A cable connection detection device for cable installation

A cable connection and detection device technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of inability to meet the detection of cables of different sizes, external cladding depressions or convex hulls, and unsatisfactory detection results. Achieve stable placement, improve stability, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

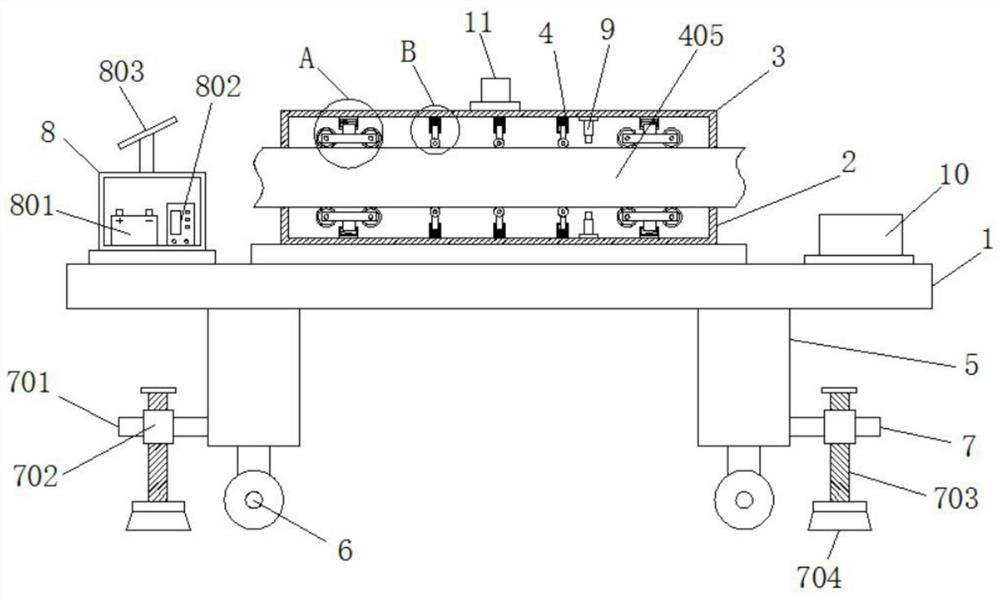

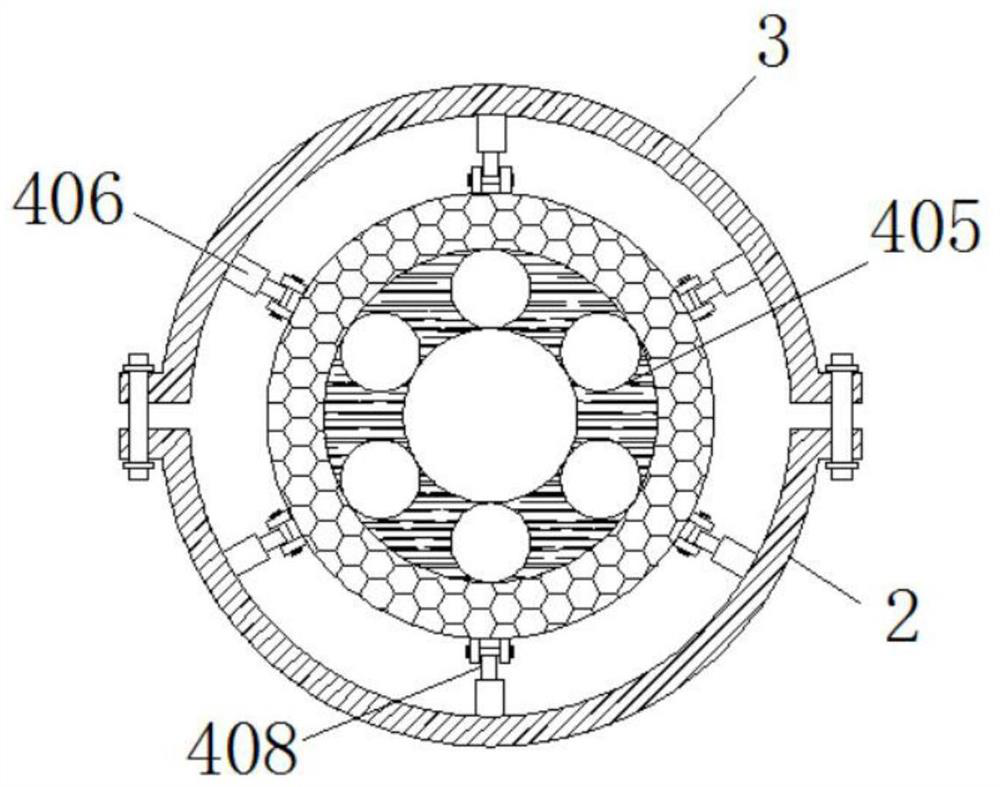

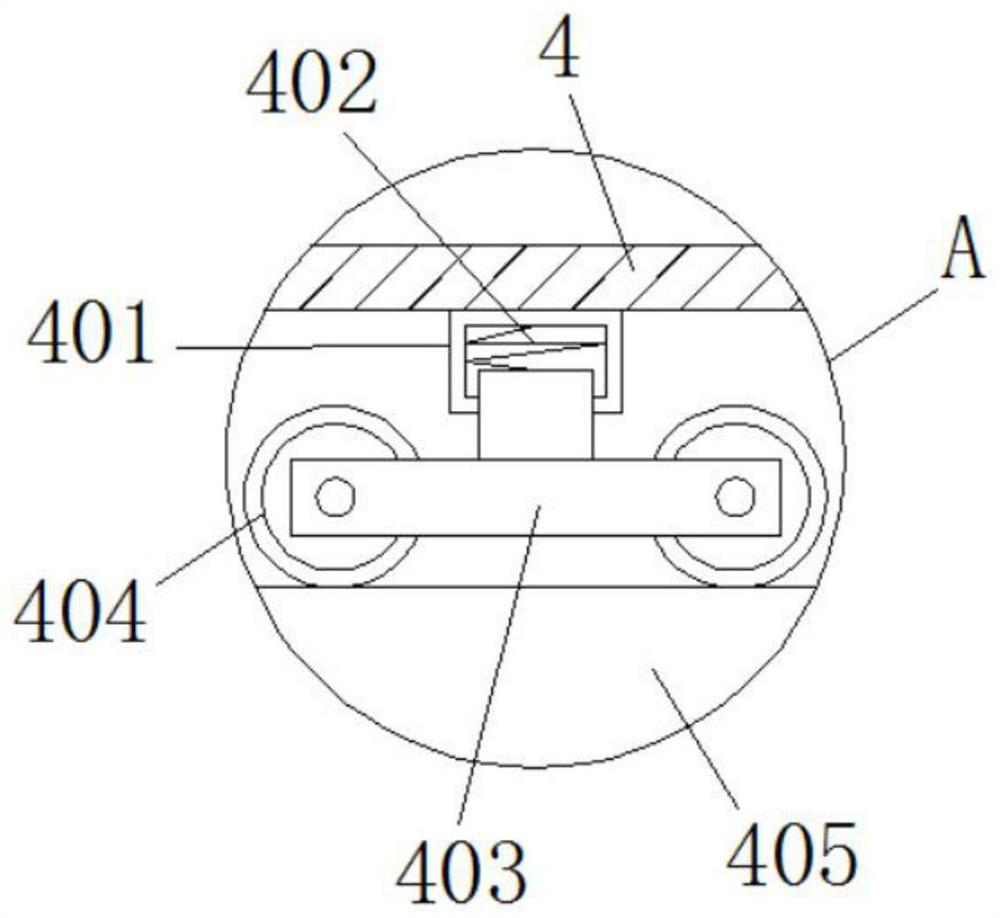

[0029] see Figure 1-4 , a cable connection detection device for cable installation, comprising a workbench 1, the top of the workbench 1 is fixedly connected with a lower sleeve 2, and the two ends of the lower sleeve 2 are fixed with an upper sleeve 3 by bolts, and the lower sleeve 2 An adjustment mechanism 4 is installed on the inner wall of the upper casing 3, and the inside of the adjustment mechanism 4 includes a through pipe 401 fixed on the inner wall of the lower casing 2 and the upper casing 3, and the inside of the through pipe 401 is fixedly connected with a first spring 402, And the other end of the first spring 402 is fixedly connected with a connector 403, and the two sides of the connector 403 are fixedly connected with a transmission wheel 404, and the outer wall of the transmission wheel 404 is fitted with a cable body 405, and one end of the connector 403 is connected to the through pipe The inner cavity of 401 is a flexible connection, and the inner walls o...

Embodiment 2

[0039] The use method of the above-mentioned cable connection detection device for cable installation is as follows:

[0040] S1. By placing the cable body 405 on the inner walls of the lower casing 2 and the upper casing 3, under the action of the first spring 402 and the second spring 407, the transmission wheel 404 and the pulley 409 press the outer wall of the cable body 405 fit.

[0041] S2. When the cable body 405 moves inside the lower sleeve 2 and the upper sleeve 3, if the surface of the cable body 405 is uneven, under the action of the second spring 407, the pulley 409 drives the inner rod 408 to the outside The inside of the tube 406 is elastically moved. When the inner rod 408 is in contact with the pressure sensor 4010, the pressure sensor 4010 sends a signal to the PLC control board 802, and the PLC control board 802 sends an instruction to the nozzle 9 and the alarm 11, so that the nozzle 9 is connected to the cable body 405. The unevenness of the outer wall is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com