A multi-ring segment tunnel test unit synchronous transport system and method

A multi-ring segment and transportation system technology, applied in the testing of machine/structural components, instruments, lifting devices, etc., can solve the problems of vulnerability, uncontrollability, deformation, etc., to avoid accidental deformation and damage, realize The effect of precise displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

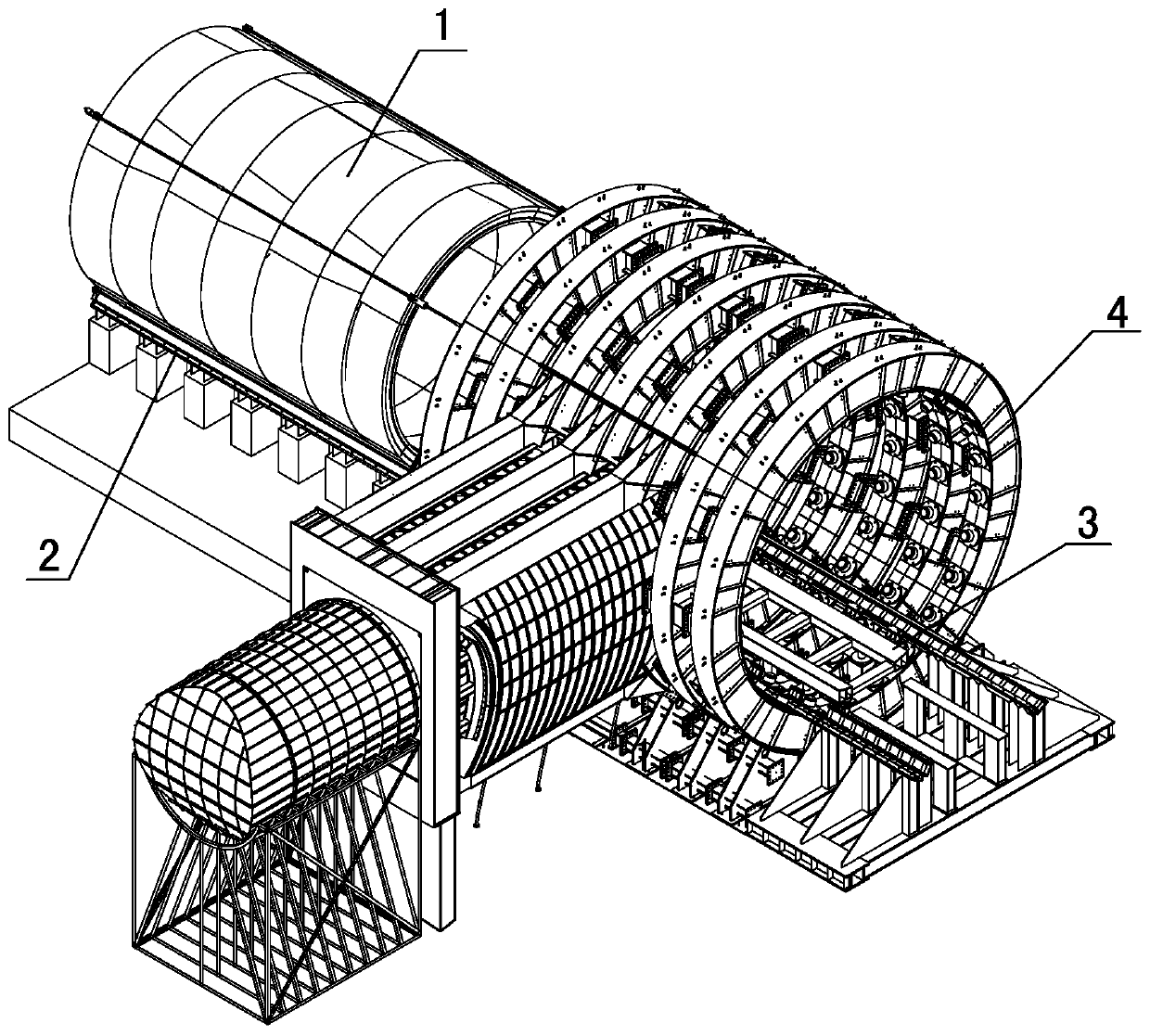

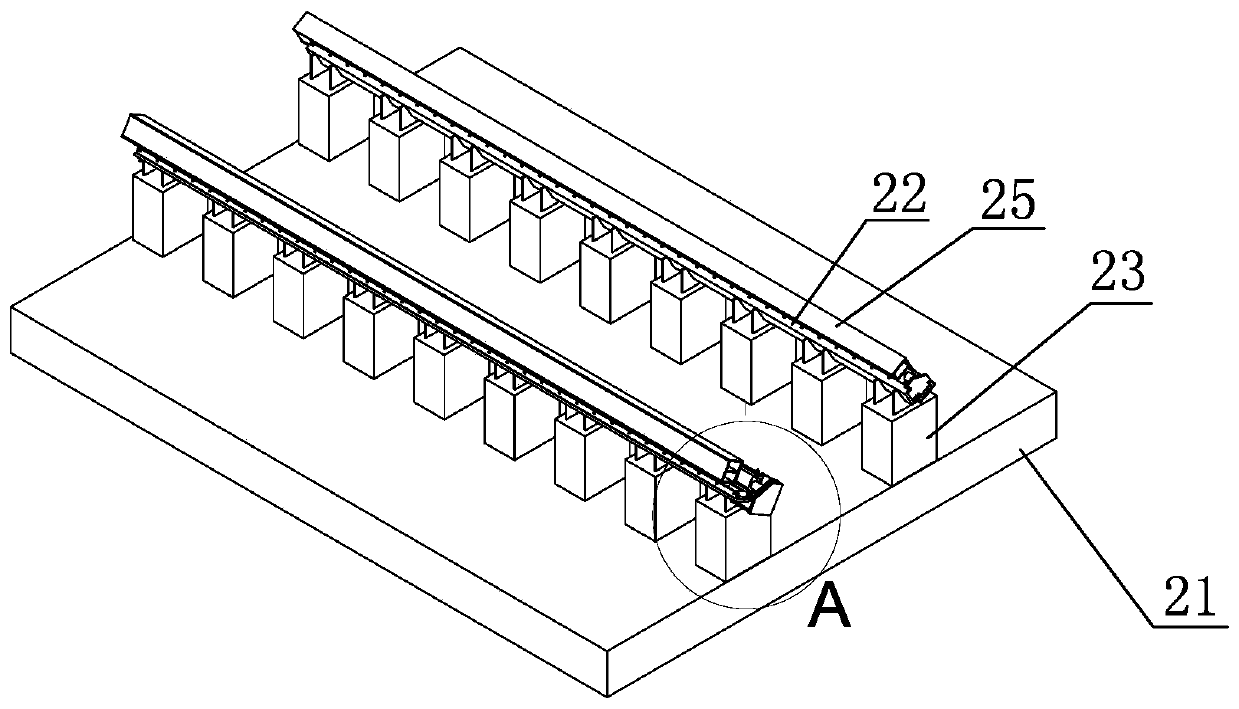

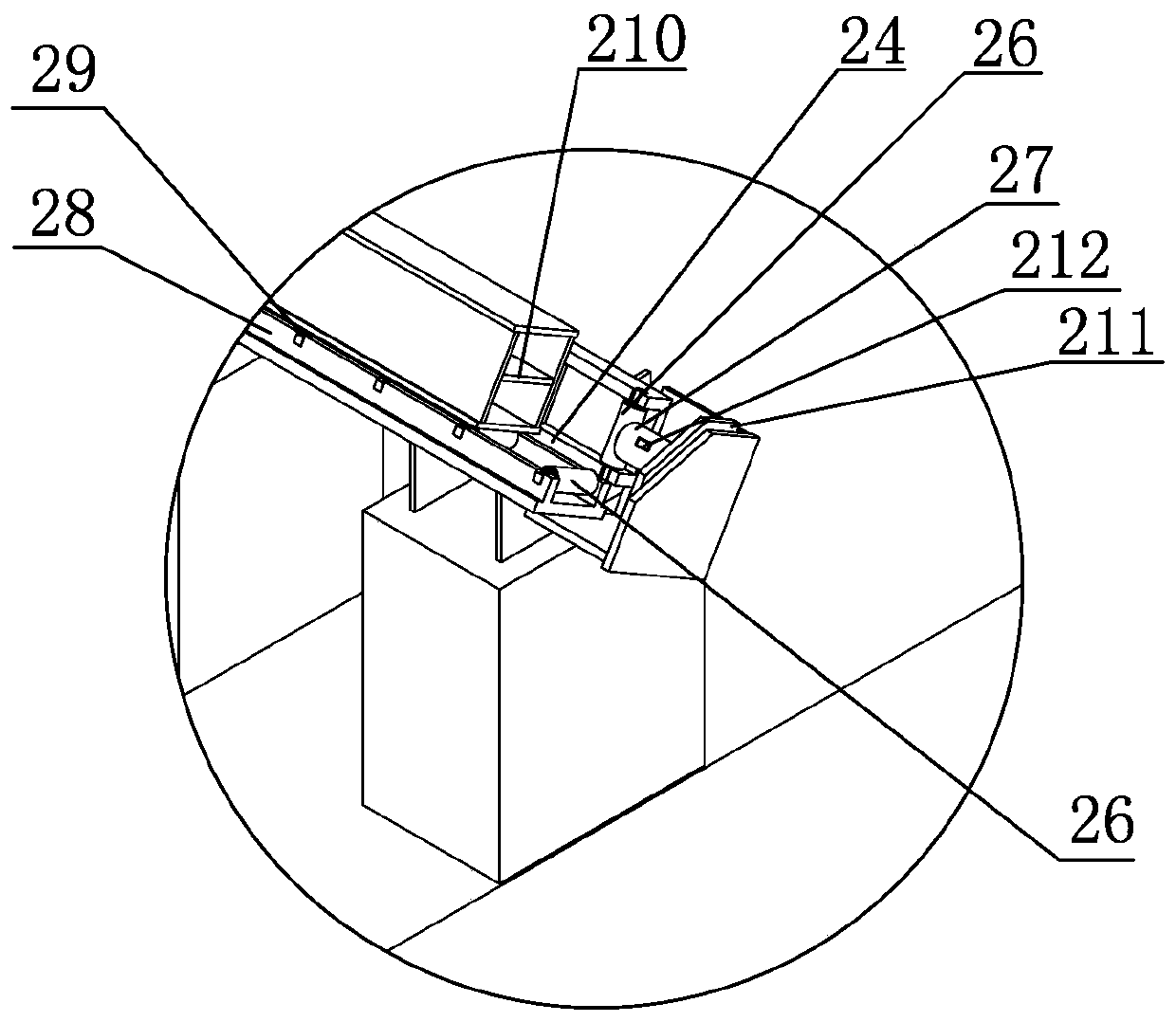

[0029] A multi-ring segment tunnel test unit synchronous transport system, such as Figure 1-Figure 6 As shown, it includes a multi-ring segment horizontal synchronous transport device 2 and a multi-ring segment synchronous lifting device 3. The multi-ring segment horizontal synchronous transport device 2 includes a synchronous transport platform base 21, and the synchronous transport platform base 21 is provided with two The horizontal support beams 22 parallel to each other, the bottom of the horizontal support beams 22 are fixed on the synchronous transport platform base 21 by several support columns 23, the horizontal support beams 22 are provided with guide grooves 24 along their length direction, and the guide grooves 24 are provided with The transport beam 25 that can slide forward along the guide groove 24 has several groups of V-shaped roller pairs consisting of two rollers 26 evenly distributed on the side wall of the guide groove 24. The transport beam 25 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com