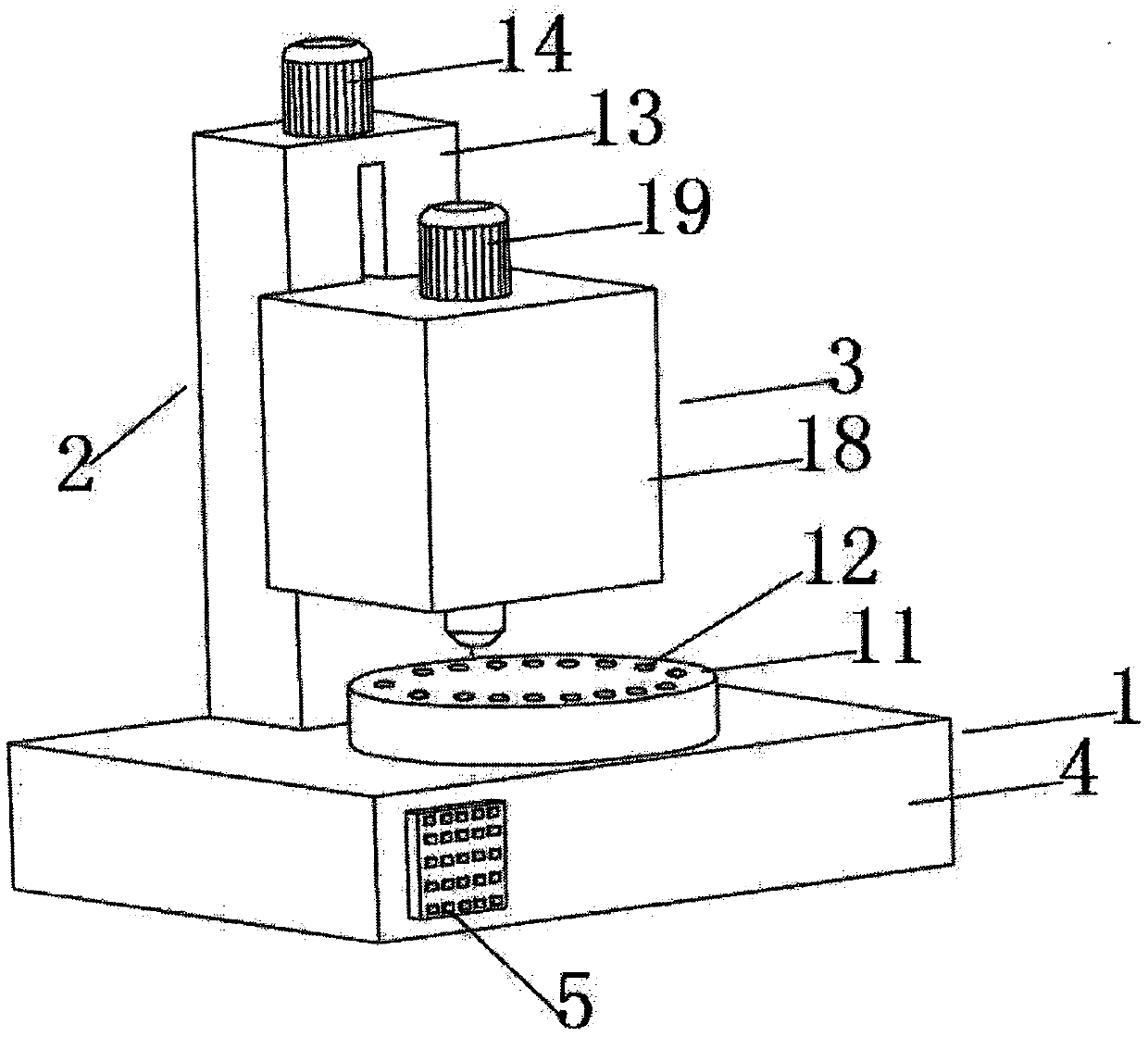

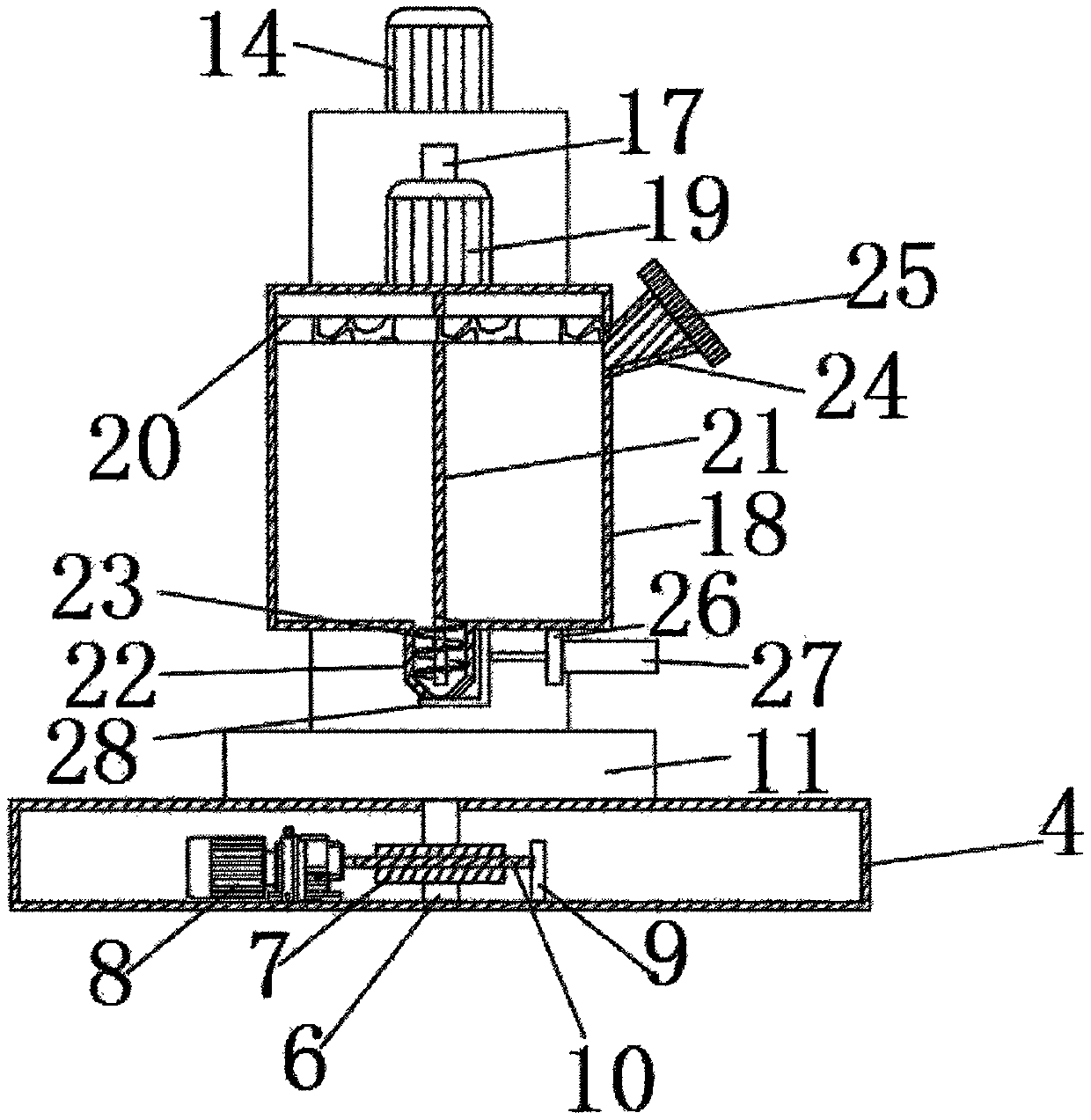

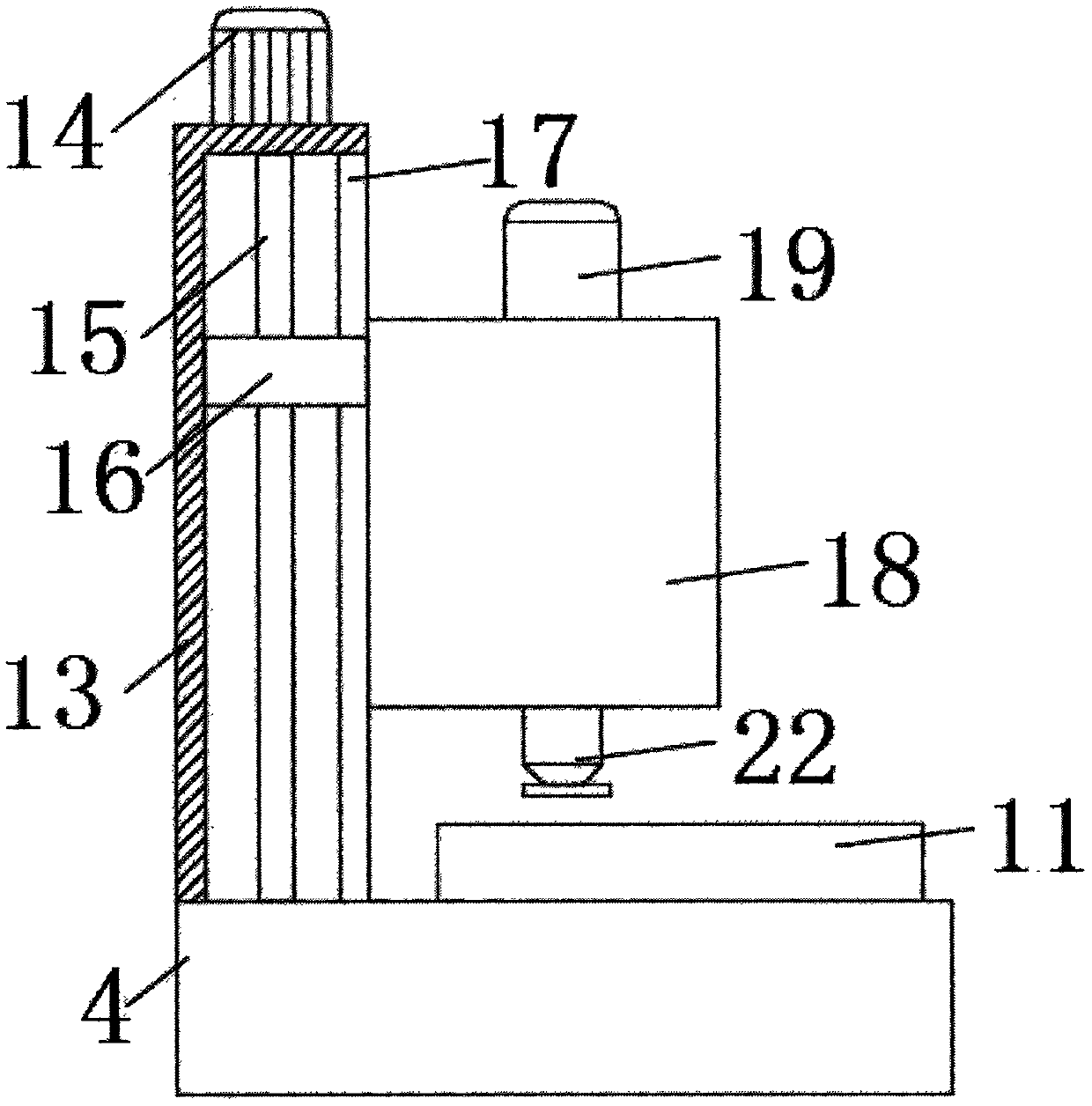

[0019] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a paint detection and sampling device, comprising a rotating mechanism 1, a lifting mechanism 2 and a sampling mechanism 3, the lifting mechanism 2 is arranged above the rotating mechanism 1, and the lifting mechanism One side of 2 is provided with sampling mechanism 3, and described rotary mechanism 1 is made of workbench 4, control panel 5, rotating main shaft 6, transmission worm gear 7, servo motor 8, support frame 9, transmission worm rod 10, rotary table 11 and place Groove 12 is formed, and the inner rotation of described workbench 4 is connected with rotating main shaft 6, and the top of described rotating main shaft 6 passes through the middle part of workbench 4 and is fixedly installed with rotating table 11, and the bottom of described rotating table 11 and working The top of the table 4 is slidingly connected, the bottom of the inner wall of the workbench 4 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com