Shaft machining, polishing and detecting device

A detection device and shaft technology, applied in the field of workpiece processing, can solve the problems of time-consuming and laborious, reduce the practicability of grinding devices, increase costs, etc., and achieve the effect of ensuring a clean environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

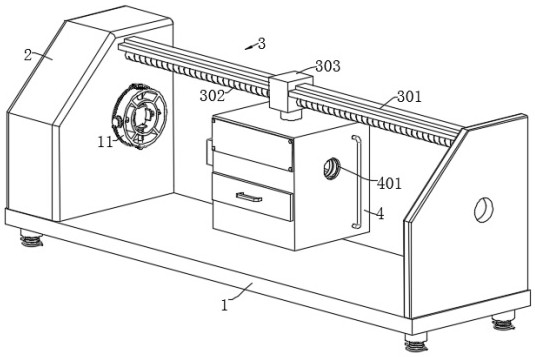

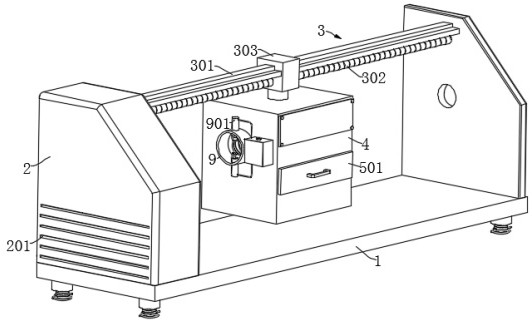

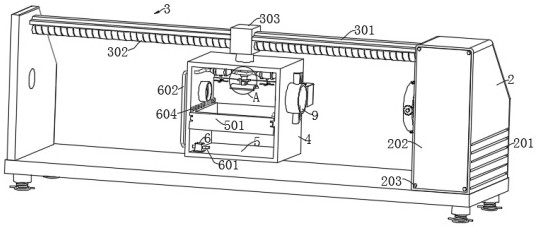

[0037] Embodiment 1: refer to Figure 1-11, a shaft processing and grinding detection device, including a bottom plate 1, also includes: a processing box 4 arranged on the bottom plate 1, a chassis 2, a conveying mechanism 3 for driving the processing box 4 to move, and the outer walls of both sides of the processing box 4 are Be provided with feed inlet 401, be provided with hairbrush 403 in feed inlet 401, wherein, processing box 4 top inner wall is provided with and is used for the grinding mechanism that shaft class is polished; The outer wall of the processing box 4; the piston cylinder 901 is fixedly connected to the collar one 9; the piston disk 902 is slidably connected in the piston cylinder 901, and the piston disk 902 is fixedly connected with a guide rod 903; the limit sleeve 905 is fixedly connected On the top of the guide rod 903, a universal ball 906 is slidably connected in the limit sleeve 905; the water nozzle 909 is fixedly connected to the inner wall of the...

Embodiment 2

[0050] Embodiment 2: refer to Figure 5 , Figure 11 , a shaft processing and grinding detection device, including a bottom plate 1, also includes: a processing box 4 arranged on the bottom plate 1, a chassis 2, a conveying mechanism 3 for driving the processing box 4 to move, and the outer walls of both sides of the processing box 4 are Be provided with feed inlet 401, be provided with hairbrush 403 in feed inlet 401, wherein, processing box 4 top inner wall is provided with and is used for the grinding mechanism that shaft class is polished; The outer wall of the processing box 4; the piston cylinder 901 is fixedly connected to the collar one 9; the piston disk 902 is slidably connected in the piston cylinder 901, and the piston disk 902 is fixedly connected with a guide rod 903; the limit sleeve 905 is fixedly connected On the top of the guide rod 903, a universal ball 906 is slidably connected in the limit sleeve 905; the water nozzle 909 is fixedly connected to the inner...

Embodiment 3

[0056] Embodiment 3: refer to Figure 11, a shaft processing and grinding detection device, including a bottom plate 1, also includes: a processing box 4 arranged on the bottom plate 1, a chassis 2, a conveying mechanism 3 for driving the processing box 4 to move, and the outer walls of both sides of the processing box 4 are Be provided with feed inlet 401, be provided with hairbrush 403 in feed inlet 401, wherein, processing box 4 top inner wall is provided with and is used for the grinding mechanism that shaft class is polished; The outer wall of the processing box 4; the piston cylinder 901 is fixedly connected to the collar one 9; the piston disk 902 is slidably connected in the piston cylinder 901, and the piston disk 902 is fixedly connected with a guide rod 903; the limit sleeve 905 is fixedly connected On the top of the guide rod 903, a universal ball 906 is slidably connected in the limit sleeve 905; the water nozzle 909 is fixedly connected to the inner wall of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com