Building board surface flatness detection device

A surface flatness and detection device technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of failure of building boards, insufficient surface flatness, and inability to guarantee surface flatness, etc., and achieve the effect of preventing construction accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

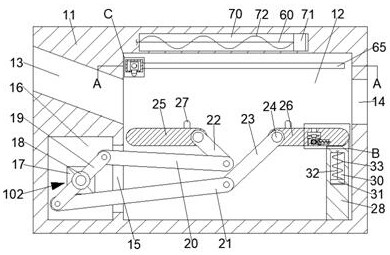

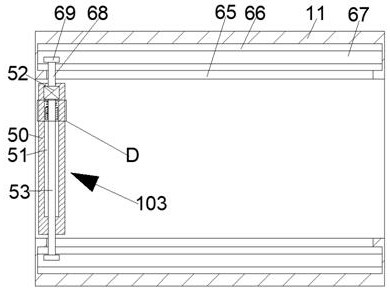

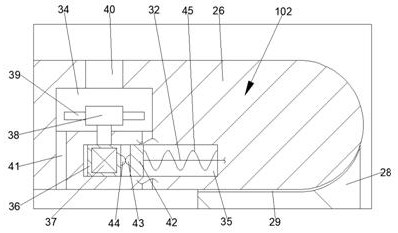

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] A device for detecting the surface flatness of building boards according to the present invention includes a detection body 11, and the detection body 11 is provided with an inversion chamber 12, and the left side of the inversion chamber 12 is connected with a door opening to the left. Feeding chamber 13, the feeding chamber 13 is set to incline from upper left to lower right, the right side of the turning chamber 12 is connected with a discharge chamber 14 with an opening to the right, between the front and rear walls of the turning chamber 12 Rotationally connected with a left-right symmetrical turning shaft 24, the outer surface of the turning shaft 24 on the left side is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com