Building formwork or floor slab construction control method and special straightedge

A control method and formwork technology, which is applied in construction, building structure, and building material processing, can solve the problems of wasting materials and manpower, cannot effectively control the thickness of the floor, and cannot guarantee the quality of the project, and achieve the goal of precise pouring construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

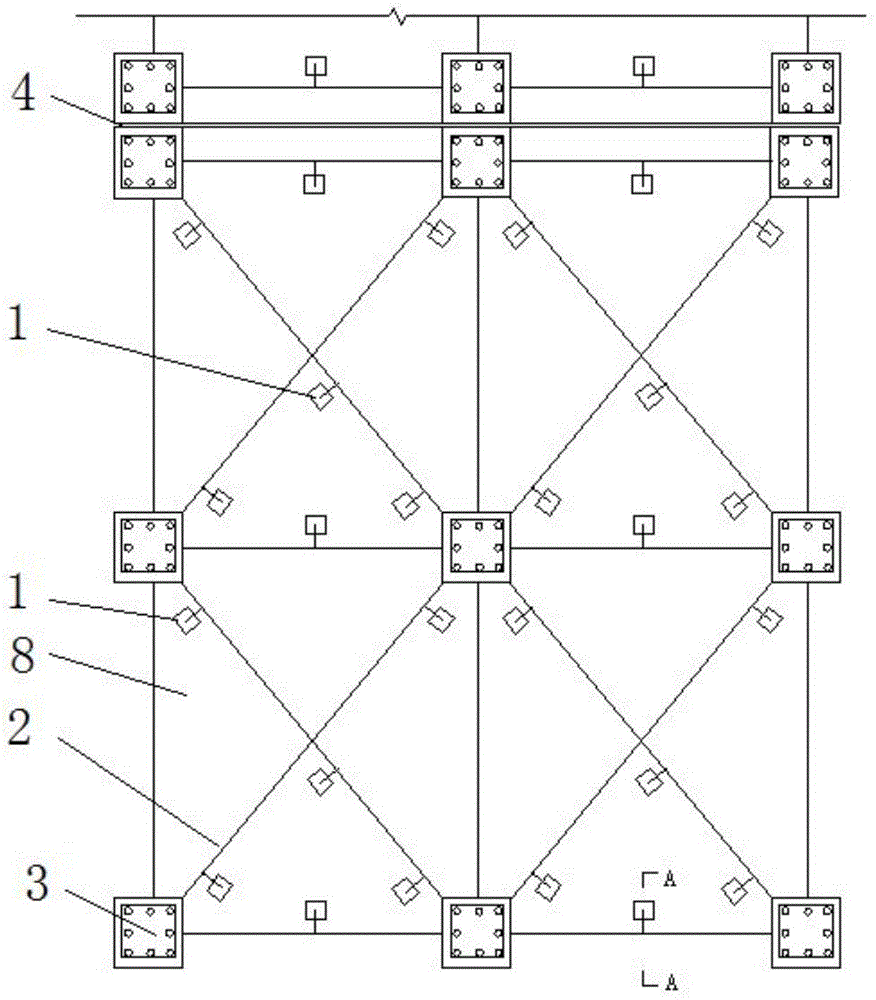

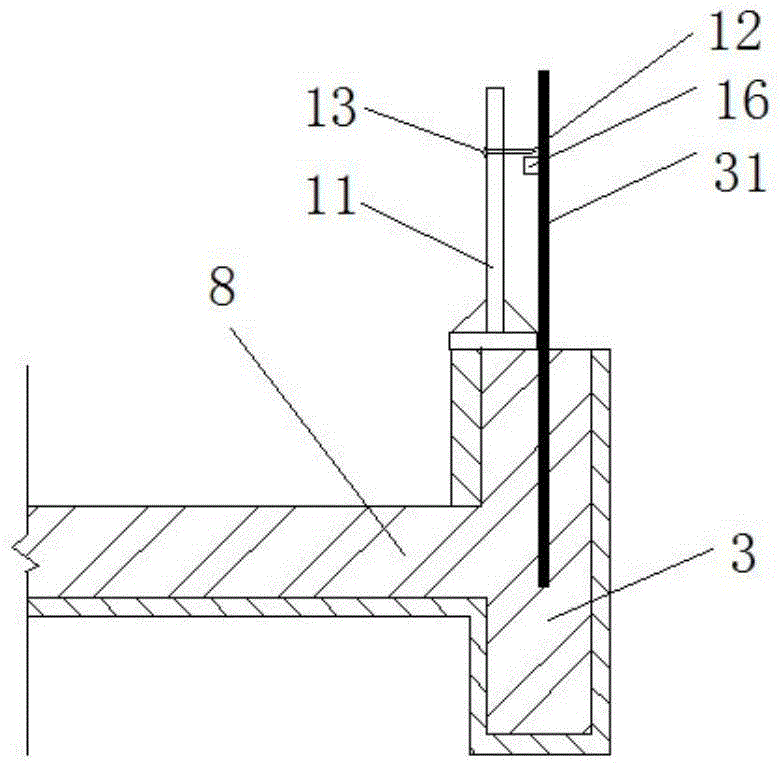

[0053] Example 1, see Figure 1-Figure 10 , Figure 17 to Figure 19 , the floor formwork or floor slab construction control method provided by the present embodiment, it comprises the following steps:

[0054] (1) Prepare a special calibration ruler 1 and a reference line rope 2; on the special calibration ruler 1, the construction reference correction point 12 of the floor template 7 or the floor slab 8 is preset, and the correction point 12 is vertical to the bottom of the special calibration ruler 1 The distance is equal to the vertical distance from the construction datum point 32 of the column steel bar to the upper surface of the floor template 7 or the floor slab 8; two nails 13 are horizontally set on the special calibration ruler 1, and the nail points of the two nails 13 are respectively the floor template 7 or the floor slab 8. Correction point 12 for floor 8 construction;

[0055] (2) Determine the elevation of the floor template 7, or the pouring thickness of th...

Embodiment 2

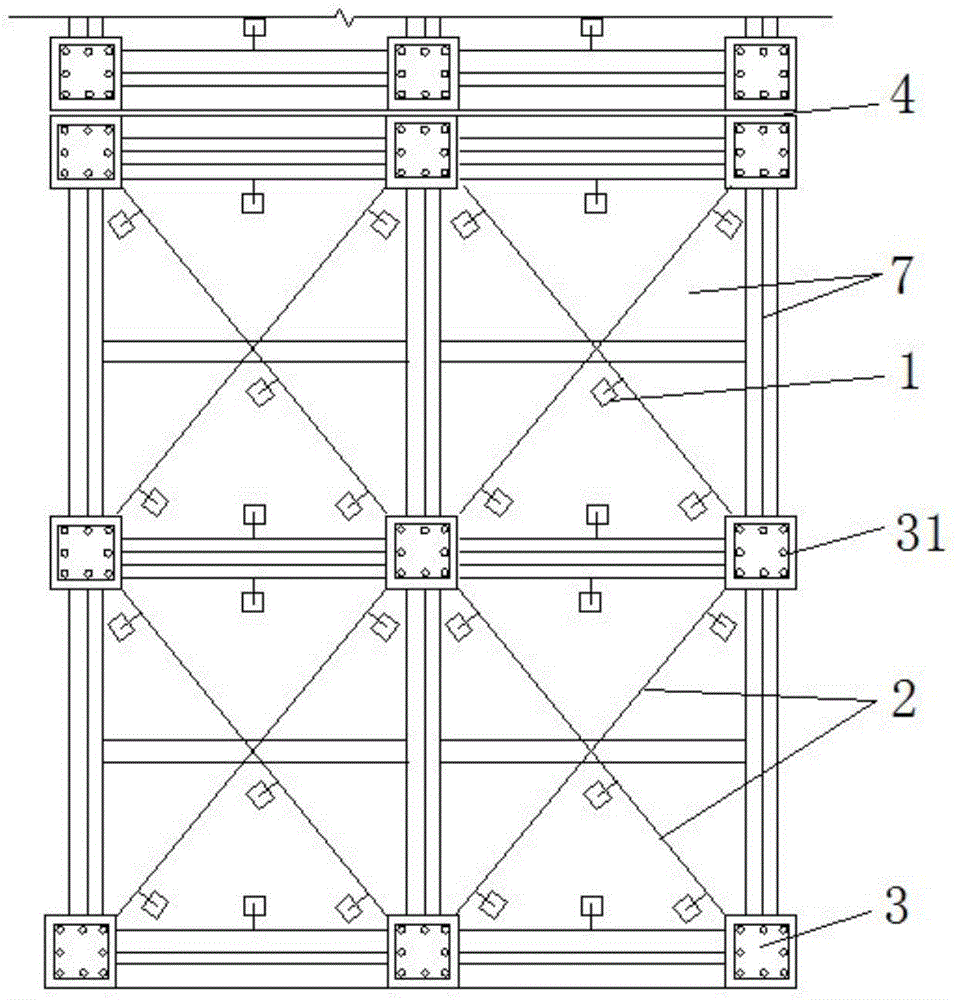

[0066] Example 2, see Figure 11 to Figure 19 The floor formwork or floor slab construction control method and the special calibration ruler 1 provided in this embodiment are basically the same as the steps, method and structure of embodiment 1. The difference is that the floor formwork or floor slab construction control method is also used for rectangular beams. 5 or formwork installation or pouring construction of ground beam 6.

[0067] see Figure 11 to Figure 13 , is a schematic diagram of the structure used for the rectangular beam 5 formwork construction and the elevation and flatness control of the inversion.

[0068] see Figure 14 to Figure 16 , is a schematic diagram of the structure used for the construction of the ground beam 6 formwork and the inverted elevation and flatness control. A ground beam 6 concrete cushion 61 is provided under the ground beam 6 .

[0069] In the above embodiments, the floor formwork correction point is set below the floor slab corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com