Multifunctional integrated assembled ground system and construction technology thereof

A construction technology and assembly technology, applied in the field of architectural decoration, can solve the problems of inconvenient disassembly and assembly of ground blocks, safe use, long construction period, etc., achieve good sound insulation performance, reduce floor loads, and increase structural life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

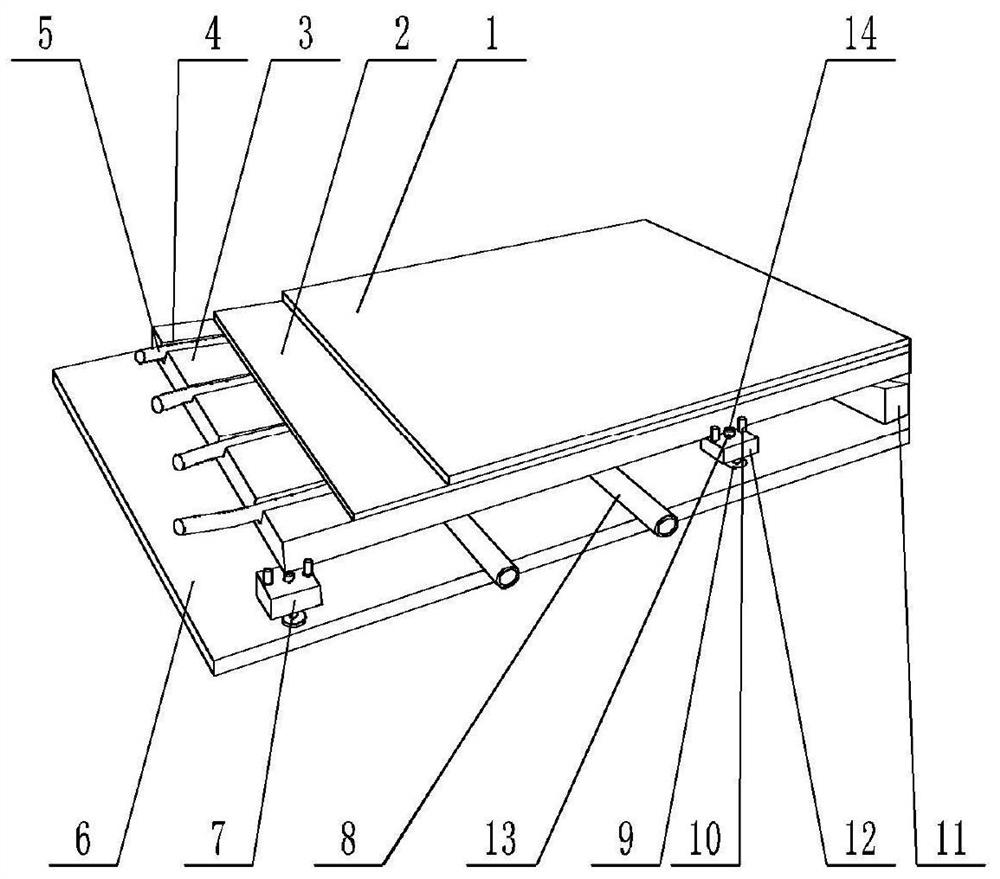

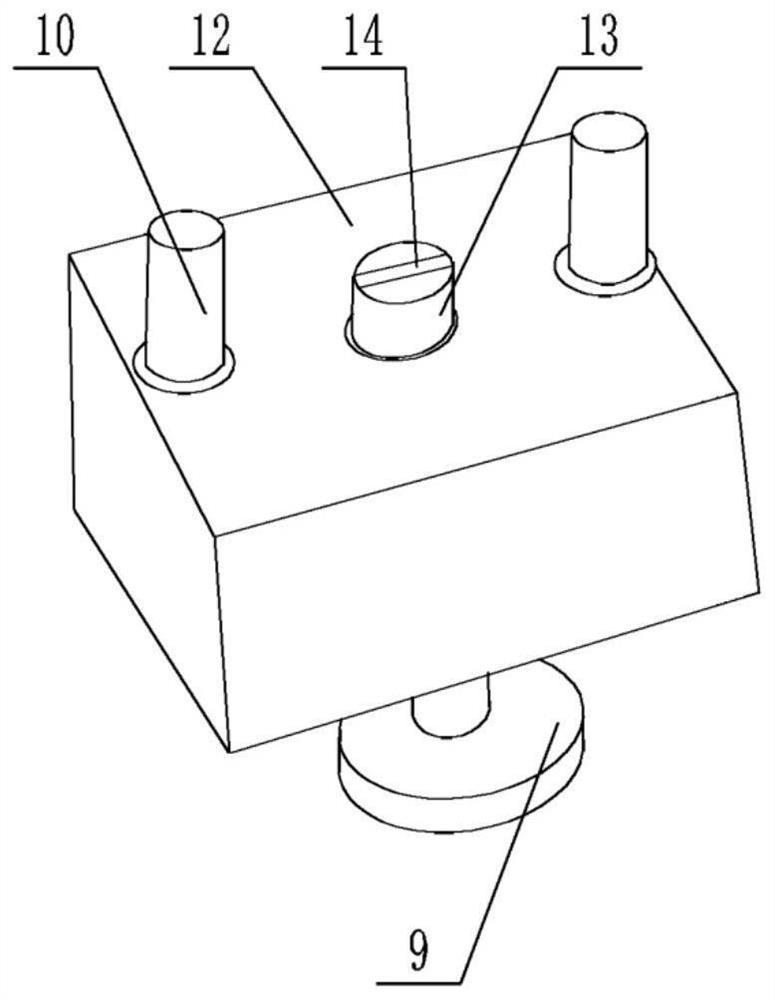

[0027] A multi-functional integrated assembled floor system, including a wooden keel frame 11, a basic structure layer 6, a foot assembly 7, a floor heating module layer 3, a heat dissipation layer 2 and a painted plate 1, and the wooden keel frame 11 is fixed on the basic structure layer At the wall above 6 along the elevation line, the floor heating module layer 3 is erected on the wooden keel frame 11 and the foot assembly 7, an overhead layer is formed between the floor heating module layer 3 and the basic structure layer 6, and the floor heating module layer 3 is provided with a buried floor heating supply The pipe groove 4 of the heat pipe 5 and the floor heating module layer 3 are coated with structural glue, and the heat dissipation layer 2 spliced by calcium carbonate boards is bonded to the structural glue. Spacers are arranged on the heat dissipation layer 2, and the threaded sleeves of the spacers face upward. The assembled painted boards 1 are laid on the heat di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com