Auxiliary feeding device for side-stepping and board-trimming in carpentry

A technology of auxiliary feeding and baffle device, which is applied in the field of auxiliary feeding device for woodworking, can solve the problems of damaging the surface of the board, reducing the feeding speed and feeding accuracy, and failing to achieve smooth feeding, so as to ensure complete The effect of improving the feeding speed and improving the feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

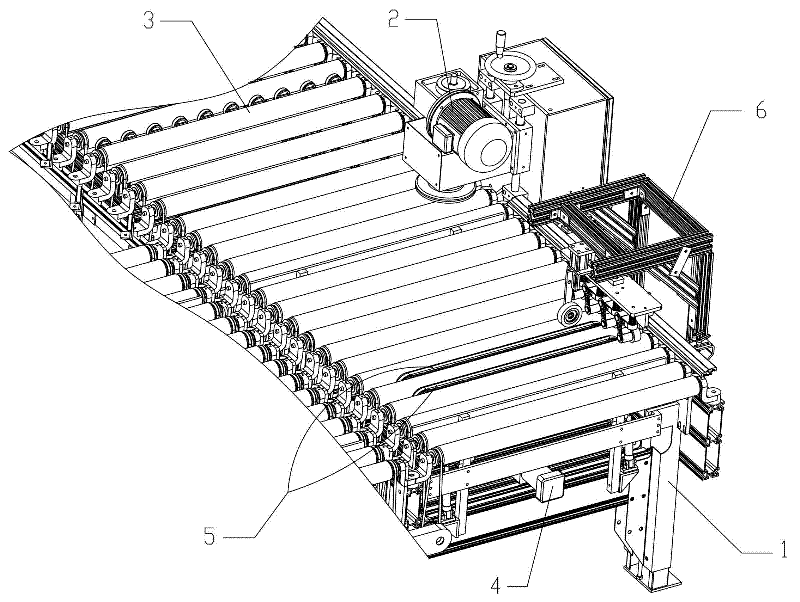

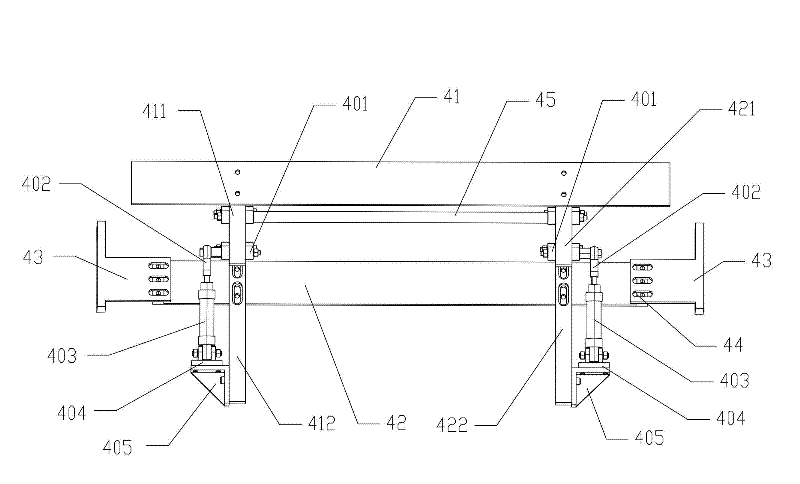

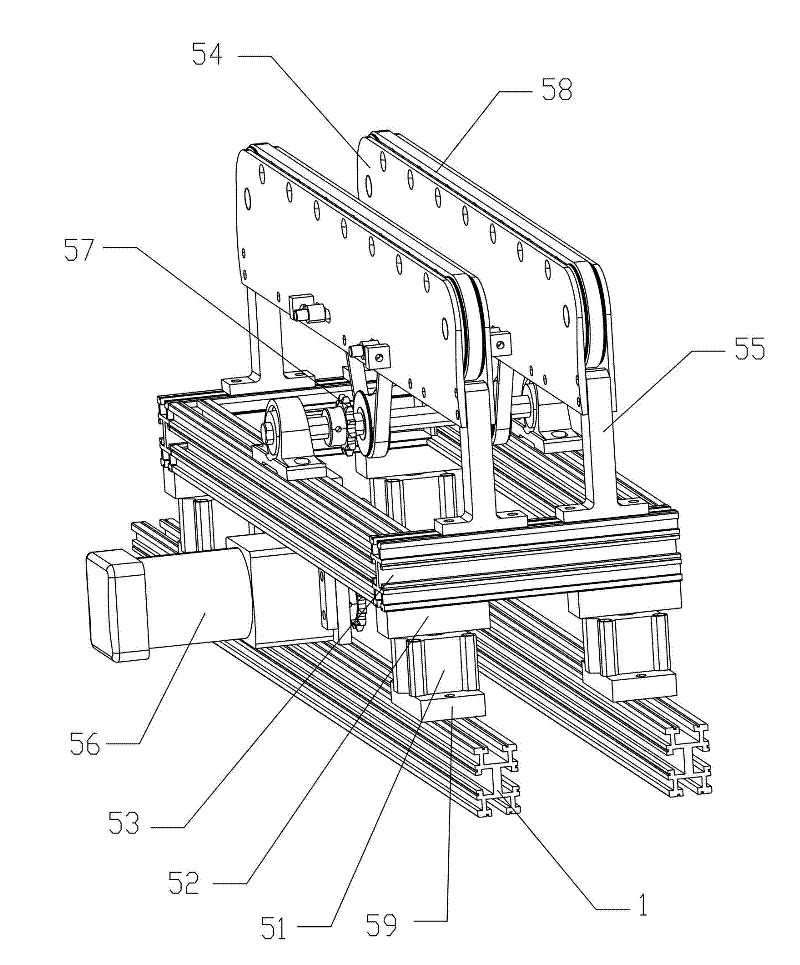

[0026] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the auxiliary feeding device used for woodworking edge alignment according to the present invention is mainly composed of a frame 1, a driving device 2 installed on the frame 1, and a roller table 3 composed of several rollers for conveying boards composed of. Among them, the frame 1 is provided with a pneumatic baffle device 4 for preventing the plate from continuing to be conveyed, a translational edge device 5 for translating the plate to the edge, and a plate pressing device 6 for stably conveying the plate to the next process. The plate device 4, the translation edge device 5 and the plate pressing device 6 are respectively connected with the driving device 2, and the pneumatic baffle device 4 and the translation edge device 5 are respectively installed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com