Hollow slab girder bridge structure and construction method using ultra-high performance concrete filler

A hollow slab girder, ultra-high performance technology, used in bridges, bridge construction, bridge parts, etc., can solve the problems of large amount of concrete, not easy to be environmentally friendly, mismatched calculation assumptions, etc., to achieve low porosity and ensure durability. Performance, the effect of low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

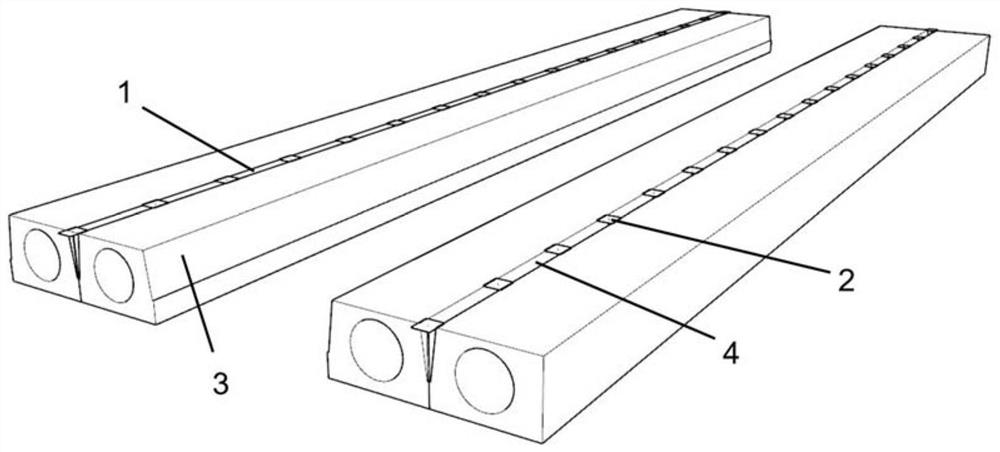

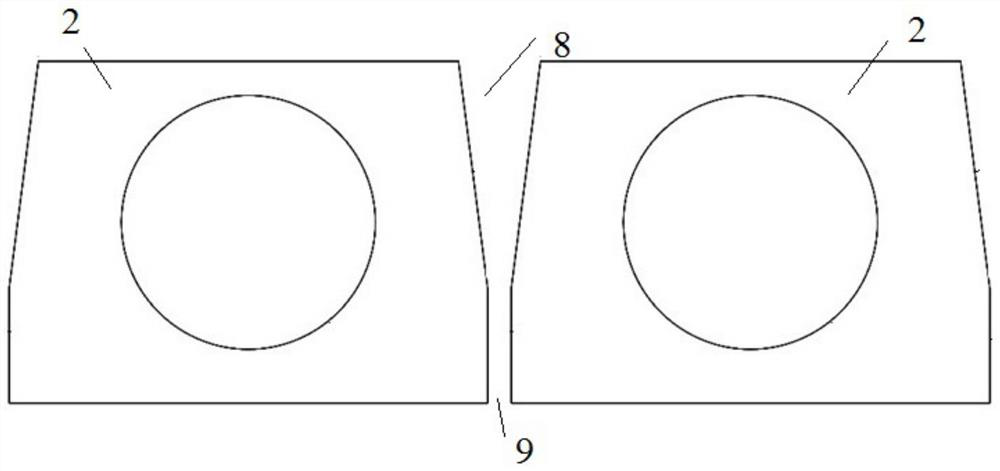

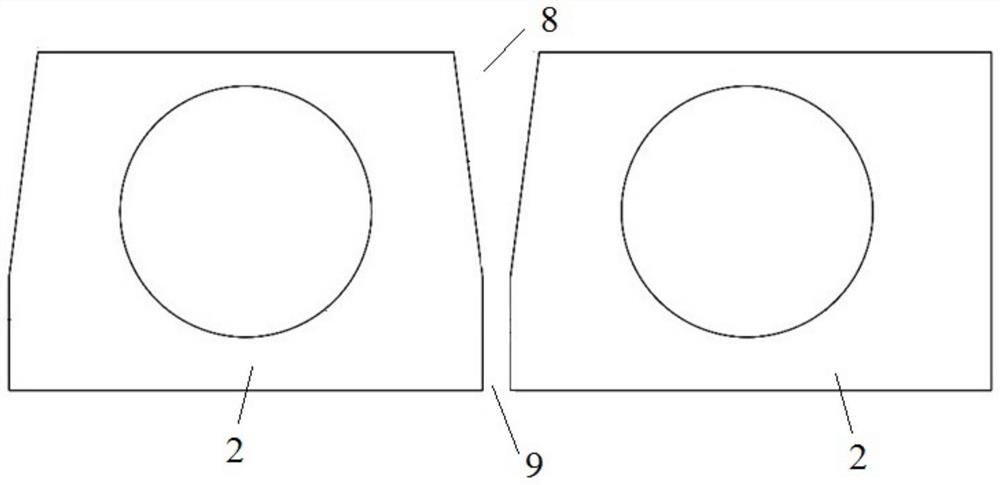

[0038] Such as figure 1 As shown, the hollow slab girder bridge structure using ultra-high performance concrete filler, the structure includes multiple hollow slab girders 2 placed side by side and hinge joints 1 connecting multiple hollow slab girders 2, the hinge joints 1 are along the gap of the slab girder 2 It is set in the length direction, including an inclined section 8 and a vertical section 9 connected up and down in sequence, the inclined section 8 is filled with ultra-high performance concrete filler, and the vertical section 9 is not filled.

[0039] Such as figure 2 As shown, two adjacent hollow slab girders 2 placed in the middle are symmetrically provided with inclined sides and vertical sides, forming an inclined section 8 and a vertical section 9 in the middle; as image 3 As shown, two adjacent hollow plate girders 2 placed on the sides, one is symmetrically provided with inclined sides and vertical sides, and the other has only one side provided with incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com