Patents

Literature

55results about How to "Check flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

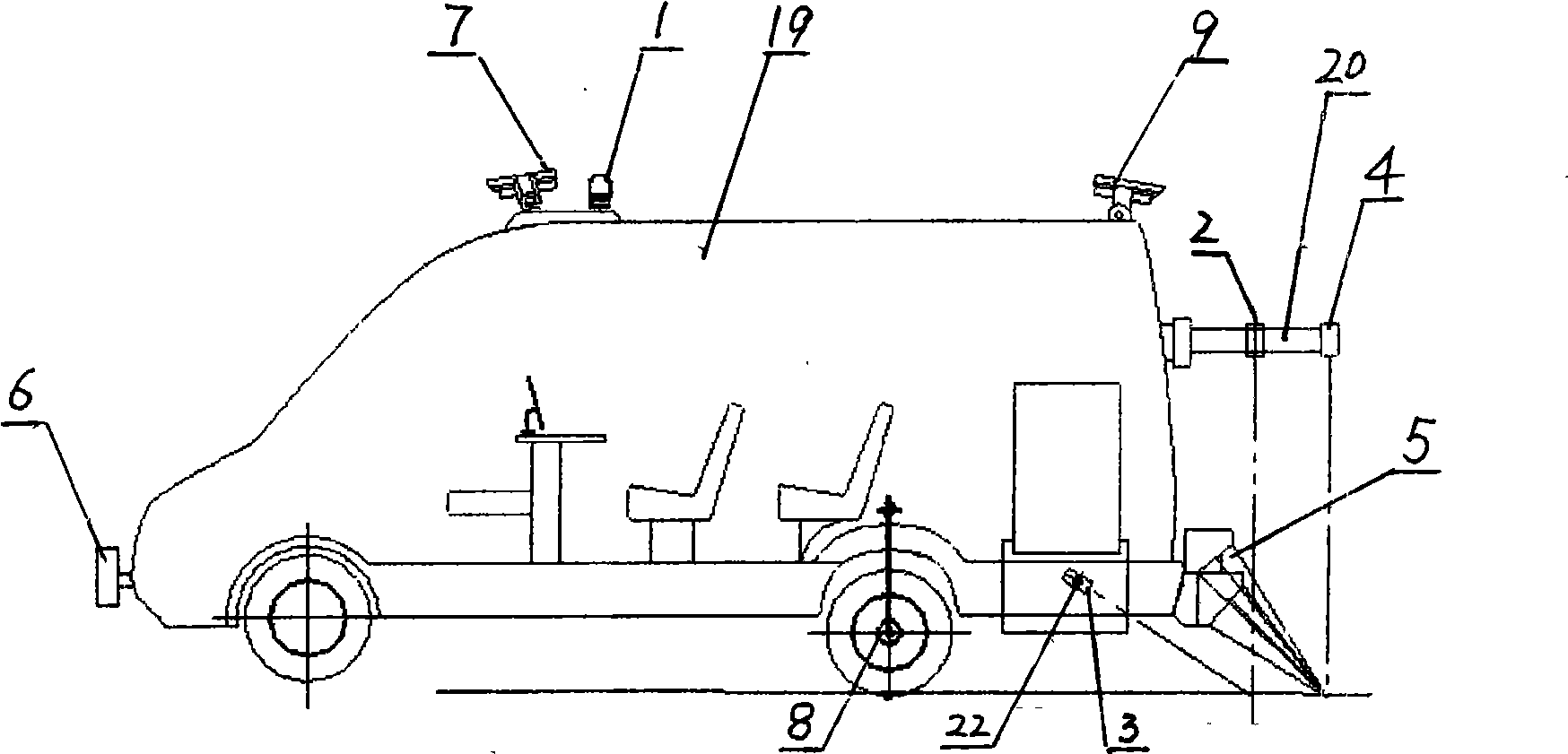

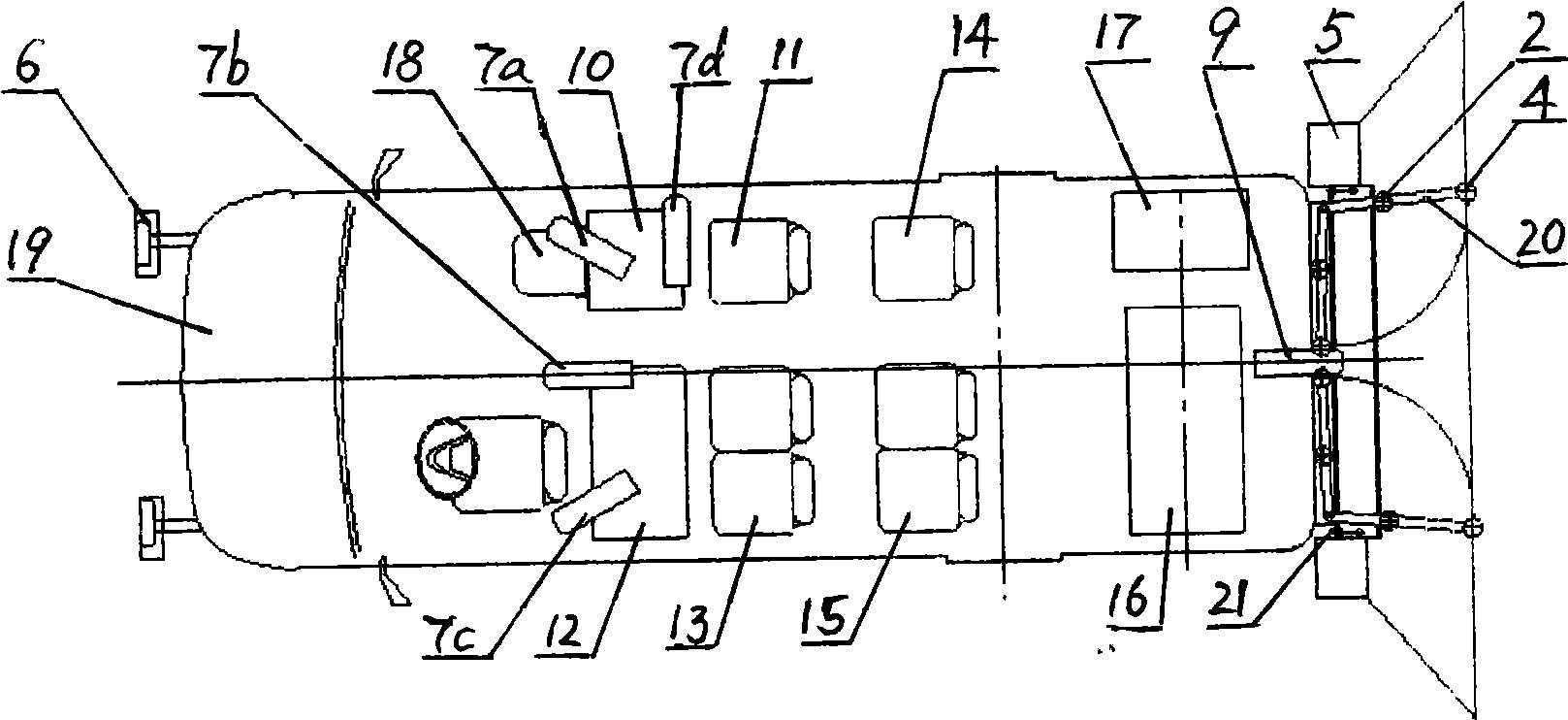

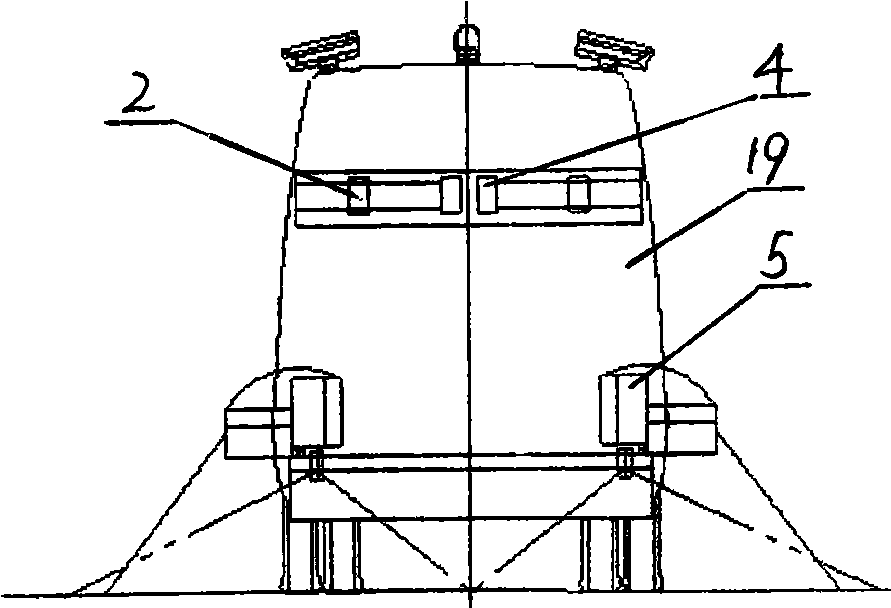

High-speed road conditions detection vehicle

InactiveCN101487224ACheck flatnessMeet the requirements of different brightness lightingRoads maintainenceLinear arrayControl circuit

The invention relates to a highway road condition detection vehicle which can be used for detecting and evaluating a plurality of road quality indexes, comprising a vehicle body with an operation chamber. The front end of the vehicle body is provided with a laser probe which can detect the evenness and the structural depth and can emit collimation laser beams downwards; the upper part of the rear end of the vehicle body is provided with a road surface wheel track detecting and photographing camera and a road surface damage linear array camera; the rear lower part of the vehicle body is provided with a high power linear laser with a linear laser source direction adjusting rotating shaft; the lower part of the rear end of the vehicle body is provided with a linear array camera LED light-focusing illumination device; and the top part of the vehicle body is respectively provided with a road environment camera, a safety monitoring camera and a GPS positioning antenna. The operation chamber of the vehicle body is internally provided with a workbench, a generator, an industrial computer cabinet and a control circuit device. Compared with the prior art, the highway road condition detection vehicle has the advantages of novel structure, full function, convenient operation and high detection precision, and can achieve the comprehensive detection of a plurality of road quality indexes, and the like.

Owner:CHANGAN UNIV

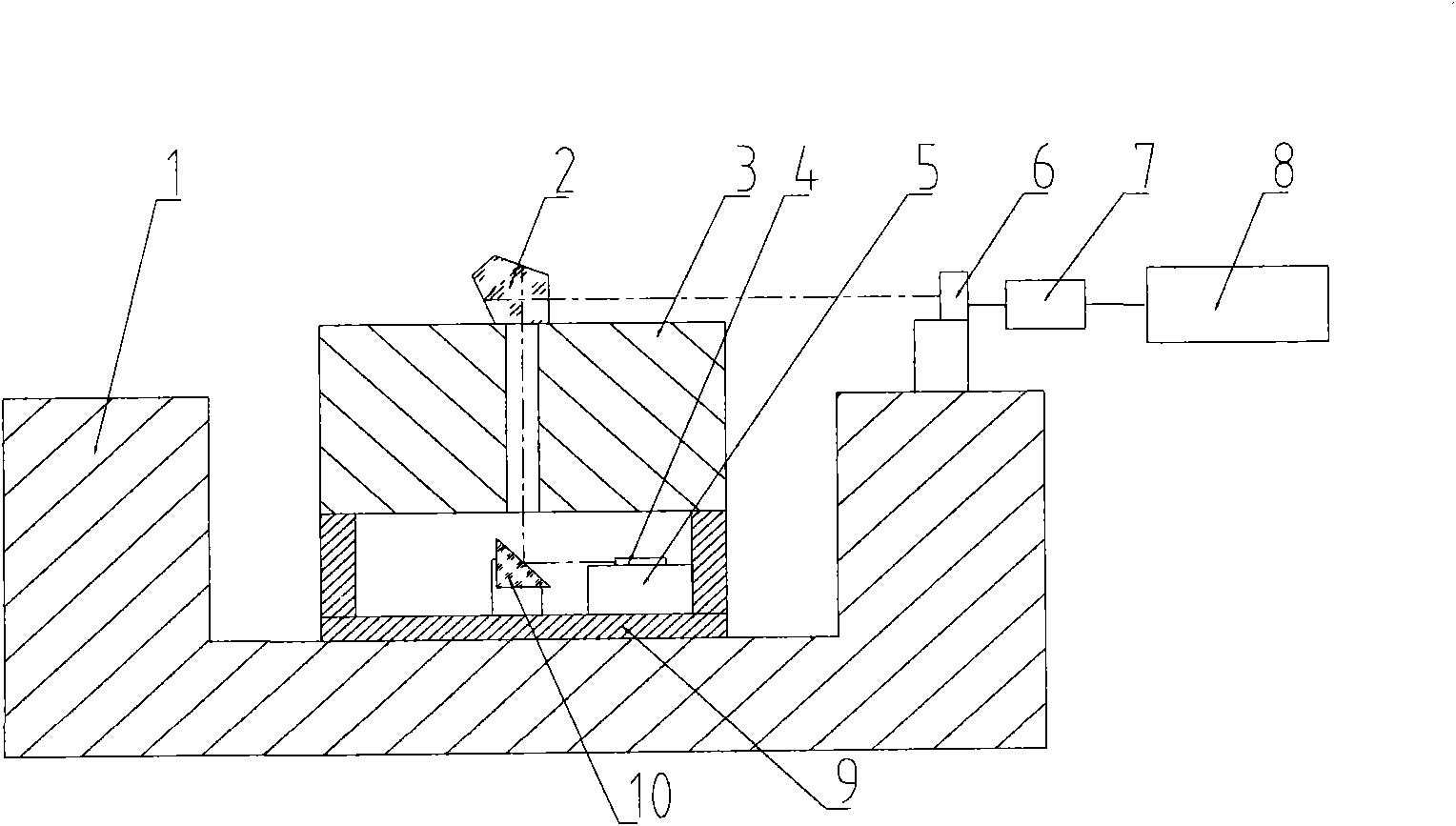

Laser planeness detector

InactiveCN102109331AGuaranteed measurement accuracySolve the detection speed is slowUsing optical meansLight beamHeight difference

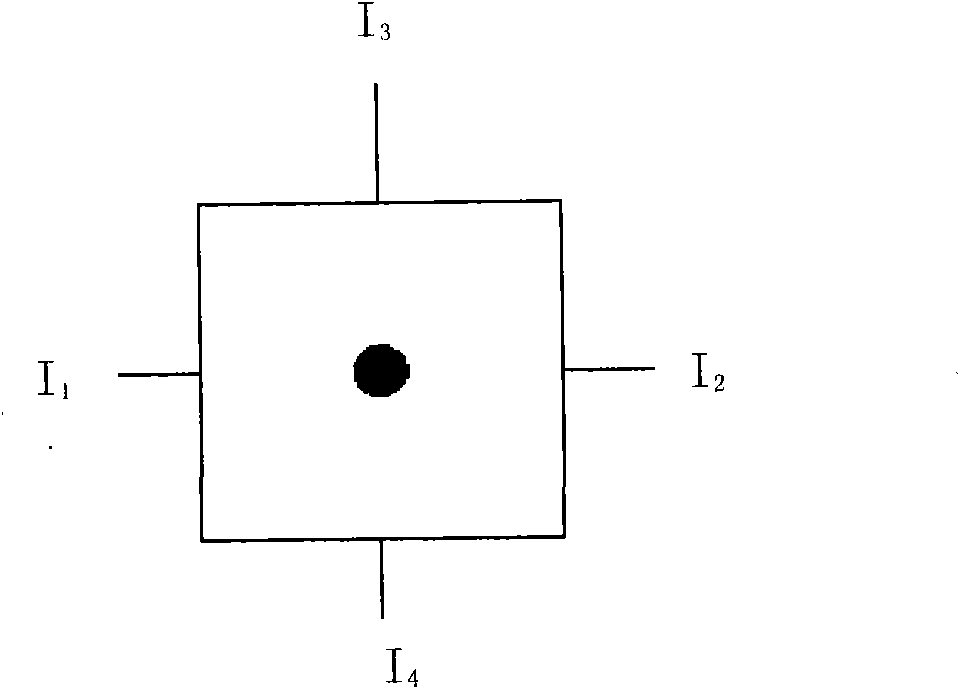

The invention relates to a laser planeness detector, consisting of a pentaprism, a rotary platform, a laser, a four-dimensional working platform, a PSD (Position Sensitive Detector) position sensor, a computer data acquisition unit, a data processing unit, a base and a planar reflecting mirror, wherein light emitted by the laser is ejected horizontally after passing through the center of the rotary platform and being reflected by the pentaprism. The pentaprism rotates along with the rotary platform, and laser which is ejected horizontally by the pentaprism also rotates along the rotary platform; and the horizontal laser beams rotate to form a reference plane. The PSD position sensor is placed on the measured plane, so that the height difference between a measured point and the reference plane formed by the laser beams can be measured, the planeness error of a detected plane can be obtained after data processing.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

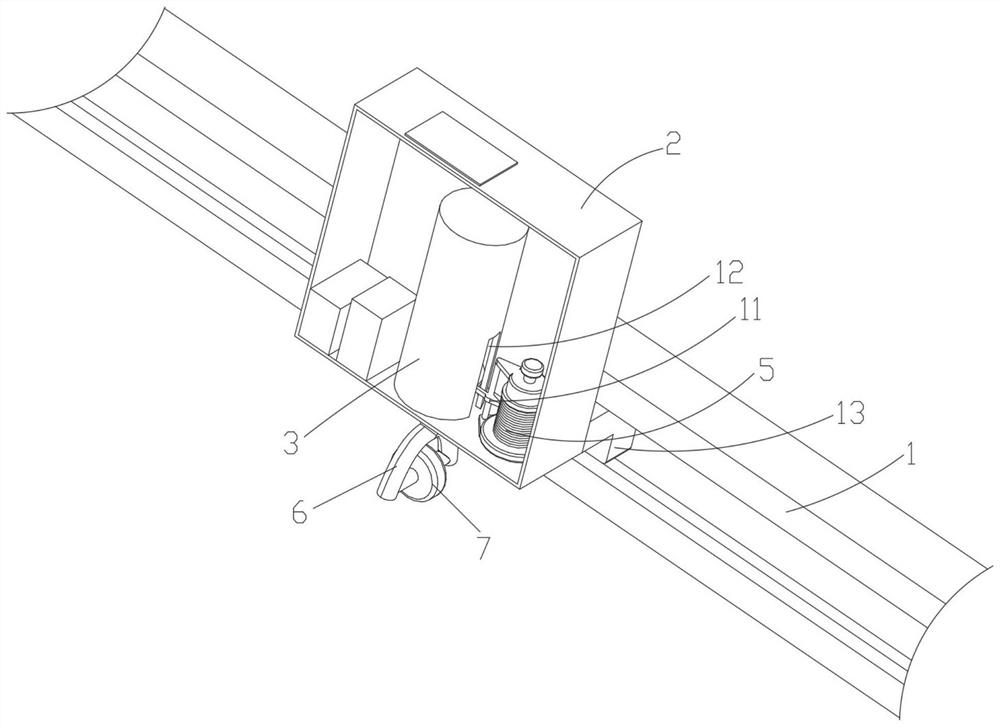

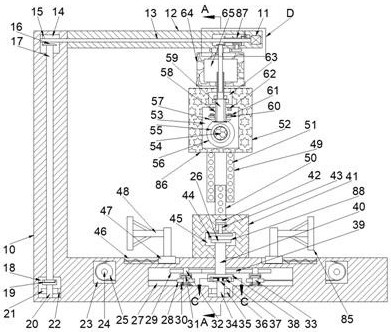

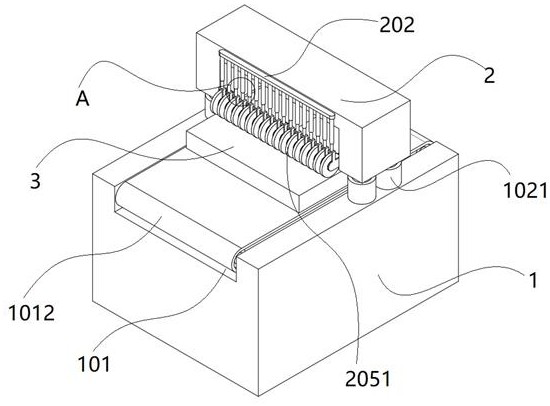

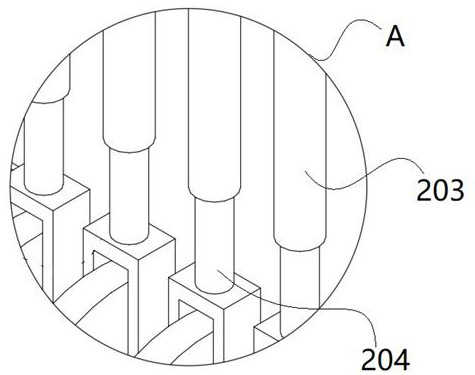

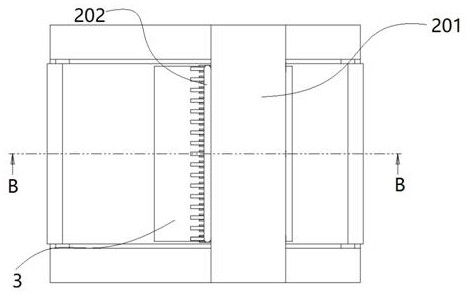

An automatic travellingtrack detector based on machine vision

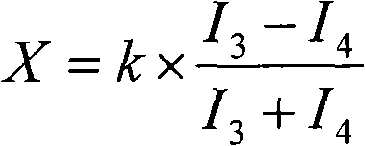

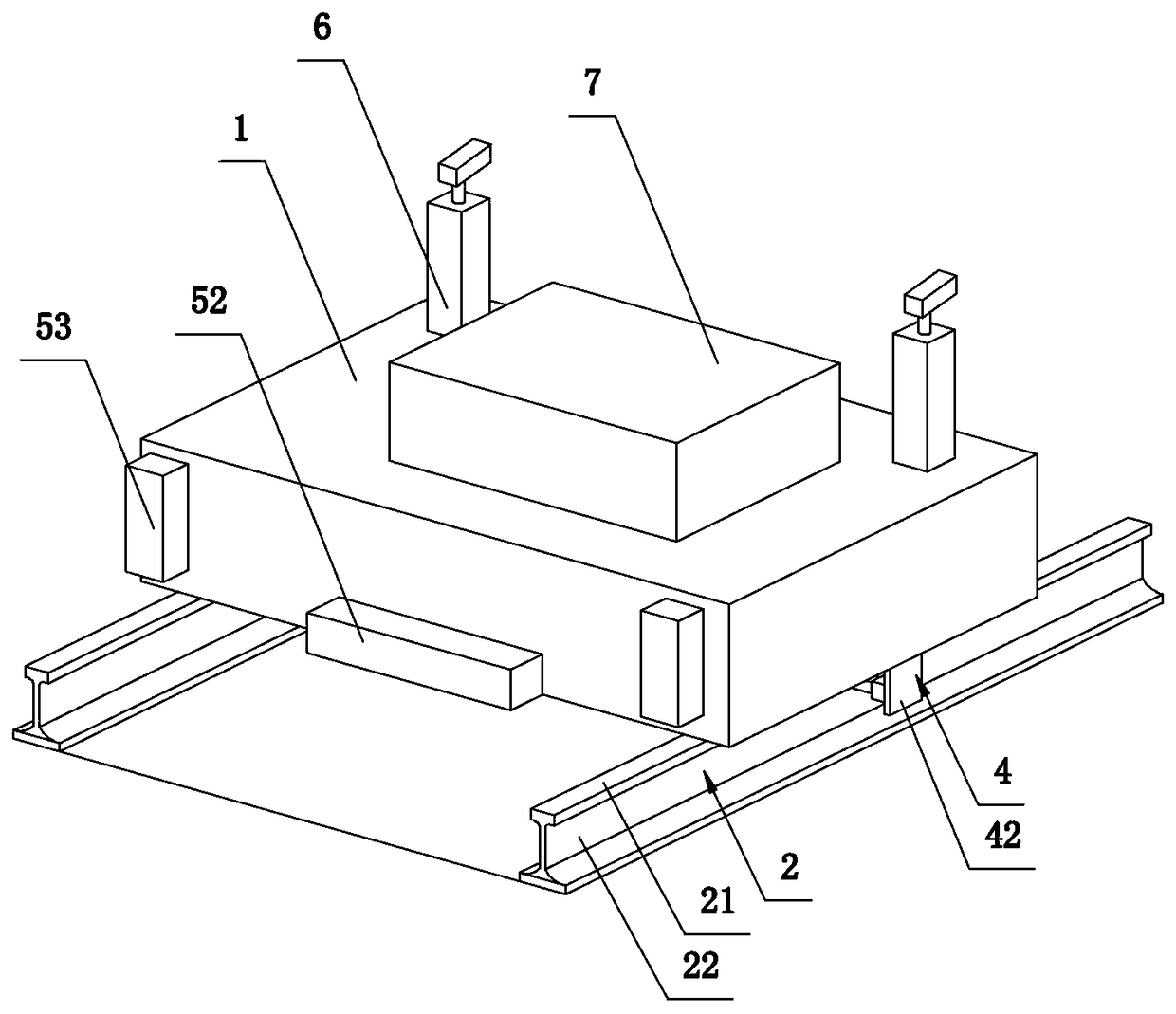

PendingCN108974045ASimple structurePracticalRailway inspection trolleysRailway auxillary equipmentCcd cameraTrack detectors

An automatic travelling track detector based on machine vision comprises a vehicle body, a traveling wheel contacting with the top surface of a rail is arranged on the lower side of the vehicle body,a driving motor is connected to the traveling wheel, and a guiding detection device is arranged on the lower side of the vehicle body. The car body is also provided with an ultrasonic probe wheel contacting with the rail top surface, a laser ranging sensor for detecting the rail height and the rail spacing, and a roughness meter for detecting the rail top surface roughness. The upper side of the vehicle body is provided with an industrial CCD camera for collecting image information of the rail and the surrounding environment of the rail; A control terminal is also installed on the vehicle body, and the control terminal can transmit the data collected by the pressure sensor, ultrasonic probe wheel, laser ranging sensor, roughness meter and industrial CCD camera to the remote server throughthe wireless communication module in the control terminal. By means of the guide detecting device, not only a guide function can be provided for the vehicle body, but also the smoothness of both sidesof the rail can be detected.

Owner:FUJIAN TIEGONG INTELLIGENT ROBOT CO LTD

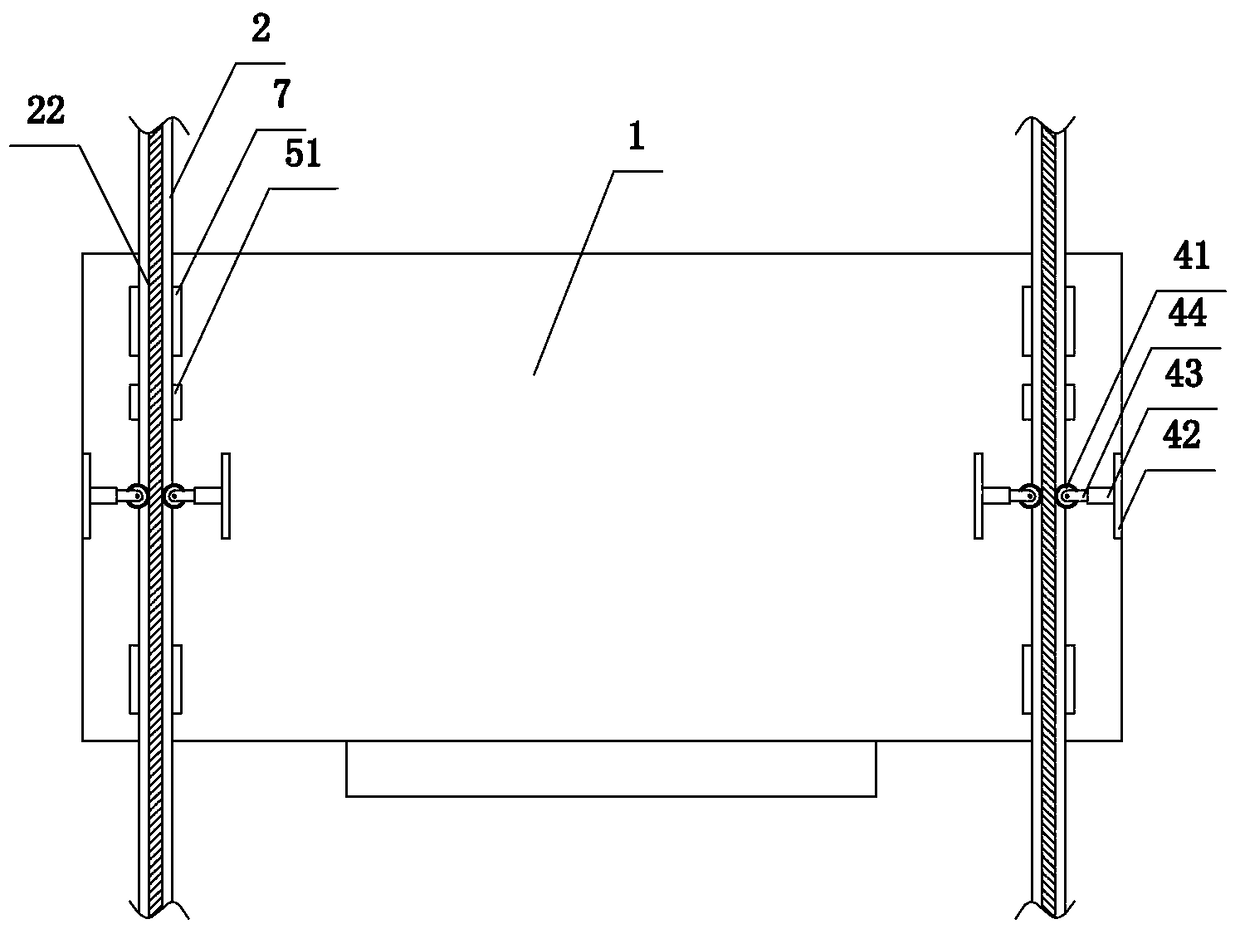

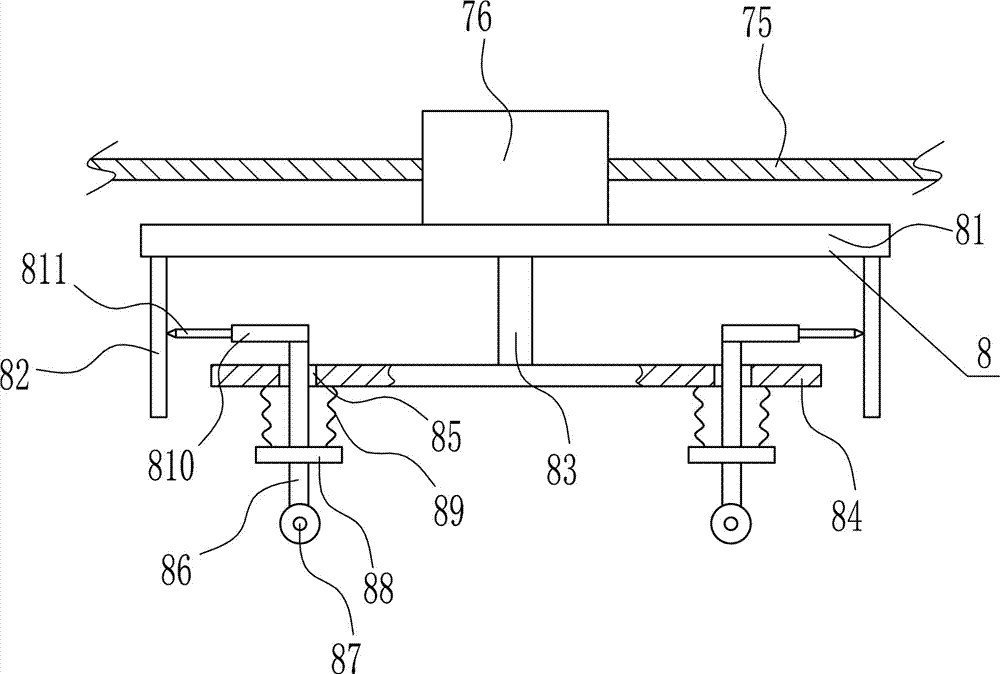

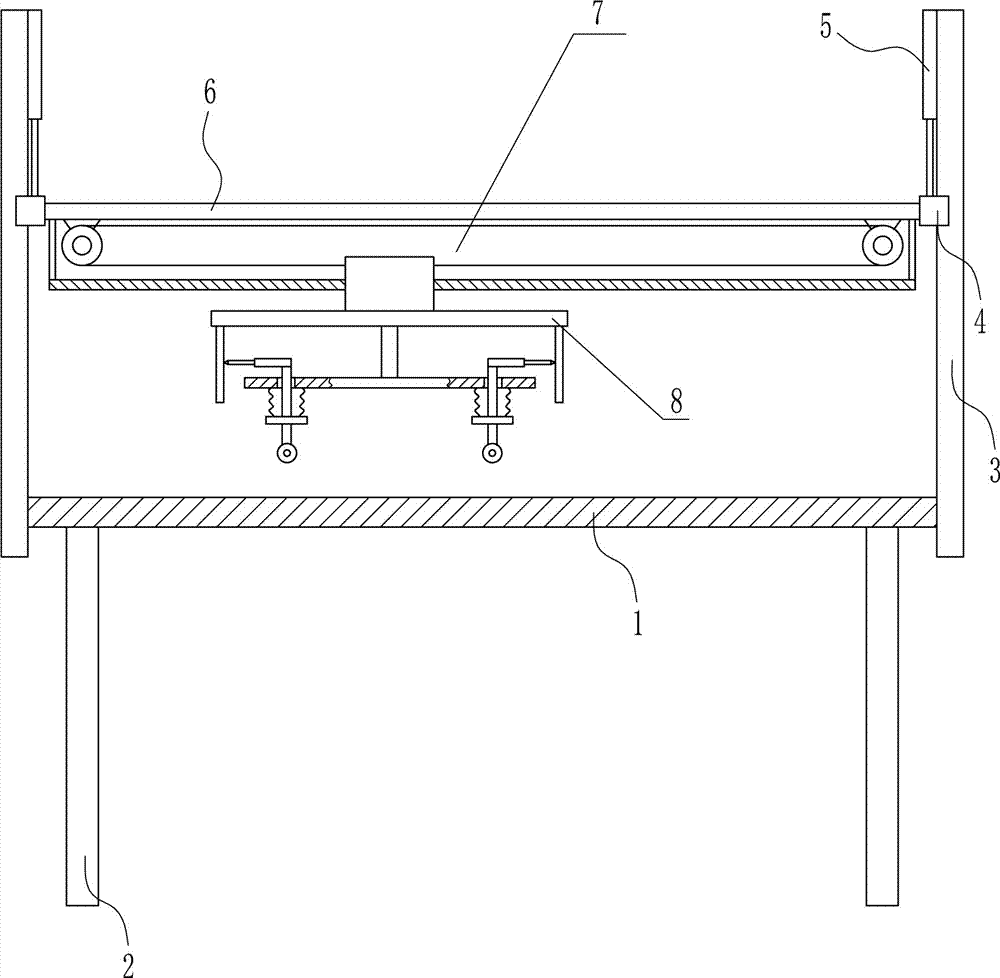

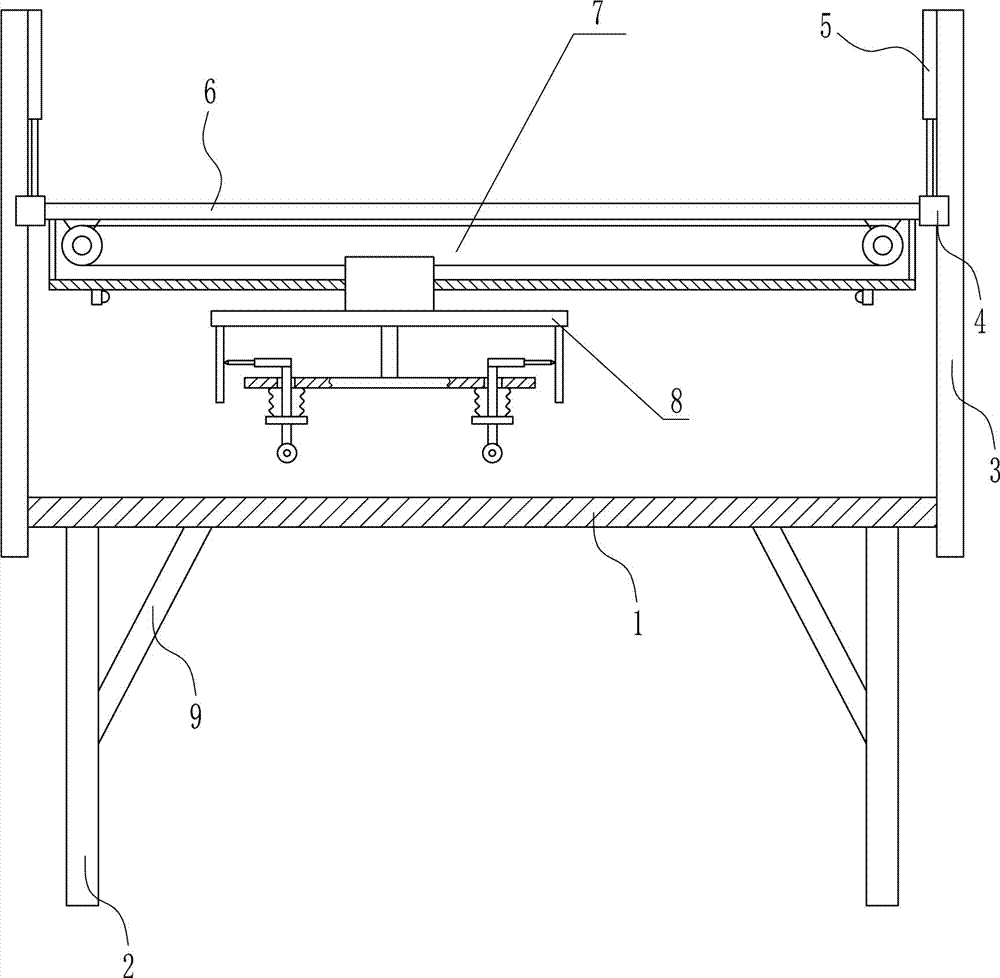

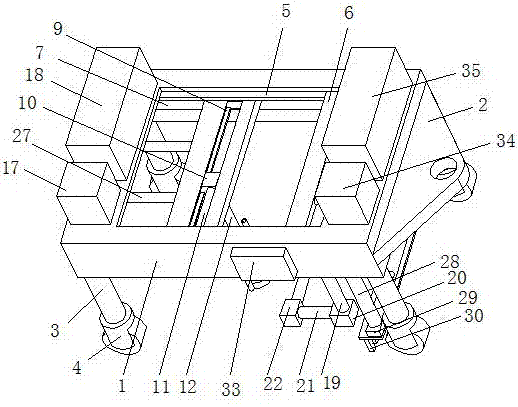

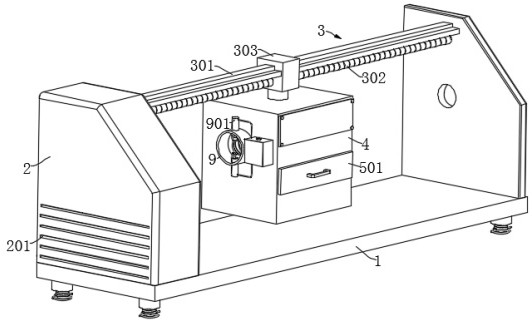

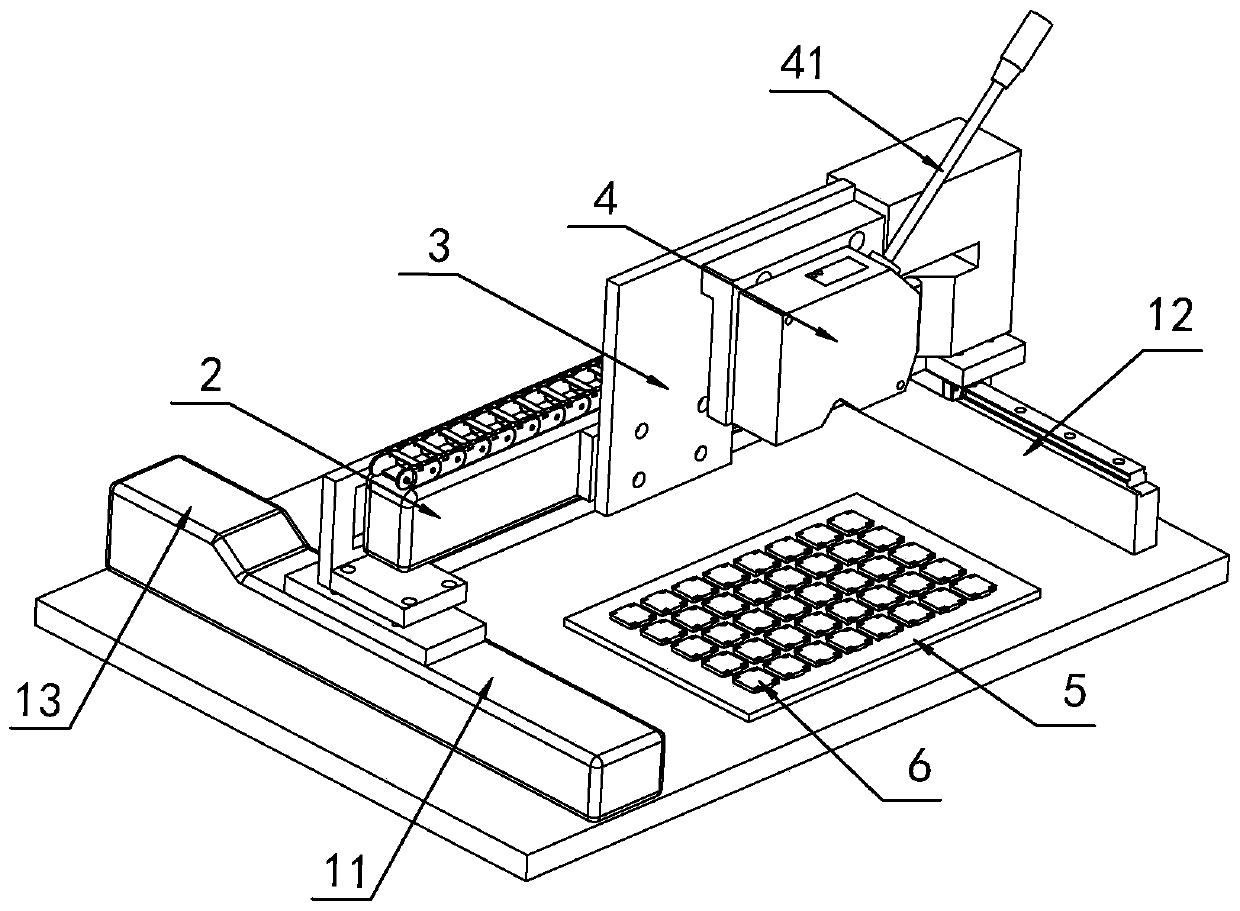

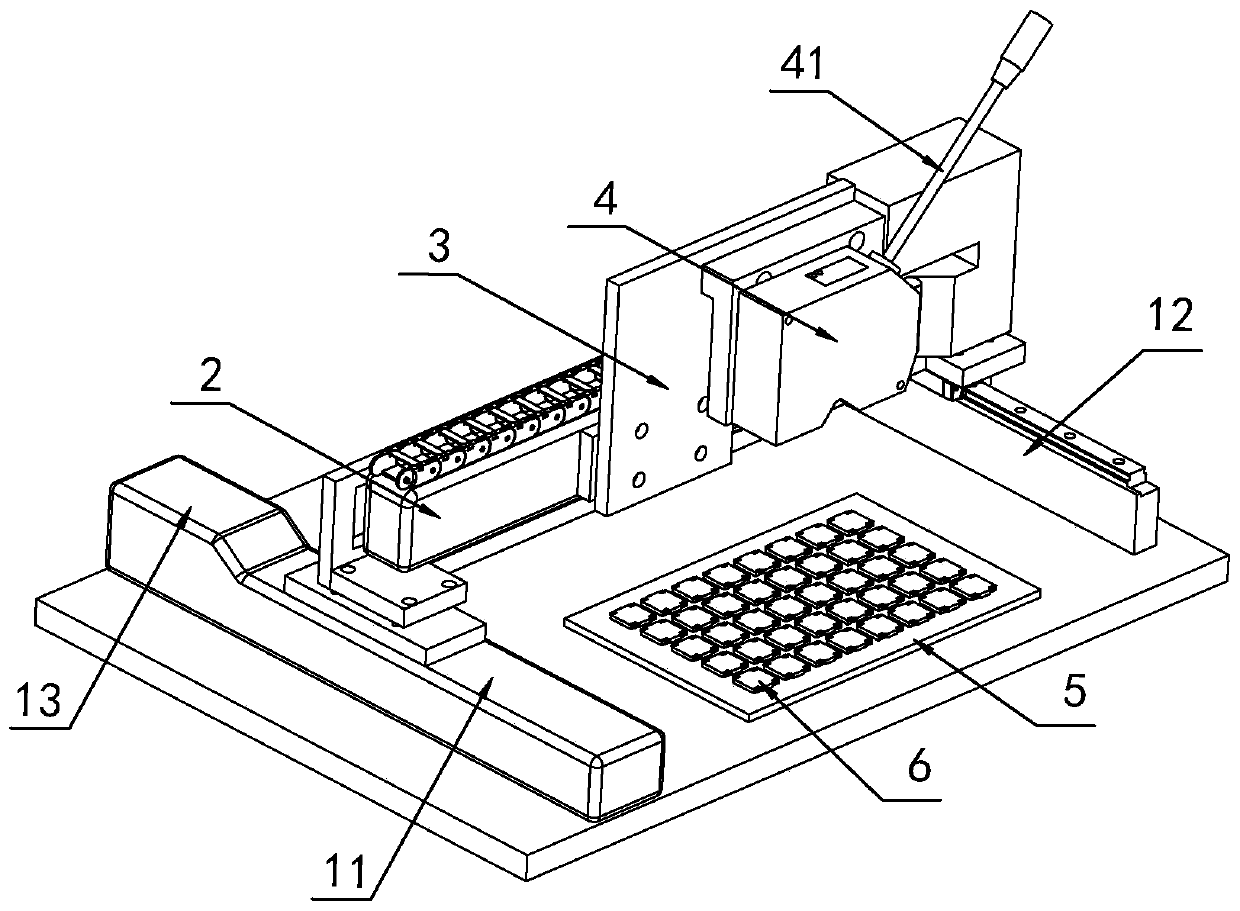

Master box flatness high efficiency detection equipment for computer technology development

ActiveCN106959069AKnow flatnessCheck flatnessMechanical roughness/irregularity measurementsTransverse planeComputers technology

The invention relates to master box flatness detection equipment for computer technology development, and specifically relates to the master box flatness high efficiency detection equipment; the detection equipment is time saving and labor saving and high in efficiency, and can comprehensively detect the master box flatness; the master box flatness high efficiency detection equipment for computer technology development comprises a top plate, a support plate, slide rails, a slide block, a first cylinder, and a first transverse plate; the support plate is arranged on the bottom of the top plate; the left and right side faces of the top plate are provided with the slide rail through a bolt connection mode, and the slide rails are vertically arranged. The detection device can move left and right and the master box can be moved front and back, thus comprehensively detecting the flatness of the master box, saving time and laboring, and realizing high efficiency effects.

Owner:大连天合物联科技有限公司

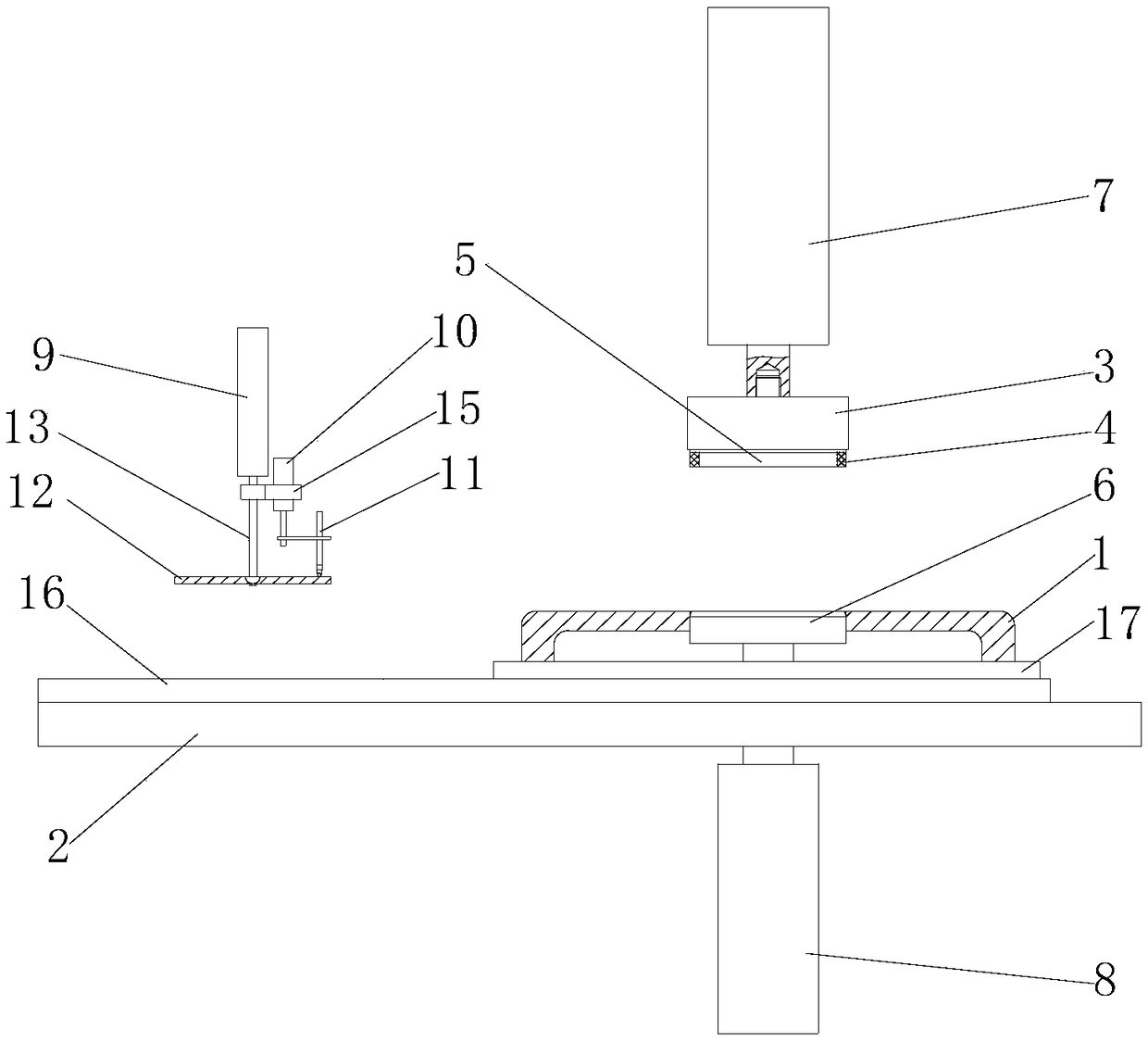

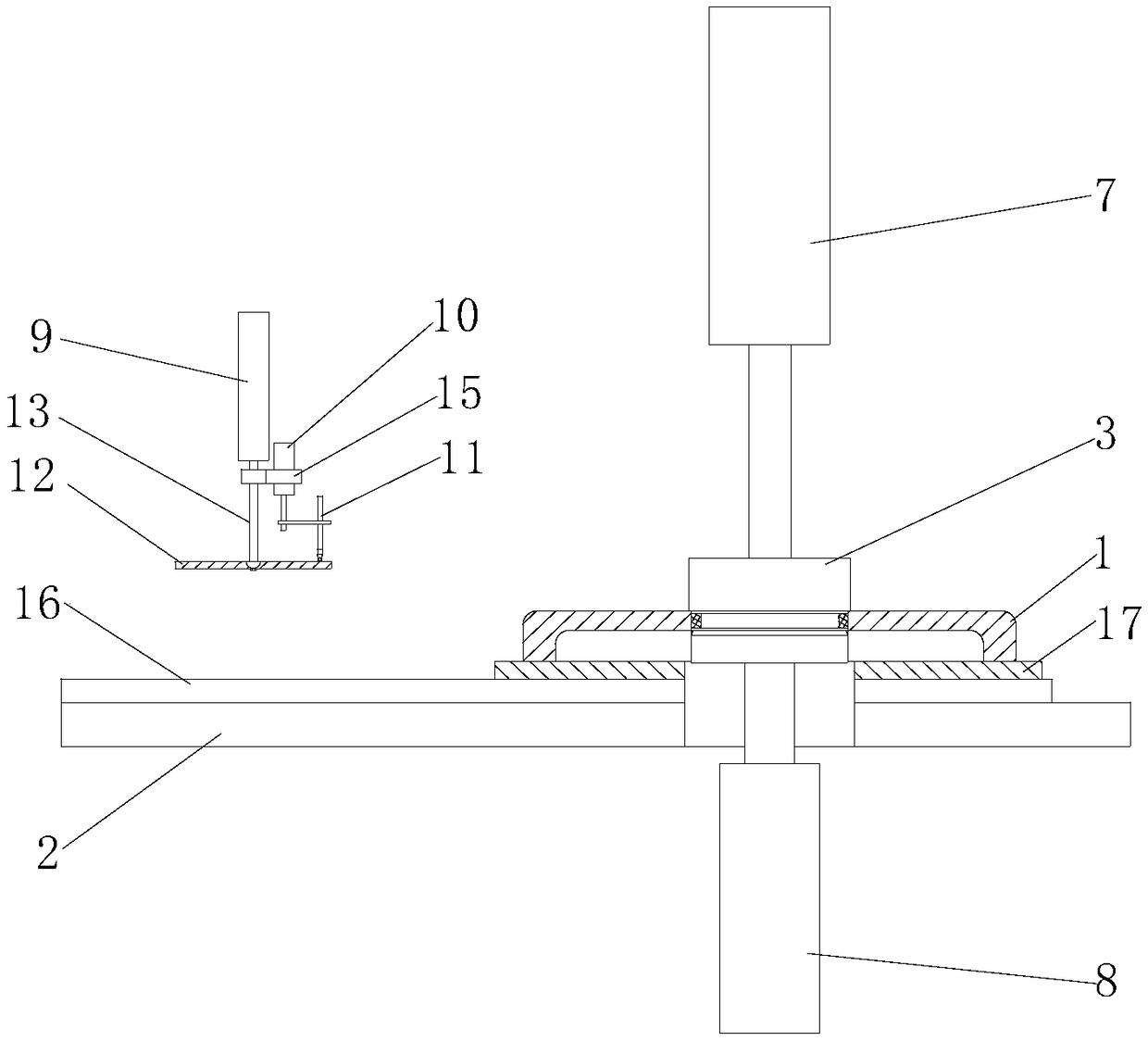

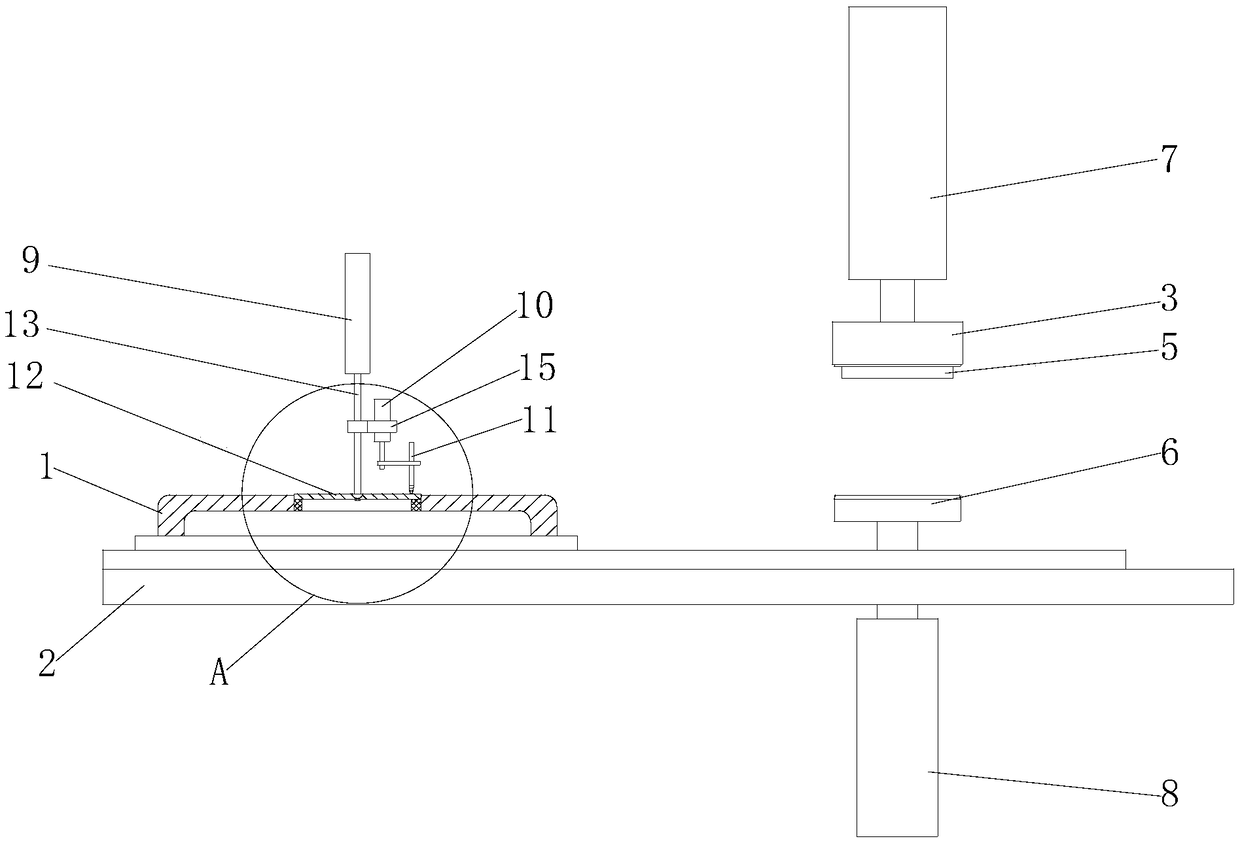

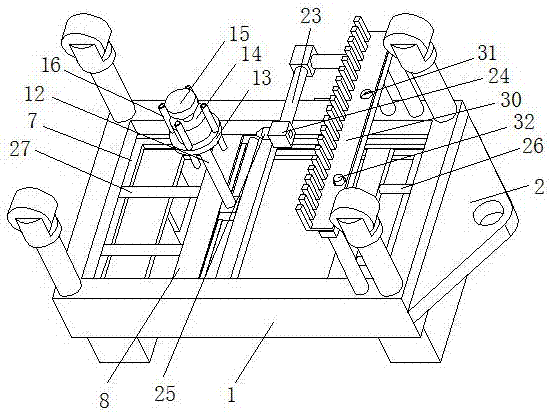

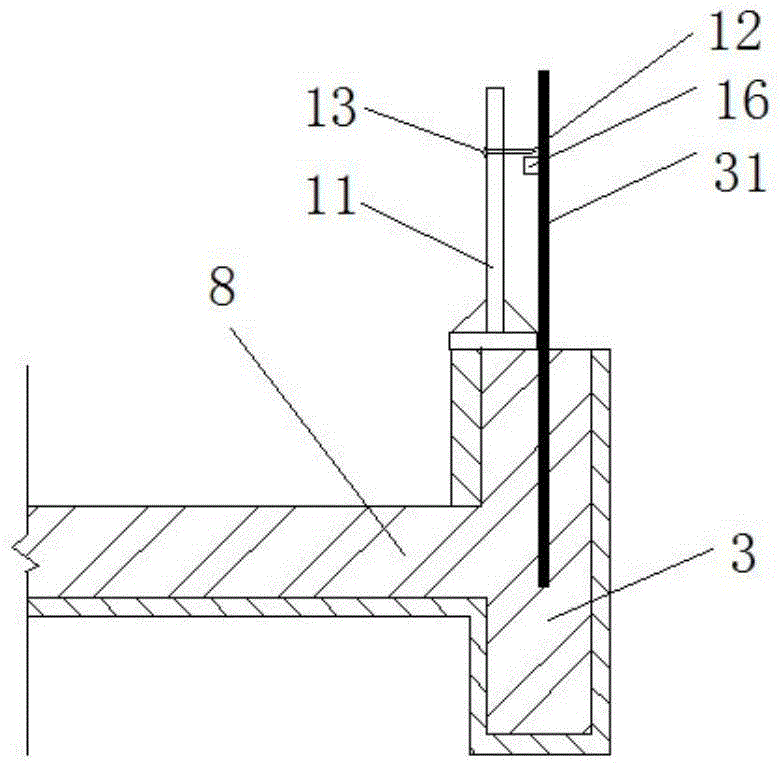

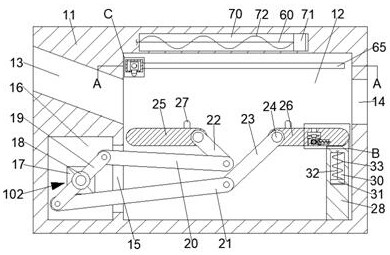

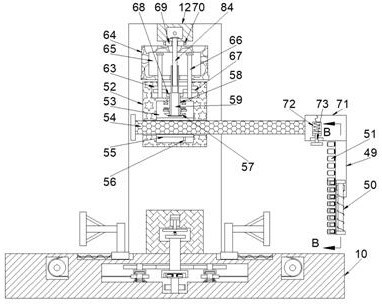

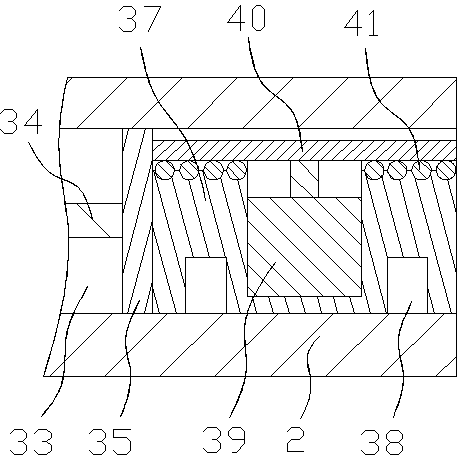

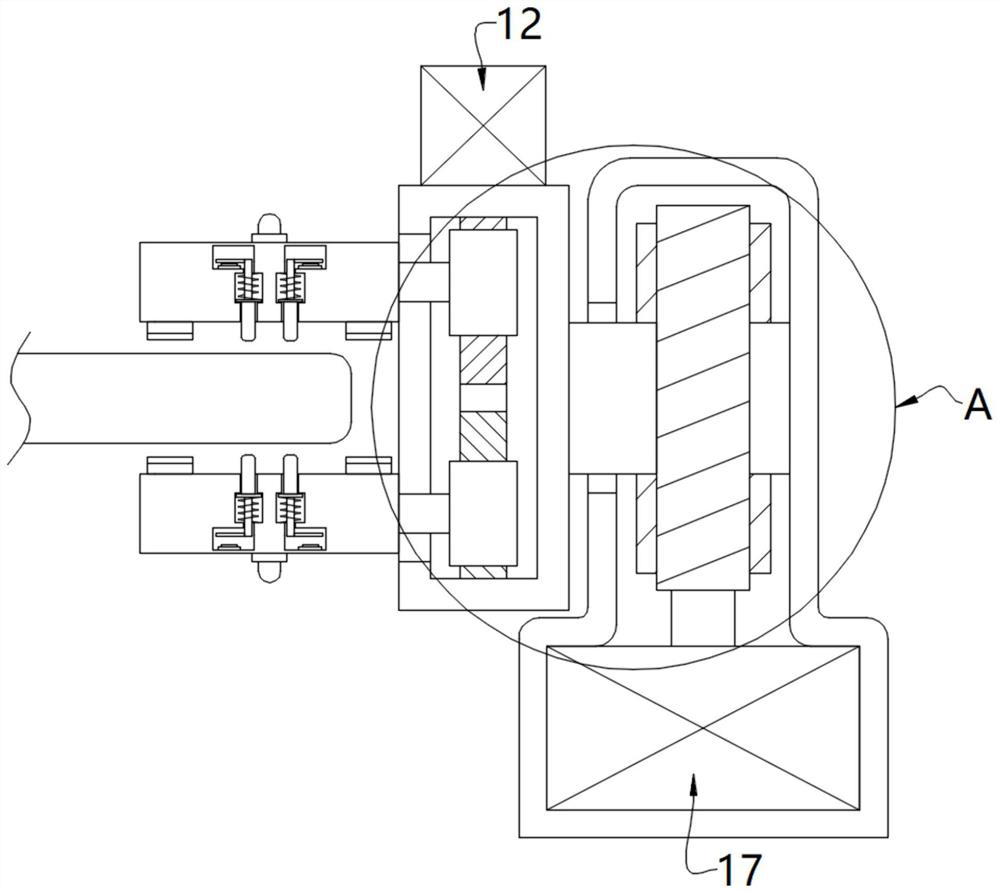

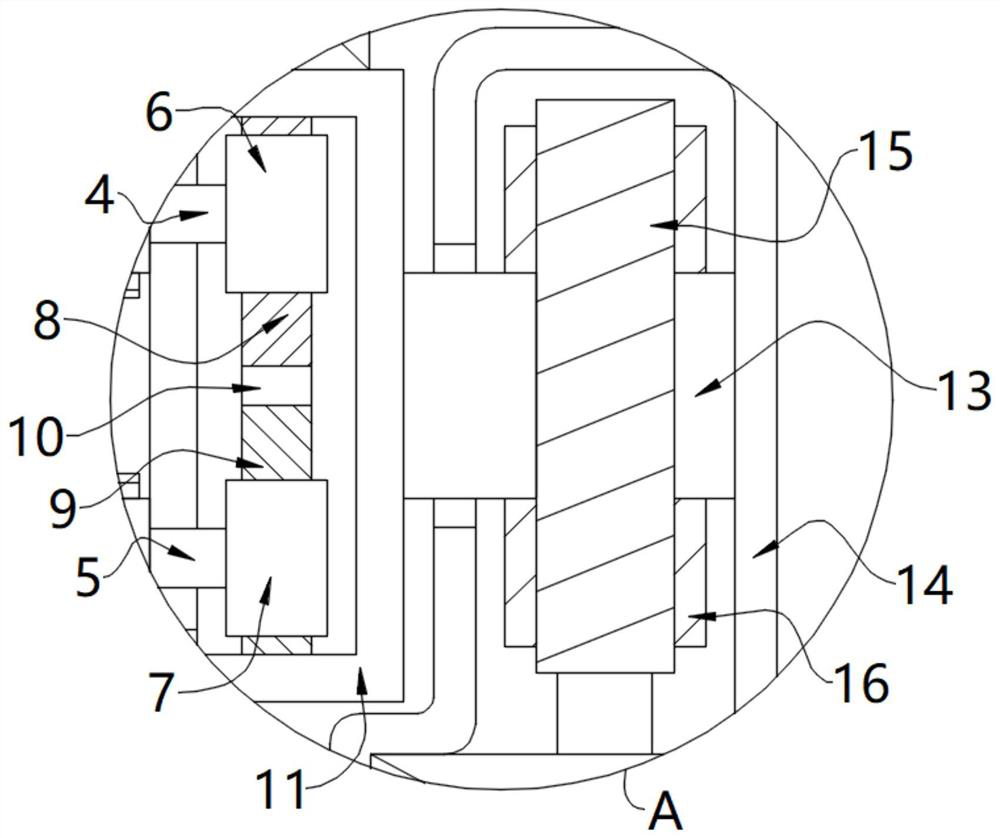

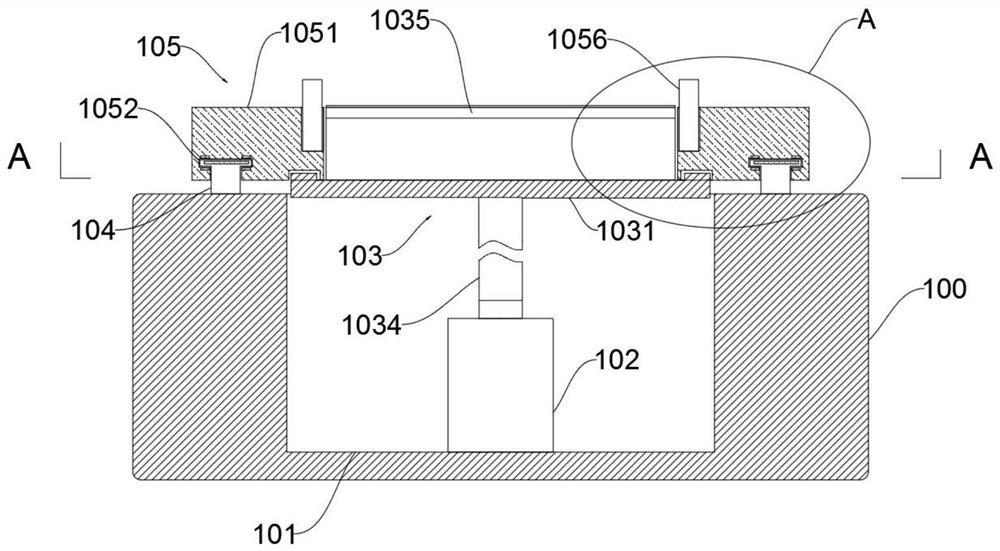

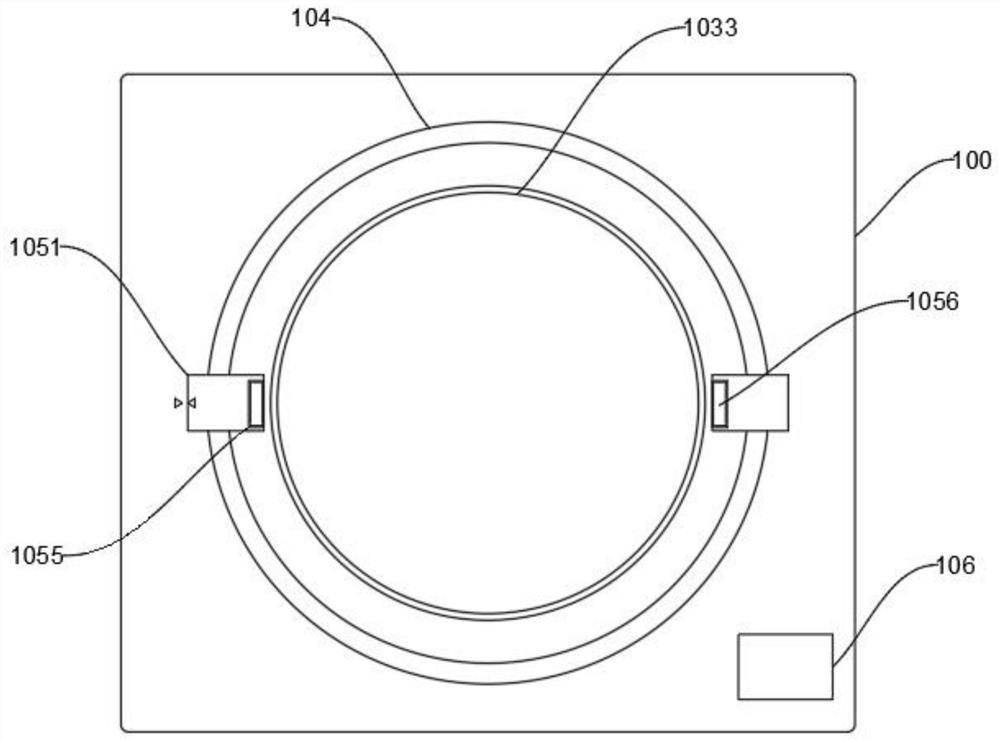

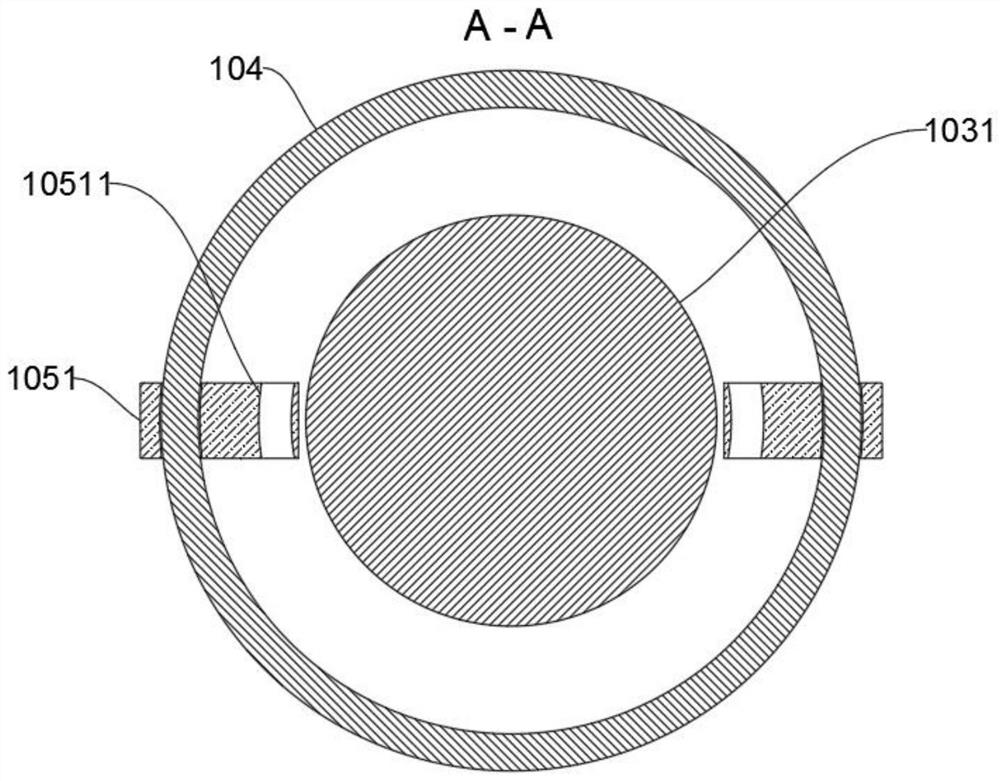

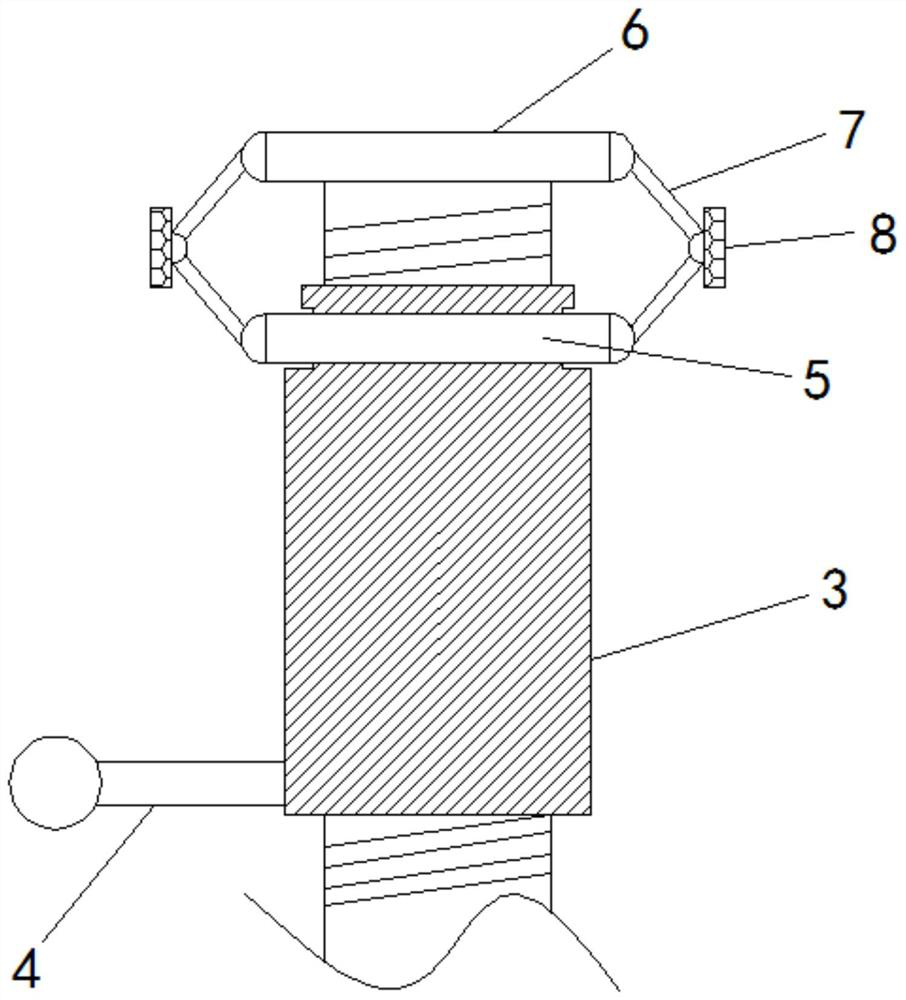

Oil seal press-fitting device

PendingCN108655702ACheck flatnessEffective detection of flatnessMetal working apparatusEngineeringMechanical engineering

The invention discloses an oil seal press-fitting device. The oil seal press-fitting device comprises a workbench used for allowing a workpiece to be contained, an oil seal pressing head capable of moving up and down is arranged above the workbench, an inserting connection port is arranged on the oil seal pressing head and is used for allowing an oil seal to be installed, a positioning block capable of moving up and down is arranged below the workbench, and the axis line of the oil seal pressing head, the axis line of the positioning block and the axis line of an oil seal hole of the workpiececoincide; the oil seal press-fitting device further comprises a plane detection mechanism and a conveying mechanism, wherein the plane detection mechanism is located above the workbench and is used for detecting the flatness of the oil seal, and the conveying mechanism is used for conveying the workpiece to the position below the plane detection mechanism. According to the oil seal press-fittingdevice, the press-fitting force and the stroke of the oil seal can be monitored in real time, moreover, the flatness of the oil seal after press-fitting can be detected, the press fitting quality of the oil seal is ensured, and the faults of oil seal oil leakage and oil seal loosening are avoided, and the situation of a large amount of cost caused by reworking of an engine is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

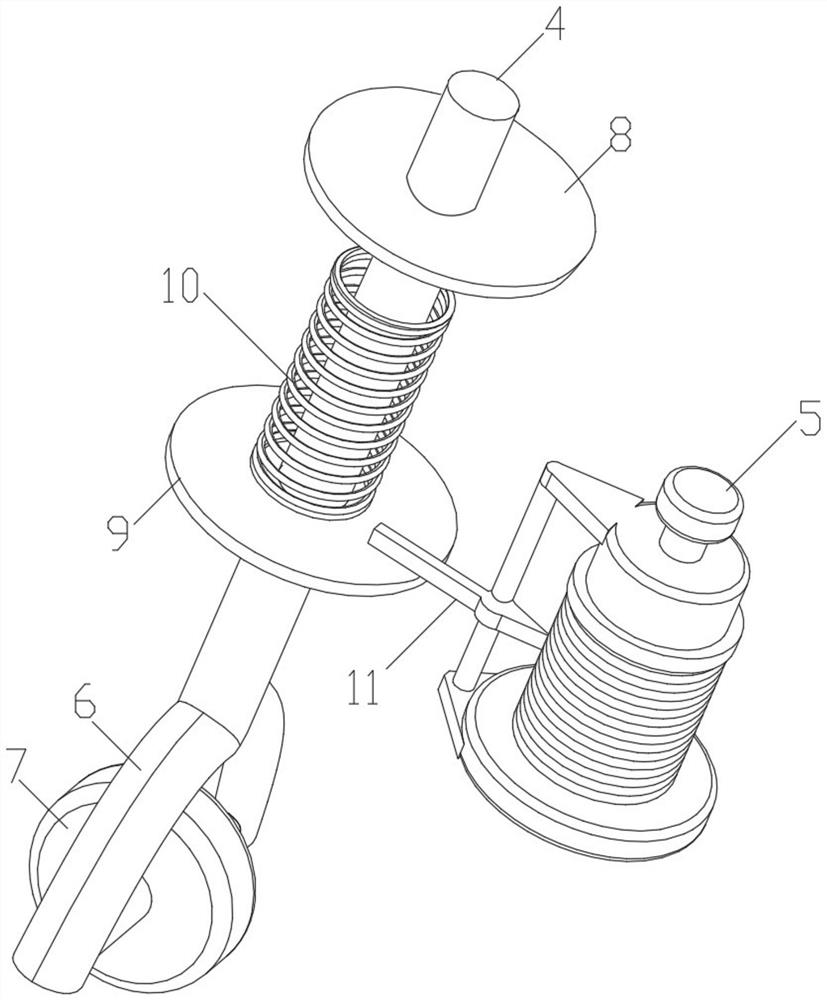

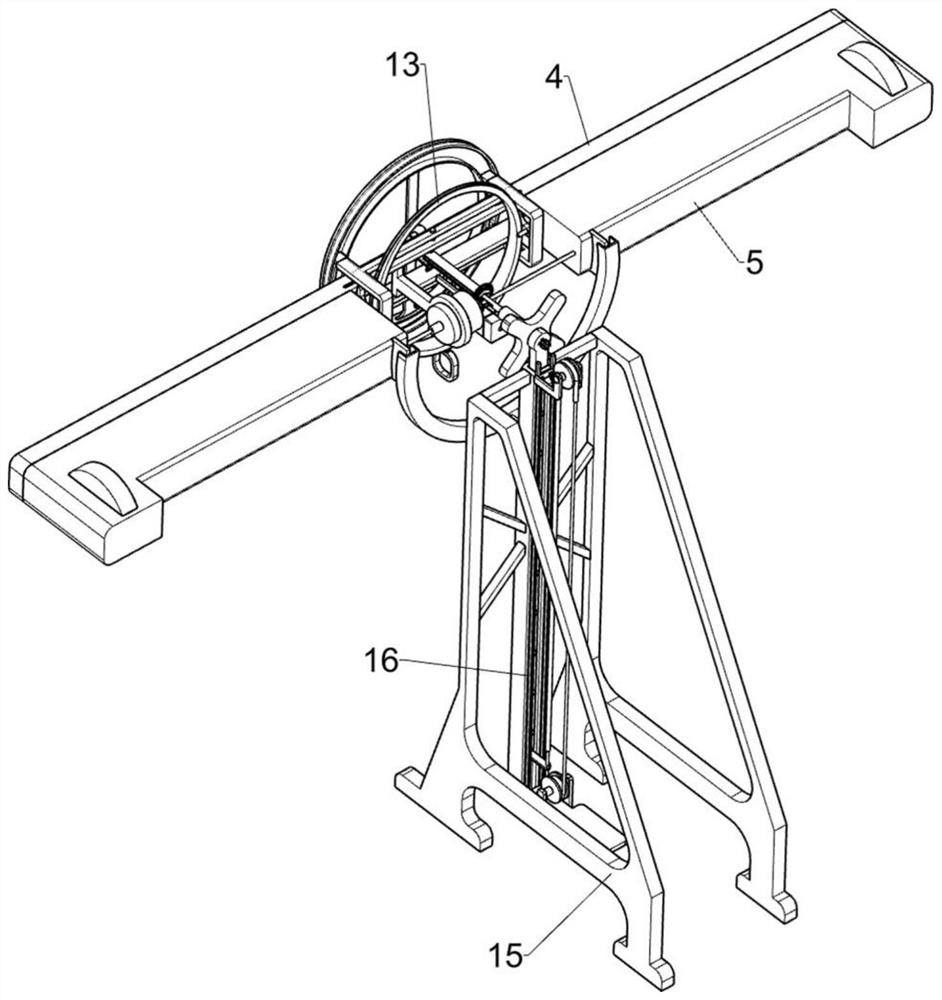

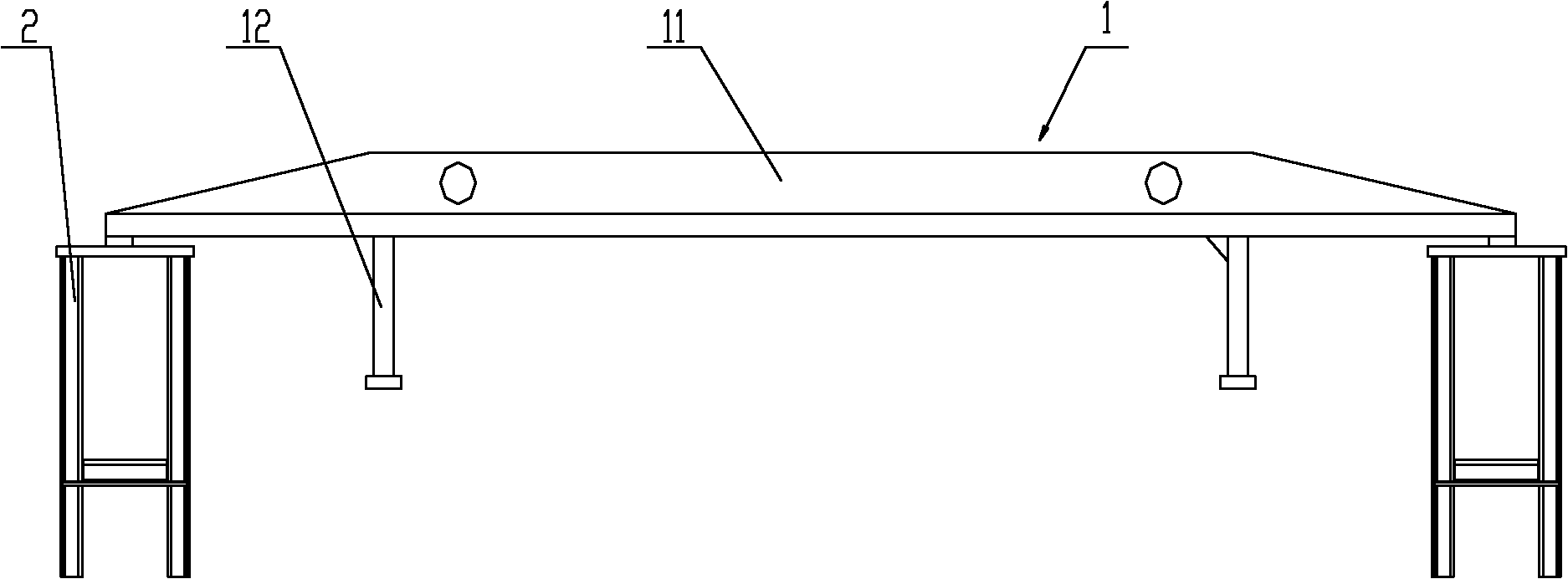

Pavement flatness detection device for road and bridge construction

InactiveCN112458849ACheck flatnessFlatness judgmentBridge structural detailsRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a pavement flatness detection device for road and bridge construction, and relates to the field of road and bridge construction. The pavement flatness detection device for roadand bridge construction comprises a to-be-detected ground and a support plate, supporting strip blocks are fixedly connected to the two sides of the bottom of the support plate, a supporting flat plate is fixedly connected to the bottoms of the supporting strip blocks, supporting columns are fixedly connected to the two sides of the bottom of the supporting flat plate, and a reinforcing mechanismcorresponding to the to-be-detected ground is arranged on the supporting flat plate. A rubber block is attached to the to-be-detected ground, a sliding plate is slidably connected to the upper surface of the support plate, a power mechanism corresponding to the support plate is arranged on the sliding plate, a hollow cylinder is fixedly connected to the top of the sliding plate, an inner cavity is formed in the hollow cylinder, a lifting block is slidably connected into the inner cavity of the hollow cylinder, and an abutting spring is arranged in the inner cavity of the hollow cylinder. Thepavement flatness detection device for road and bridge construction is convenient to use for detecting the flatness of the to-be-detected ground, is not easy to damage, and is low in use cost.

Owner:尚福涛

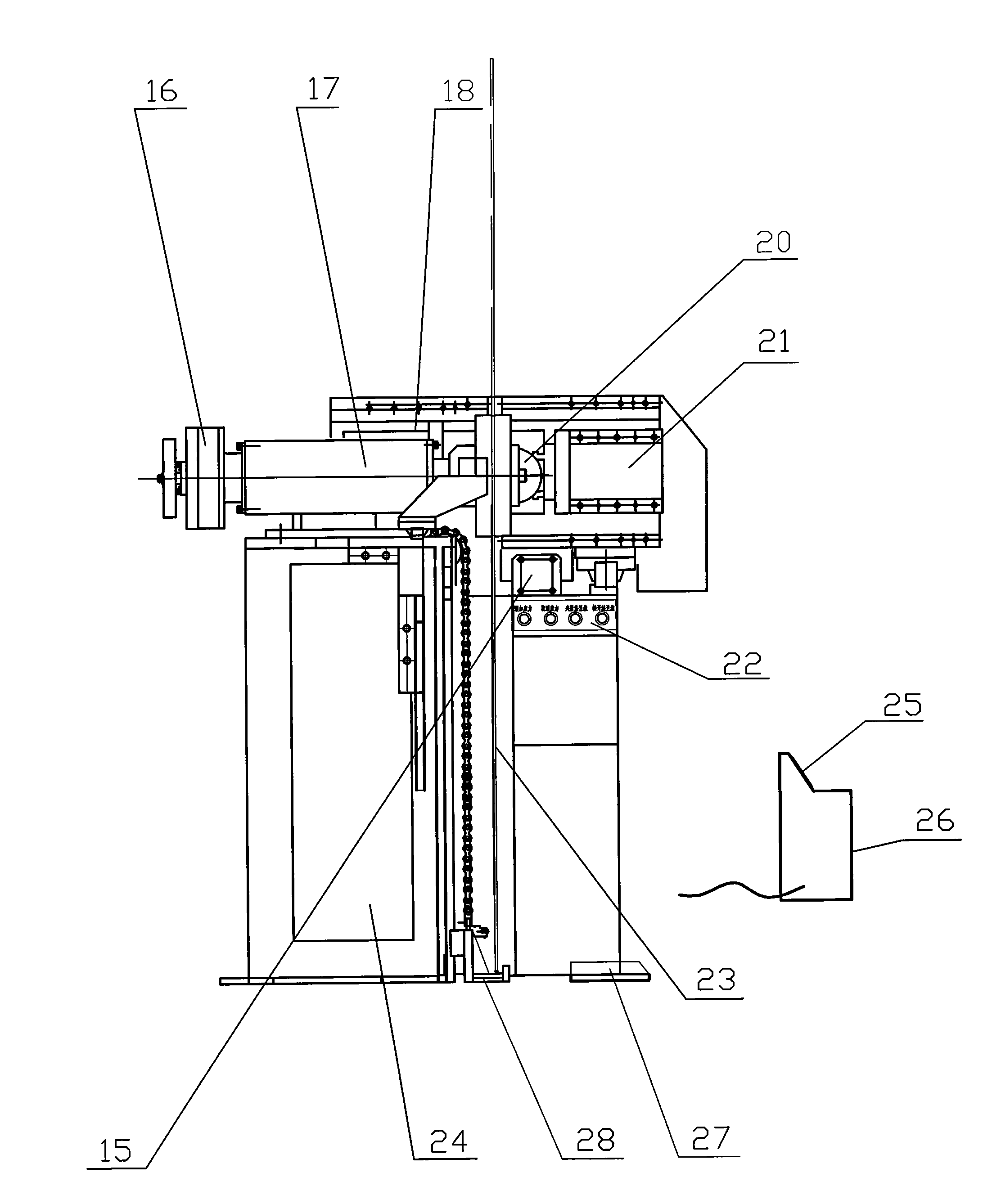

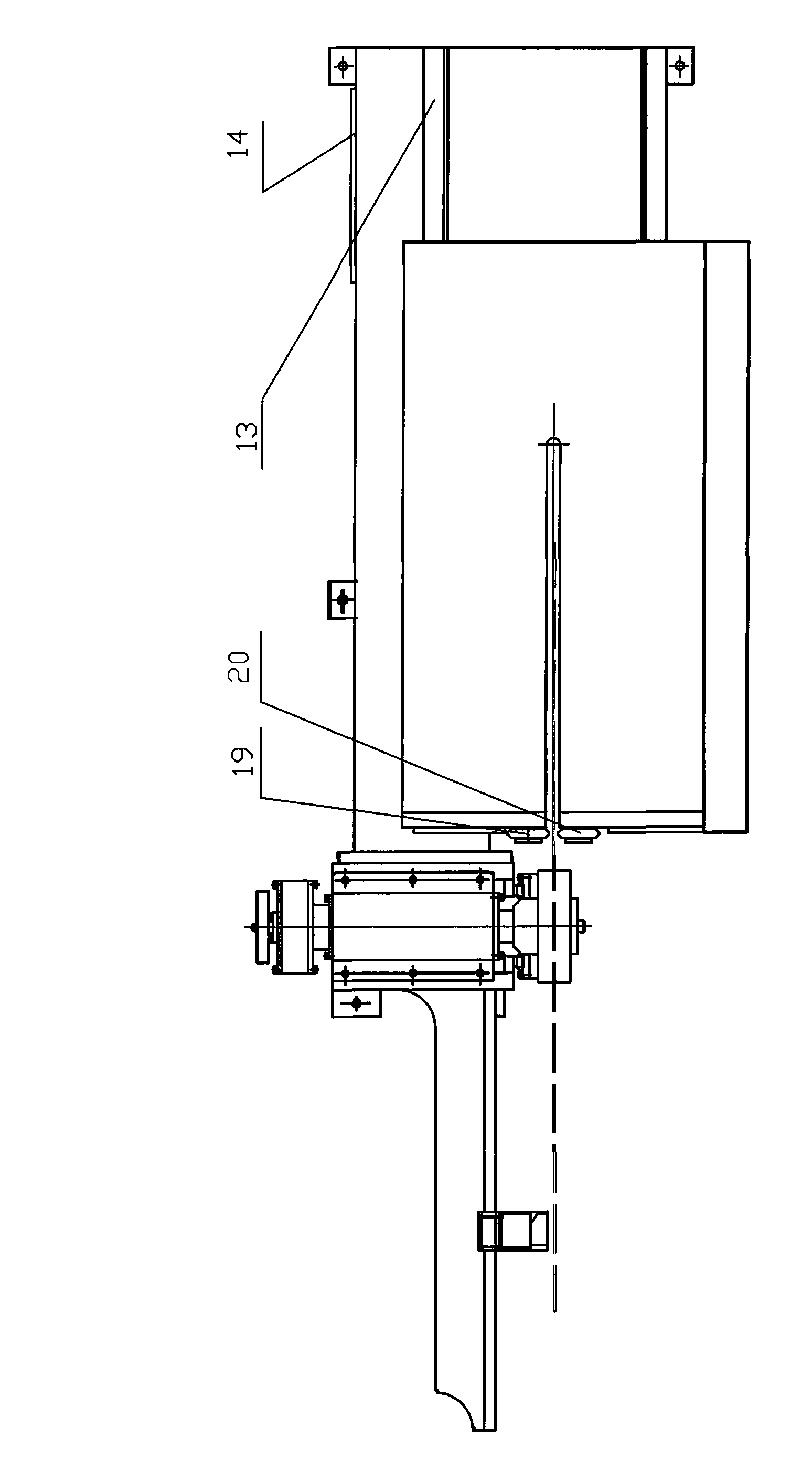

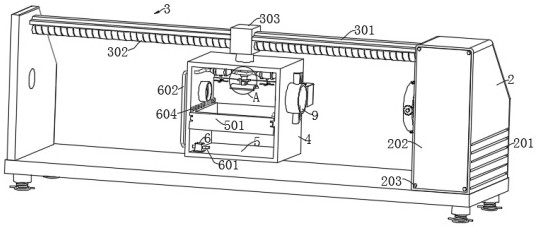

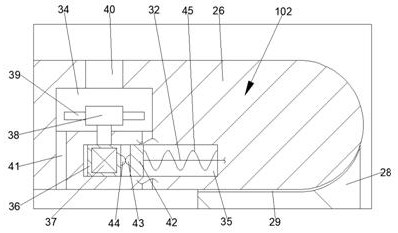

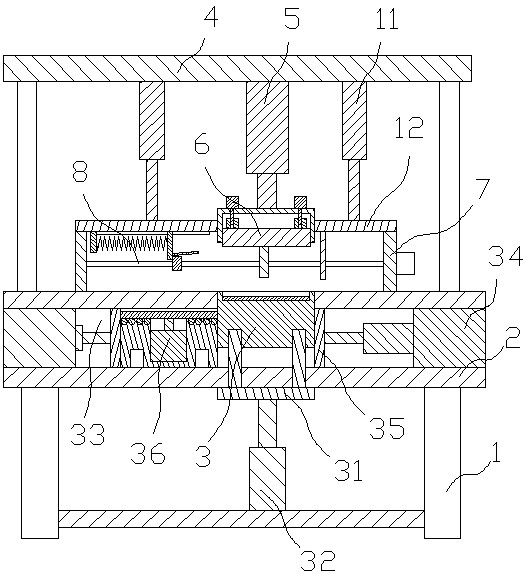

Vertical rolling-compaction tester

ActiveCN101637834ARealize vertical processingQuick clampingMetal sawing tool makingForce measurement by measuring optical property variationEngineeringLarge size

The invention discloses a vertical rolling-compaction tester, relating to saw blade processing machinery. Large-size saw blades can be vertically processed with the processing dimension reaching 2,500mm by arranging a clamping device in a way that the axis of the clamping device is perpendicular to the direction of motion of a rolling-compaction head and parallels to the horizontal plane. As the impact head of the vertical rolling-compaction tester can impact different points on the circumference of a workpiece, the vertical rolling-compaction tester can test the internal stress, flatness andend-face run-out of the workpiece by matching with test devices and test computers. The vertical rolling-compaction tester can re-allocate the internal stress of the workpiece, form an integrated rolling-compaction ring on the surface of the workpiece and accurately measure the internal stress, flatness and end-face run out of the saw blade workpiece; the invention improves the production efficiency, reduces the production cost and reduces the labor intensity, thereby achieving various purposes; and the tester body and the rolling-compaction head are made from high-quality steel plates, thereby improving the durability of the vertical rolling-compaction tester.

Owner:YICHANG DISEN MACHINERY

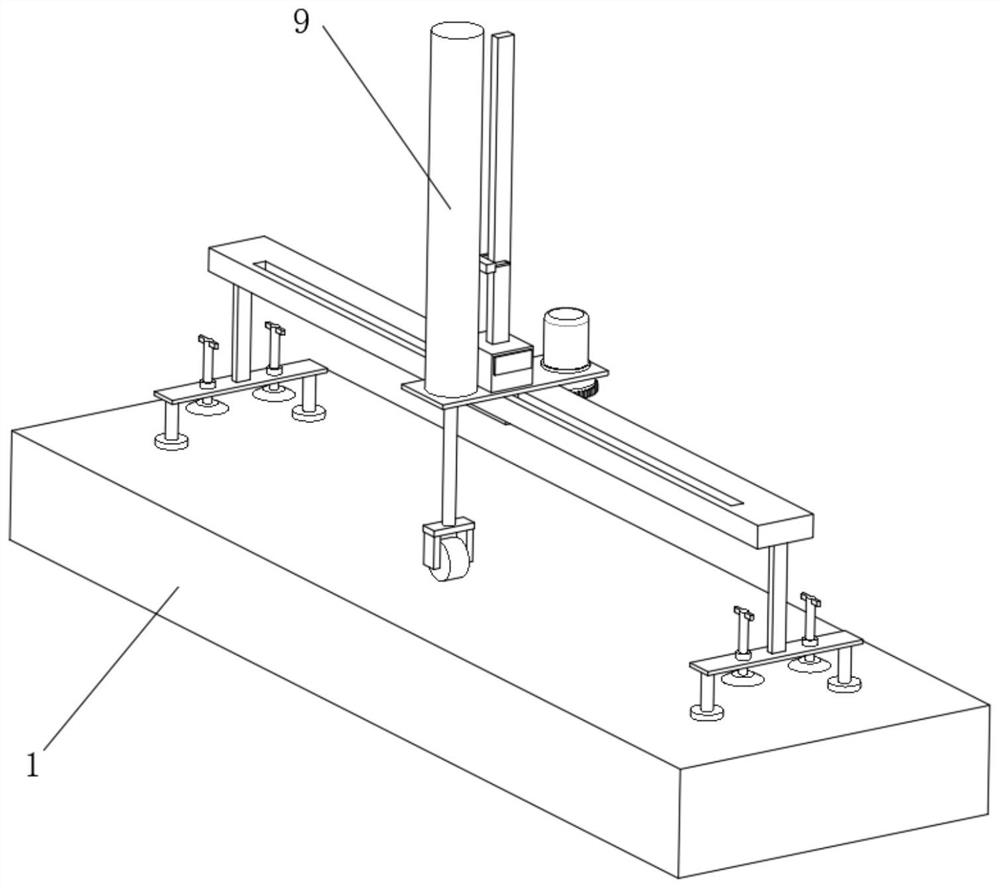

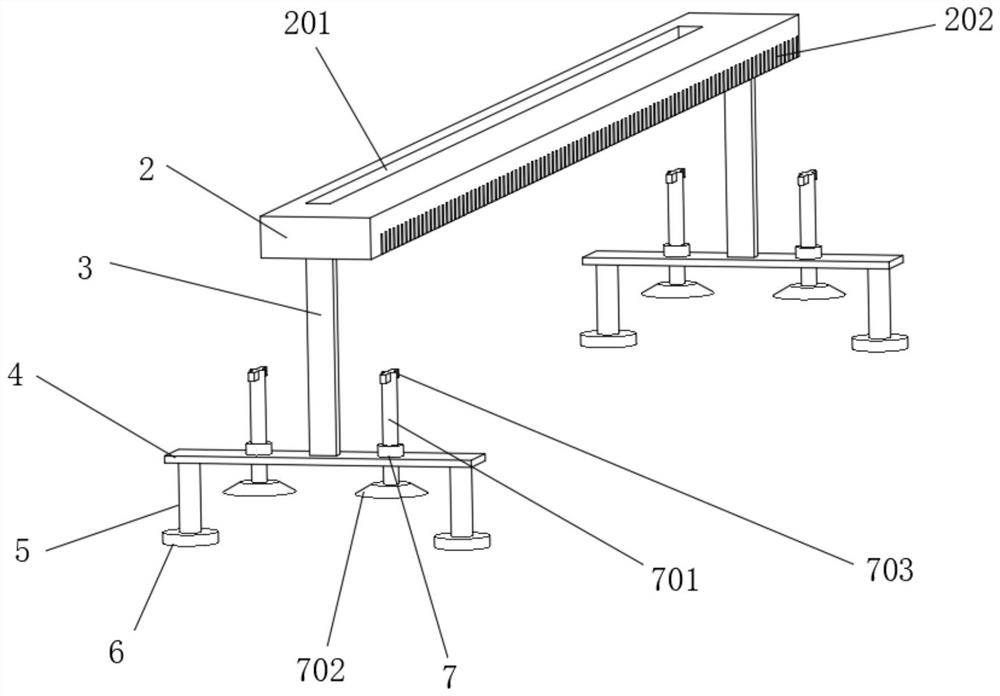

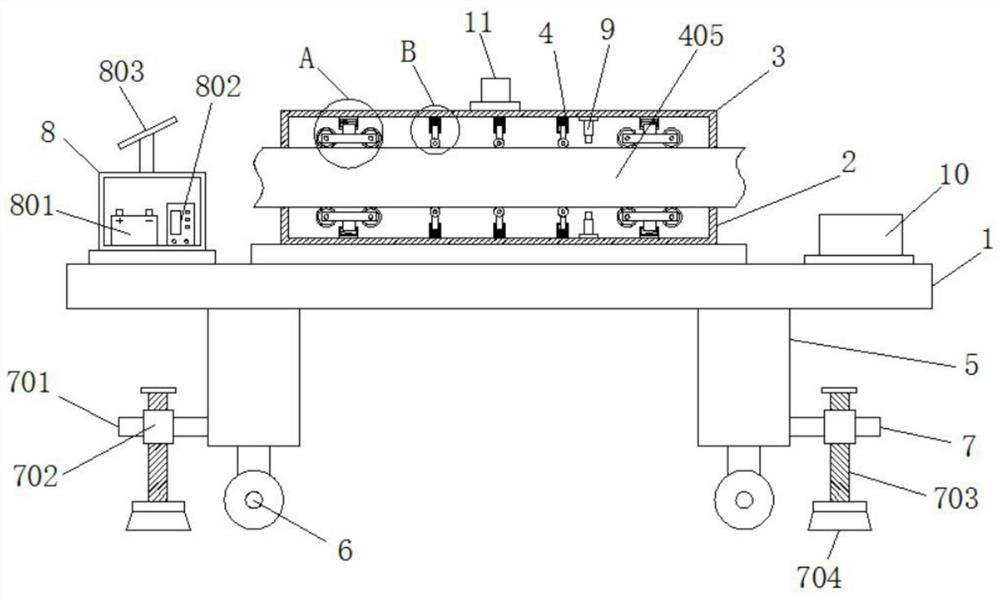

Efficient intelligent automatic cleaning and milling device based on internet of things

The invention discloses an efficient intelligent automatic cleaning and milling device based on internet of things. The efficient intelligent automatic cleaning and milling device comprises a mountingframe, a connecting frame is connected to the side face of the mounting frame, and a supporting column is arranged at the bottom end of the mounting frame. Universal wheels are arranged at the bottomend of the supporting column, a first sliding groove is formed in the mounting frame, and an ultrasonic detector is slidably connected into the first sliding groove. A second sliding groove is formedin the position, below the first sliding groove, of the mounting frame, a sliding plate is slidably connected in the second sliding groove, and a third groove is formed in the sliding plate. According to the efficient intelligent automatic cleaning and milling device based on the internet of things, the condition of the road surface is detected through the ultrasonic detector and then sent to a PLC, the PLC compares and analyzes detected data and cloud end data, so that the flatness of the road surface is measured, and meanwhile through control over work of an eighth electric telescopic rod,the position of the ultrasonic detector is adjusted.

Owner:重庆铭控仪器仪表有限公司

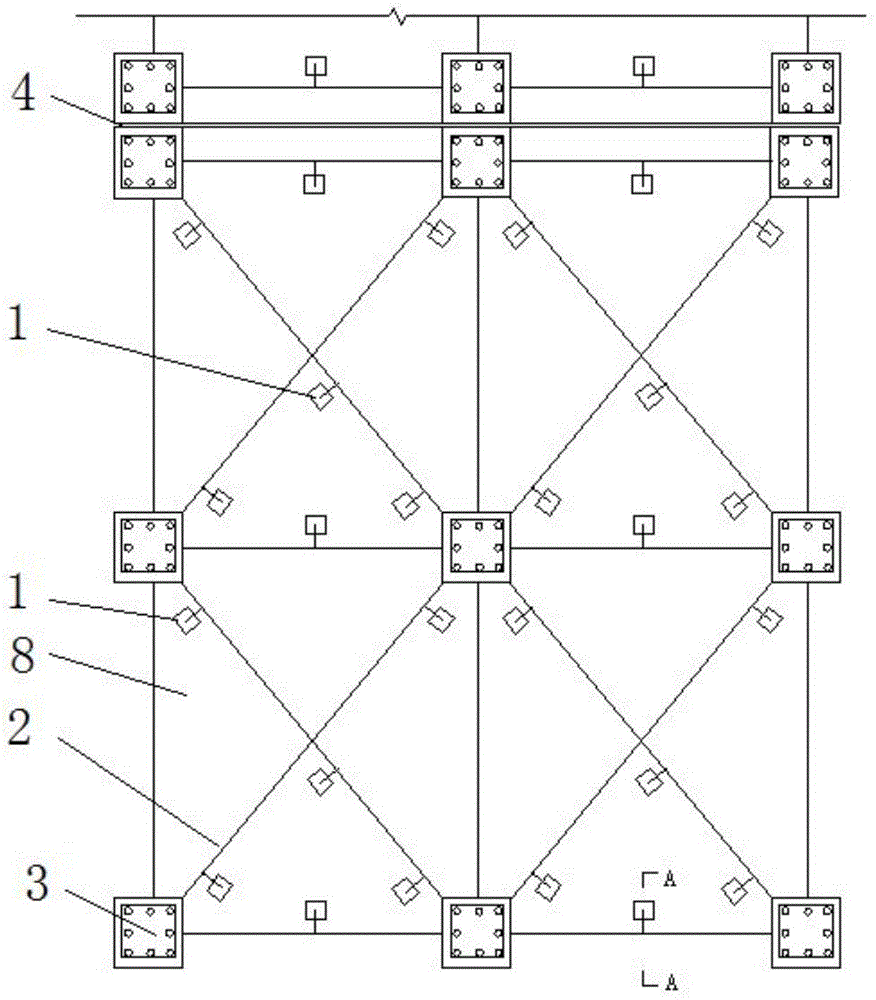

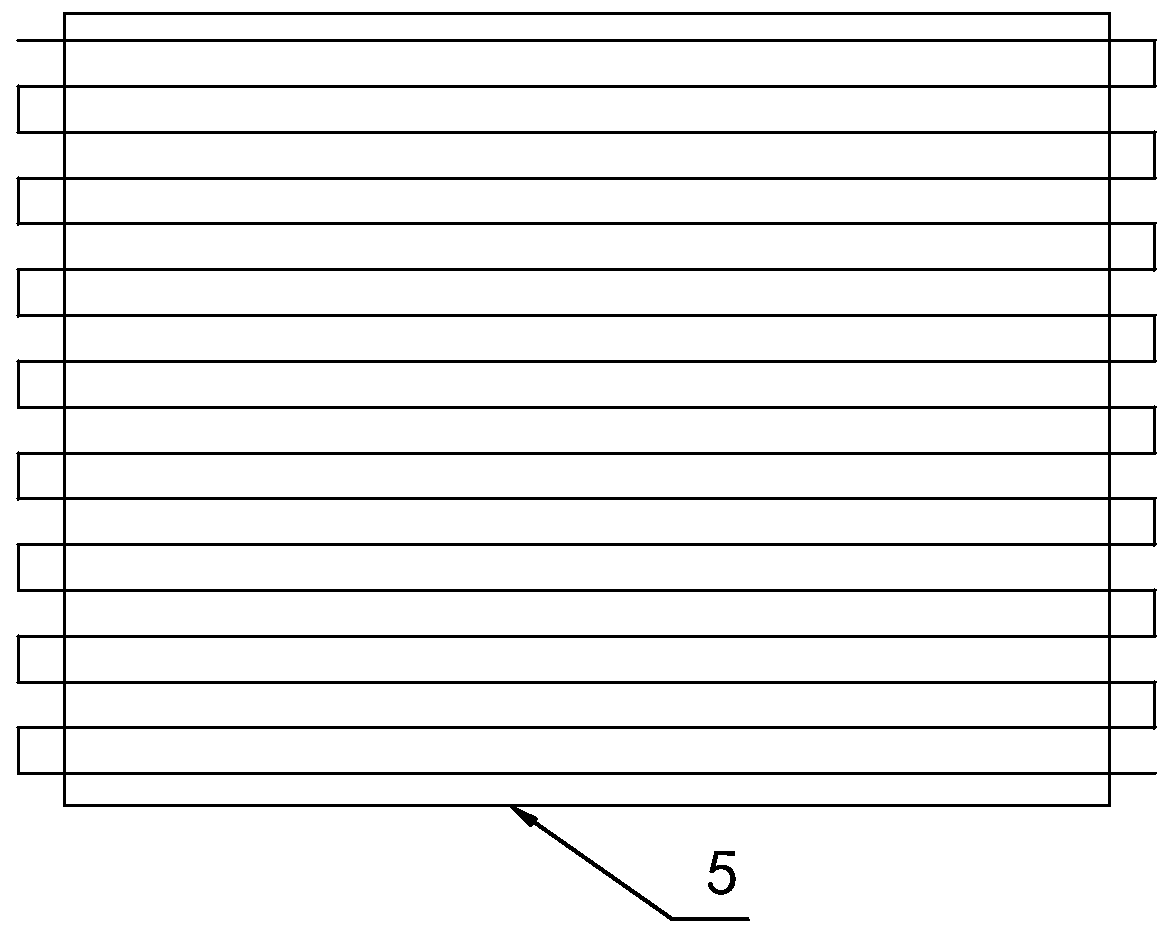

Building formwork or floor slab construction control method and special straightedge

InactiveCN103912127AEfficient pouring constructionPrecise pour constructionBuilding material handlingStraightedgeFloor slab

The invention discloses a building formwork or floor slab construction control method. The method is characterized by comprising the following steps: (1) preparing special straightedges and datum cords; (2) determining elevation of a building formwork or pouring thickness of a floor slab, and marking construction datum points on column steel bars; (3) marking construction datum points on other column steel bars; (4) connecting the construction datum points via the datum cords to mesh structures positioned on the same plane so as to form a datum plane for construction, wherein the mesh datum cords are construction data of the building formwork or floor slab; (5) after the building formwork is mounted or the floor slab is poured, correcting mounting and construction accuracy of the building formwork or floor slab with the special straightedges to realize elevation control and flatness control of building formwork mounting or floor slab pouring. The invention further discloses the special straightedge for implementing the control method. By the method, efficient and accurate building formwork mounting construction or floor slab pouring construction is realized, and elevation and flatness control of construction is realized.

Owner:DONGGUAN JIANZHIDU CONSTR ENG

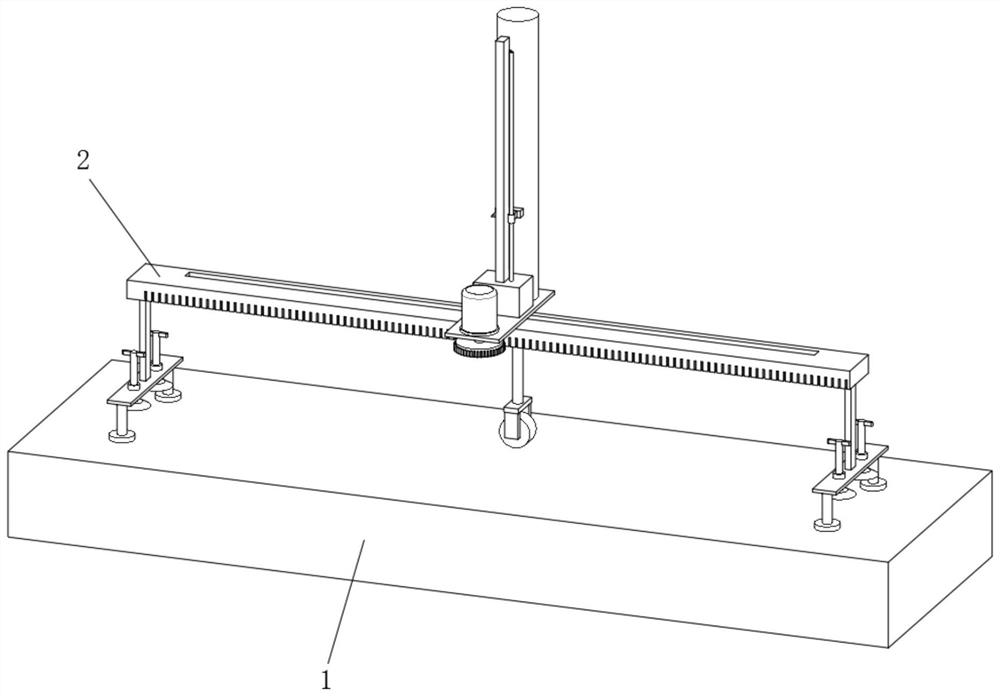

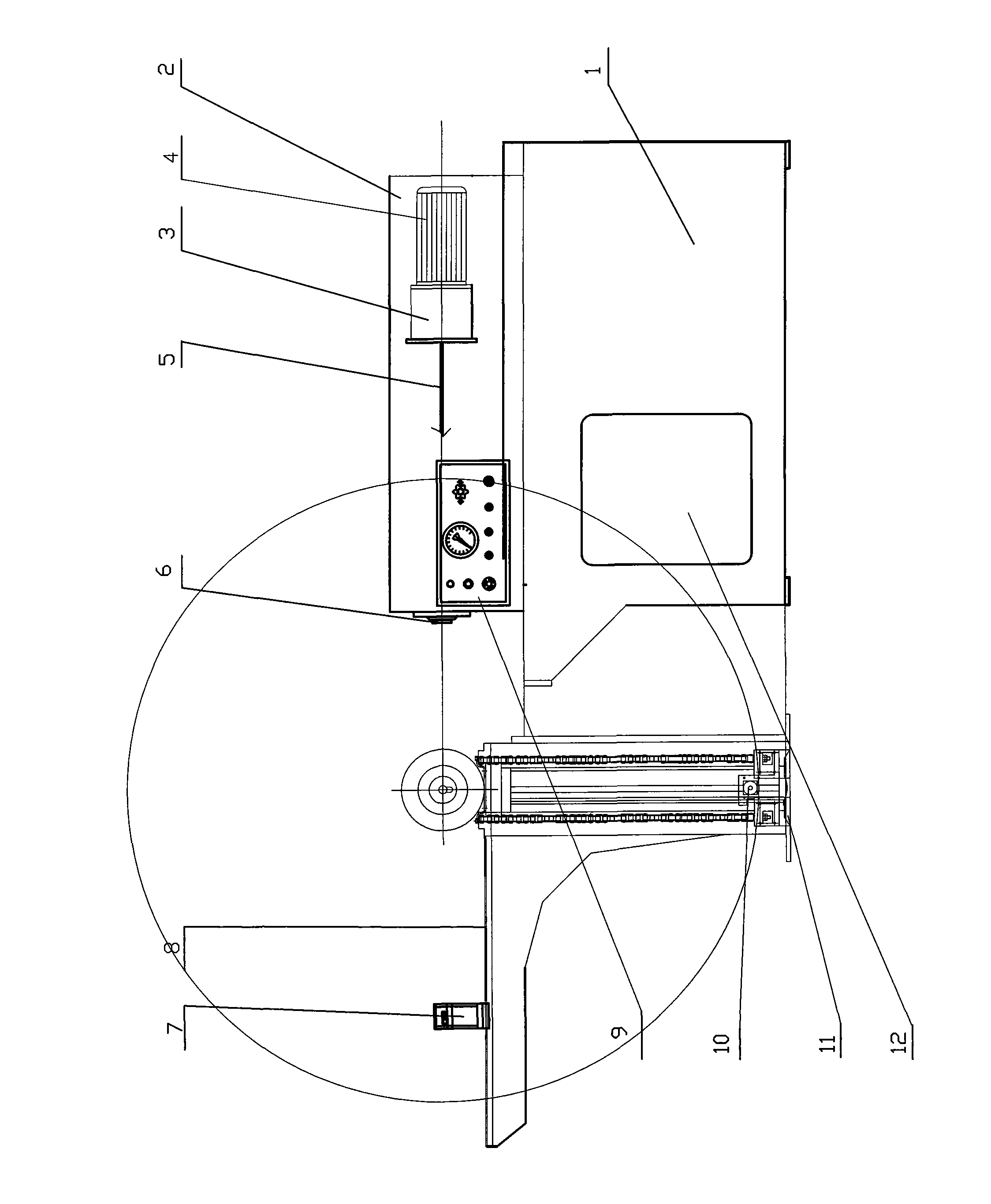

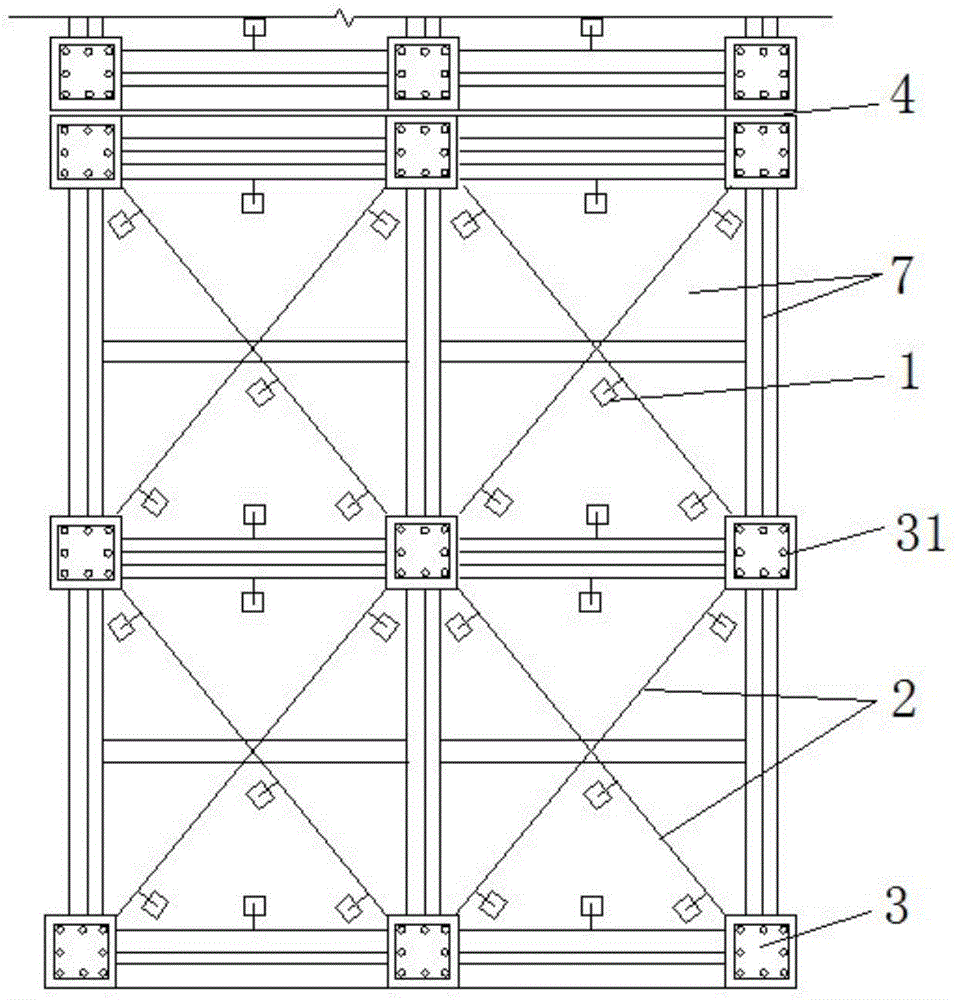

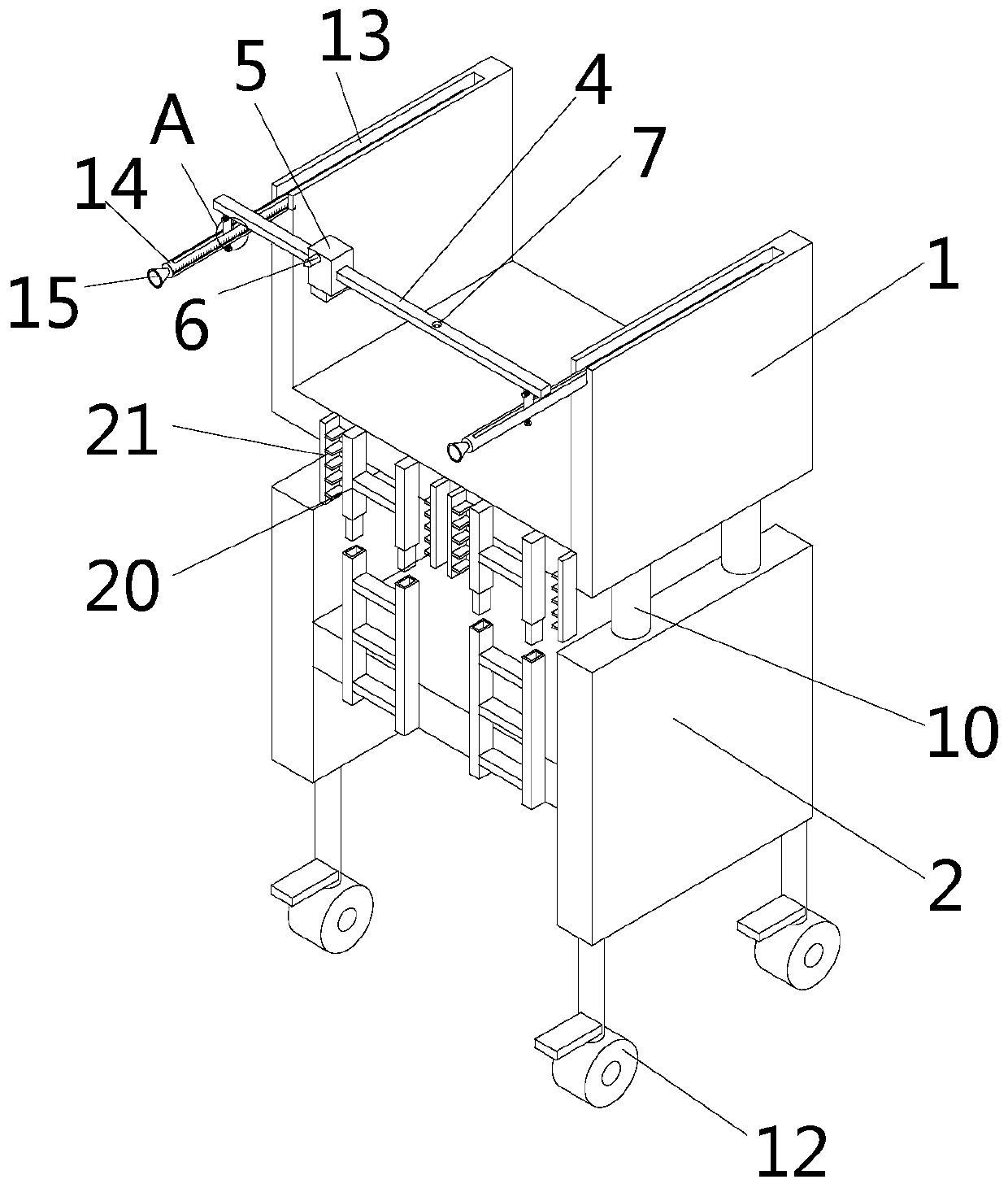

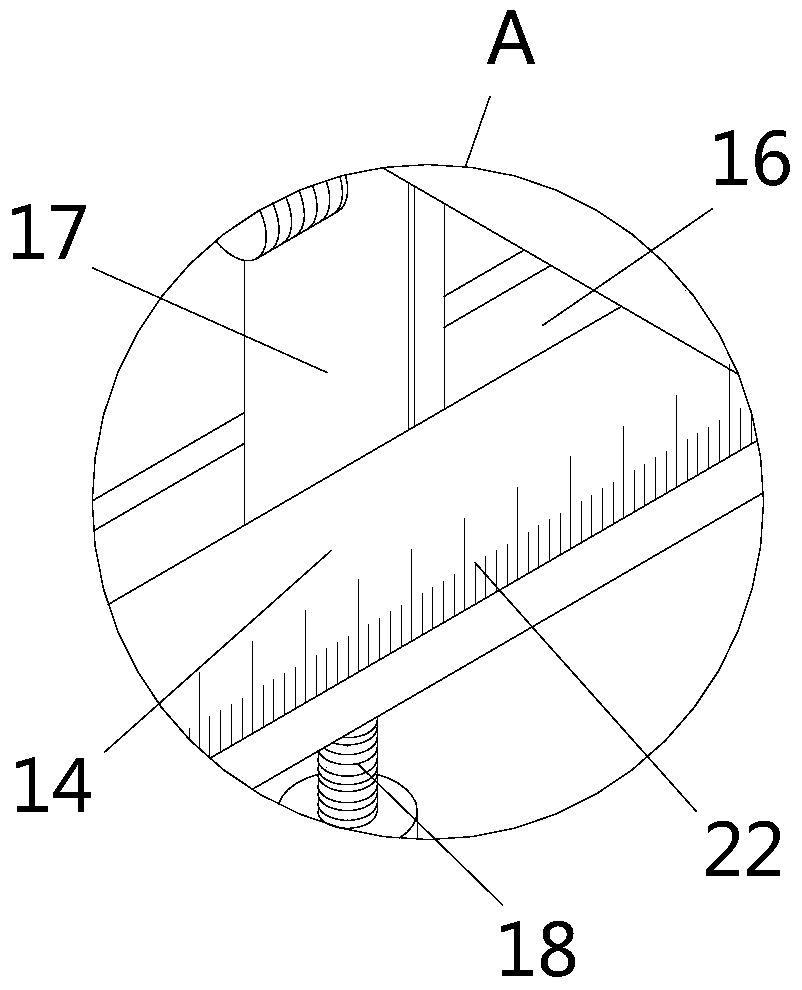

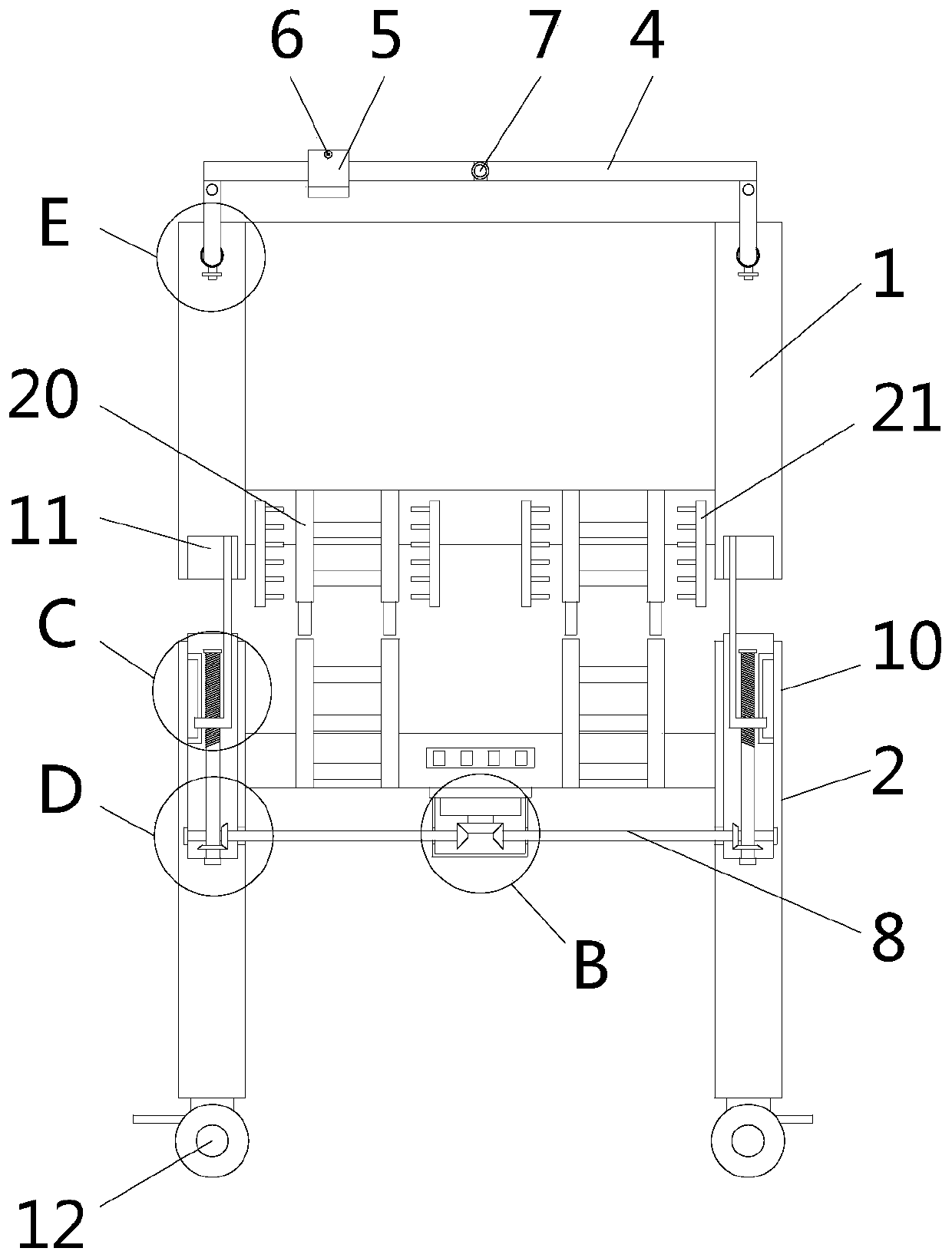

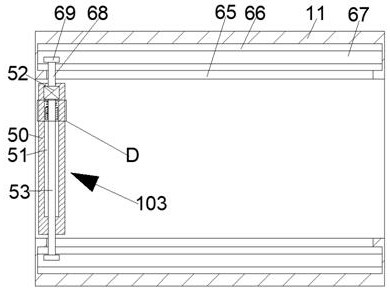

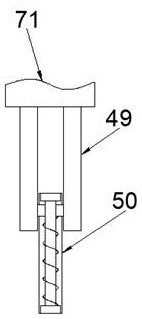

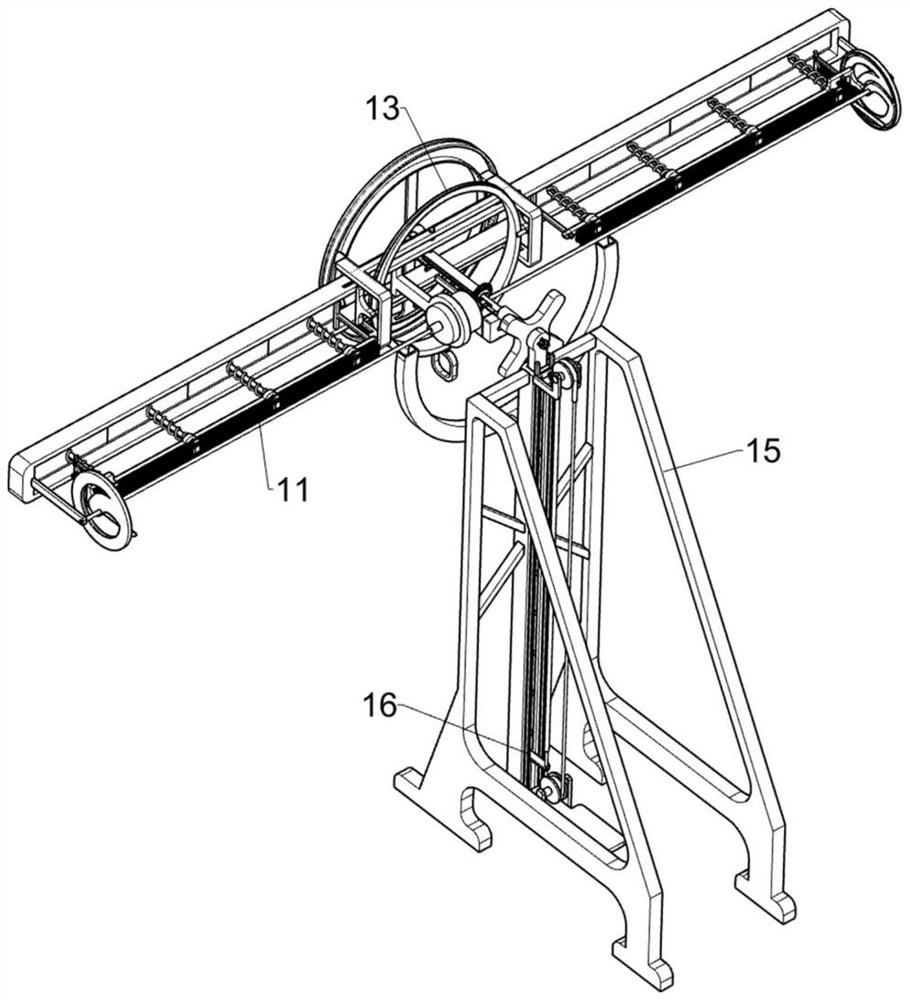

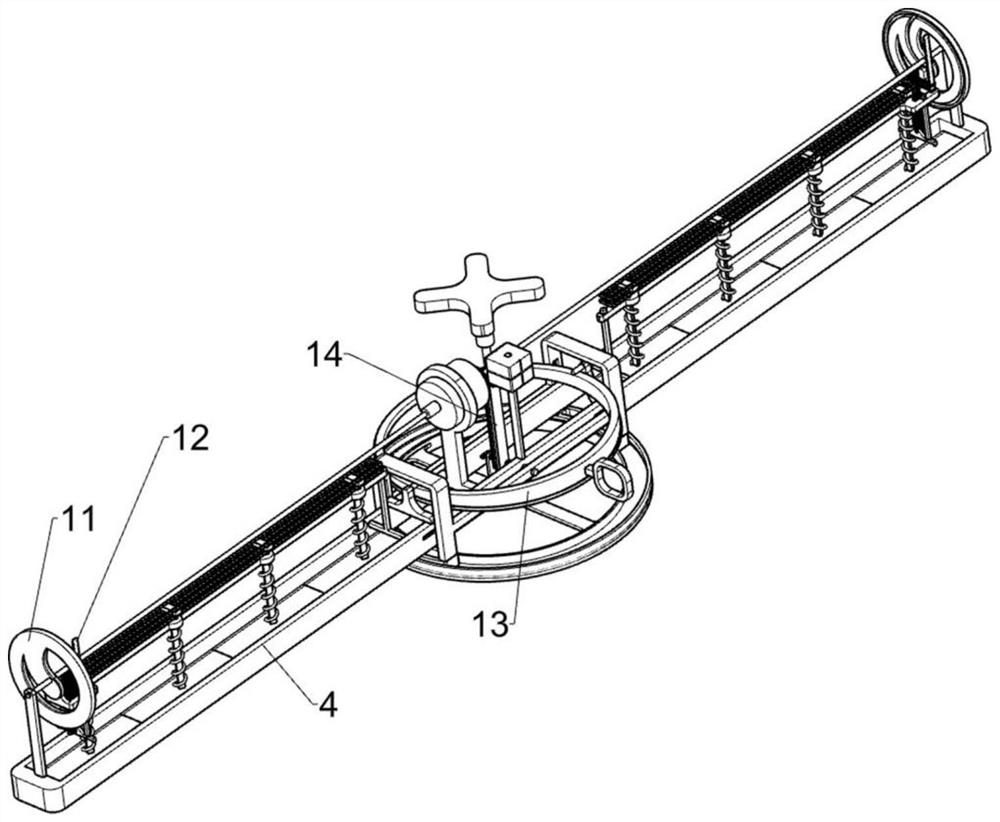

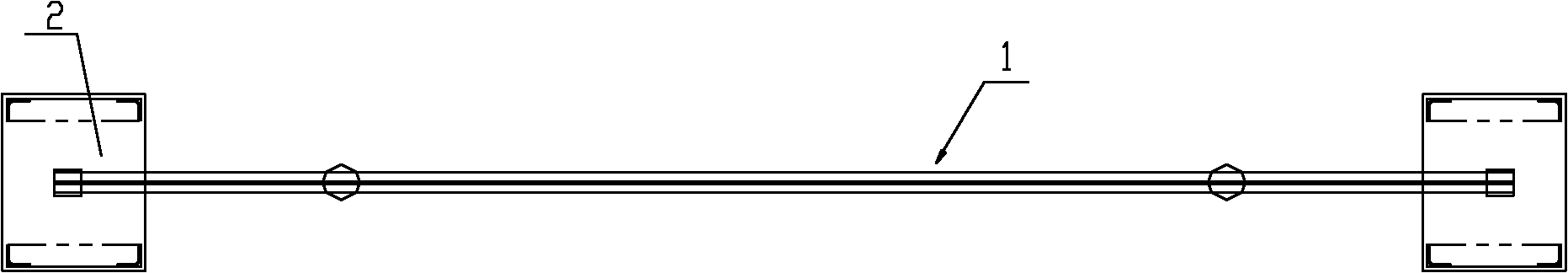

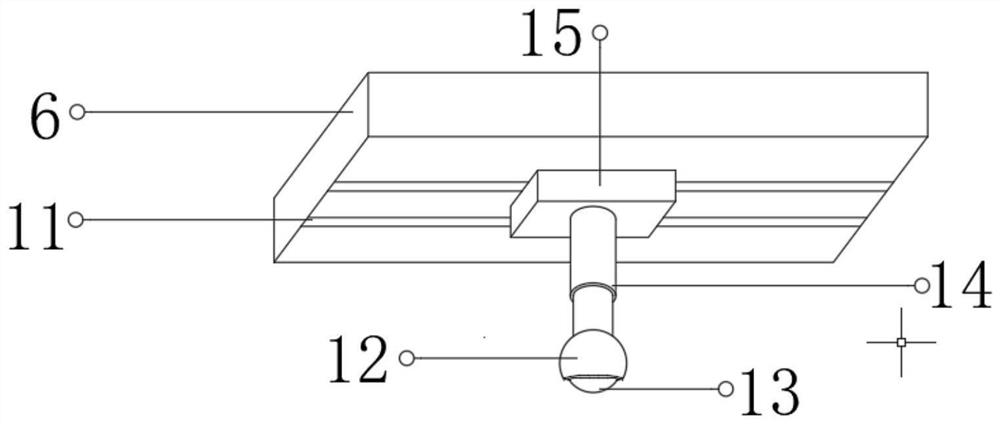

Pavement flatness detection device

PendingCN111705605ASimple structureEasy to operateRoads maintainenceTransformerStructural engineering

The invention provides a road surface flatness detection device, which comprises a guide rail and a detection mechanism matching the guide rail. The detection mechanism adopts a sliding transformer principle to realize the detection of the road surface flatness. A C-shaped groove is formed in one side of the guide rail, and the detection mechanism is connected with the C-shaped groove of the guiderail in a sliding mode through a connecting piece. And the detection mechanism comprises a shell, a sleeve, a sliding rod, a sliding rheostat, a fork rod and a sliding wheel which are arranged in theshell. The device is simple in structure, high in practicability, easy to operate, convenient to carry and high in use flexibility, the influence of manual subjectivity is reduced substantially, andthe detection efficiency and the detection precision are improved; the device is suitable for the construction, detection, maintenance and other processes of various pavements; the slide sheet of theslide rheostat slides to change the resistance of the slide rheostat, and the slide sheet of the slide rheostat slides to cause the change of voltage and current, so that the flatness of a road surface is detected.

Owner:WUYI UNIV

Arched tunnel side wall flatness detection device

InactiveCN111336904AReduce the difficulty of cooperationImprove accuracyMechanical roughness/irregularity measurementsElectric machineryStructural engineering

The invention relates to the technical field of detection of highway engineering field construction, and discloses an arched tunnel side wall flatness detection device which comprises a vehicle body,a vehicle seat, a motor, a ruler, a section tester, a section printer and a level bubble, the vehicle body is movably mounted at the top of the vehicle seat, and the motor is mounted at the bottom ofthe vehicle seat. Through the arched tunnel side wall flatness detection device, a lifting mechanism is arranged between vehicle bodies, the vehicle body can ascend and descend at will, and the flatness of the side wall of a tunnel can be detected more conveniently; compared with the prior art, the device has the advantages that auxiliary tools are not needed, and matching difficulty of detectionis reduced; through arrangement of telescopic rods, suction cups, fixing rods and adjusting knobs, the telescopic rods are moved, the suction cups at the top ends of the two telescopic rods are attracted to the side wall of the tunnel, the ruler is moved and adjusted through the fixing rods and the adjusting knobs, and the problem that the ruler cannot be directly close to the side wall for detection due to tunnel soil accumulation is solved.

Owner:YANGZHOU POLYTECHNIC INST

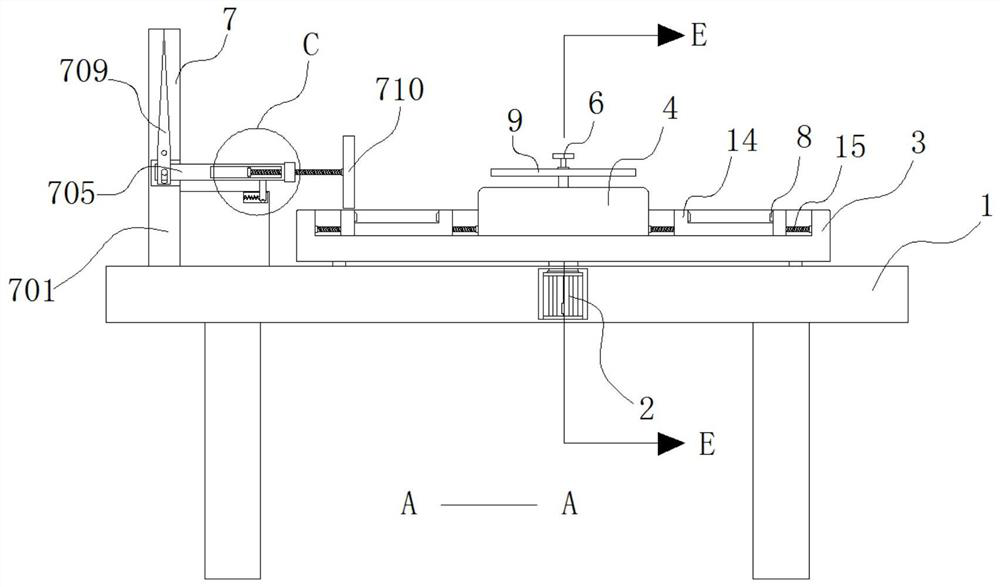

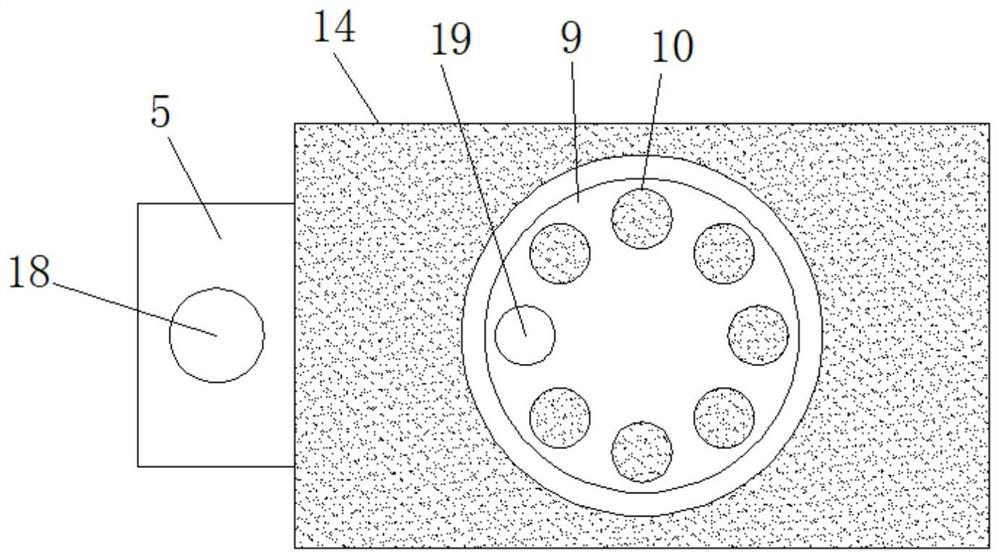

Detection equipment for cable processing

PendingCN112504841ACheck surface smoothnessCheck flatnessMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric machineryWorkbench

The invention discloses detection equipment for cable processing. The equipment comprises a pedestal and a cable body, and the top end of the pedestal is provided with a workbench and a pay-off device. Through the arrangement of a first sleeve and a box body, the flatness of the surface of the cable body and the tensile capacity of the cable body can be detected, when the motor drives the cable roller to rotate in a reciprocating manner, the first gear at the top end of the first fixing rod is driven to rotate in a reciprocating manner, and the first gear drives the second gear to rotate in areciprocating manner through the crawler belt, a third gear thus rotates in areciprocating manner, the third gear is engaged with the fan-shaped gear, the fan-shaped gear drives the cable body fixed in the limiting pipe to swing left and right in a reciprocating mode through the L-shaped plate, when the swinging cable body makes contact with detection photoelectricity, the number of swinging timesof the cable body can be known, and the cable can be subjected to a breaking test; the motor drives the cable roller to rotate in a reciprocating manner, and meanwhile, the cable body can be dragged.

Owner:杭州艾特线缆有限公司

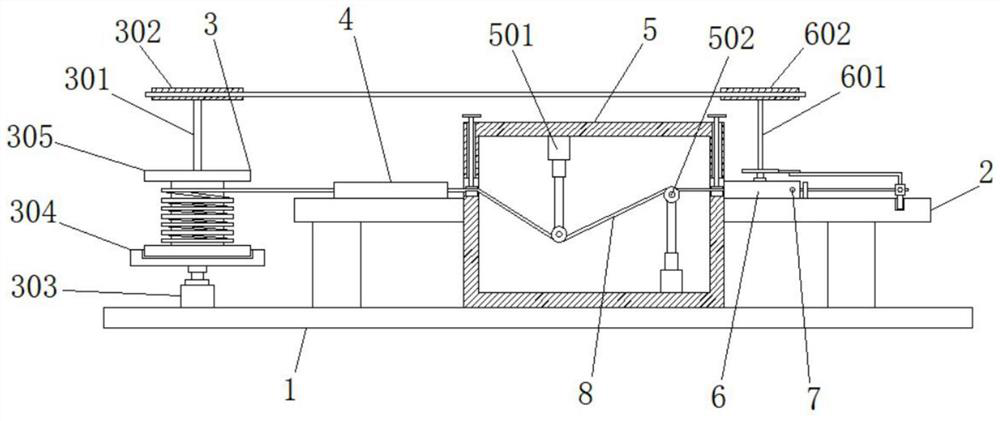

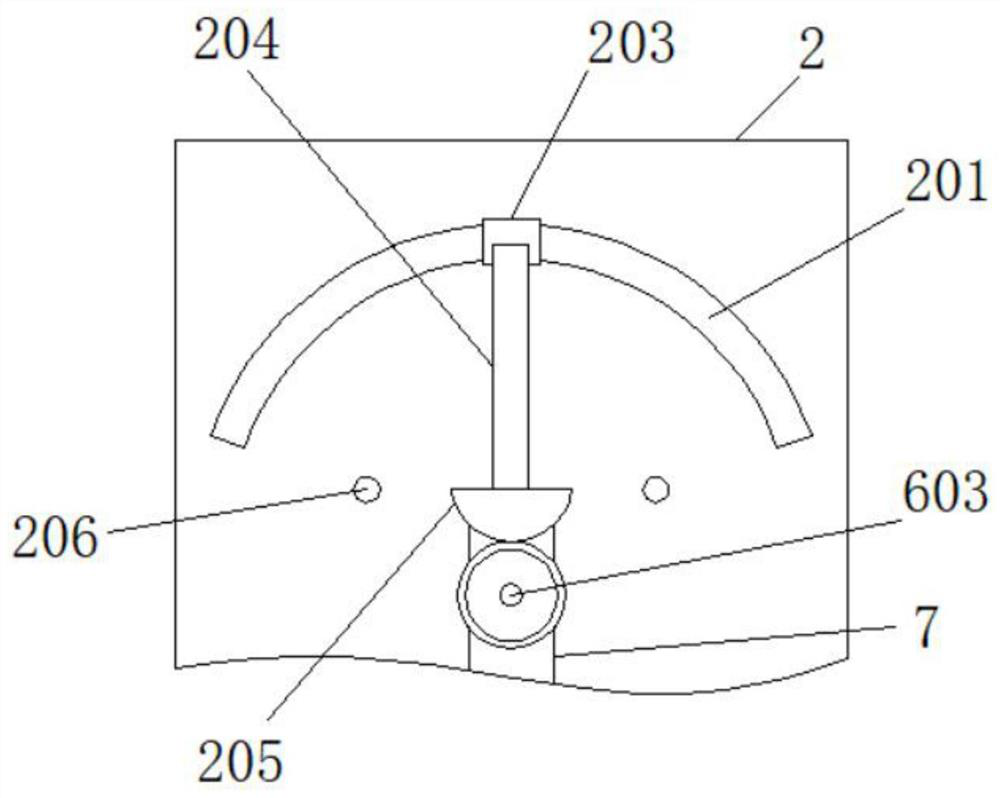

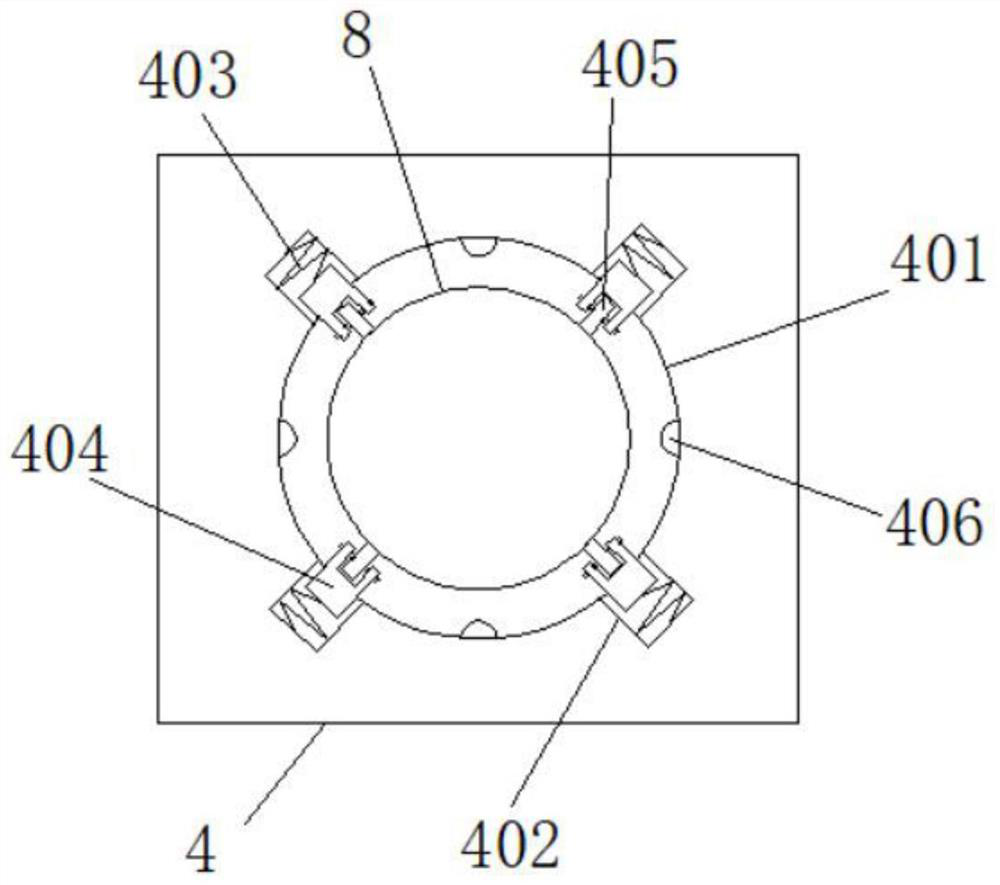

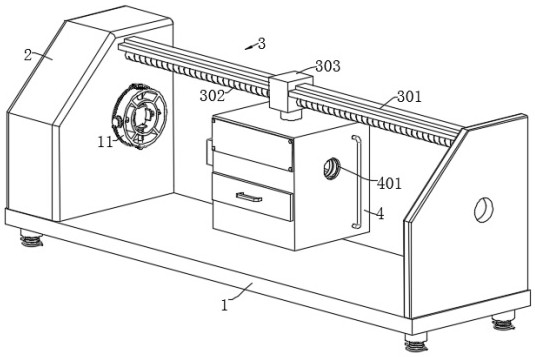

Shaft machining, polishing and detecting device

PendingCN114559310AKeep the environment tidyEasy to achieve clamping limitRevolution surface grinding machinesGrinding work supportsPolishingWater storage tank

The invention discloses a shaft machining, polishing and detecting device, and belongs to the technical field of workpiece machining. The shaft machining, polishing and detecting device comprises a bottom plate and further comprises a machining box arranged on the bottom plate, a machine box and a conveying mechanism used for driving the machining box to move, feeding ports are formed in the outer walls of the two sides of the machining box, brushes are arranged in the feeding ports, and the conveying mechanism is arranged on the machine box. A grinding mechanism used for grinding the shafts is arranged on the inner wall of the top of the machining box. The lantern ring I and the water storage tank are fixedly connected to the outer wall of the processing box; according to the shaft polishing device, when a shaft is polished, four sets of clamping plates can be driven to correspondingly extend or retract in a third lantern ring through a telescopic clamping cylinder, then the shafts of different specifications and sizes can be clamped and limited conveniently, and after polishing is completed, the flatness of the overall surface of the shaft can be detected; and the protruding part of the outer surface of the shaft can be marked in the detection process.

Owner:DALIAN DEMAISHI PRECISION TECH CO LTD

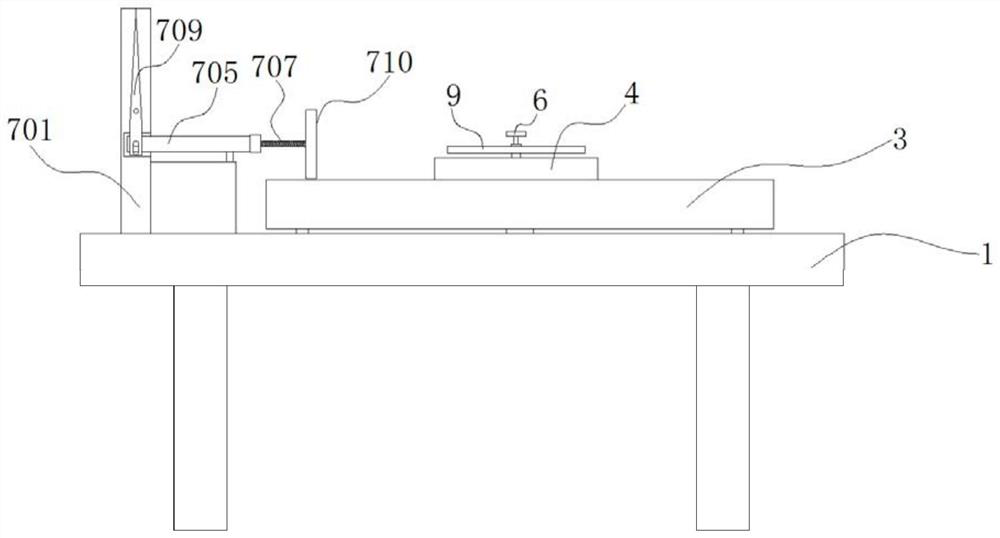

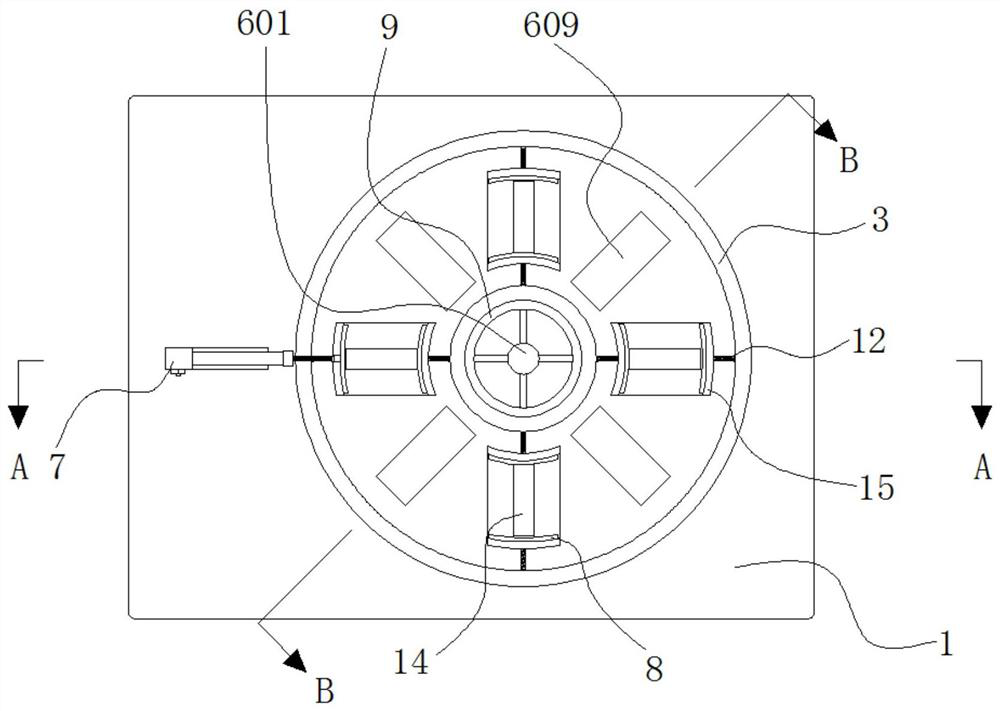

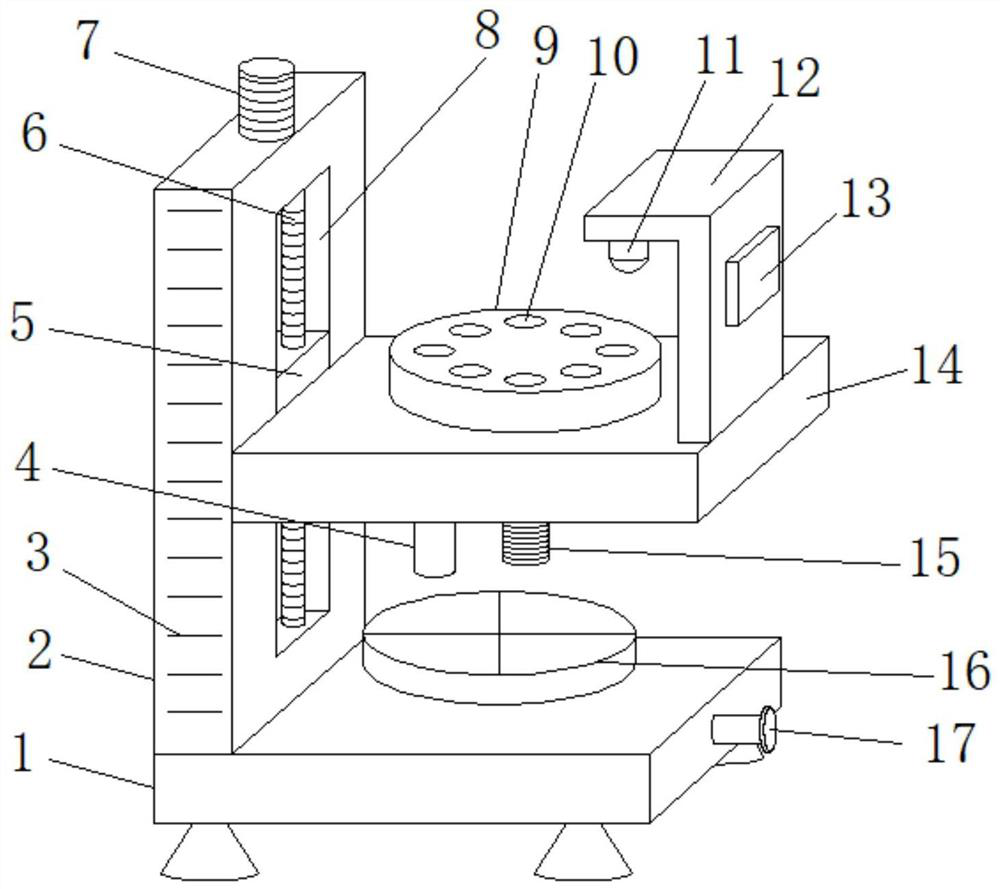

Surface flatness high-precision detection device for rolling bearing manufacturing

The invention discloses a surface flatness high-precision detection device for rolling bearing manufacturing, and the device comprises: a motor which is fixedly connected to the interior of a bottom plate; a rotating disc, wherein the lower surface of the rotating disc is in key connection with the top end of the motor, and the rotating disc is in sliding connection with the upper surface of the bottom plate; a fixed frame which is fixedly connected to the upper surface of the rotating disc; a rotating shaft which is in shaft connection with the interior of the fixed frame; and a pushing structure which is arranged in the rotating disc. According to the surface flatness high-precision detection device for rolling bearing manufacturing, the fixing device can be correspondingly adjusted according to a rolling bearing needing to be detected, then the rolling bearing can be rapidly fixed, the surface flatness of the rolling bearing can be judged according to the change of a pointer, the rolling bearing is taken out by pressing a pressing device, and therefore, the flatness of the rolling bearing can be detected more conveniently.

Owner:王京礼

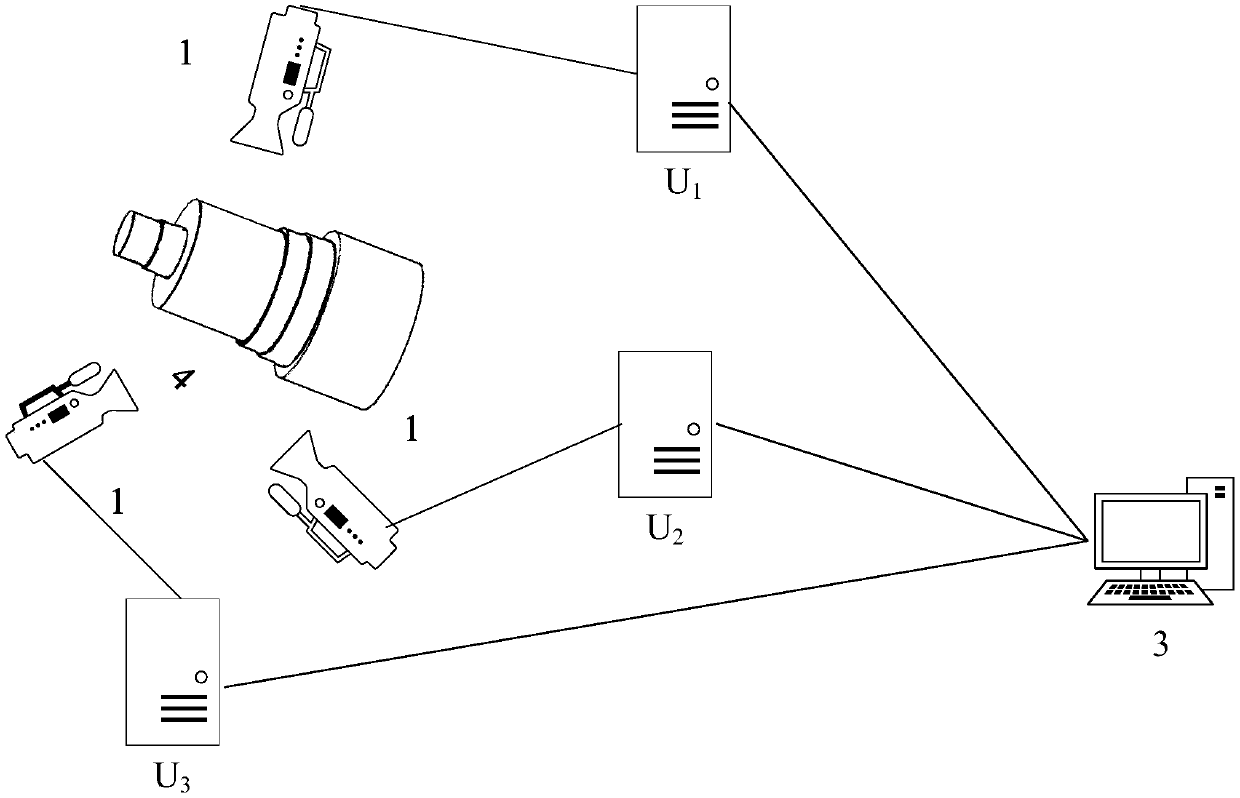

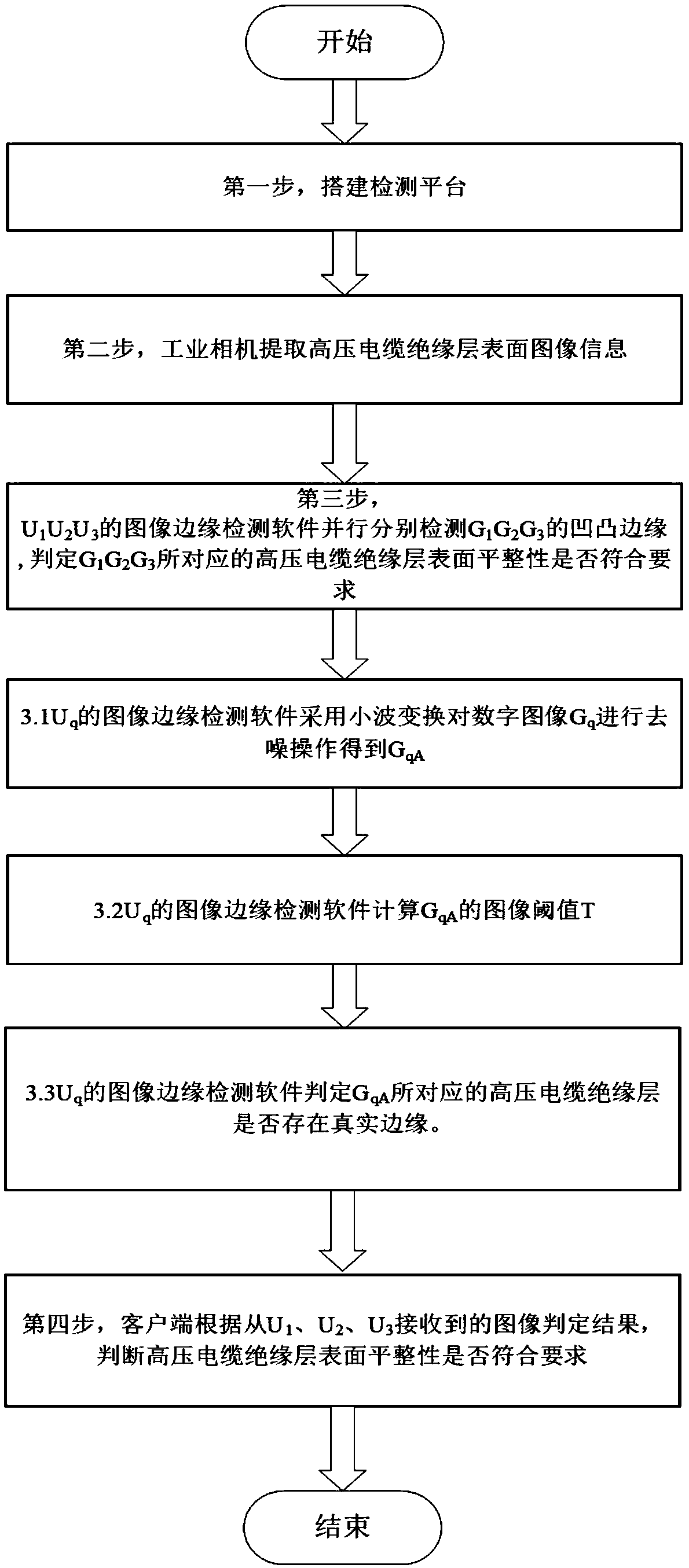

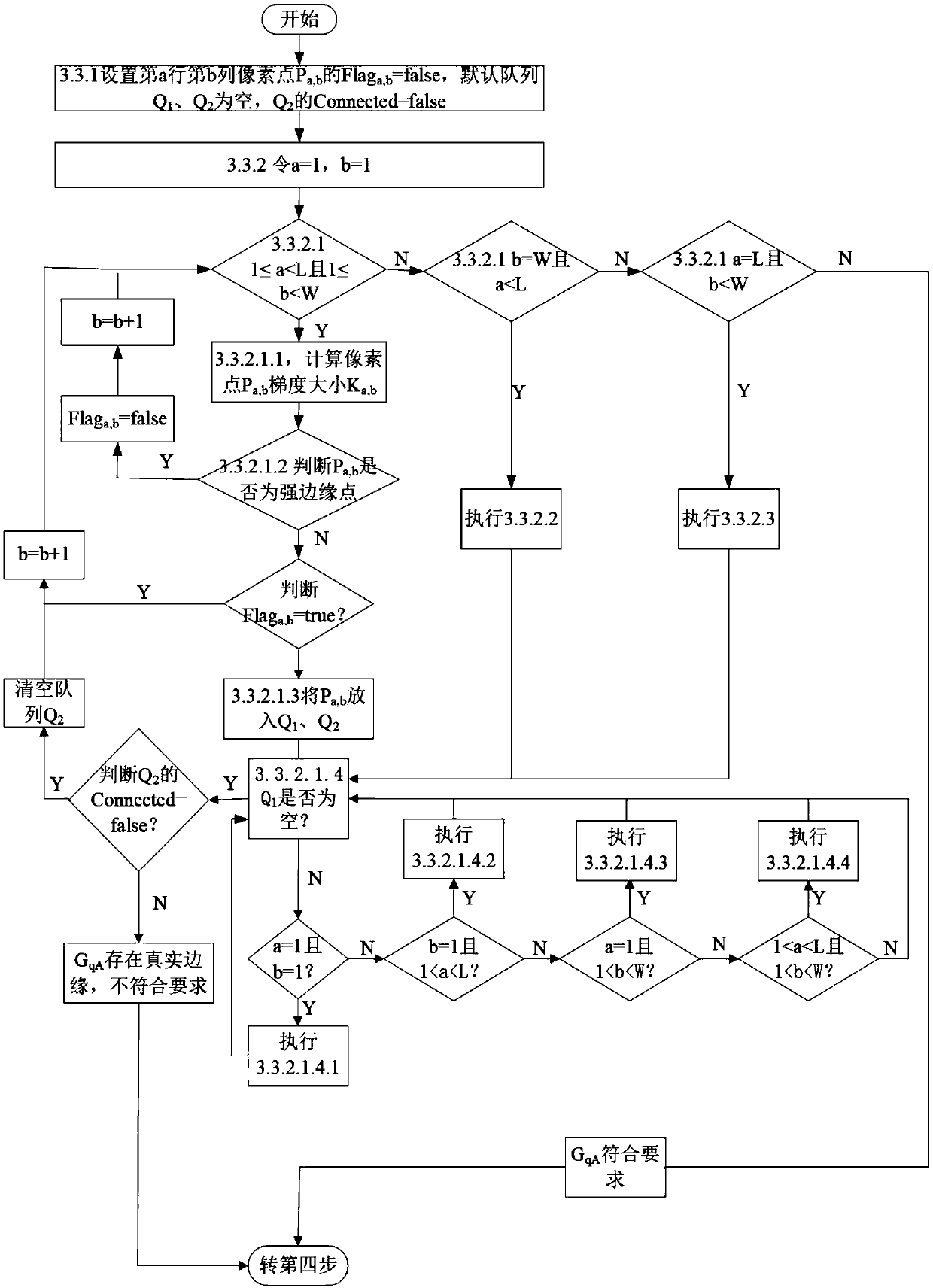

A crosslinked polyethylene insulating layer surface flatness detection method based on edge detection

ActiveCN109559306ACheck flatnessImprove accuracyImage enhancementImage analysisCross-linked polyethyleneHigh pressure

The invention discloses a crosslinked polyethylene insulating layer surface flatness detection method based on edge detection, and aims to solve the problems of low efficiency, low accuracy and the like of an existing method. According to the technical scheme, a detection platform composed of an industrial camera, a digital image processor and a client is established, image edge detection softwareis burned in the digital image processor, and result judgment software is installed on the client. The three industrial cameras extract image information of the surface of the high-voltage cable insulating layer; three images are obtained respectively, the three pieces of image edge detection software are used for denoising the three pieces of images in parallel respectively; carrying out edge detection on concave and convex areas in the denoised image in parallel respectively, and judging whether a real edge exists on the high-voltage cable insulating layer corresponding to the denoised image or not, so as to judge whether the surface flatness of the corresponding high-voltage cable insulating layer meets the requirement or not; and the result judgment software carries out comprehensivejudgment according to the three results. According to the invention, the speed and the judgment accuracy can be improved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Building board surface flatness detection device

InactiveCN112197718ACheck flatnessAvoid construction accidentsUsing optical meansArchitectural engineeringStructural engineering

The invention discloses a building board surface flatness detection device, which comprises a detection machine body, wherein a turn-over cavity is formed in the detection machine body, a feeding cavity with a leftward opening is formed in the left side of the turn-over cavity in a communicating mode, the feeding cavity is inclined from the upper left portion to the lower right portion, a discharging cavity with a rightward opening is formed in the right side of the turn-over cavity in a communicating mode, turn-over rotating shafts which are symmetrical left and right are rotatably connectedbetween the front wall and the rear wall of the turn-over cavity, the outer circular surface of the turn-over rotating shaft on the left side is fixedly sleeved with a first bearing plate, and the turn-over rotating shaft on the left side is located on the right side in the first bearing plate. The building board surface flatness detection device adopts a mode of turning over the building board and detecting the same simultaneously, the building board is placed on the upper end face of the first bearing plate firstly, then the building board is turned over to the upper end face of the second bearing plate through using a connecting rod, the lower end face of the second bearing plate faces upwards, flatness of the upper end face and the lower end face of the second bearing plate is detectedconveniently, and meanwhile the building board surface flatness detection device can assist the building board when the building board is turned over to prevent construction accidents.

Owner:武汉康圣金水晶工艺品有限公司

Surface flatness detection equipment for hub manufacturing

InactiveCN112595224ADetermine eligibilityCheck flatnessMechanical roughness/irregularity measurementsEngineeringMachine

The invention relates to the related field of intelligent manufacturing, in particular to surface flatness detection equipment for hub manufacturing, which comprises a machine body and a first transmission cavity fixedly arranged in the machine body, and is characterized in that a positioning and clamping mechanism located on the upper side of the first transmission cavity is arranged on the top wall of the machine body; the positioning and clamping mechanism is used for clamping and fastening a hub to facilitate subsequent detection, and meanwhile, the positioning and clamping mechanism can also inform a detection result through sound, so that the surface flatness detection equipment for hub manufacturing provided by the invention can be used for detecting the flatness of the outer surface of the hub needing to be detected; and the inner side wall is clamped, the outer surface cannot be damaged due to too large clamping force, meanwhile, the device is suitable for hubs of different specifications, detection is rapidly conducted in a surrounding mode, the result is rapidly obtained to determine the qualification of the hubs, and the device is high in efficiency and universality.

Owner:湖北顽强石头网络科技有限公司

Thin-sheet punching machine capable of automatically performing equipment health maintenance

InactiveCN108746302AKeep healthyImprove the efficiency of health maintenanceMetal working apparatusPunchingComputer module

The invention relates to a thin-sheet punching machine capable of automatically performing equipment health maintenance. The machine comprises a rack, and a mounting plate which is arranged on the rack, wherein a punching rack is arranged on the mounting plate, and a punching cylinder is arranged on the punching rack; a fitting pressing head is connected to the lower part of the punching cylinder;an embedding port which fits the pressing head by position is formed in the mounting plate, and a horizontal switching groove which communicates with the embedding port is formed in the mounting plate; switching pushing cylinders are arranged at two ends of the switching groove and are connected to switching pushing blocks; a grinder and a punching module are arranged between the two switching pushing blocks; a jacking lifting cylinder is arranged at a part, at the lower part of the embedding port, of the rack; and the jacking lifting cylinder is connected to a jacking device which penetratesthe switching groove. According to the machine, the working stations of the grinder and the punching module can be automatically switched, so that the pressing head can be automatically regularly grinded and maintained through the grinder, and the pressing head can be kept in health all the time; the health maintenance efficiency is extremely improved; and the time cost and the labor cost can bedecreased.

Owner:DONGGUAN UNIV OF TECH

Novel online detection device and detection method for surface flatness of paper ream of anti-counterfeiting paper

PendingCN113959330ACheck flatnessThe test result is accurateElectric/magnetic roughness/irregularity measurementsControl engineeringMechanical engineering

The invention discloses a novel online detection device and detection method for the surface flatness of paper ream of an anti-counterfeit paper, and relates to the technical field of quality detection equipment. The device comprises a comprehensive adjusting table and a flattening detector, a solenoid coil and a sliding contact block are arranged in the flattening detector and form a sliding rheostat structure, and a roller in the flattening detector and a conveying belt in the comprehensive adjusting table are both in contact with paper reams and extrude each other. According to the invention, the solenoid coil, the sliding contact block, the roller and the conveying belt are arranged, a basic sliding rheostat working principle is utilized, mechanical signals and electric signals are directly converted, and the flatness of the surface of paper ream can be detected more conveniently; wherein the roller and the conveying belt are used for pressing the paper ream, so that the detection result is more accurate, the slide rheostat structure can be directly replaced by the existing potentiometer and the like, the cost of the whole device is lower, and the whole detection cost is reduced while the detection accuracy is ensured.

Owner:莱阳银通纸业有限公司

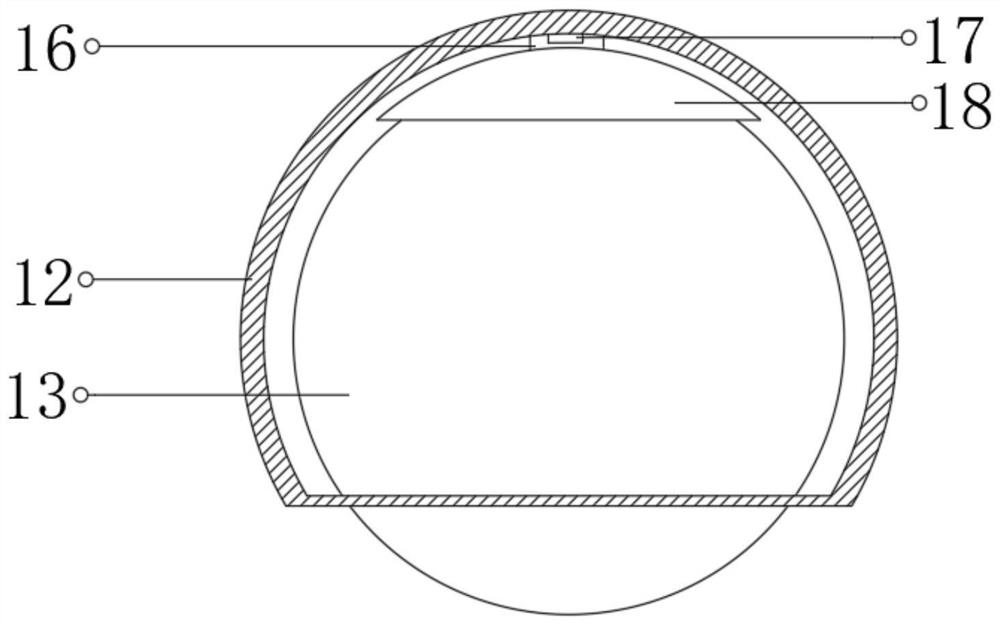

Flatness detection device for engineering supervision and use method thereof

PendingCN114166100AAccurate detectionGuaranteed accuracyMechanical roughness/irregularity measurementsSafety coefficientControl theory

The invention relates to the field of project supervision, in particular to a flatness detection device for project supervision and a use method thereof, and the flatness detection device comprises a detection ring, a first sliding block, a rotating frame, a swinging frame, an outer frame, a second sliding block and the like; the front side of the detection ring is symmetrically and slidably connected with first sliding blocks, a rotating frame is fixedly connected between the two first sliding blocks, the middle of the rotating frame is movably connected with a swing frame, the front side of the swing frame is symmetrically and fixedly connected with an outer frame, the rotating frame is symmetrically and slidably connected with a pair of second sliding blocks, and the second sliding blocks are slidably matched with the swing frame. The equipment is supported through the support, the leveling block faces the wall surface, so that the equipment can detect the flatness of the wall surface, meanwhile, the cross-shaped handle and the devices on the cross-shaped handle can ascend and descend, the equipment can detect the flatness of the high position of the wall surface, the safety coefficient is high, and the practicability is high. The purpose of detecting the flatness of the high position of the wall surface is achieved.

Owner:烟台景上科技有限公司

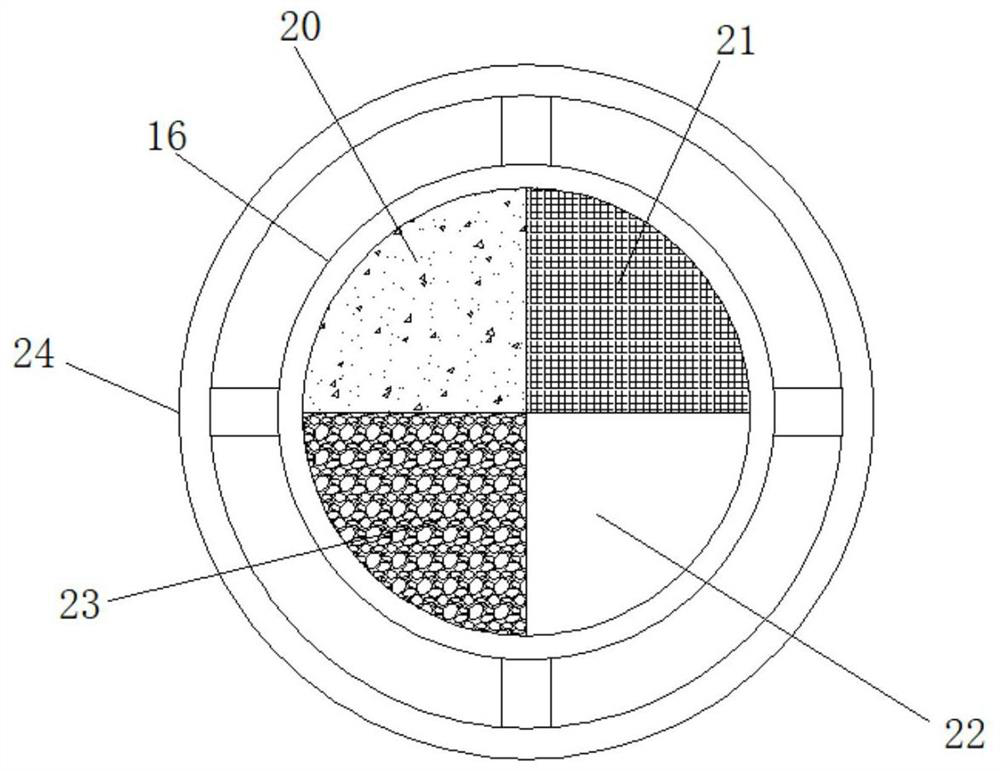

Test equipment for hearing aid production

InactiveCN113473344AComprehensive testQuality improvementHearing aids testing/monitoringElectric machineryEngineering

The invention discloses test equipment for hearing aid production, which comprises a base, the left side of the top of the base is fixedly connected with a fixed plate, and the right end of the fixed plate is provided with a chute. Through arrangement of the first motor, the second motor, the sliding groove, the lead screw, the moving block, the supporting plate, a conveying disc, a testing disc, a bearing, a wood plate area, a ceramic tile area, a cement ground area and a ground area, the second motor drives the conveying disc to rotate, and a hearing aid is pushed to fall onto the testing disc from a through hole in the supporting plate; the test disc is divided into a wood board area, a ceramic tile area, a cement ground area and a ground area, so that the anti-falling performance of the hearing aid falling to different grounds can be simulated, the test height of the hearing aid can be adjusted by starting the first motor, and the anti-falling performance of the hearing aid falling on patients with different heights can be simulated; the hearing-aid test is comprehensive, and the quality of hearing-aid production is improved.

Owner:苏州海卡缔听力技术有限公司

Pad detecting device

PendingCN109916345ACheck flatnessGuarantee welding qualityUsing optical meansLaser rangingEngineering

The invention discloses a pad detecting device, which comprises a first guiding rail, a second guiding rail, a laser range finder, an object stage, a first driving device and a second driving device,wherein the second guiding rail is driven by the first driving device to move along the first guiding rail; the laser range finder is driven by the second driving device to move along the second guiding rail; the object stage is flat; and the laser range finder faces the object stage. According to the pad detecting device disclosed in the invention, a detected element is placed on the object stage, the laser range finder scans the detected element from different positions, the flatness of the detected element can be effectively detected, the flatness of the pad in the detected element can be detected accurately and efficiently, a qualified element can thus be selected, the welding quality of the element is ensured, the production quality of a product is enhanced, the phenomena of false detection, misdetection and missed detection by the traditional manual visual detection can be avoided, the detection efficiency is effectively improved, and the manual cost is reduced. The pad detectingdevice is used in the field of detecting equipment.

Owner:广州佳昕机电科技有限公司

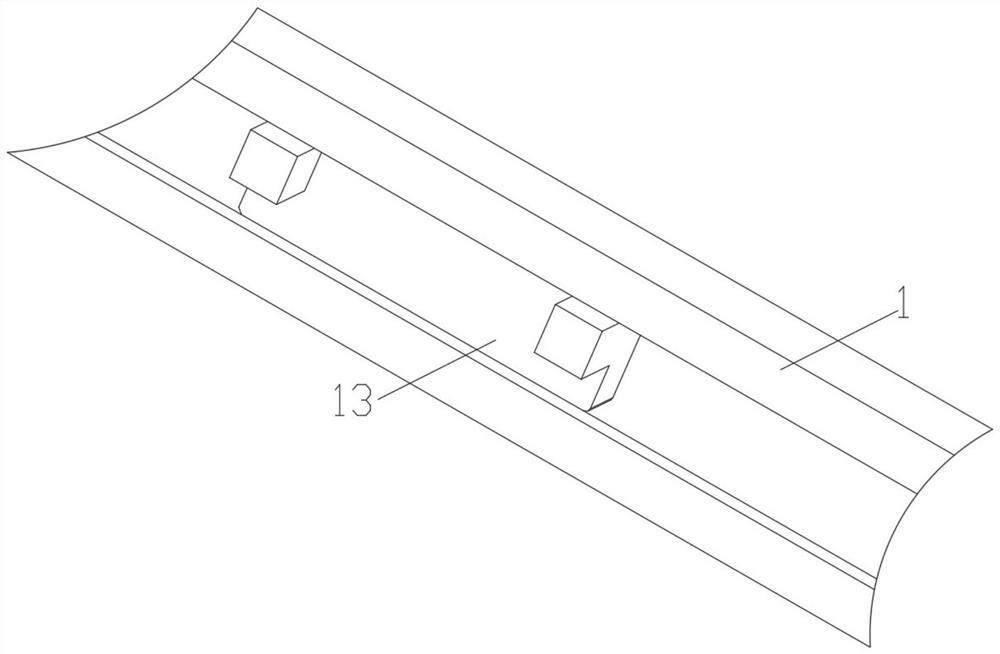

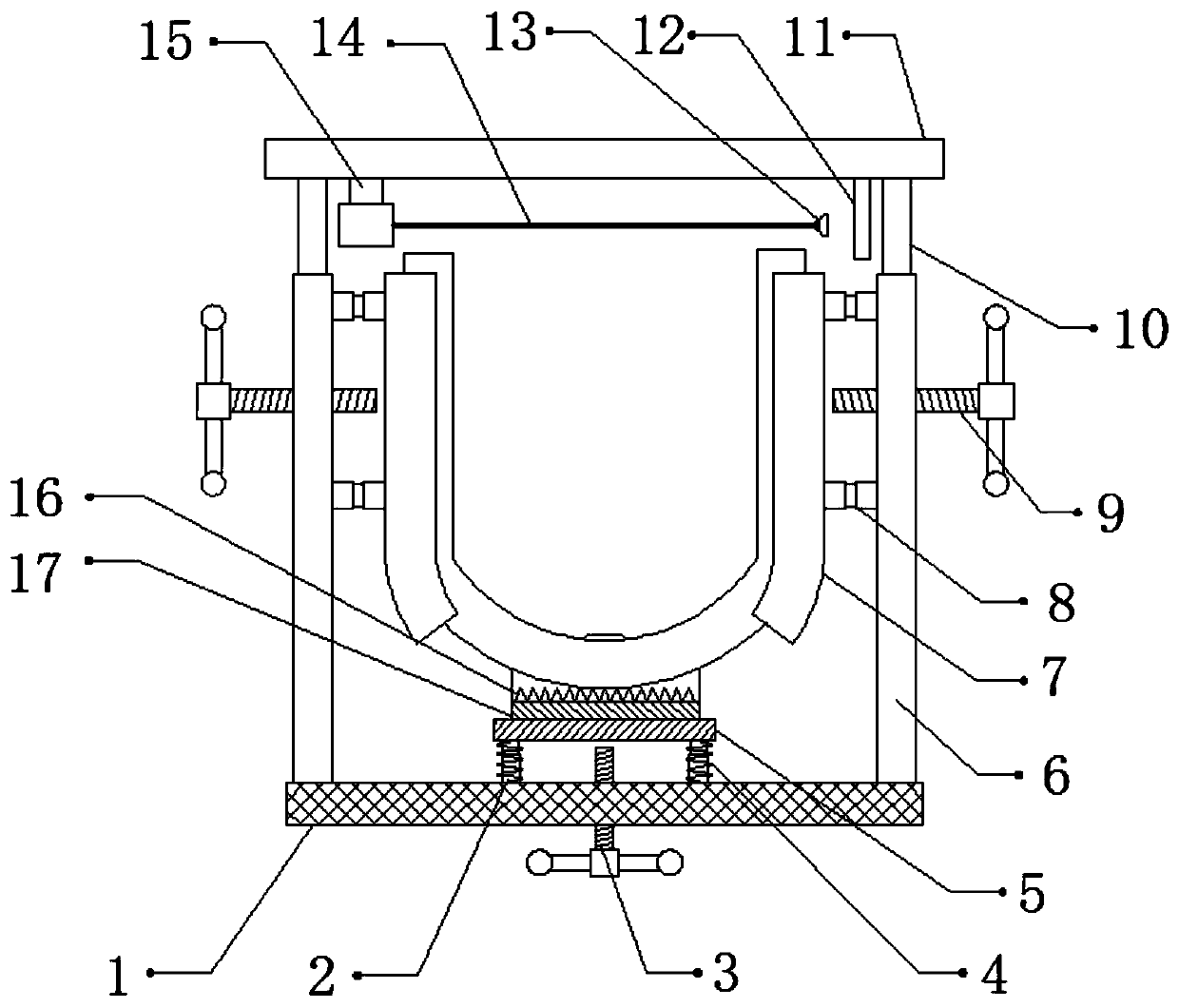

Detection device for pipe fitting production

PendingCN111288878AEasy to detect and handleAvoid breakageMechanical roughness/irregularity measurementsPrimary canine toothProtruding tooth

The invention discloses a detection device for pipe fitting production. The device comprises a fixed base, and fixing rods are fixed to the two sides of the outer wall of the top of the fixed base. Two second telescopic rods are fixed on the outer walls of the opposite sides of the two fixed rods; a clamping plate is fixed to the outer wall of one side of the second telescopic rod. Fixing groovesare formed in the outer walls of the opposite sides of the two clamping plates, restraining plates are bonded to the inner walls of the opposite sides of the fixing grooves, a plurality of convex teeth distributed at equal intervals are arranged on the outer walls of the sides of the restraining plates and the inner walls of the sides of the fixing grooves, wherein the convex teeth are in a caninetooth shape; and fixing shafts are fixed to the outer walls of the tops of the two fixing rods. According to the detection device, a U-shaped pipe is prevented from sliding off from the clamping plate and thus the deviation of detection data of the U-shaped pipe is avoided, the U-shaped pipe is prevented from sliding off to influence detection of the U-shaped pipe, and the clamping plate is prevented from clamping the U-shaped pipe with large force to damage the surface of the U-shaped pipe.

Owner:上海派腾特商务咨询有限公司

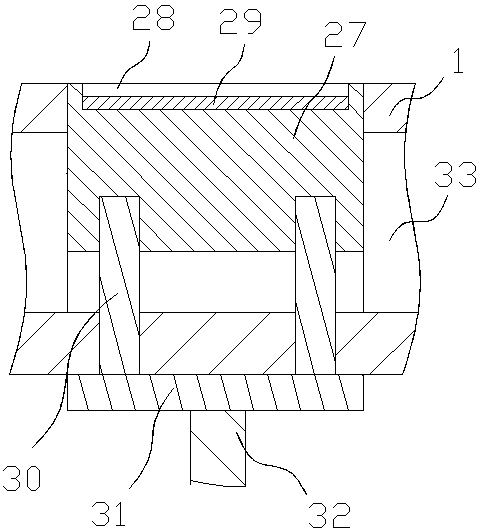

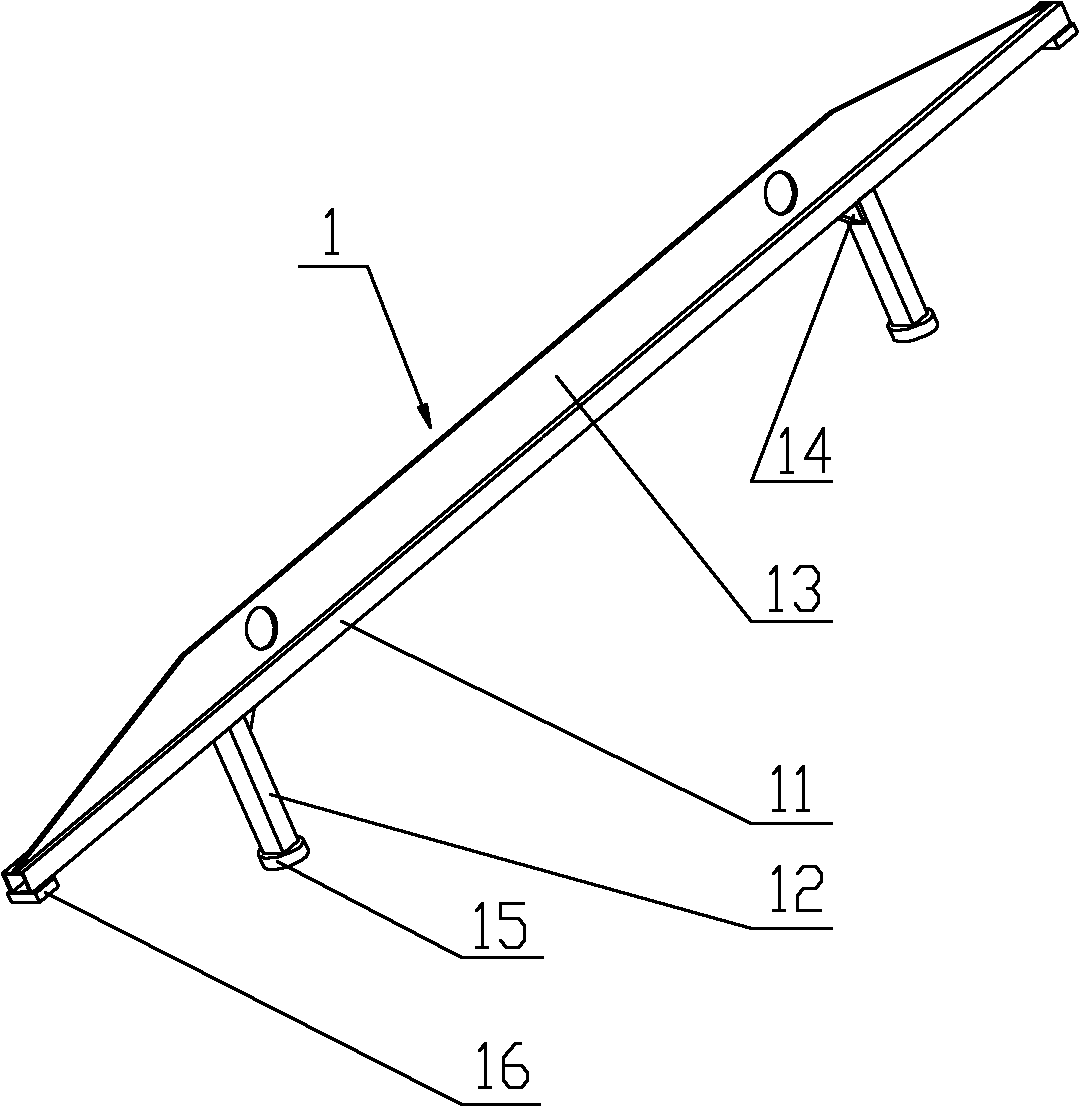

Planeness detection device

InactiveCN102759340ACheck flatnessCheck assembly qualityMeasurement devicesEngineeringBearing surface

The invention discloses a planeness detection device, which comprises a detection frame and two support seats of the same height, wherein the detection frame comprises a cross beam and at least one detection arm; the detection arm is vertically mounted on the cross beam; support planes are arranged at the upper parts of the support seats; the two ends of the cross beam of the detection frame are overlapped on the support planes of the support seats; the planeness detection device further comprises a detection platform; the detection platform is provided with a bearing surface for a flat plate work piece; and the lower ends of the support seats are fixed on the bearing surface of the detection platform. The planeness detection device provided by the invention has the advantages that through measuring the value of a clearance between the lower end surface of the detection arm and a mounting plane of the flat plate work piece, the planeness of the mounting plane of the flat plate work piece can be detected simply, conveniently and rapidly; and meanwhile, the assembly quality of other work pieces mounted on the mounting plane can be detected, and assembly adjustment can be made at any time according to detection situations, thereby improving the quality and the efficiency of assembly production of the equipment.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

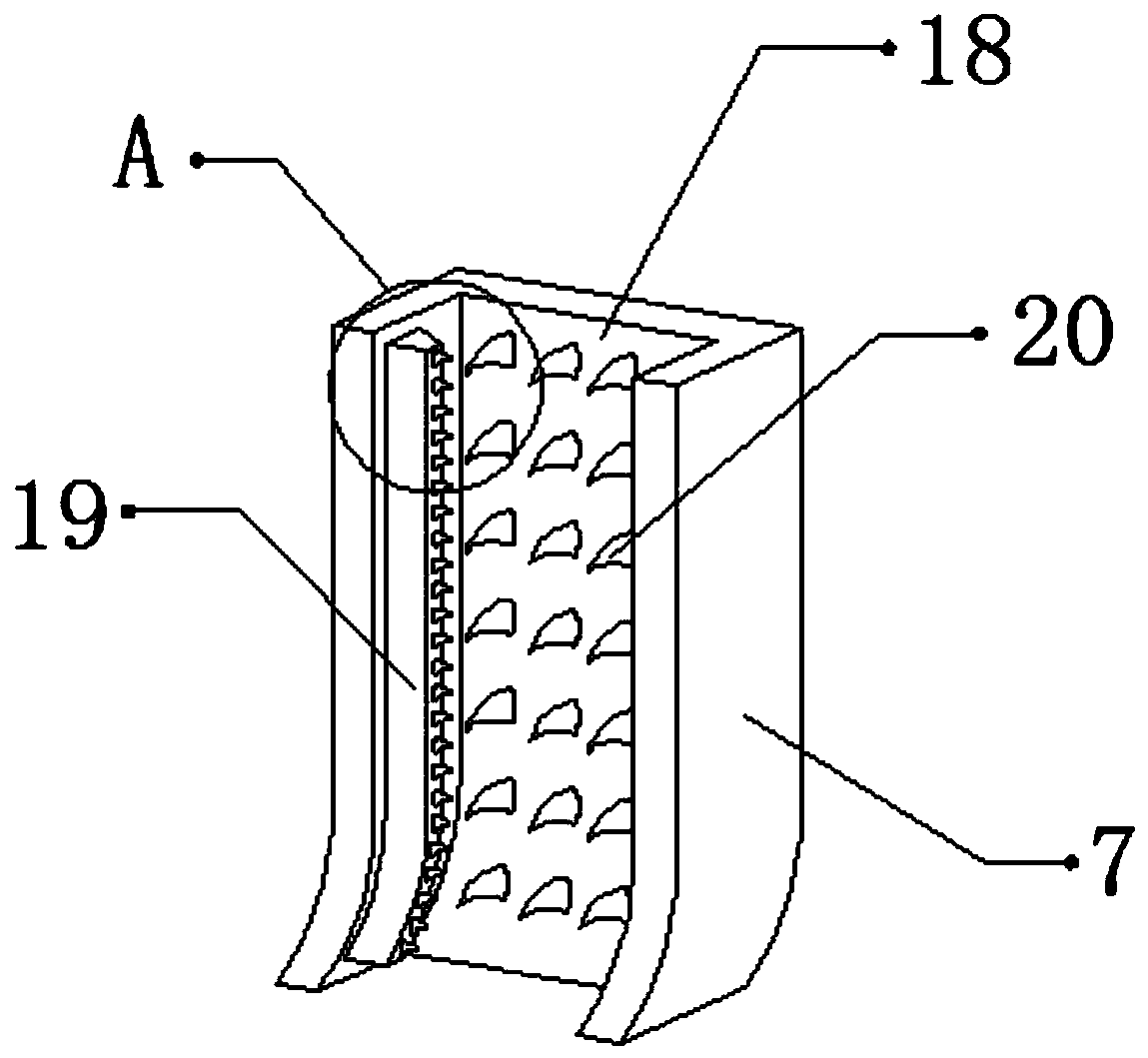

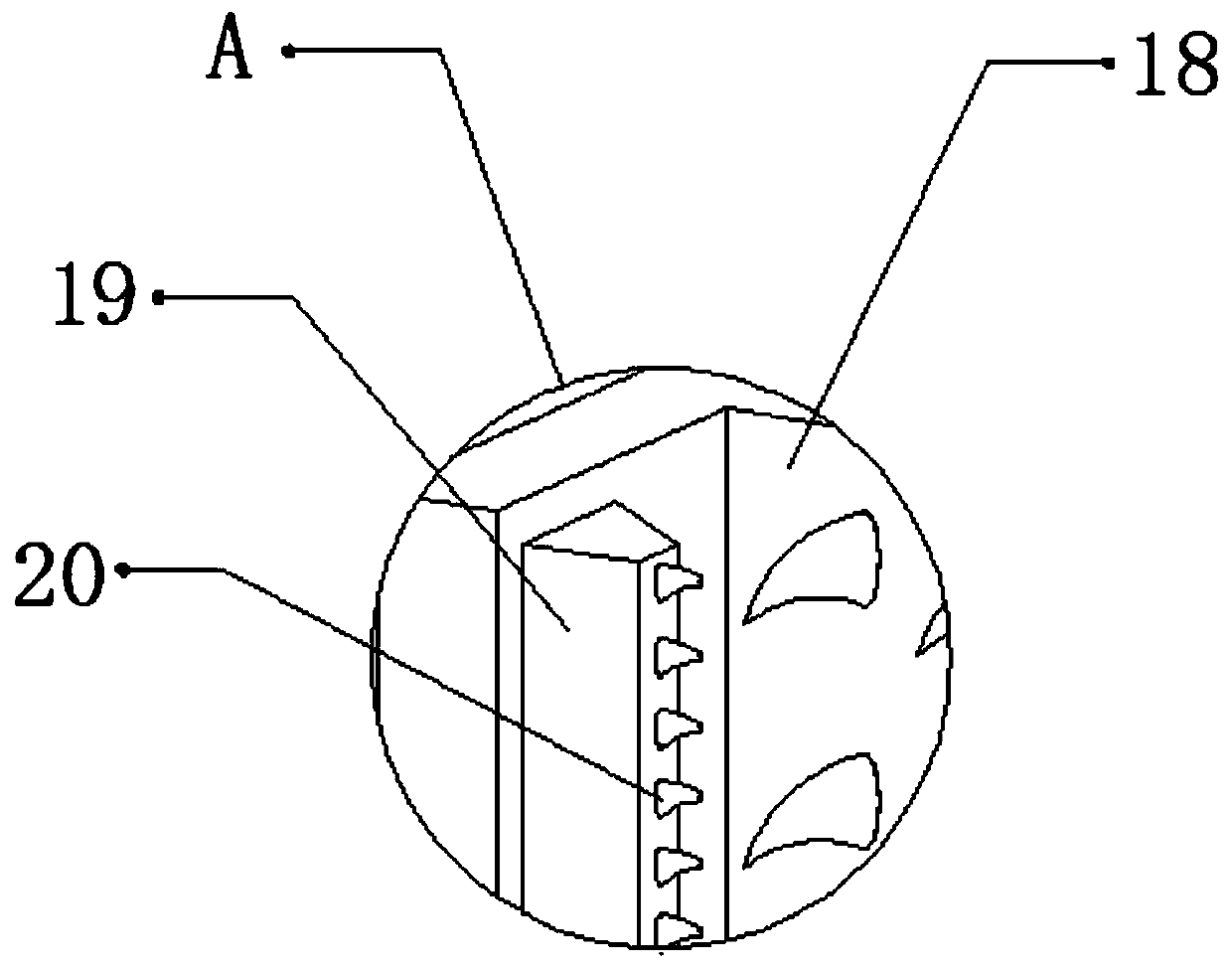

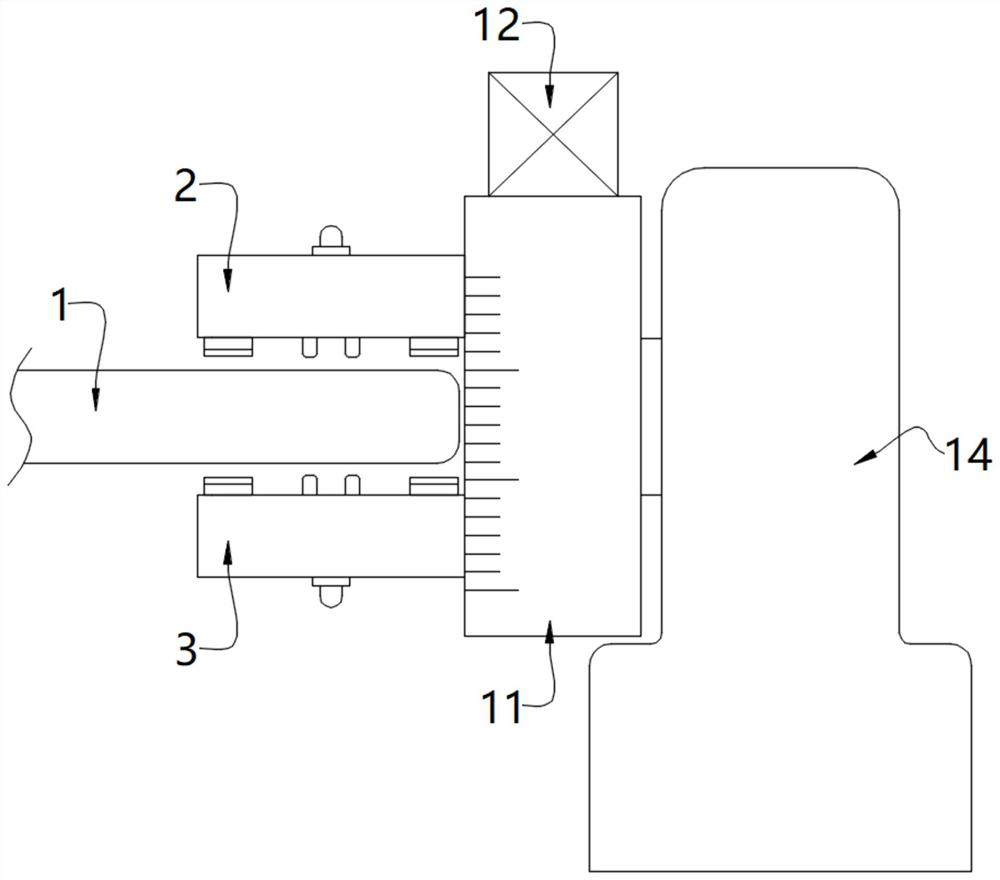

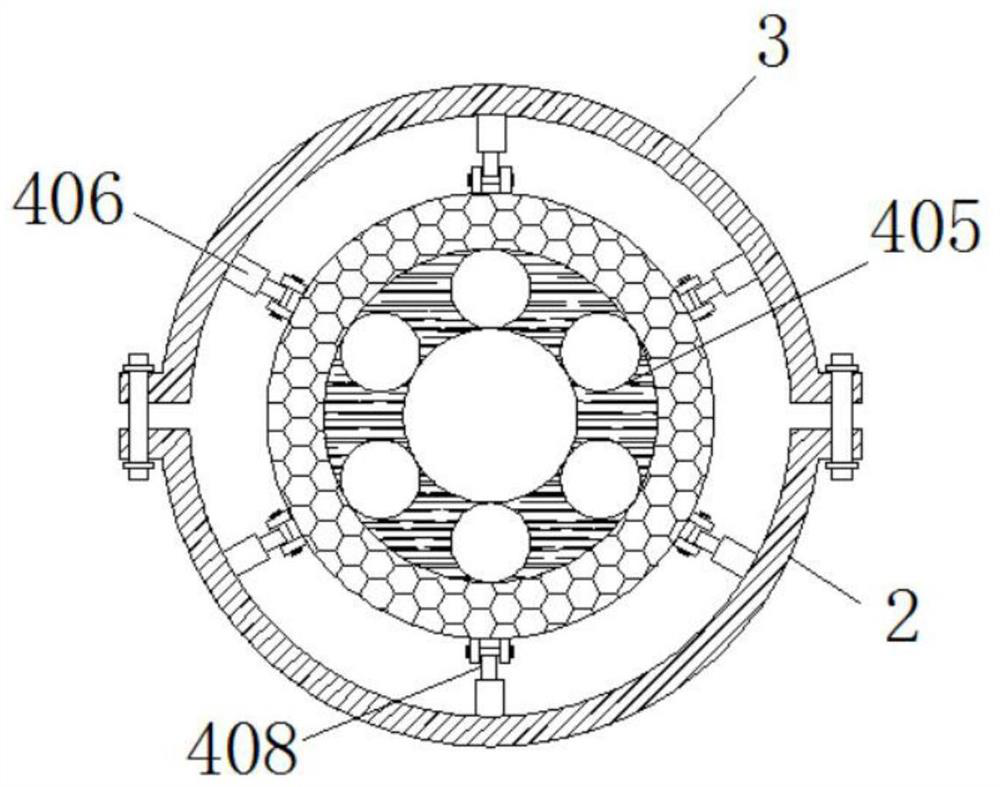

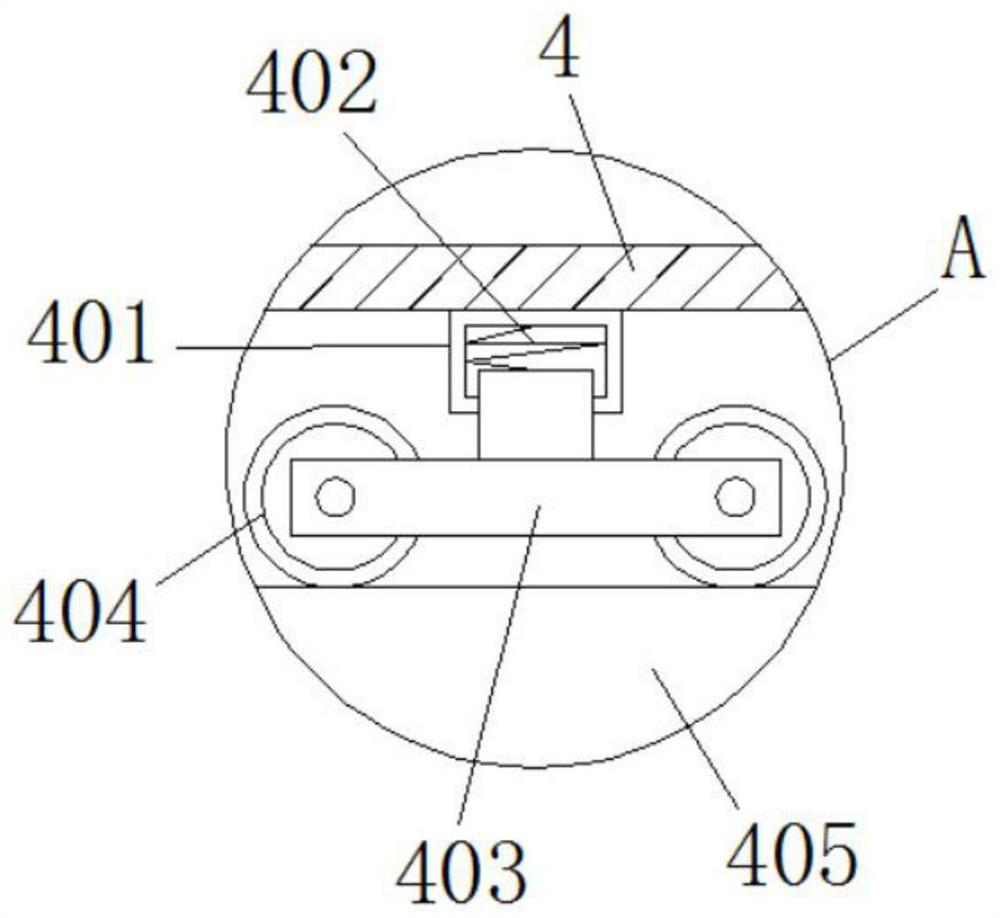

Fiber composite material cable core characteristic detection device

ActiveCN113063657ATorsion resistance detectionVersatileMechanical diameter measurementsMaterial strength using steady torsional forcesFiberStructural engineering

The invention relates to a fiber composite material cable core characteristic detection device which comprises an upper clamping plate, a lower clamping plate, a control assembly and a detection assembly. The control assembly is connected with the upper clamping plate and the lower clamping plate and drives the upper clamping plate and the lower clamping plate to move in opposite directions so as to realize clamping or clamping release of a cable core; the driving assembly is connected with the control assembly and can drive the control assembly, the upper clamping plate and the lower clamping plate to rotate around the shaft when the tail end of the cable core is clamped, and torsion detection of the cable core is achieved. The detection assembly is arranged on the upper clamping plate and the lower clamping plate, and when the cable core moves in the axial direction of the cable core and in the gap between the upper clamping plate and the lower clamping plate, the detection assembly detects the flatness of the surface of the cable core. Compared with the prior art, the torsion resistance of the cable core can be detected, the diameter of the cable core can be measured, the surface flatness of the cable core can be detected, the overall detection efficiency is high, and operation is convenient.

Owner:SHANGHAI UNIV OF ENG SCI

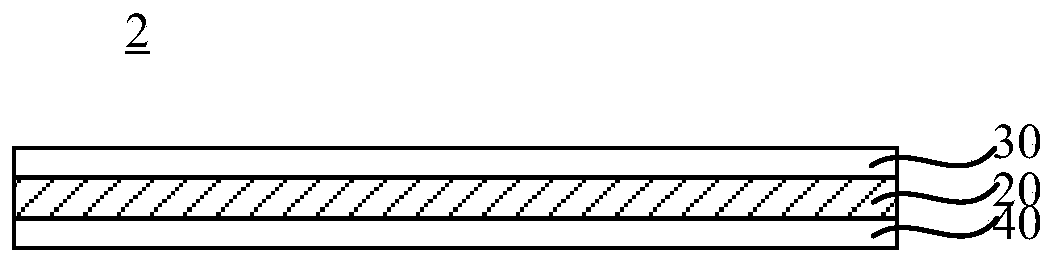

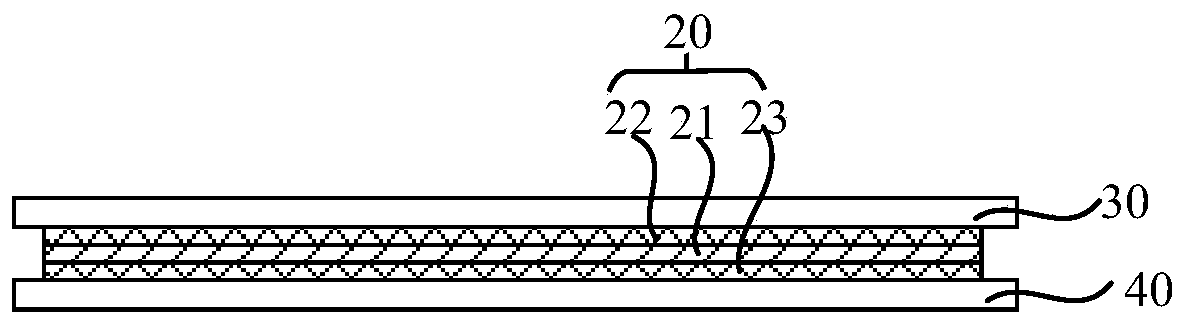

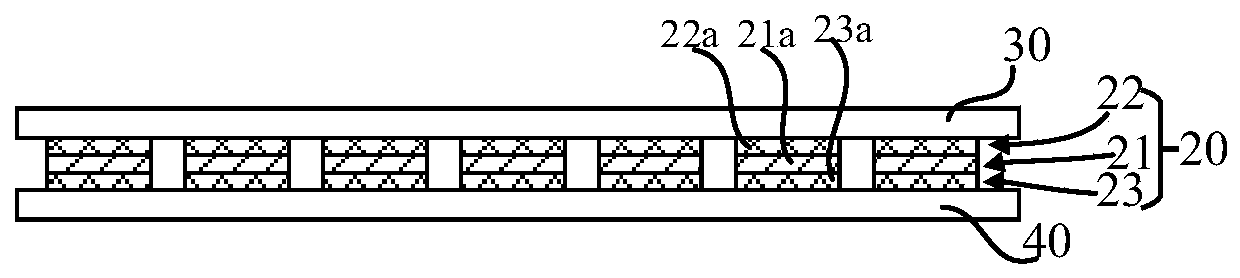

Detection device, evaporation system and detection method

The invention discloses a detection device, an evaporation system and a detection method. The detection device is used for detecting the flatness of a to-be-detected substrate in the evaporation process; an induction layer is included, and can be arranged on the surface of a magnetic plate so that the magnetic plate can be used for attracting a mask plate; in the pasting process of the mask plateand the to-be-detected substrate, the induction layer can be pasted to the to-be-detected substrate, and the induction layer can generate an induction signal according to the flatness of the surface,pasted to the induction layer, of the to-be-detected substrate. According to the detection device, when the surface, pasted to the induction layer, of the to-be-detected substrate is not flat, the induction layer can generate the induction signal; through the induction signal, whether the surface, pasted to the induction layer, of the to-be-detected substrate is flat or not can be judged, then when it is detected that the surface of the to-be-detected substrate is not flat, evaporation on the to-be-detected substrate can stop in time, and waste of an evaporation material is avoided.

Owner:YUNGU GUAN TECH CO LTD

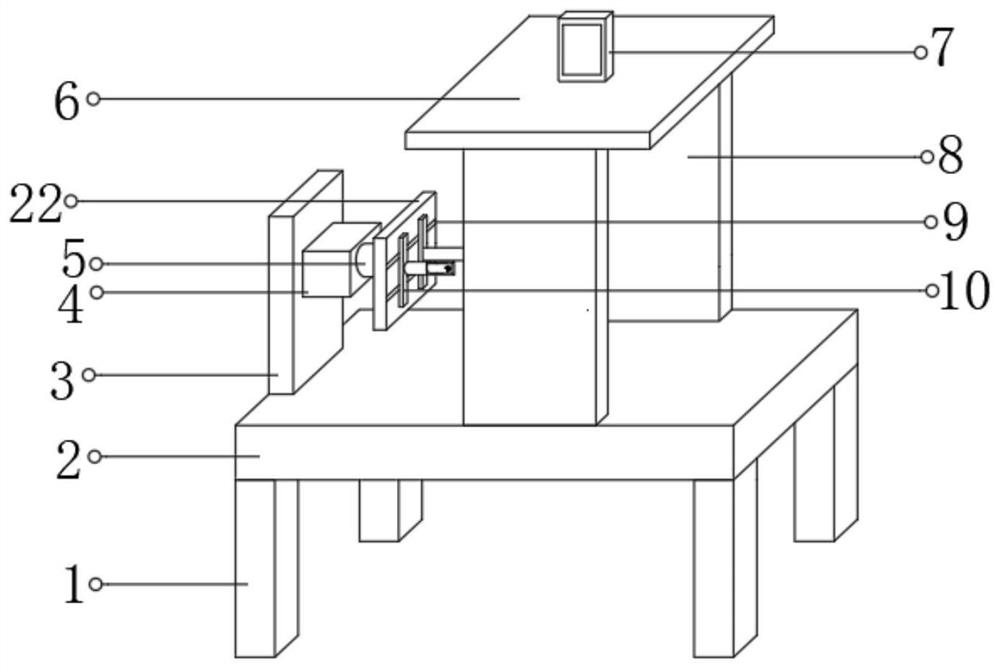

Metal tube detection device

InactiveCN111721187ACheck flatnessSimple and fast operationSpraying apparatusMechanical roughness/irregularity measurementsElectric machineEngineering

The invention discloses a metal tube detection device, which comprises a workbench, wherein a vertical plate is fixed to one side of the outer wall of the top of the workbench, a rotating motor is fixed on the outer wall of one side of the vertical plate, supporting plates are fixed to the two ends of the outer wall of the top of the workbench, a top plate is fixed to the top outer wall of the supporting plate, a sliding rail is arranged on the outer wall of the bottom of the top plate, a sliding block is slidably connected to the outer wall of the bottom of the sliding rail, a telescopic rodis fixed to the outer wall of the bottom of the sliding block, a sliding ball sleeve is fixed to one end of the telescopic rod, a pressure sensor is fixed to the inner wall of the top of the sliding ball sleeve, a limiting sleeve is fixed to the outer wall of the bottom of the pressure sensor, and a sliding ball is arranged in the limiting sleeve. The flatness of the whole outer wall of the metaltube can be detected, warning sound is sent out and displayed in a display screen when unevenness is found, the metal tube can be doubly fixed, deviation of the metal tube during detection can be avoided, and the metal tube can be marked at the same time so as to facilitate distinguishing.

Owner:张贵阳

Cast part blank rapid inspection tool

PendingCN113091690ACheck flatnessComprehensive detectionSpecial purpose weighing apparatusWorkbenchStress sensors

The invention discloses a cast part blank rapid inspection tool. The rapid inspection tool comprises a workbench, a cylindrical groove is formed in the workbench, an electric cylinder is arranged in the cylindrical groove, a lifting mechanism is arranged at the top of the electric cylinder, and the lifting mechanism comprises a supporting plate matched with the cylindrical groove, an annular strip, a supporting plate, a connecting rod and a pressure sensor. An annular track is arranged on the outer side of the cylindrical groove on the workbench, a detection mechanism is arranged on the annular track in a sliding mode, and the detection mechanism comprises a plurality of sliding bases, a sliding groove matched with the annular track, a plurality of permanent magnets, a plurality of coils, a mounting groove and a distance measuring sensor. A controller is arranged on one side of the annular track on the upper surface of the workbench and electrically connected with the electric cylinder. The sliding bases slide to drive the distance measuring sensor to move circumferentially around a part, so that the surface of the part is comprehensively detected.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

A cable connection detection device for cable installation

ActiveCN112484615BEasy to disassembleImprove applicabilityMechanical roughness/irregularity measurementsElectric cablesWorkbench

The invention relates to a cable connection detection device for cable installation, comprising a workbench, the top of the workbench is fixedly connected with a lower sleeve, the two ends of the lower sleeve are fixed with an upper sleeve by bolts, and the connection between the lower sleeve and the upper sleeve is fixed. An adjustment mechanism is installed on the inner wall, and the inside of the adjustment mechanism includes a through pipe fixed on the inner wall of the lower casing and the upper casing. The inside of the through pipe is fixedly connected with a first spring, and the other end of the first spring is fixedly connected with a connecting piece. Both sides of the part are fixedly connected with drive wheels. The lower casing and the upper casing are fixed by bolts, making the device easy to disassemble or install; by setting the first spring and the second spring, the transmission wheel and the pulley can be pressed and fitted to the outer wall of the cable body of different sizes, Therefore, the detection of cable bodies with different sizes is realized, and the applicability is improved.

Owner:深圳市成天泰电缆实业发展有限公司

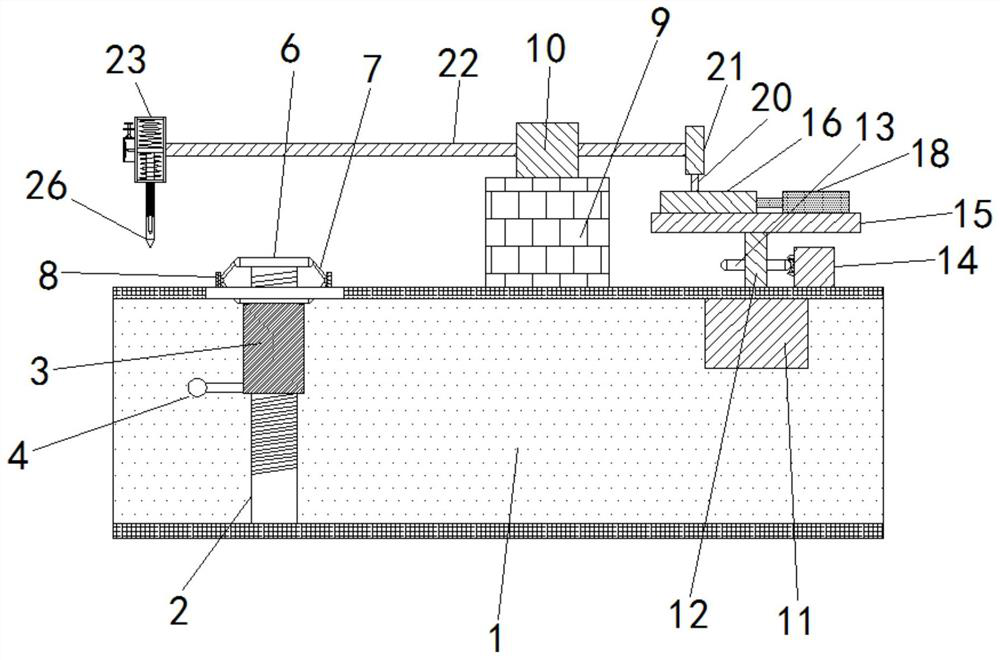

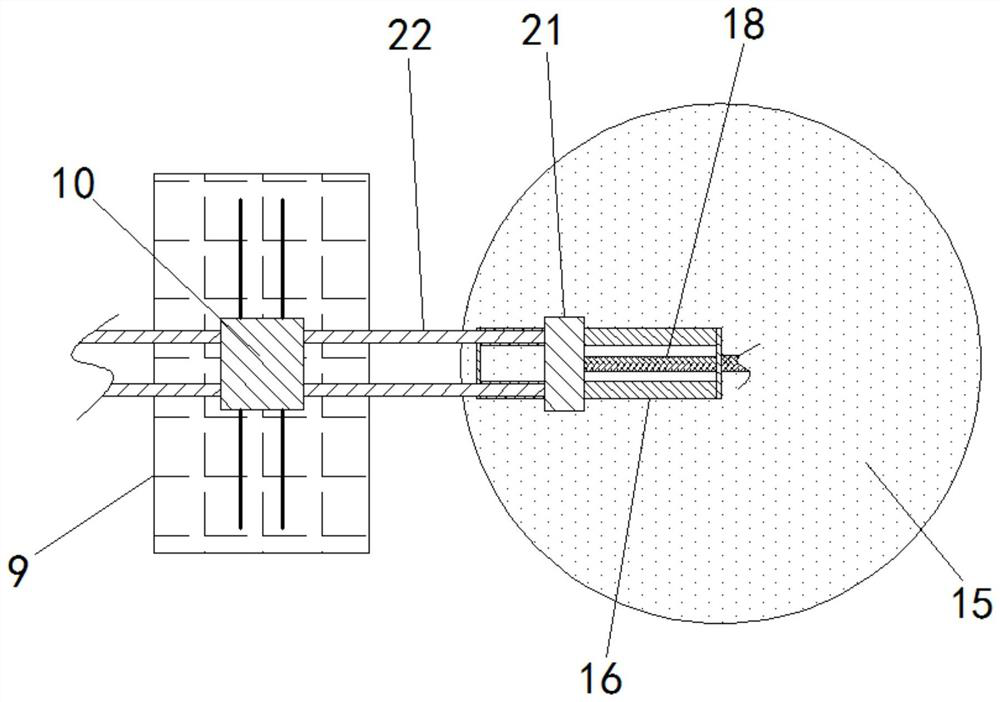

A flatness detection device for brake discs of new energy vehicles

ActiveCN110926316BEasy to fixCheck flatnessMechanical roughness/irregularity measurementsNew energyStructural engineering

The invention relates to the technical field of brake discs, and discloses a flatness detection device for brake discs of new energy vehicles, which includes a workbench. There is a sleeve ring on the movable sleeve, and a fixed ring is fixedly sleeved on the top of the column. Symmetrical connecting rods are arranged on the fixed ring and the ring, and rubber braces are arranged between the connecting rods. A driving device is installed, and the upper end of the driving device is provided with a rotating shaft, and the upper end of the rotating shaft is provided with a turntable. The flatness detection device for brake discs of new energy vehicles first fixes the brake discs through rubber supports, cooperates with the driving device to drive the detection pen to detect, and then cooperates with the air duct blowing and cleaning and the liquid spray pipe to spray paint, so as to achieve the smoothness of the brakes. Different areas on the disc are detected, the detection accuracy is improved, and the uneven area on the brake disc can be marked and reminded.

Owner:龙口市江达汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com