Fiber composite material cable core characteristic detection device

A fiber composite material and detection device technology, which is applied in the direction of measurement device, analysis material, strength characteristics, etc., can solve the problem of single function, inability to detect the torsion resistance of carbon fiber composite material cable cores, and inability to measure the diameter and diameter of carbon fiber composite material cable cores. Surface flatness and other issues, to achieve the effect of diversification of functions and detection of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

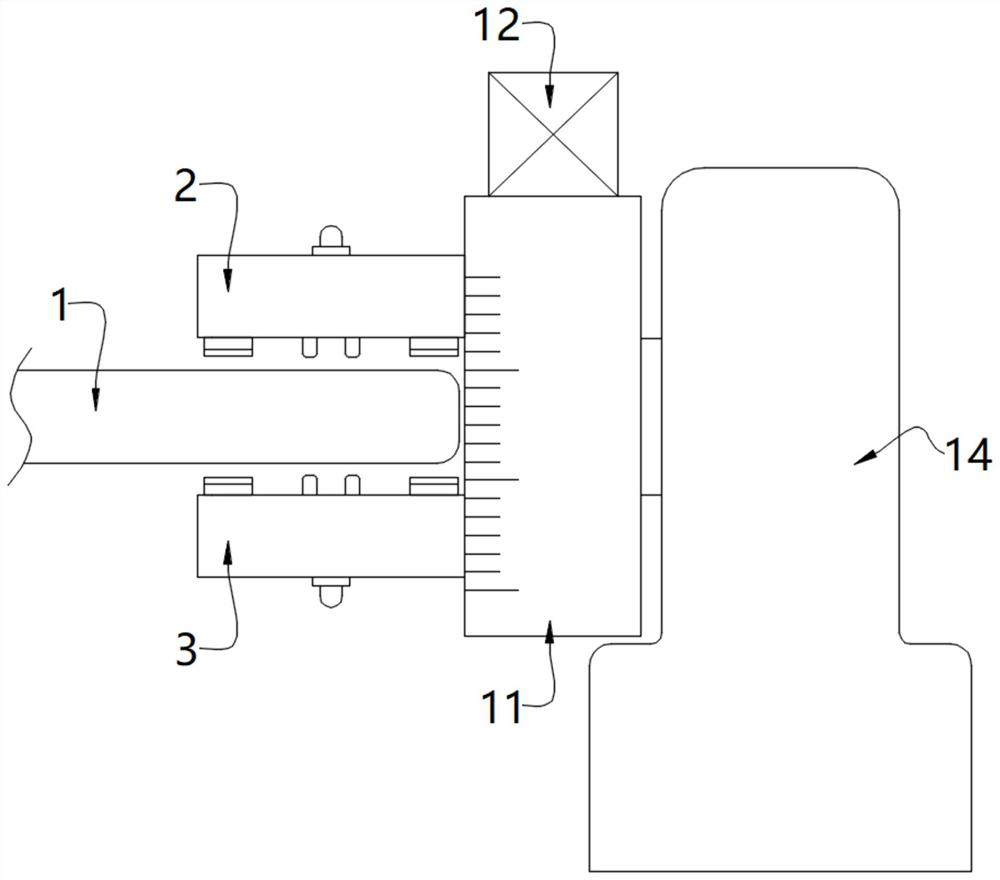

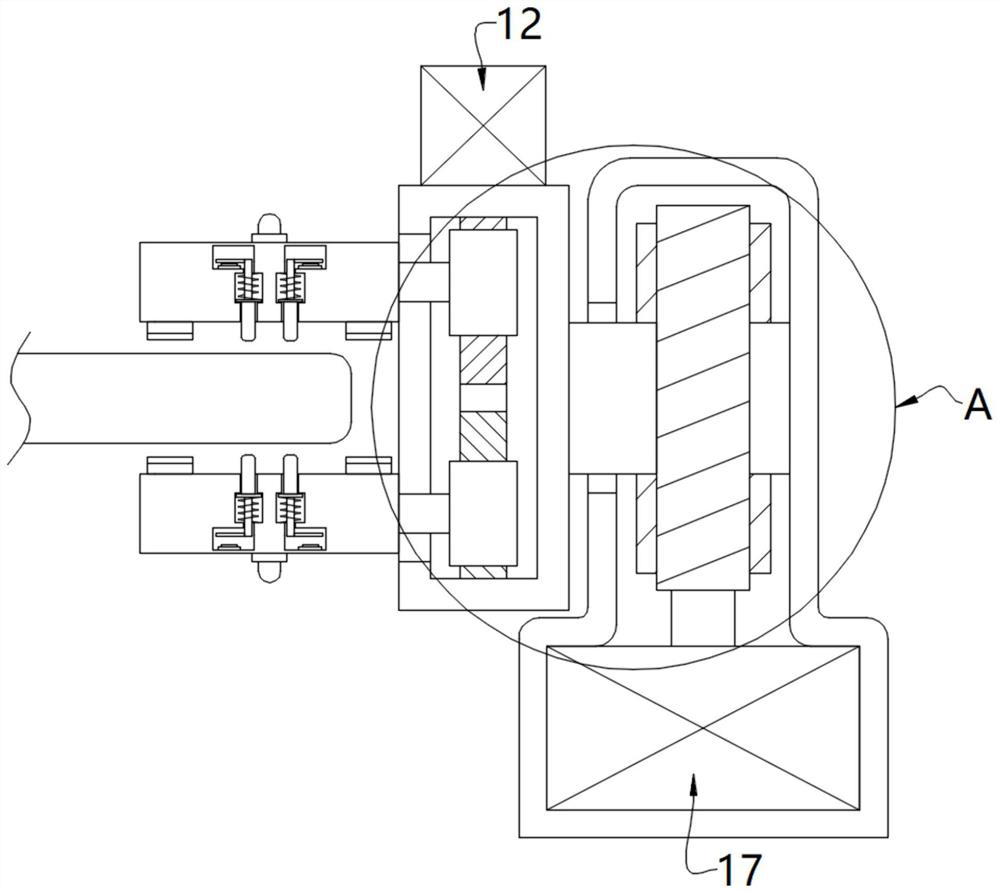

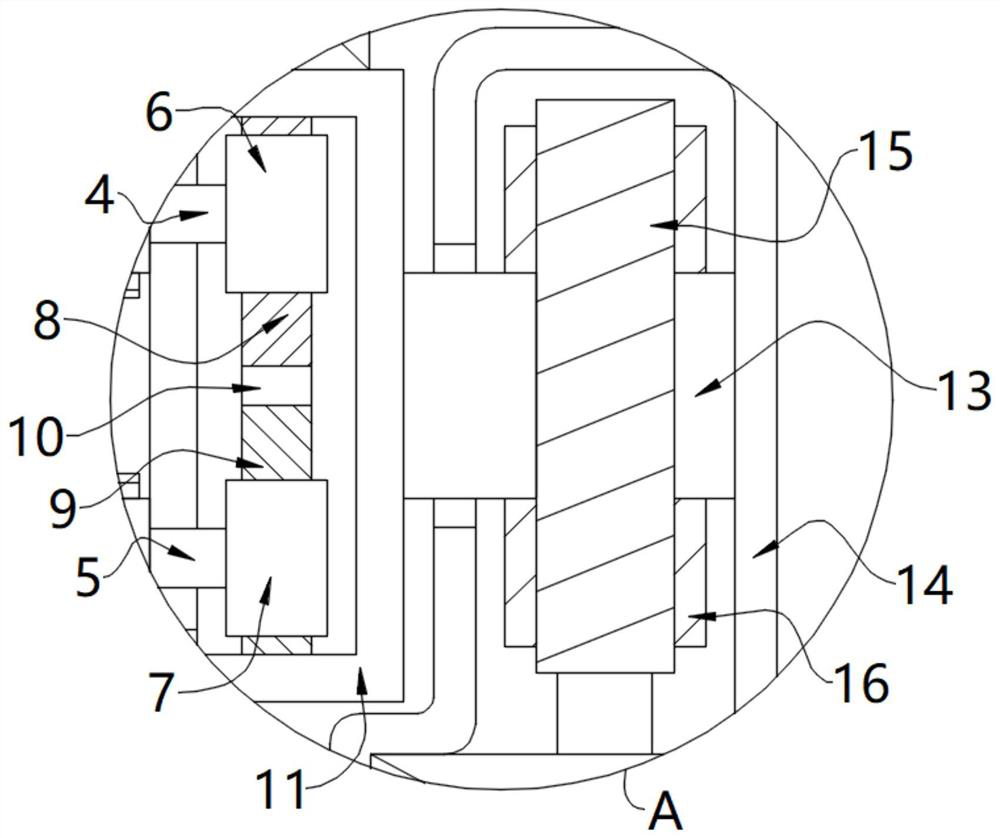

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] see Figure 1-7 , in the fiber composite material cable core characteristic detection device in the present embodiment, the upper splint 2 is arranged movably on the top of the cable core 1, and the lower splint 3 is movably arranged at the bottom of the cable core 1, and the upper splint 2 and the lower splint are arranged The control assembly at the end of 3 drives the upper splint 2 and the lower splint 3 to move in reverse.

[0044] The driving assembly connected with the control assembly through the rotating shaft 13 drives the control assembly, the upper splint 2 and the lower splint 3 to rotate around the axis.

[0045] Both the upper splint 2 and the lower splint 3 are equipped with detection components, which are used to detect the flatness of the surface of the cable core 1 when the cable core 1 moves axially in the gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com