Heating spiral type material conveying device

A conveying device and a spiral technology, which is applied in the field of waste resource disposal equipment, can solve the problems of oil sludge that is difficult to transfer heat and cannot be broken into semi-solid oil sludge, and achieve the effects of improving heat utilization efficiency, uniform heating, and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

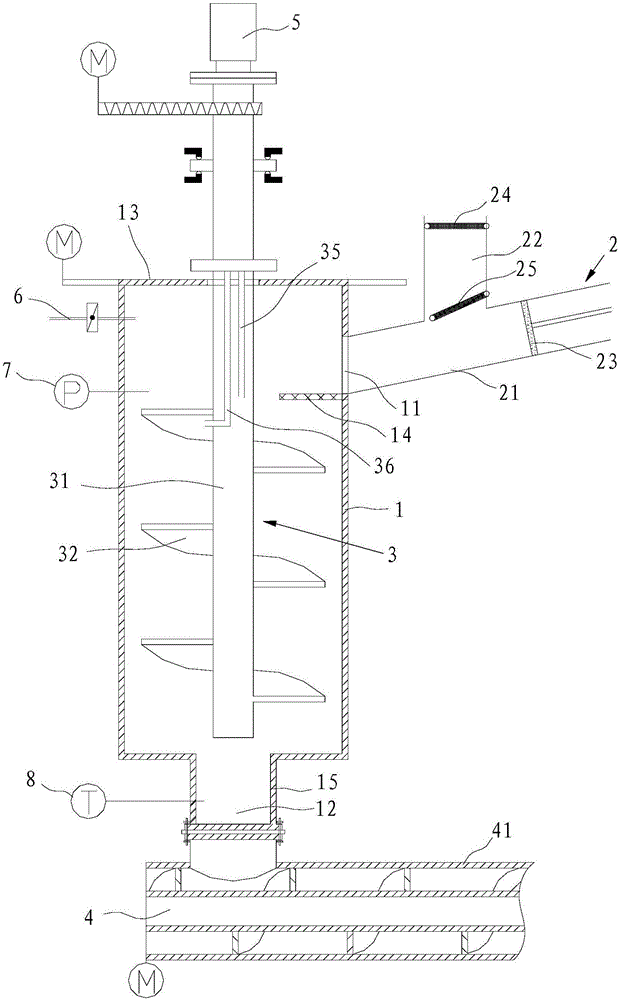

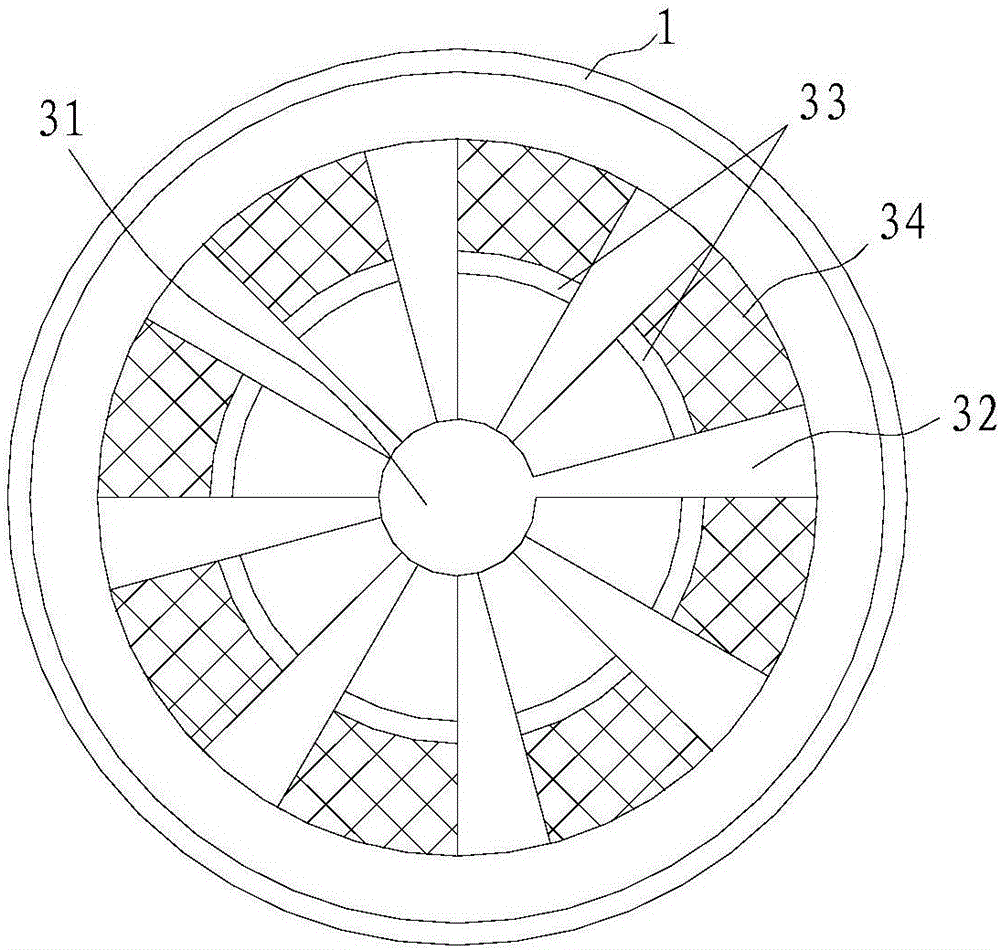

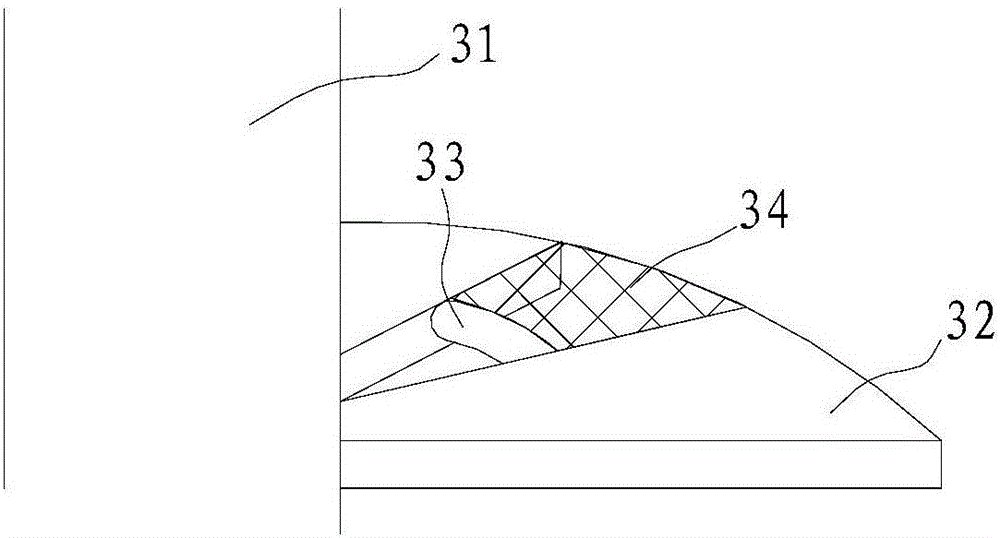

[0028] like Figure 1~4 As shown, a heating screw type material conveying device includes a storage bin housing 1, a feeding mechanism 2, a stirring paddle 3 disposed in the storage bin housing 1, and a horizontally arranged conveying stirring cage 4. The storage bin shell 1 has a material inlet 11 and a material outlet 12 for heating and stirring materials. The top of the storage bin housing 1 is provided with a bin cover 13, and the bin cover 13 is composed of two semicircular covers 131 that can move horizontally. Of course, it can be realized by adding slide rails to the semicircular covers 131, and then driving the opening and closing of the bin cover 13 by a motor. automation. When the stirring paddle 3 is installed, the compartment cover 13 is opened first, and after the stirring paddle 3 is installed, the compartment cover 13 is closed again. The inner wall of the storage bin housing 1 is located below the feed opening 11 and is provided with a feed buffer net 14 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com