Metal tube detection device

A detection device and metal tube technology, which can be applied to measurement devices, mechanical measurement devices, injection devices, etc., can solve the problems of inability to comprehensively detect the surface of metal tubes and low detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

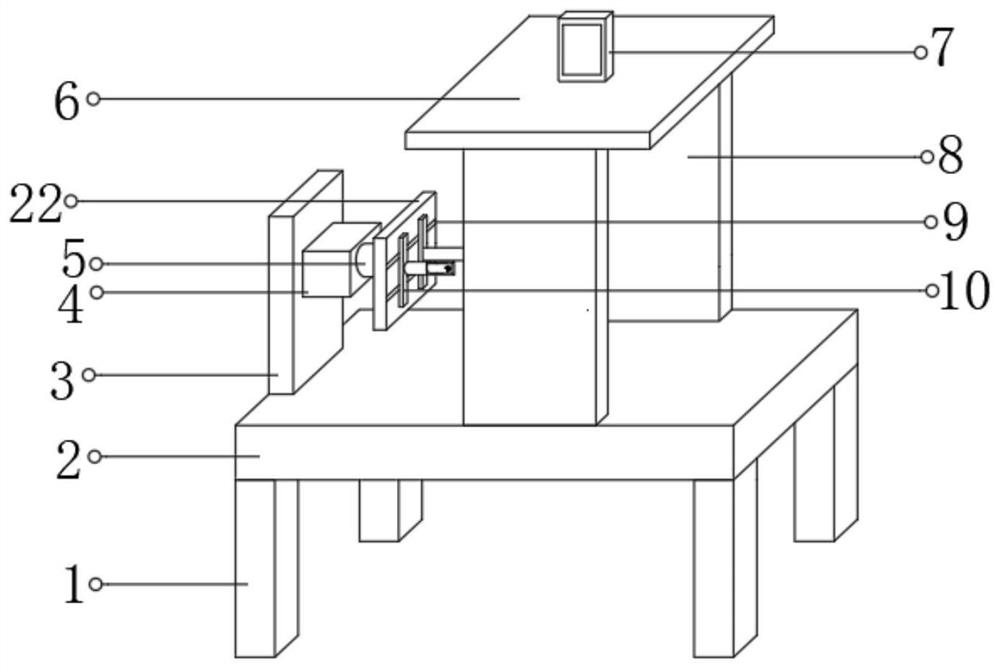

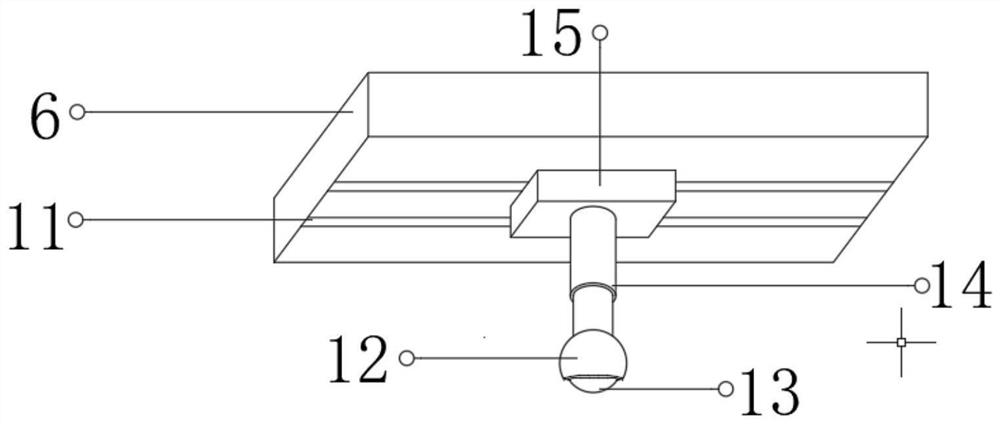

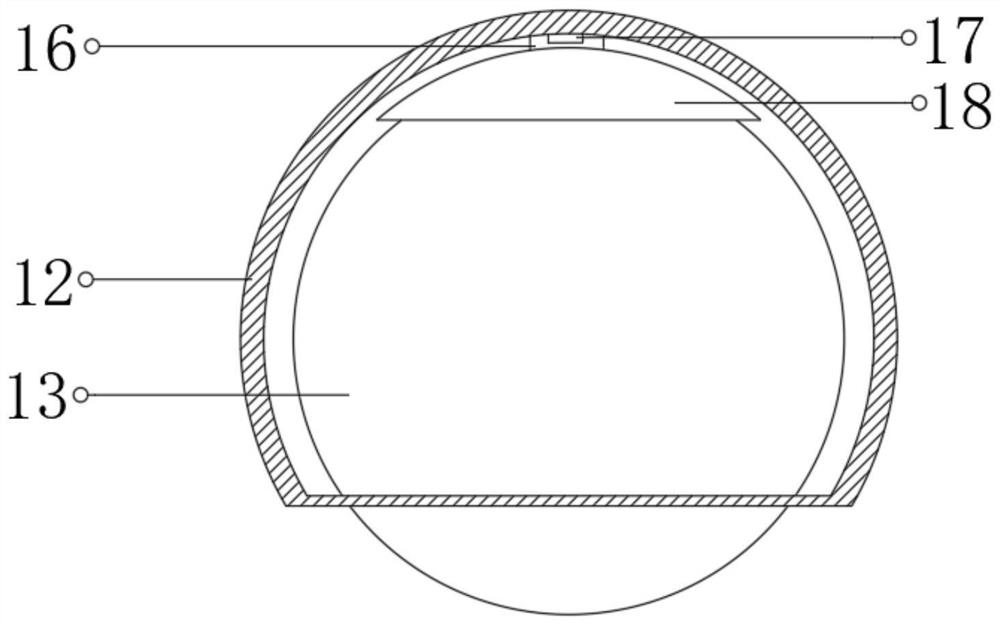

[0027] refer to Figure 1-4 , a metal pipe detection device, comprising a workbench 2, one side of the top outer wall of the workbench 2 is connected with a vertical plate 3 by bolts, and the outer wall of one side of the vertical plate 3 is connected with a rotating motor 4 by bolts, and the outer wall of the rotating motor 4 rotates A rotating rod 5 is connected, and the outer wall on one side of the rotating rod 5 is connected with a fixing mechanism by bolts. Both ends of the top outer wall of the workbench 2 are connected with a support plate 8 by bolts, and the top outer wall of the support plate 8 is connected with a top plate 6 by bolts. 6 The outer wall of the top is connected with the console 7 by bolts, and the surface of the console 7 is embedded with a display screen, which can display the pressure. The outer wall of the bottom of the top plate 6 is provided with a slide rail 11, and the bottom outer wall of the slide rail 11 is slidably connected with a slider 15 ...

Embodiment 2

[0031] refer to Figure 5 , a metal pipe detection device, also includes a support plate 8 one side outer wall is connected with a watercolor paint box 24 by bolts, and the watercolor paint box 24 side outer wall is connected with a nozzle 23 by bolts, can detect the metal pipe with uneven surface Spray paint to mark for subsequent identification.

[0032]Working principle: When in use, first gather the sliding blocks 10 in the chute 9, and at the same time control the hydraulic rod 21 to shrink, put the metal pipe to be detected on the two fixed rods 19, and move the two sliding blocks 10 in the opposite direction to make Two fixing rods 19 support the metal pipe. After being supported, the hydraulic rod 21 is controlled to stretch, and the metal pipe is fixed again from the inside of the metal pipe. Double measures prevent the metal pipe from shifting during the detection process, and then let the telescopic rod 14 stretch Make the slide ball 13 contact the surface of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com