Measuring and leveling device and method of using same

A horizontal calibration, flat technology, applied in the direction of ruler, printing, writing utensils for direct reading, etc., can solve problems such as difficulty in reading scale, difficulty in accurate marking, and troublesome use of a spirit level with a small glass tube with blisters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

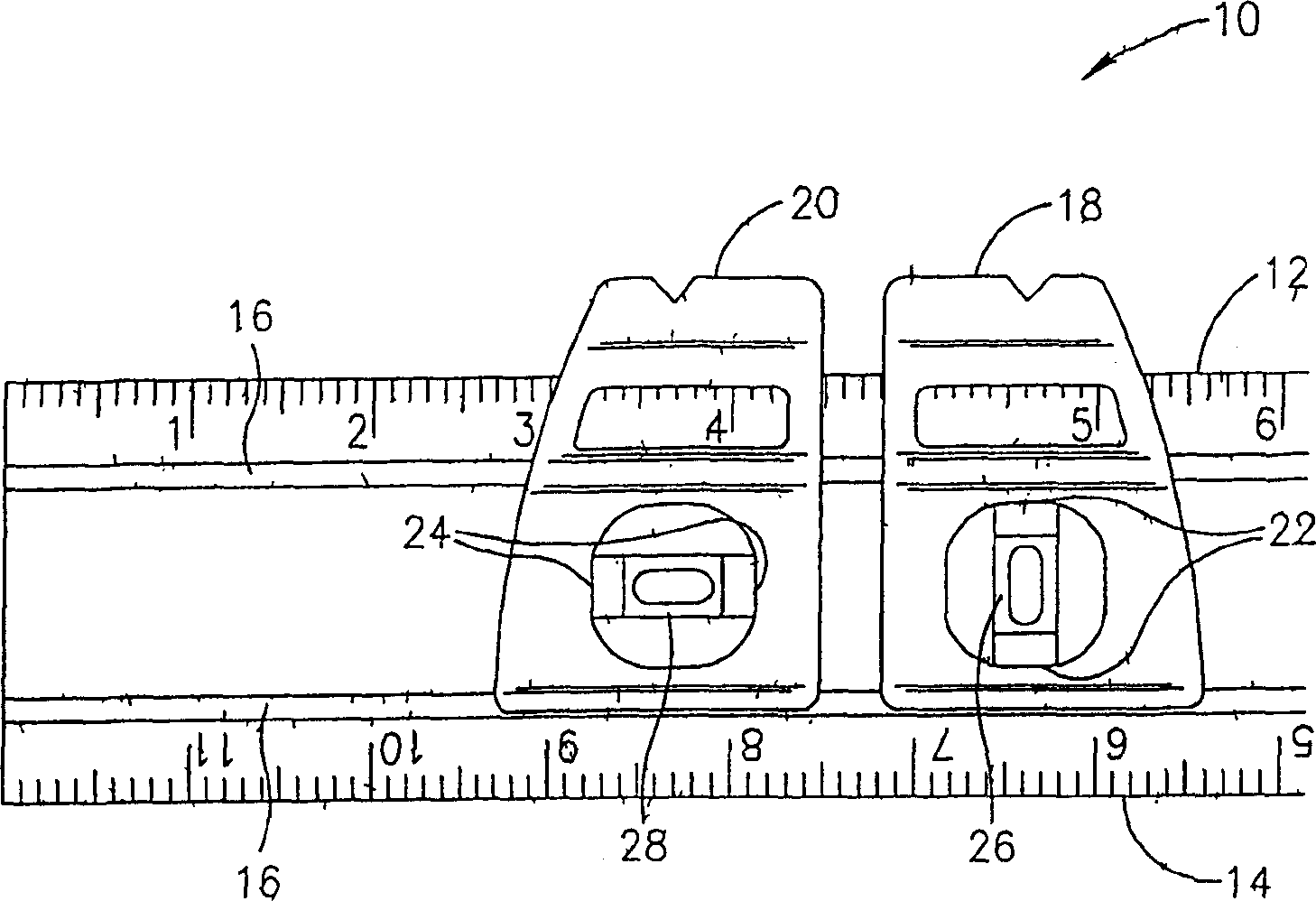

[0021] See now figure 1 , figure 1 Shows a general view of the measuring and leveling instrument 10 constructed and operated in accordance with the preferred embodiment of the present invention.

[0022] The measuring and leveling calibrator 10 includes two horizontal calibration surfaces 12 and 14, each of which is equipped with a ruler for measuring the distance between two points. Like a regular ruler, the two sides are beveled to have flat edges, and measurement scales are marked on the two flat edges. The main part of the measuring and leveling calibrator 10 contains two parallel holding rails 16 which are equidistant and straight parallel to the horizontal calibration planes 12 and 14.

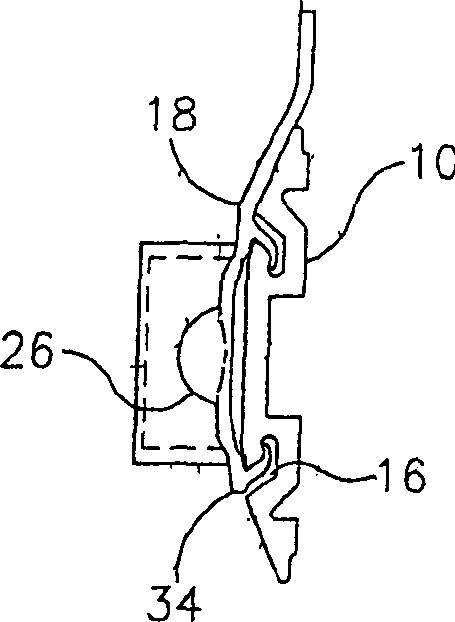

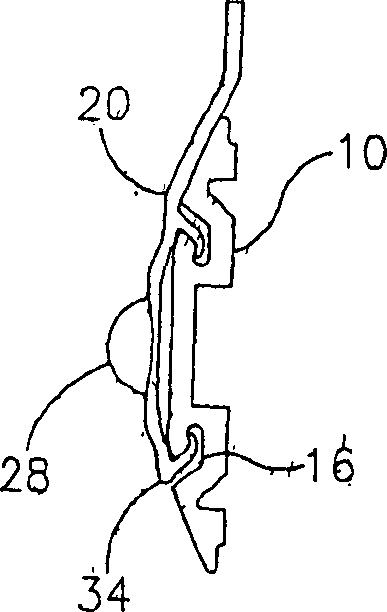

[0023] The main part of the level aligner is provided with two sliding splints 18 and 20. The sliding splint is combined with a claw-shaped protrusion 34 protruding downward from its lower surface. The claw-shaped protrusion 34 can be released by inserting it into the holding rail 16 The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com