Patents

Literature

36results about How to "Realize pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

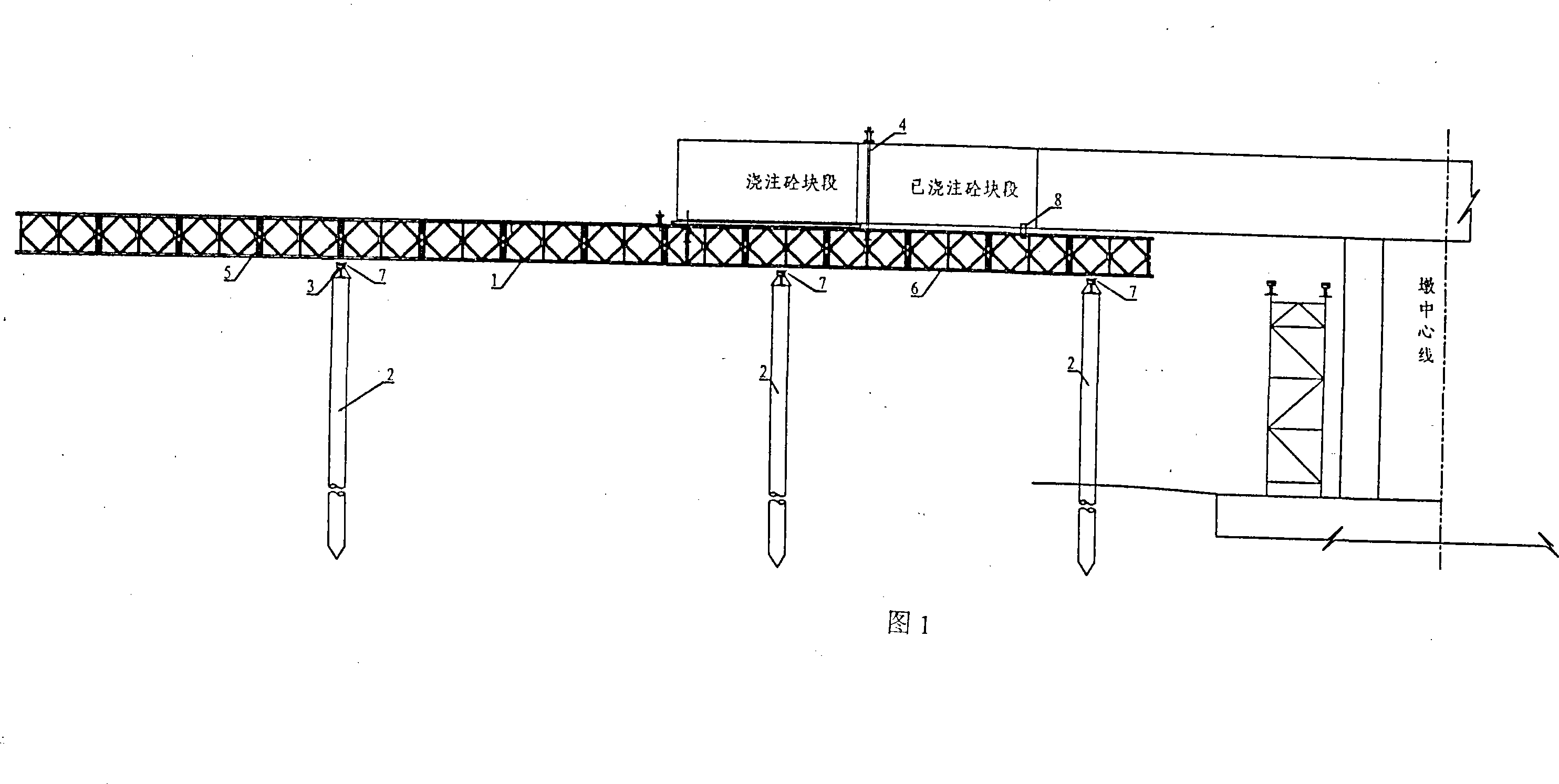

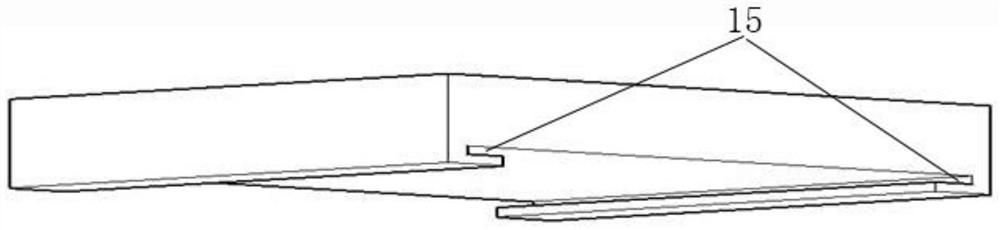

Cable-stayed bridge main-beam sliding form frame system and construction method

InactiveCN101158146ARealize pouringReduce lateral stiffnessBridge erection/assemblyCable stayedPre stress

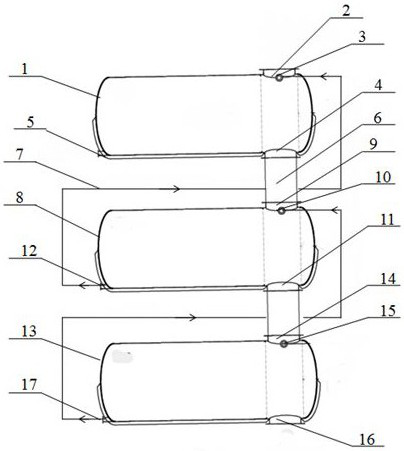

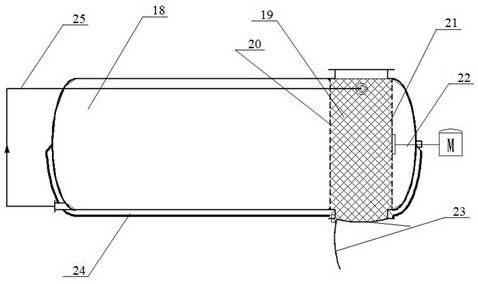

The invention relates to a main girder slide die carrier system and a construction method of cable-stayed bridges, with steps as follows: when the construction 0# segment is finished, a bailey truss sliding die carrier is extended, which is divided into three groups that respectively move forward to next row of supporting piers; a construction segment bottom die is dragged to place; a fore-fulcrum elevation of the die carrier is adjusted; suspenders are stretched ahead; segmental steel bars and prestressing tendons are bound; segmental concrete is poured; segmental pre-stressing tendons are stretched; the die carrier is down adjusted; the bottom die is moved forward to next segmental place; and the steps are repeated. The invention has the advantages that by using the stress system of front supporting and back cable staying, one part of load has transferred to a cast girder segment, and the other part is borne by temporary piers, stressing is definite, calculation is easy, working condition is unified, and main girder linear adjustment control is convenient. The invention is applicable not only to concrete connecting girders and T-frames, but also to cable-stayed bridges with various cross-sectional shapes, achieves single cable plane, small transverse stiffness, wide flange plate cross section main girder, and whole section global casting, saves labor and materials, enjoys a short construction period and standardized construction, and is stable, safe and reliable.

Owner:THE 2ND ENG CO LTD MBEC

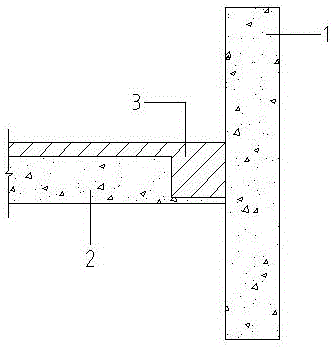

Edge joint connecting structure and method of prefabricated integrated type frame column beam

The invention relates to an edge joint connecting structure and method of a prefabricated integrated type frame column beam, and belongs to the field of prefabricated concrete structure engineering. The edge joint connecting structure of the prefabricated integrated type frame column beam is characterized by further comprising a tensile longitudinal bar, a U-shaped reinforcing steel bar, roughening layers and a concrete connecting layer, the upper connecting steel bar, namely the tensile longitudinal bar and the lower U-shaped steel bar are arranged at the joint portion of a prefabricated column, and right sections of the tensile longitudinal bar and the U-shaped steel bar are both tied with a stirrup I and buried in the prefabricated column. The edge joint connecting method of the prefabricated integrated type frame column beam includes producing the prefabricated column and a prefabricated beam in a factory, respectively arranging the roughening layers, correspondingly binding the tensile longitudinal bar and the U-shaped steel bar on the prefabricated column with a longitudinal bar and a stirrup II on the connecting section of the prefabricated beam corresponding on the construction site, and making the cast-in-place normal concrete connecting layer to realize connection between the column and the beam. Construction is facilitated, the period of construction is shortened, and seismic performance is enhanced.

Owner:CHINA MCC17 GRP

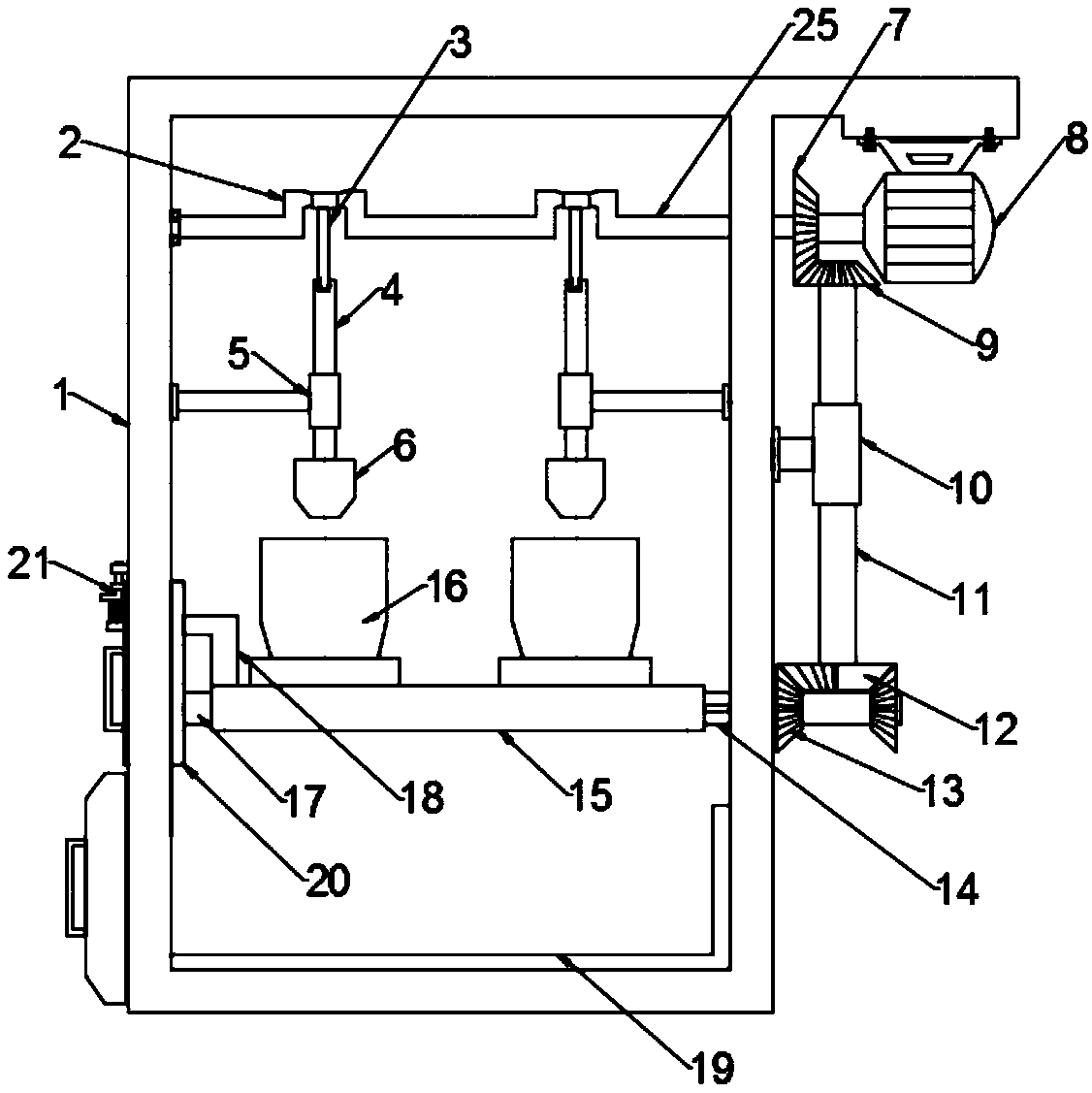

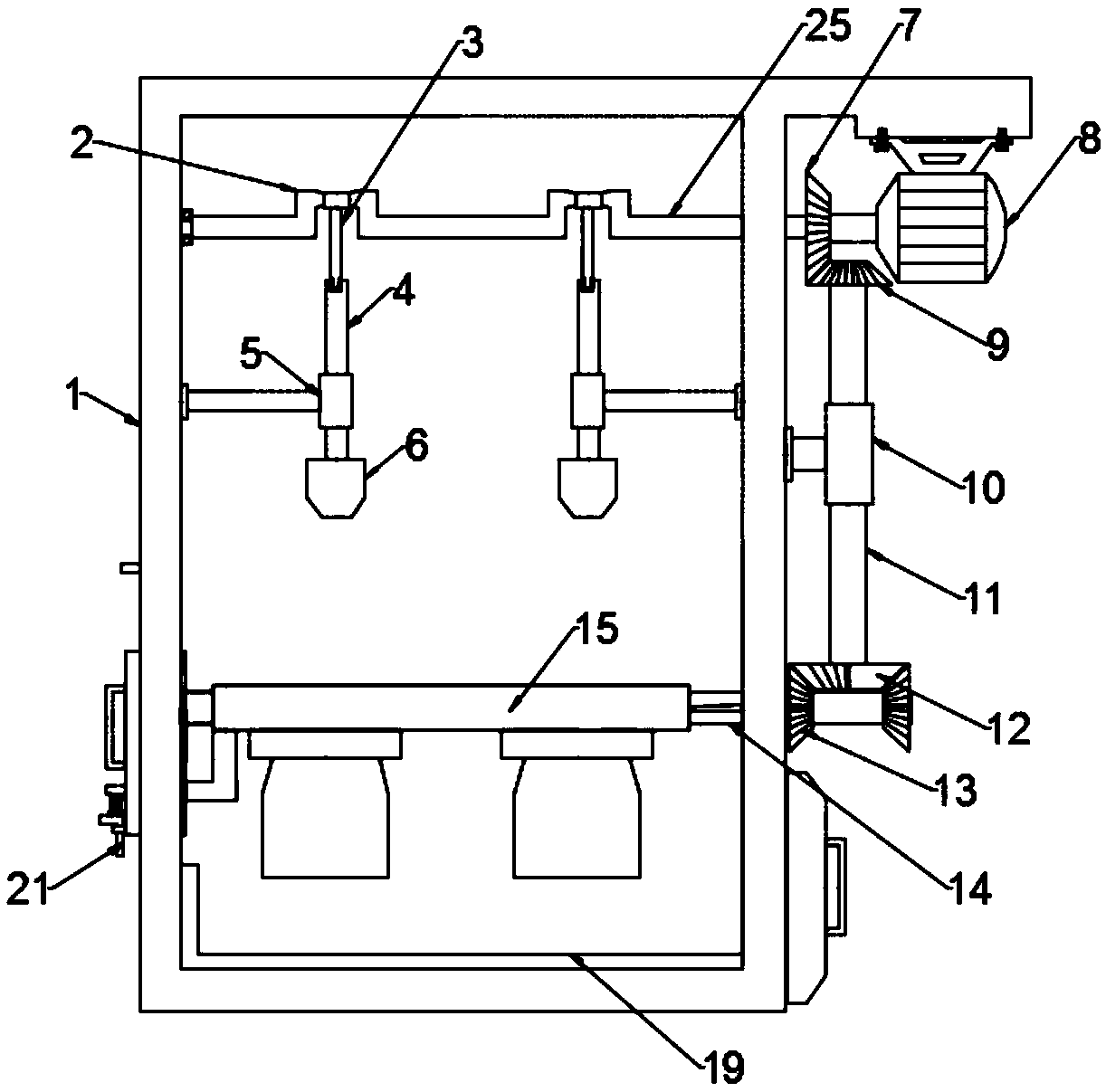

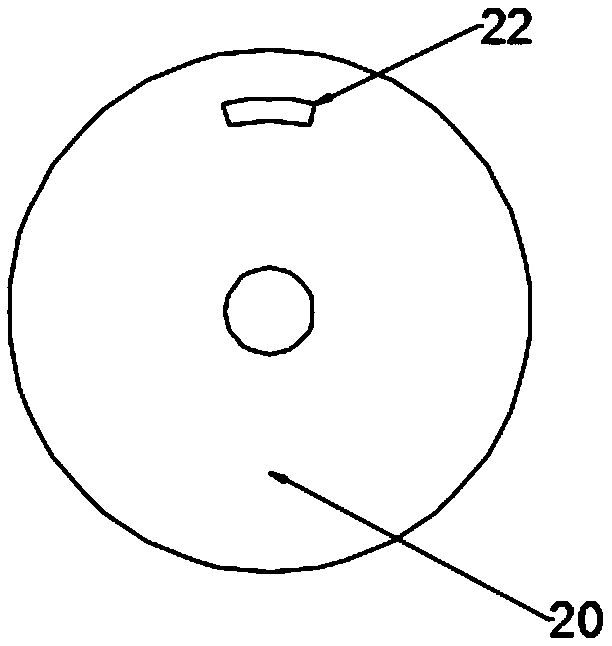

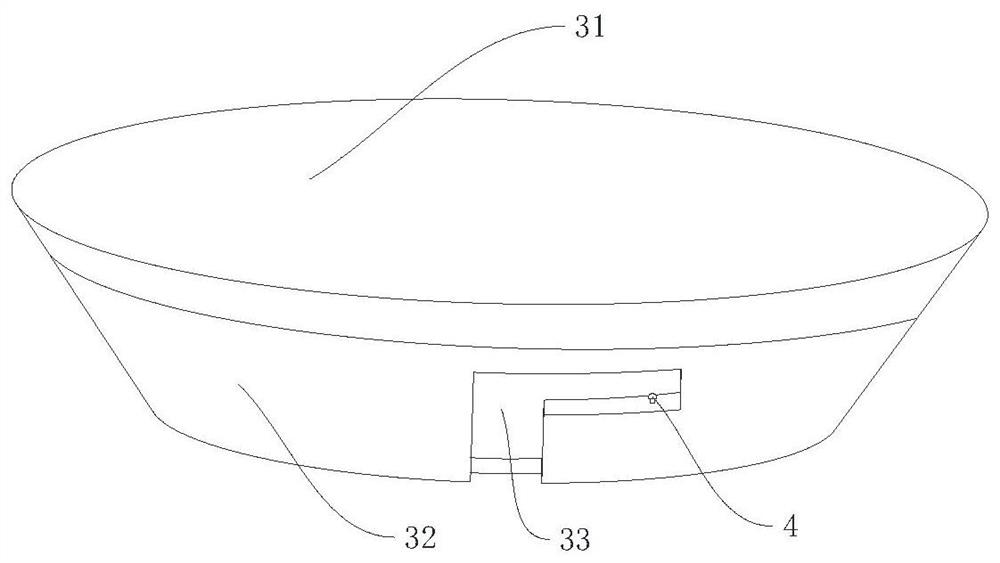

Traditional Chinese medicinal material mashing device facilitating material discharging

The invention discloses a traditional Chinese medicinal material mashing device facilitating material discharging. The device comprises a shell, a pounding mechanism, a sleeve, a collecting groove anda disc. According to the device, the design is novel, a crankshaft drives a tamping hammer to move up and down in a reciprocating mode under the action of a connecting rod and a pushing rod, so thatthe medicine smashing process is realized; when a rotating shaft rotates, a first rotating rod is driven to rotate, the first rotating rod drives a second rotating rod to do reciprocating rotation through an incomplete bevel gear and a bevel gear C, and a medicine tamping groove can be driven by the sleeve to swing back and forth in a reciprocating mode when the second rotating rod rotates, so that the effect of material homogenizing is achieved, and the mashing effect of the traditional Chinese medicine is further improved; and when the mashed traditional Chinese medicine needs to be taken down, a fixing pin is opened to enable the disc to be in a free state, then at the moment, the disc is pulled to enable a strip-shaped groove in the sleeve to leave the strip-shaped protruding block, and then the rotating disc is rotated; and the medicine tamping groove is driven to rotate through a third connecting rod and the sleeve, so that material pouring out is realized, and the problem that the defect of an material outlet internally arranged in an existing material tamping groove is solved.

Owner:邓帅

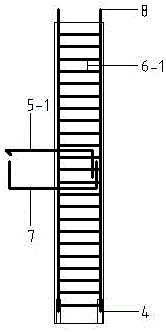

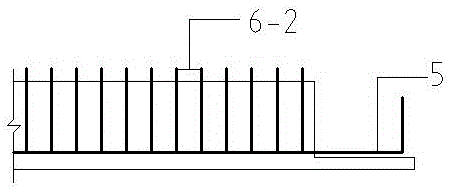

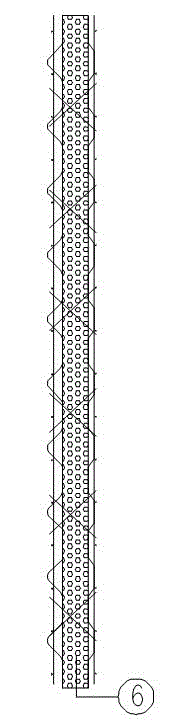

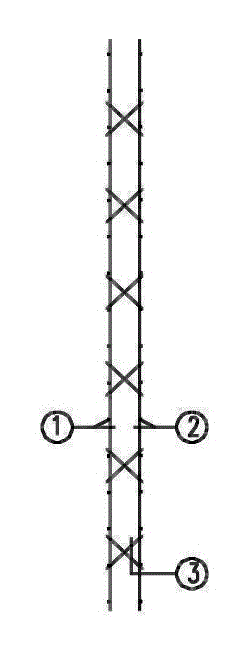

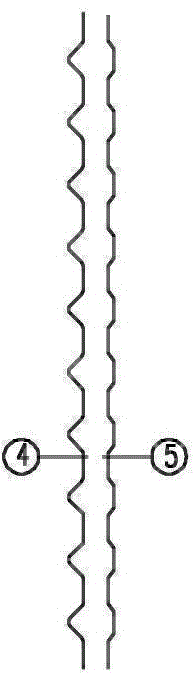

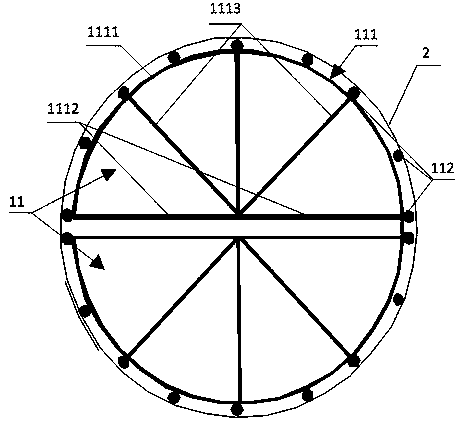

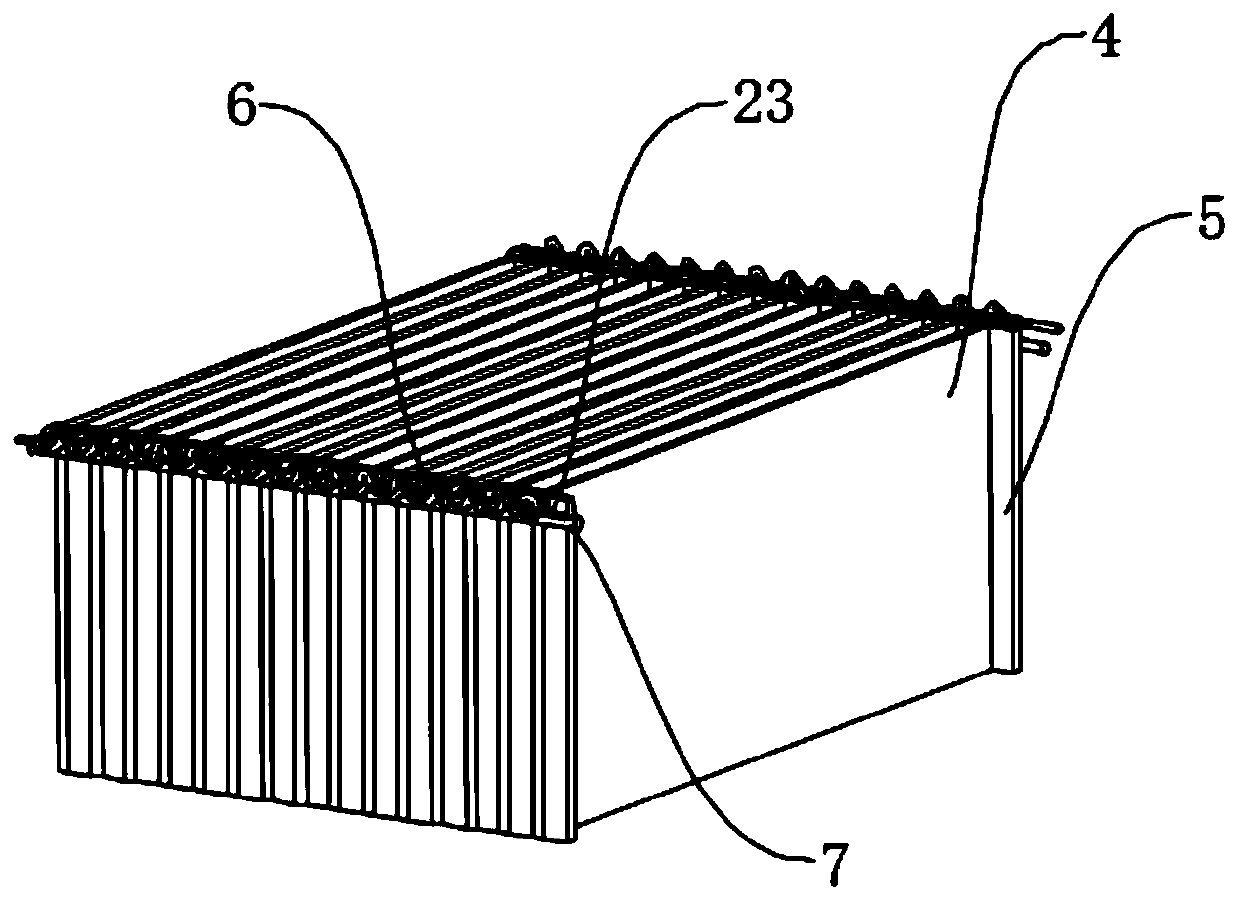

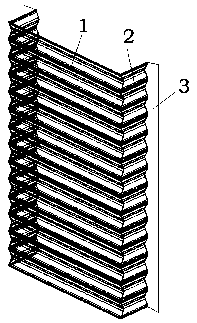

Cast-in-place belt net rack self-limiting sandwiched heat insulation plate for construction wall

The invention relates to a cast-in-place belt net rack self-limiting sandwiched heat insulation plate for a construction wall and belongs to the technical field of construction materials. The cast-in-place belt net rack self-limiting sandwiched heat insulation plate comprises a heat insulation plate, a heat insulation plate fixing steel wire net rack and a heat insulation plate limiting piece. The heat insulation plate fixing steel wire net rack comprises a heat insulation plate outer side flat net and a heat insulation plate inner side flat net, and the heat insulation plate outer side flat net is fixedly connected with the heat insulation plate inner side flat net through a crossed connecting rib. The heat insulation plate limiting piece comprises an outer side wave-shaped limiting vertical rib and an inner side concave-convex limiting vertical rib. The heat insulation plate fixing steel wire net rack is laid on the surface of the heat insulation plate, and the crossed rib and a horizontal rib are connected to form the net rack, so that the intensity of the heat insulation plate and the integral stability are improved. Pouring of concrete on the inner side and the outer side of the heat insulation plate can be achieved; meanwhile, the fixing of the heat insulation plate is guaranteed. The cast-in-place belt net rack self-limiting sandwiched heat insulation plate has the effects of being thermal-insulating, fireproof, waterproof, durable, sound-insulating, sound-absorbing, antiseptic, land-saving, material-saving and time-saving and prolonging service life.

Owner:万保金

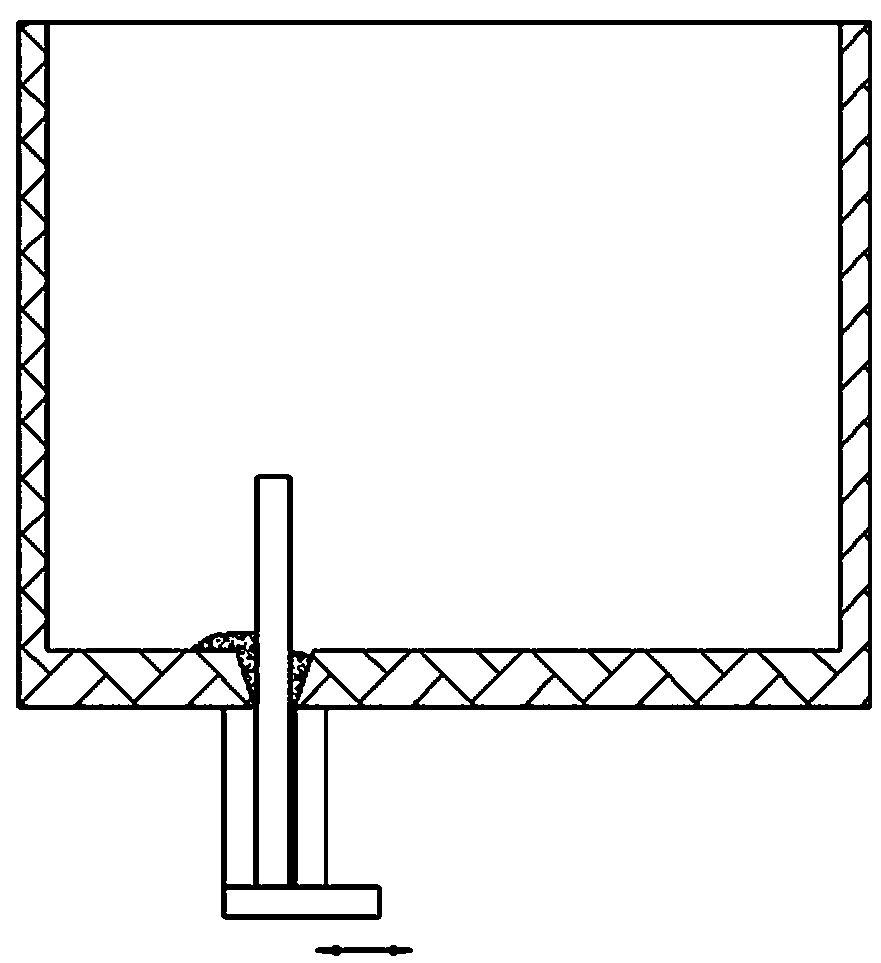

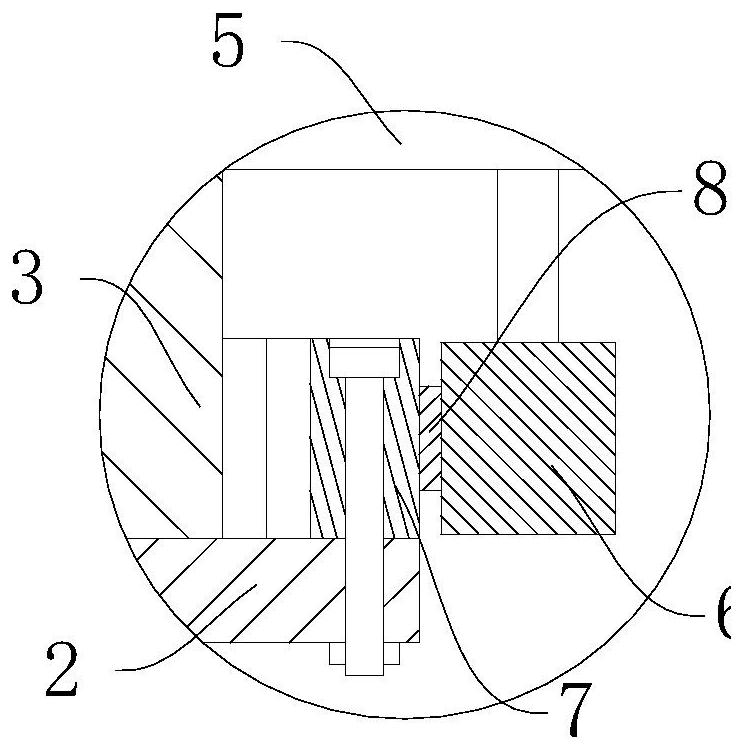

External sleeve of automatic steel ladle flow guiding device

PendingCN110961613APrevent moistureAvoid pollutionMelt-holding vesselsThin walledManufacturing engineering

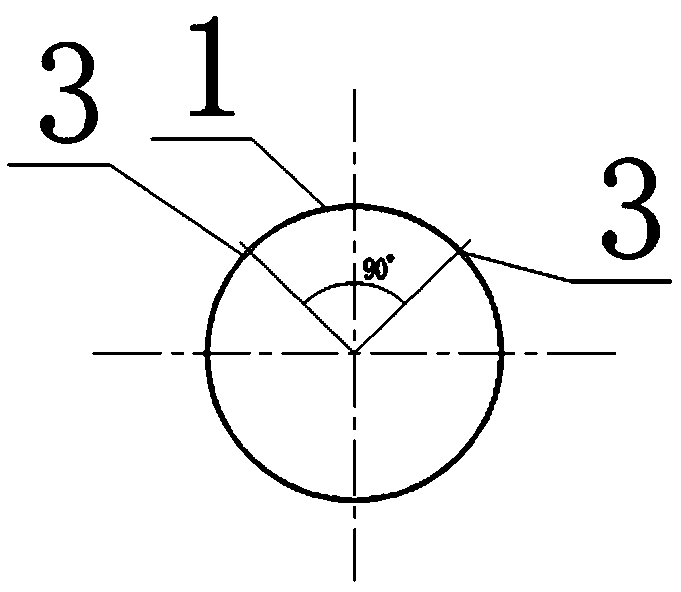

The invention discloses an external sleeve for an automatic steel ladle flow guiding device. The external sleeve is provided with a thin-wall steel cylinder for containing stuffing sand; the upper endof the thin-wall steel cylinder is closed, and the lower end of the thin-wall steel cylinder is of an open structure; the lower end of the thin-wall steel cylinder is sealed through low-temperature molten plastic; two long-strip-shaped holes are formed side by side in a side wall of the thin-wall steel cylinder in the length direction of the side wall, wherein the side wall extends out of the bottom of a steel ladle; an included angle between the two long-strip-shaped holes is 85-95 degrees; and the two long-strip-shaped holes are sealed by the low-temperature molten plastic. Compared with the prior art, the external sleeve enables the stuffing sand fills the space between a flow guiding rod and a nozzle brick cup, and has the advantages of high pouring rate, easiness in operation, labor-saving and material-saving performance.

Owner:XIXIA XINYUE METALLURGICAL MATERIAL DEV CO LTD

Prefabricated concrete structure interlayer seismic isolation method

ActiveCN109594833AAchieve vibration-isolated connectionsRealize pouringProtective buildings/sheltersShock proofingSeismic isolationFlange

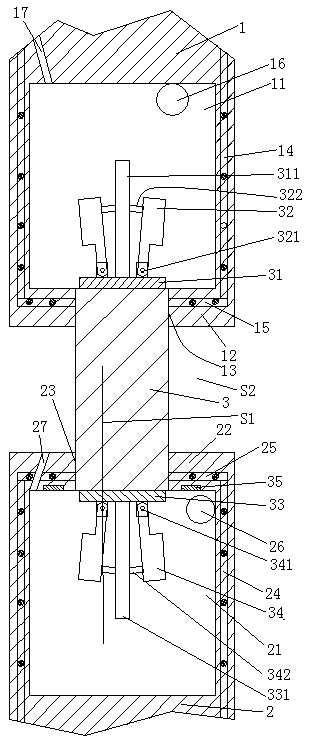

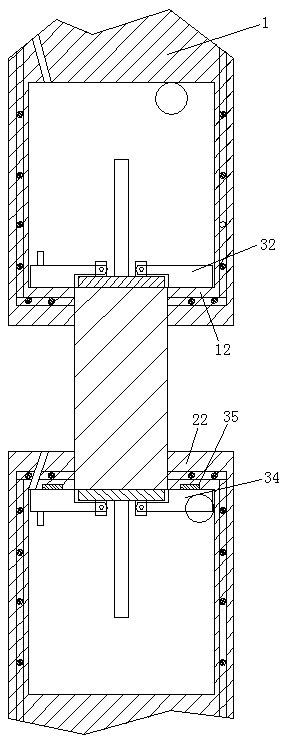

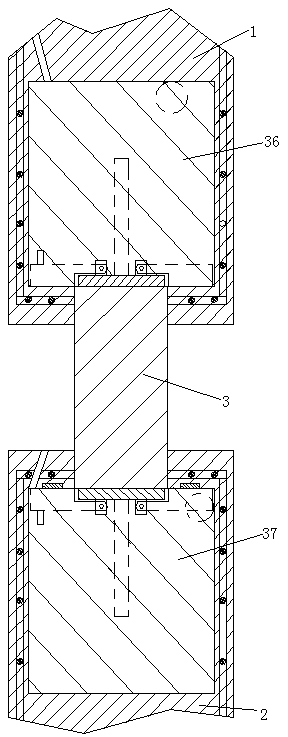

The invention relates to a prefabricated concrete structure interlayer seismic isolation method. The method comprises the following steps: step 1, forming an upper connecting hole in an upper concretecolumn, and forming a lower connecting hole in a lower concrete column to prepare a rubber seismic isolation column; step 2, inserting the lower end of the rubber seismic isolation column into the lower connecting hole; step 3, fixing the upper concrete column above the lower concrete column in a liftable manner; step 4, inserting the upper end of the rubber seismic isolation column into the upper connecting hole; step 5, overlapping lower fixing claws on a lower hole portion inner flange and overlapping upper fixing claws on an upper hole portion inner flange; step 6, pouring concrete in theupper connecting hole and pouring concrete in the lower connecting hole; and step 7, dismantling a support structure after the concrete in the upper connecting hole and the concrete in the lower connecting hole are solidified. By adopting the prefabricated concrete structure interlayer seismic isolation method provided by the invention, the problem of a poor seismic isolation effect between layers of the existing prefabricated concrete structure is solved.

Owner:ZHEJIANG SCI-TECH UNIV

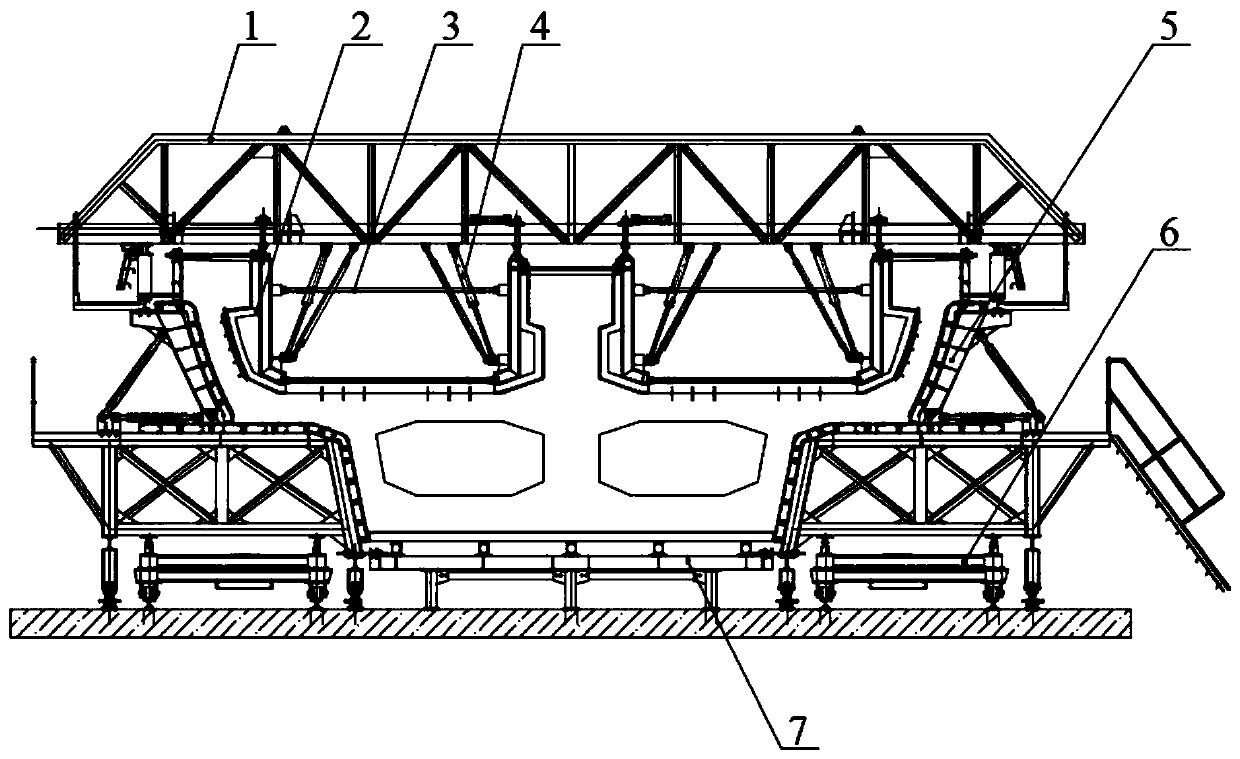

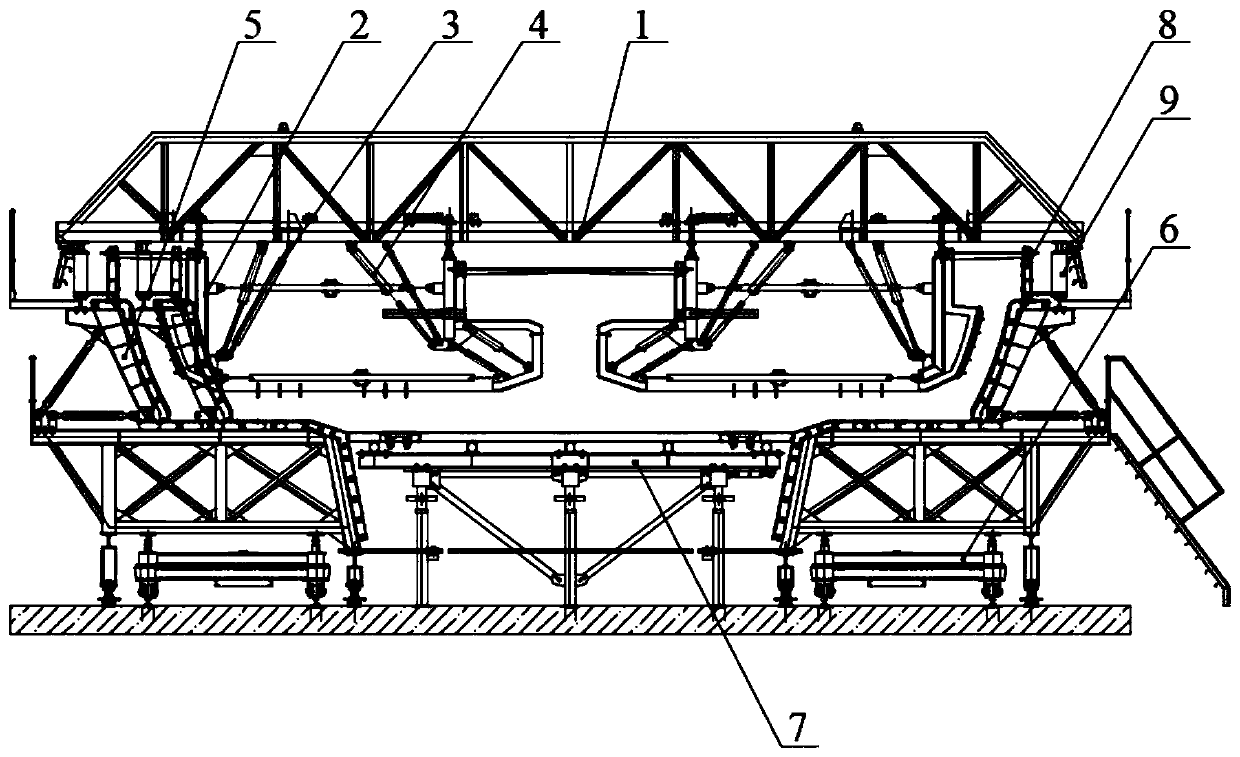

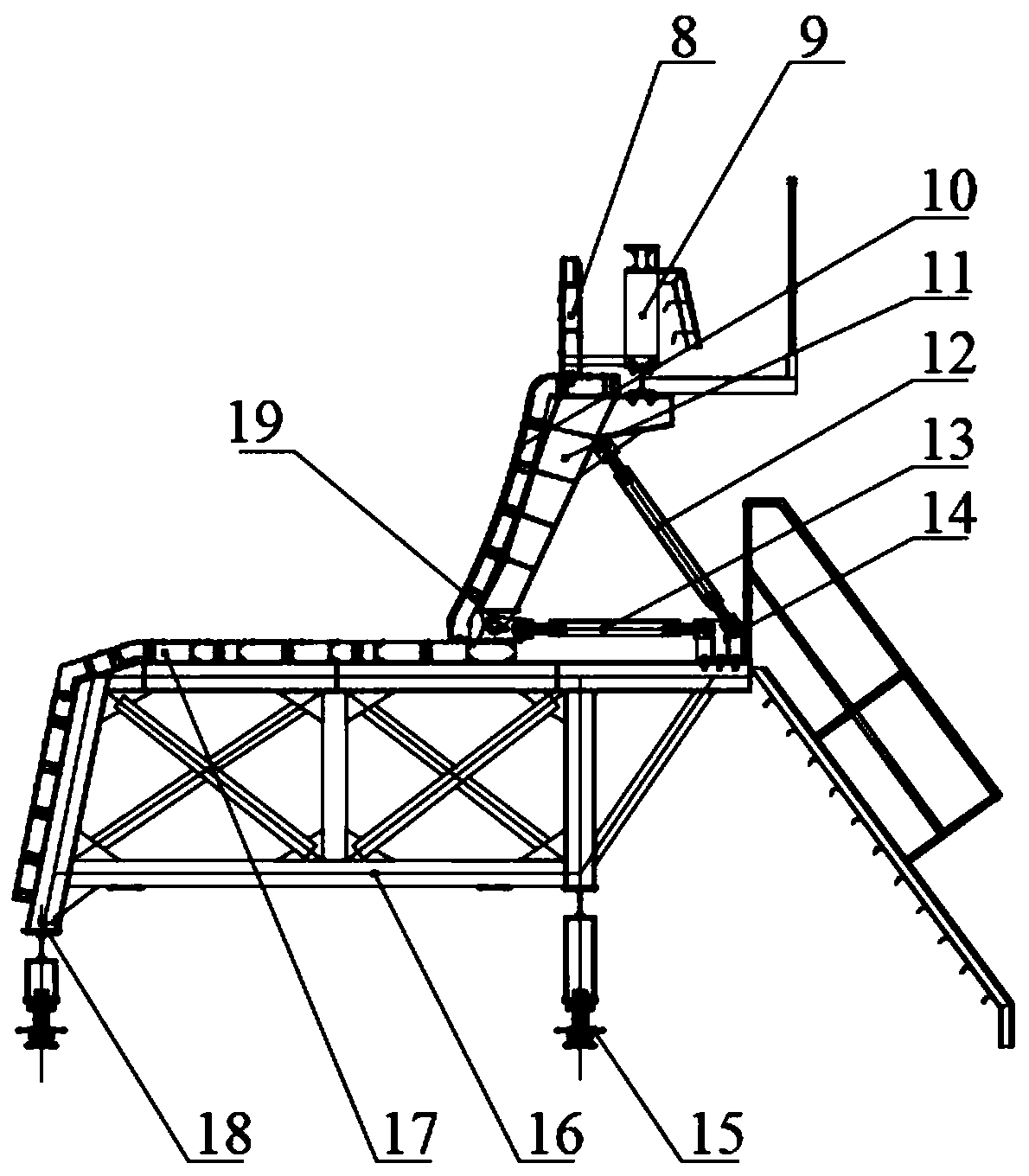

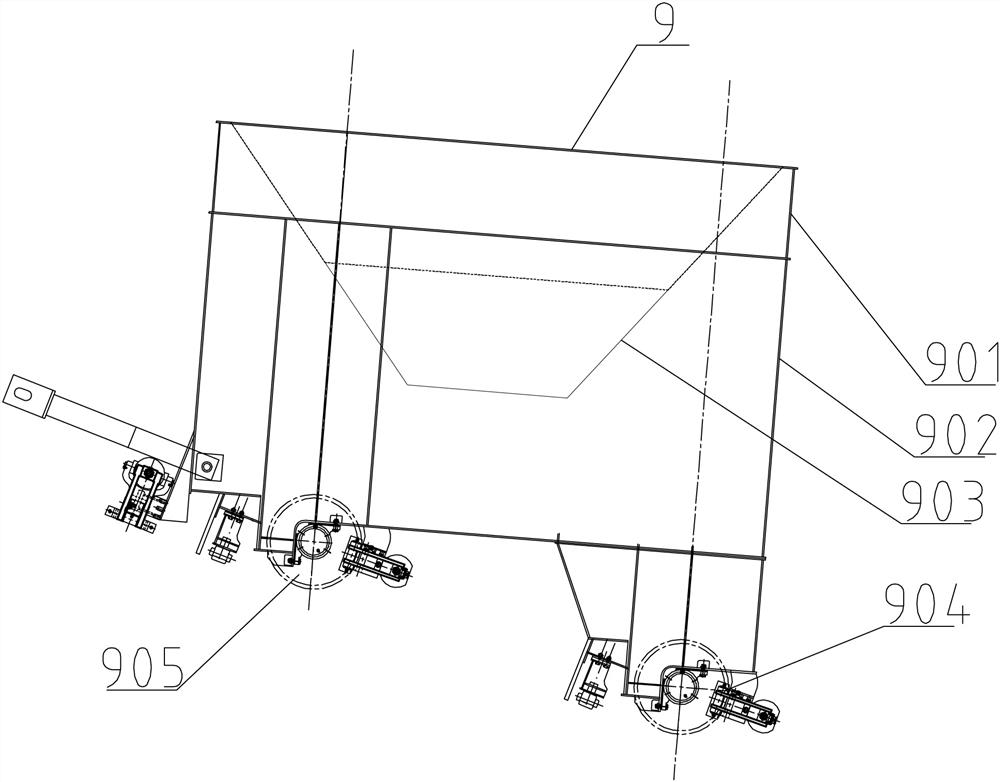

Action regulation fabricated formwork for U-box combined continuous beam segment cast-in-place

PendingCN110184924AAchieve regulationMeet the pouring useBridge erection/assemblyHydraulic cylinderContinuous beam

The invention discloses an action regulation fabricated formwork for U-box combined continuous beam section cast-in-place. The action regulation fabricated formwork comprises an inner mold, a bottom mold and side dies which are oppositely arranged on the two sides of the continuous beam pouring direction and are detachably connected with the inner mold and the bottom mold correspondingly, whereinthe inner mold comprises a top cross beam, an inner mold hydraulic cylinder and a plurality of groups of oppositely-arranged mold sections, the mold sections and the inner mold hydraulic cylinder arehinged to the bottom of the top cross beam, the output end of the inner mold hydraulic cylinder is hinged to the inner walls of the mold sections, a plurality of linear guide rods for supporting the mold sections are hinged in each group of oppositely-arranged mold sections, the side molds comprise upper side molds and lower side molds, the upper side molds are connected with the lower side moldsin an adjustable mode, the top cross beam is fixedly supported at the tops of the upper side molds, a rail car for adjusting the positioning heights and the horizontal torsion angles of the lower sidemolds is hydraulically supported at the bottoms of the lower side molds, and the two sides of the bottom mold are both fixedly connected with the lower side molds and cooperate with the lower side molds to adjust the supported the horizontal positions and the horizontal twisting angles. The action regulation fabricated formwork is suitable for casting the U-box combined continuous beam with variable section width segments.

Owner:THE FOURTH ENGIENERING OF CHINA RAILWAY18 BUREAU GROUP +1

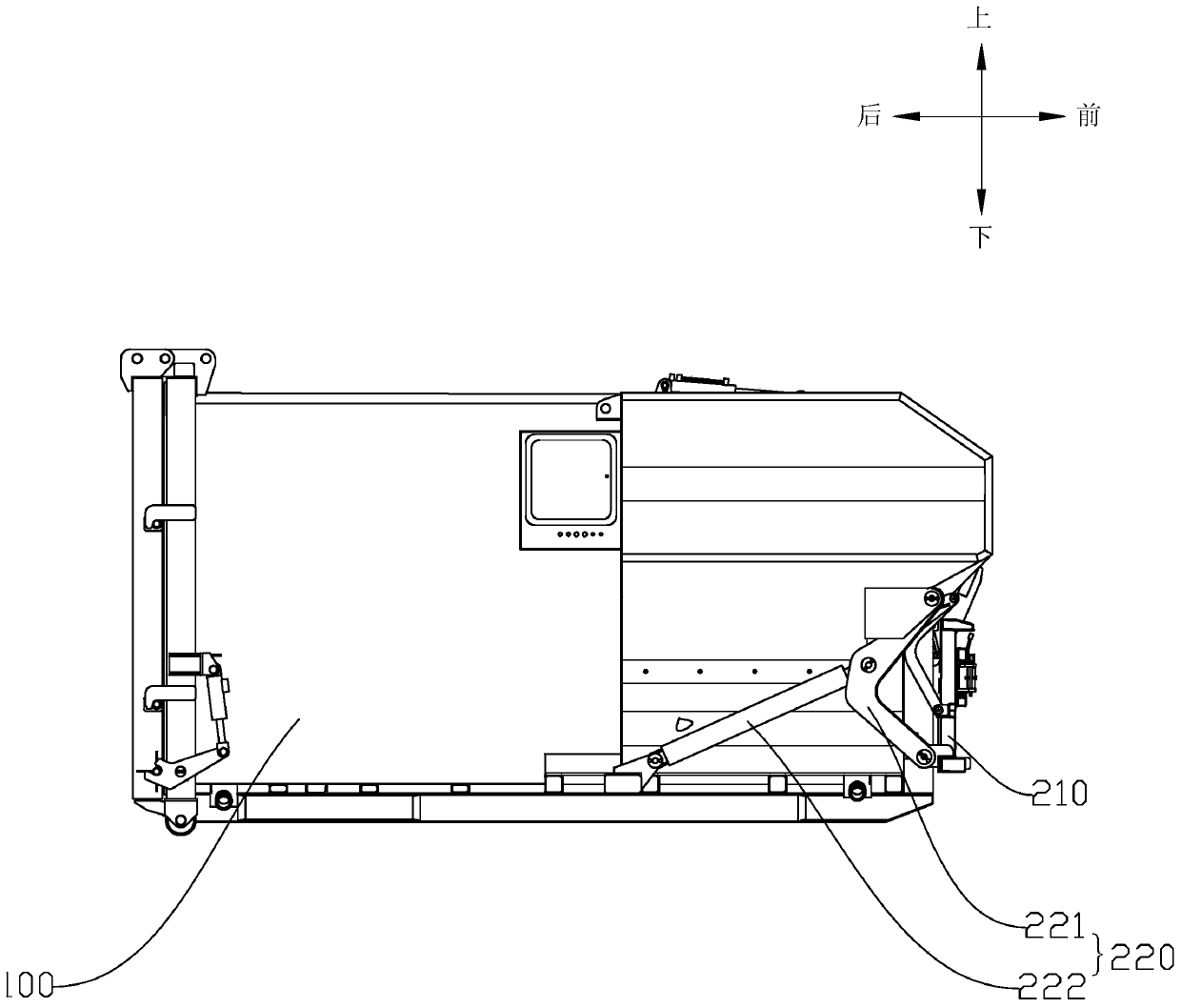

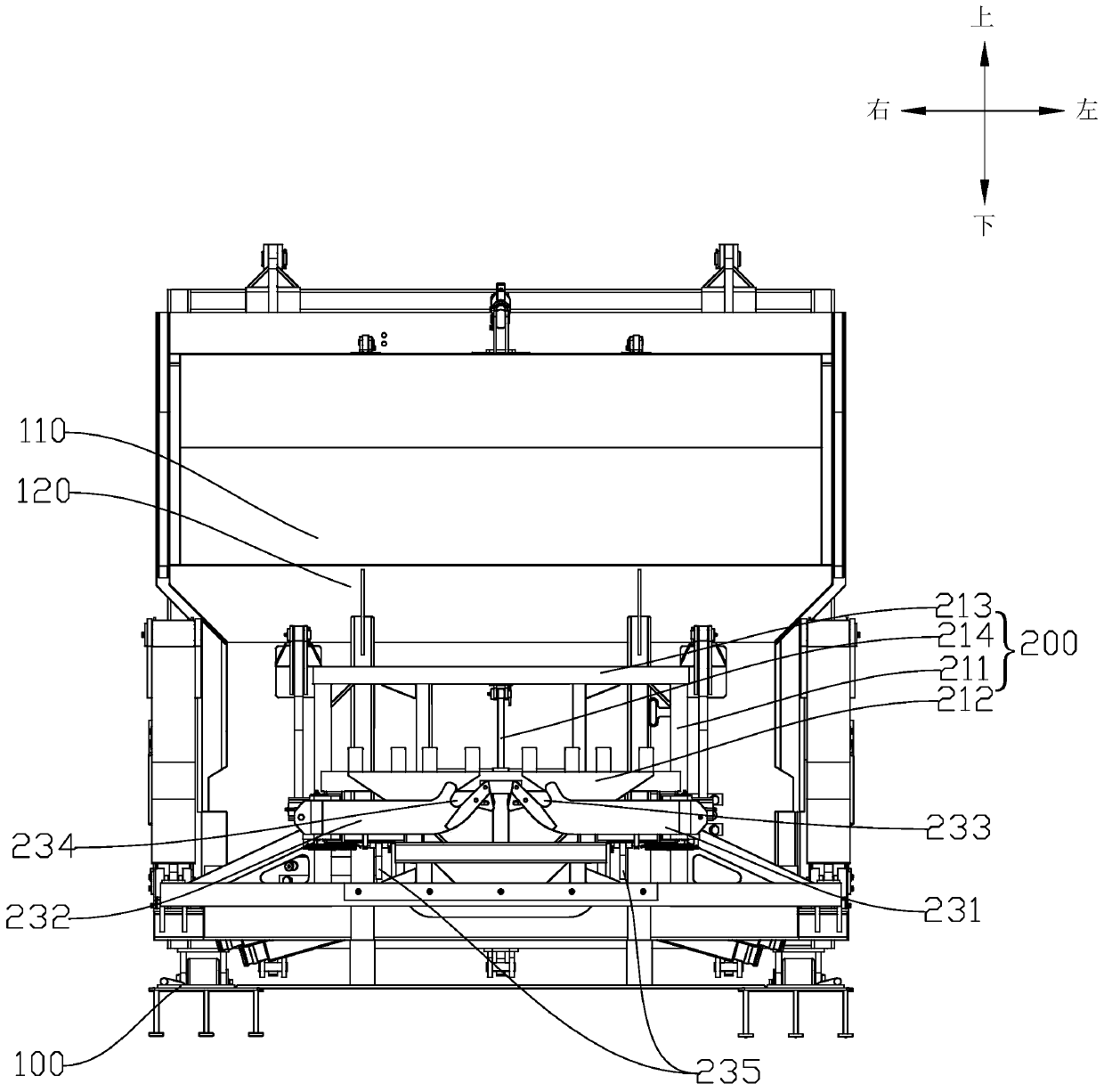

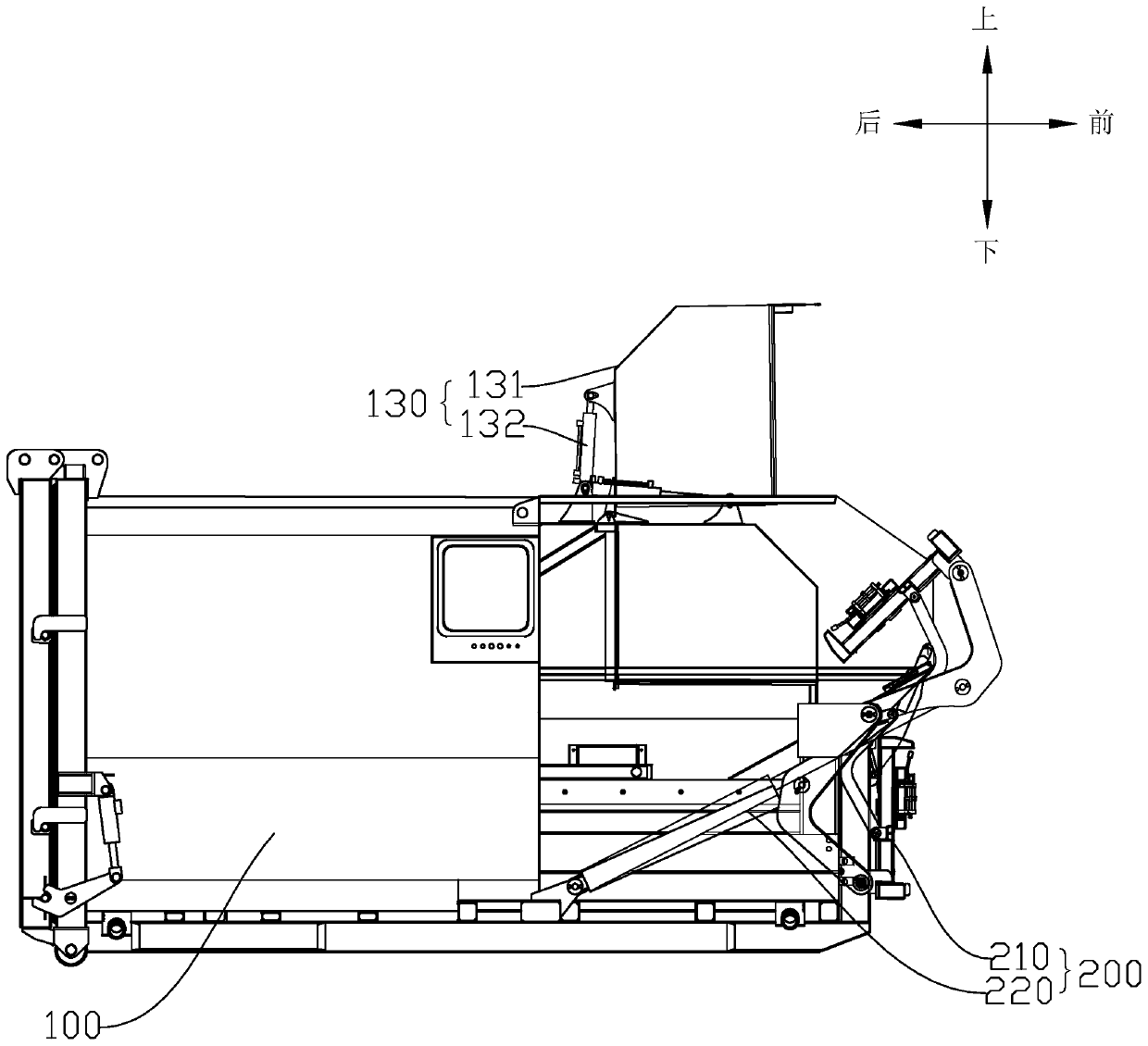

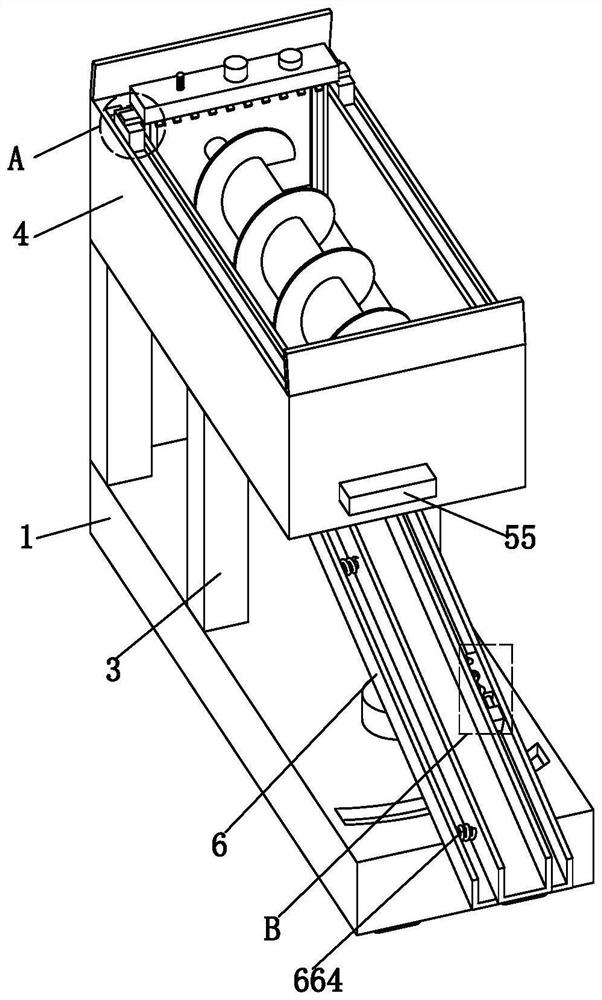

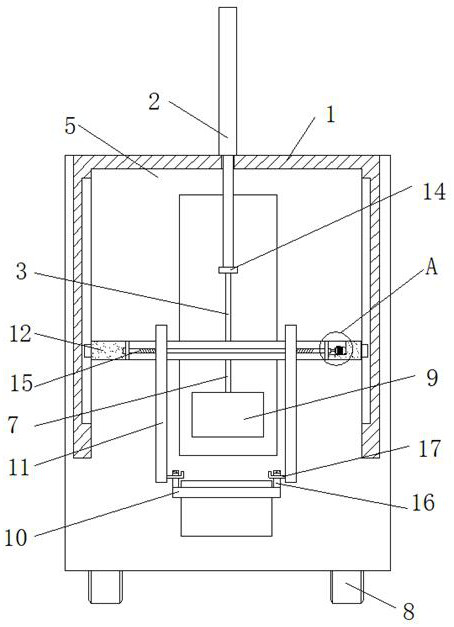

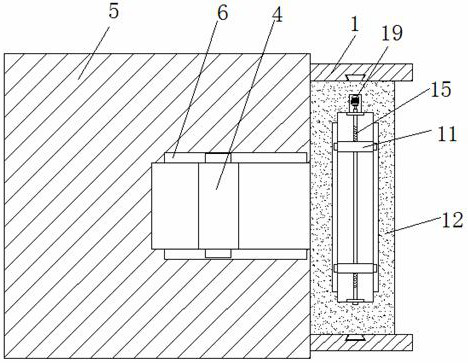

Mobile bin reversing waste compressor

PendingCN110884809ASave spaceRealize pouringRefuse transferringStorage devicesMechanical engineeringEnvironmental engineering

The invention discloses a mobile bin reversing waste compressor used for receiving waste poured from a waste bin and a waste collection vehicle. The mobile bin reversing waste compressor comprises a machine body and a bin reversing mechanism, wherein a feeding hole and a waste receiving plate are arranged at the front end of the machine body; and the bin reversing mechanism comprises a fixed frameand a turnover mechanism. According to the mobile bin reversing waste compressor provided by the invention, the feeding hole is formed in the front end, so that the lowest height of the feeding holeis reduced, and meanwhile, due to the arrangement of the waste receiving plate, the waste collection vehicle can be directly close to the waste receiving plate without being interfered with other components of the waste compressor, so that the mobile bin reversing waste compressor is able to receive the waste poured from the waste collection vehicle, also able to automatically empty the waste bin,and thus is convenient to use, efficient, economical and practical.

Owner:湖南中佳华悦环保科技有限公司

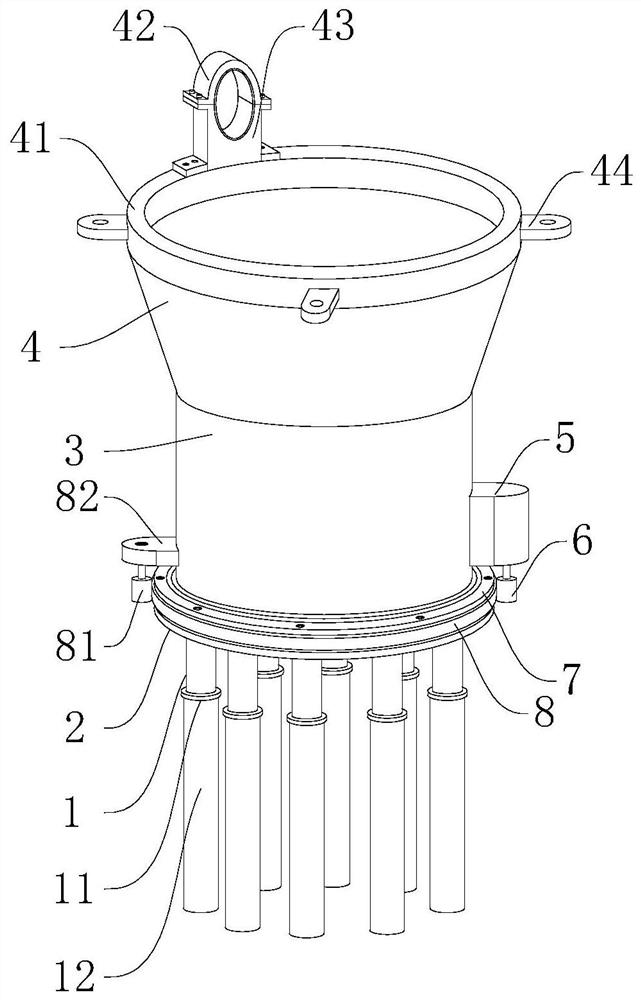

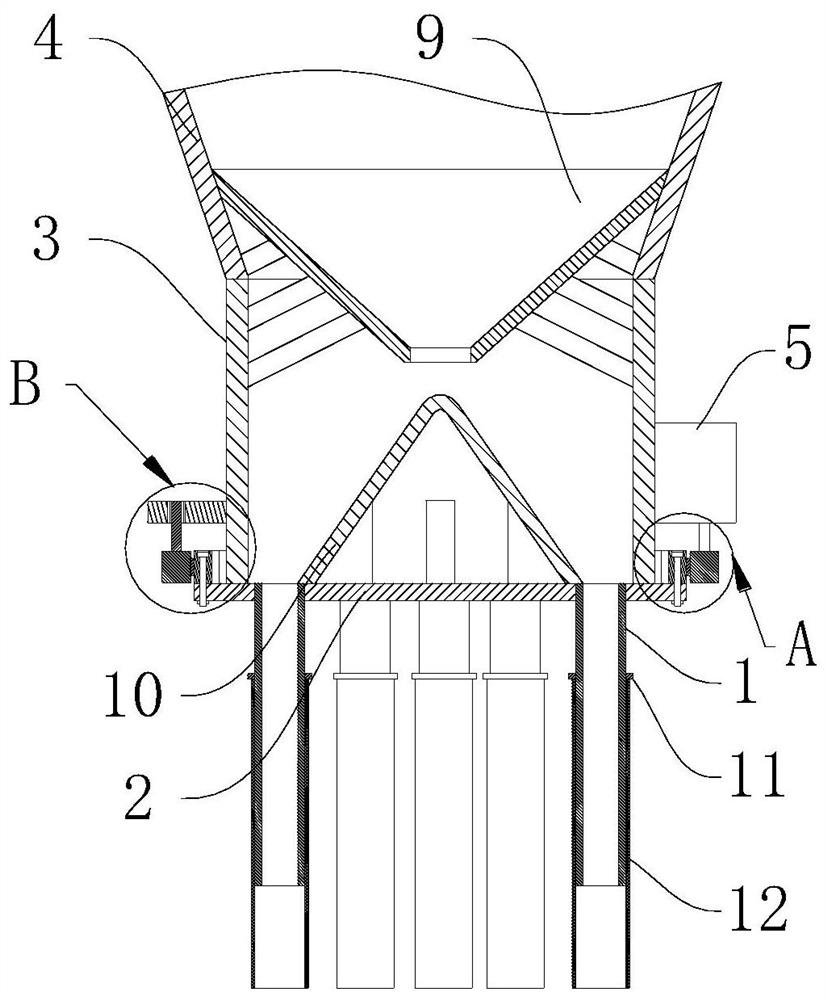

Lime distributing device for concrete pouring

The invention provides a lime distributing device for concrete pouring. The lime distributing device comprises a straight cylinder. The circular outer end of the lower side of the straight cylinder isrotationally connected with an auxiliary ring. The middle of the circular outer end of the auxiliary ring is fixedly connected with a ring gear. The lower end of the auxiliary ring is fixedly connected with a fixed disc through bolts. At least four lime slipping pipes are disposed on the edge of the lower end of the fixed disc at equal intervals. A driving motor is fixedly connected with the right end of the straight cylinder. An output shaft of the driving motor is fixedly connected with a transmission gear which meshes the right end of the ring gear. The middle of the upper end of the fixeddisc is fixedly connected with a big-end-down conical cover. At least four lime slipping pipes are disposed at the circular outer end of the position, connected with the fixed disc, of the conical cover. Compared with the prior art, the lime distributing device has the beneficial effects that by means of the driving motor, the transmission gear and the ring gear, the at least four lime slipping pipes can rotate, so that uniform pouring is realized, labor intensity is lowered and the pouring effect is improved.

Owner:山东晟达新材料有限公司

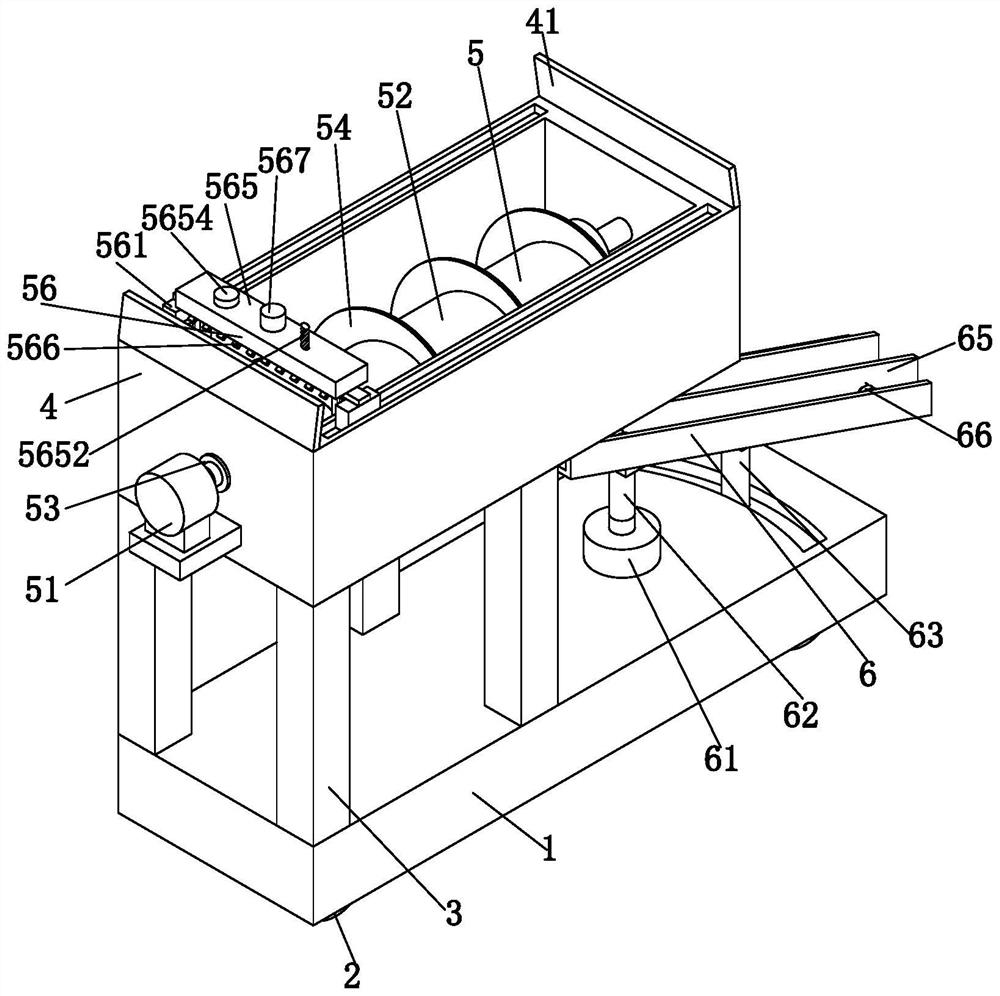

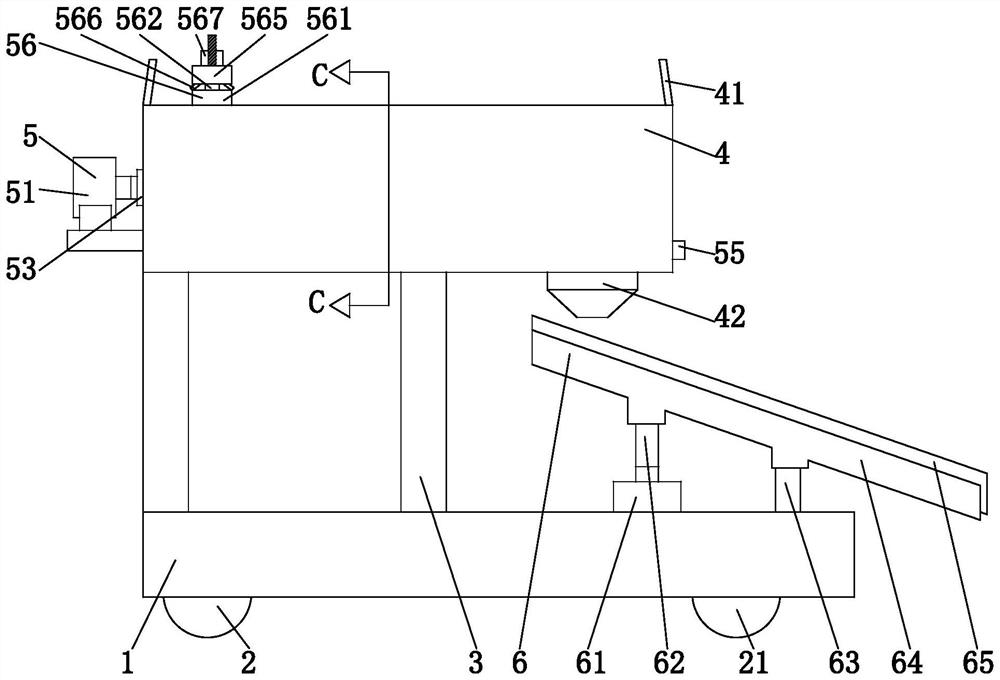

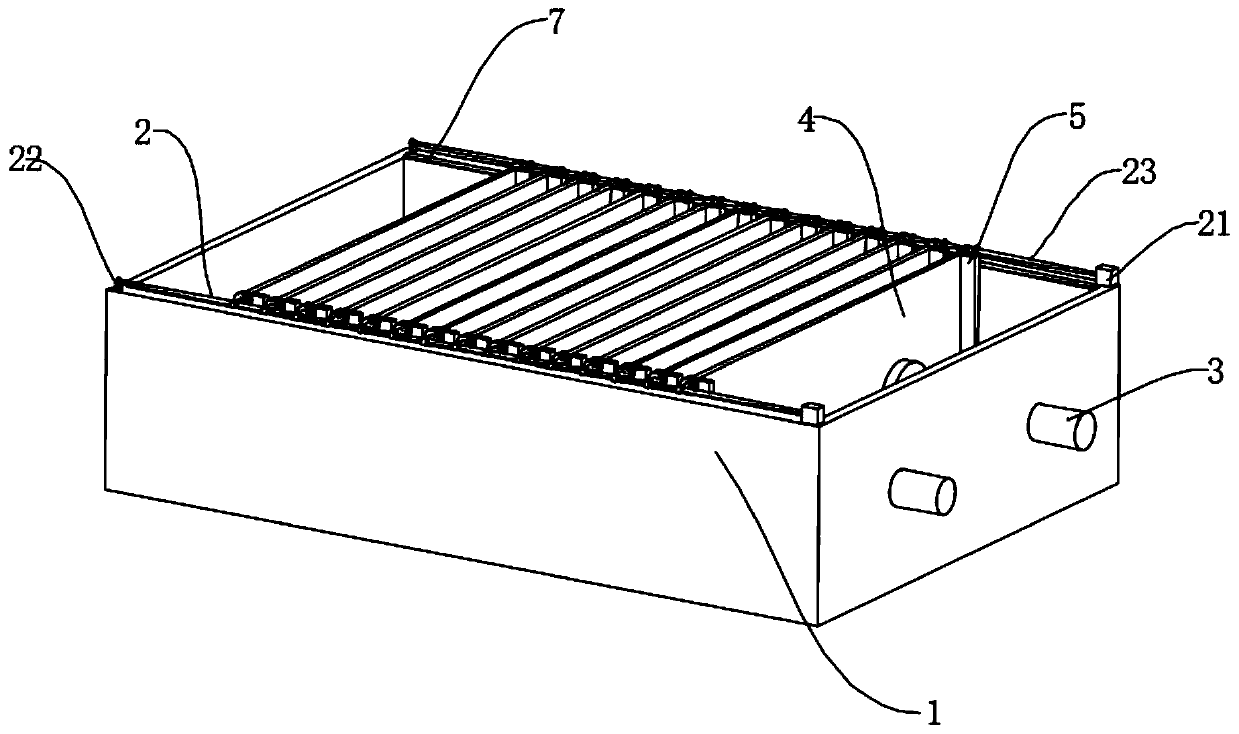

Fabricated type building module pouring device

ActiveCN113246261ARealize pouringSolid waste managementCeramic shaping plantsArchitectural engineeringSlide plate

The invention relates to the field of fabricated buildings, and discloses a fabricated type building module pouring device. The device comprises a rack, the top end of the rack is connected with a connecting plate, the connecting plate is connected with a stirring barrel, a stirring unit is arranged in the stirring barrel, the stirring barrel is communicated with a feeding hopper and a discharging pipe, and the rack is fixedly connected with a fixed plate. The fixed plate is located below the stirring barrel, a sliding plate is horizontally and slidably arranged on the fixed plate and is matched with the fixed plate, a mold groove box with the open top end is arranged on the sliding plate, the discharging pipe is arranged right opposite to the top of the mold groove box, and an elastic piece is connected between the rack and the sliding plate. A driving unit for intermittently pushing the sliding plate to horizontally slide is arranged on the rack. Concrete in the mold groove box can be uniformly distributed, so that the quality of a prefabricated module is improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

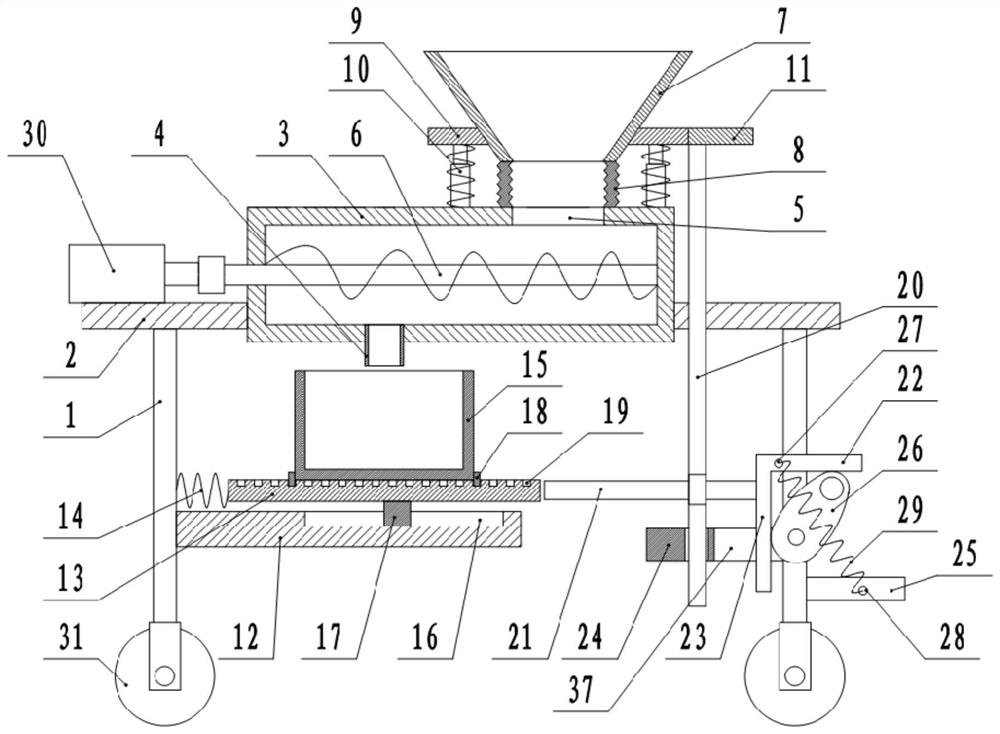

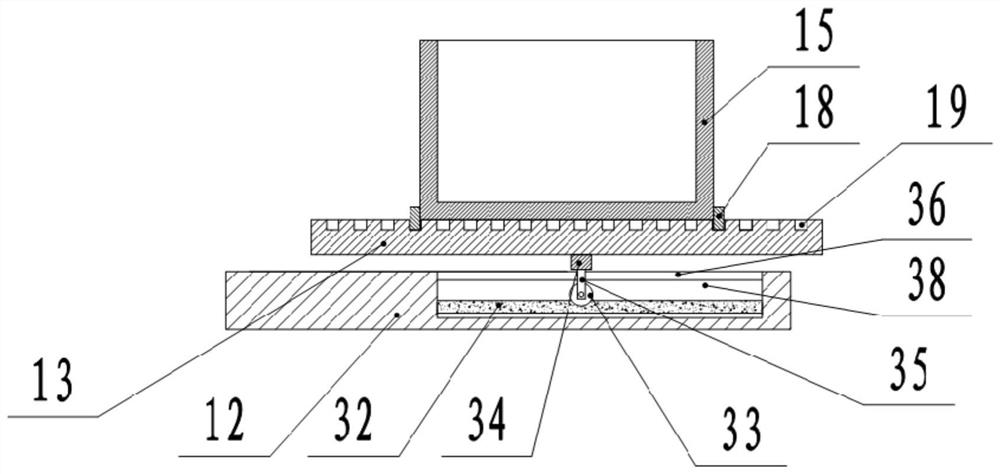

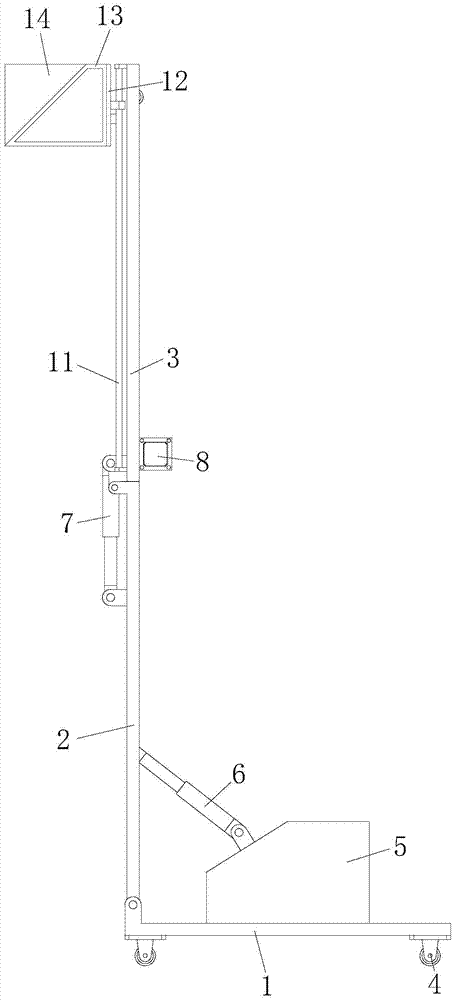

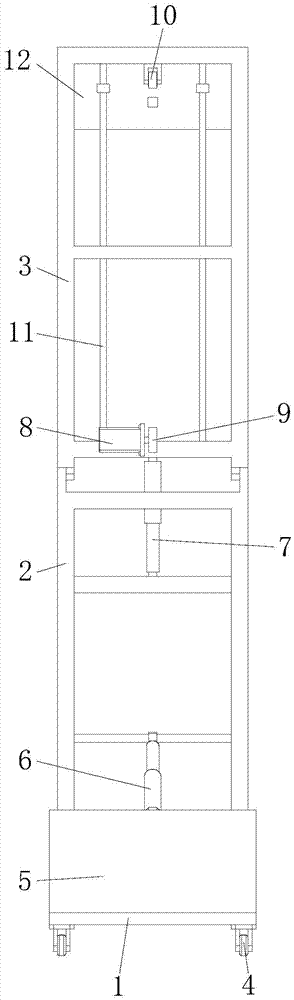

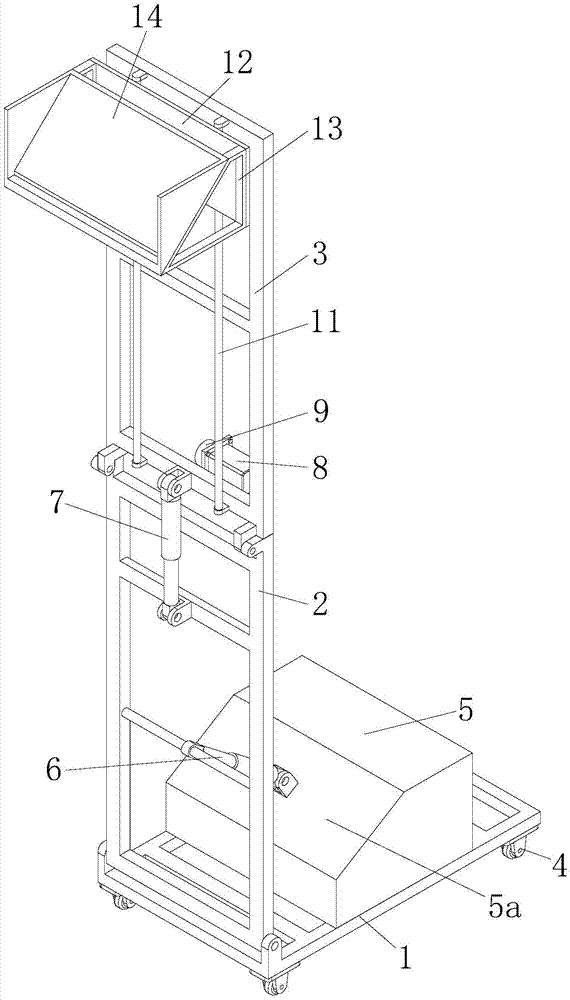

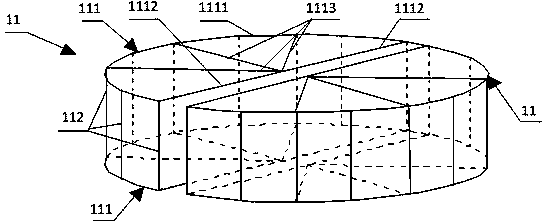

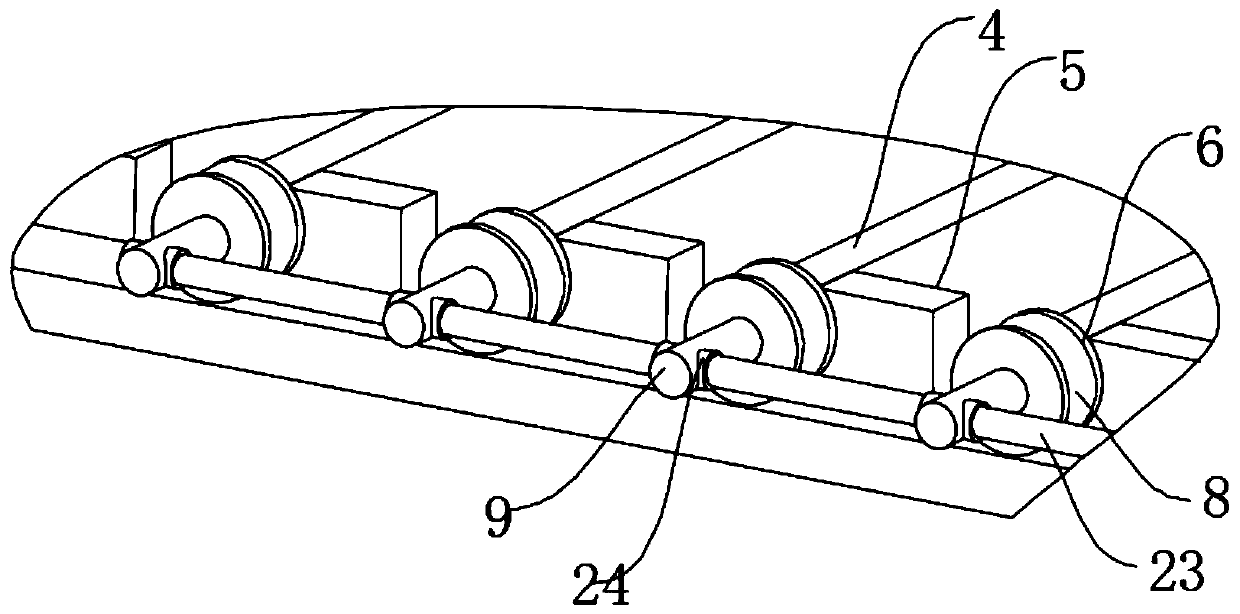

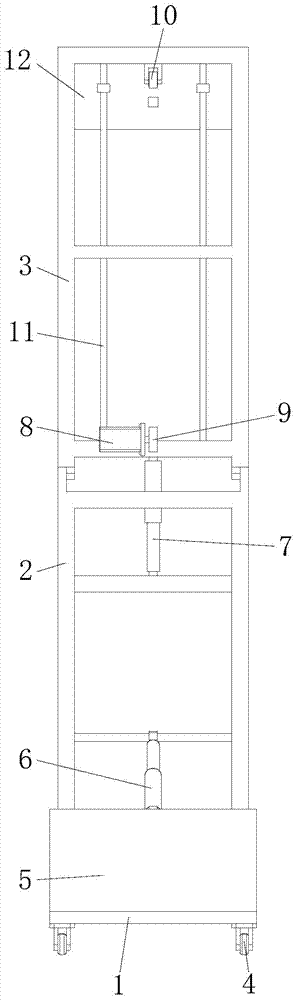

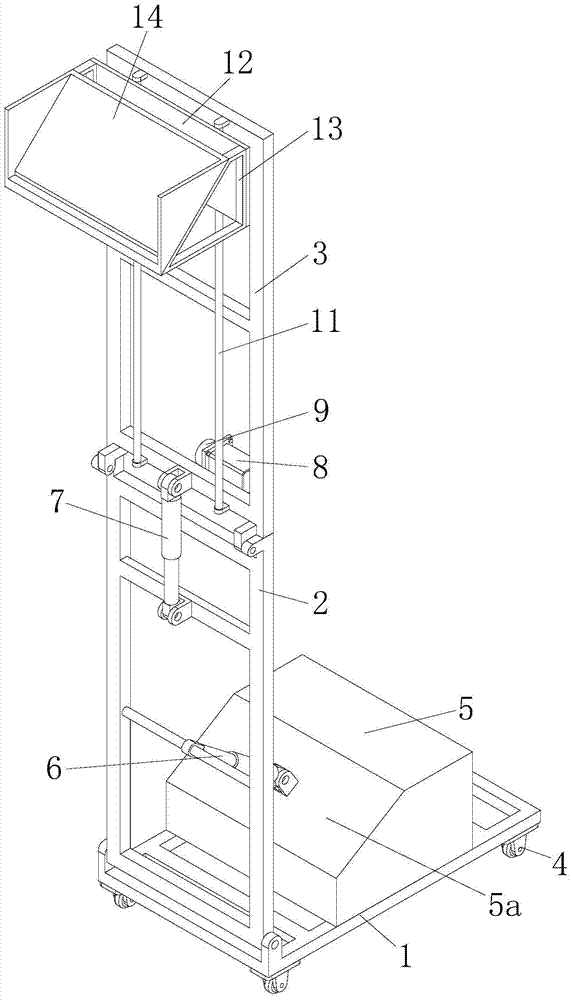

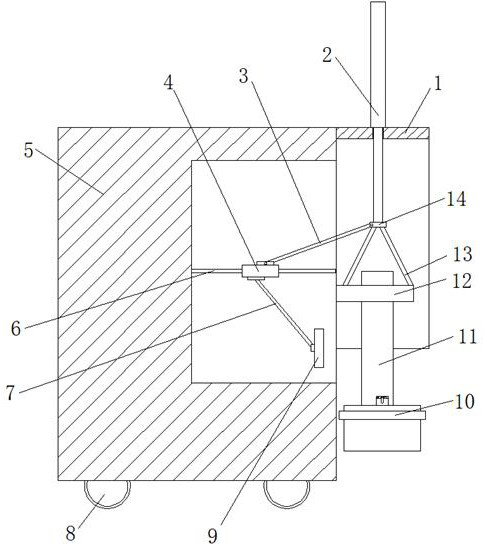

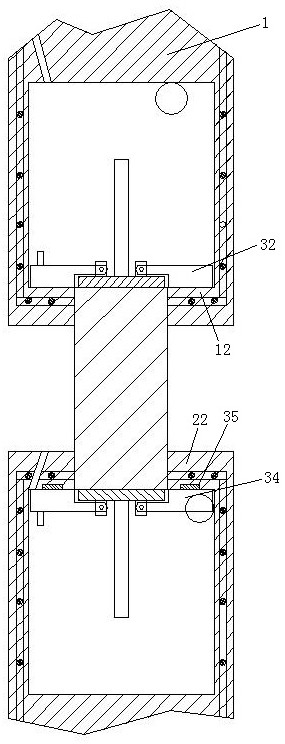

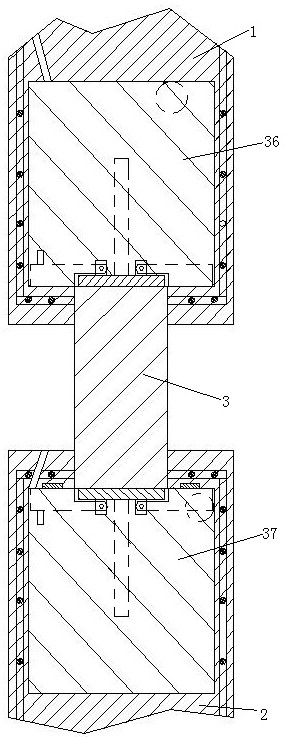

Concrete false bracket supporting device

ActiveCN105442846ARealize pouringQuality assuranceBuilding material handlingHydraulic cylinderDrive wheel

The invention discloses a concrete false bracket supporting device which comprises a base. A lower support is fixed to the front end of the base, an upper support is fixed to the upper end of the lower support, a casing is fixed to the upper end of the base, a first hydraulic cylinder is fixed to the upper end of the casing, a second hydraulic cylinder is fixed to the front end of the lower support, and a motor is installed at the rear end of the upper support. A driving wheel is fixed to a shaft of the motor, a supporting wheel is installed on the upper support, guide pillars are installed on the left and right of the upper support, a sliding plate is arranged in the front of the upper support, a supporting frame is fixed to the front end of the sliding plate, and a manufacturing groove is fixed to the front end of the supporting frame. The concrete false bracket supporting device has the advantages of being small in occupied space and convenient to use. Through the matching of the manufacturing groove, the lower support and the upper support, the pouring of a concrete false bracket is performed, the preparation time for pouring is reduced, manpower and material resources are saved, and the concrete pouring quality is guaranteed.

Owner:TAIZHOU TECHSENCE WIRES

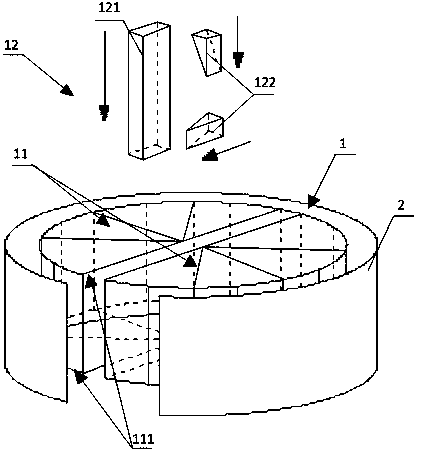

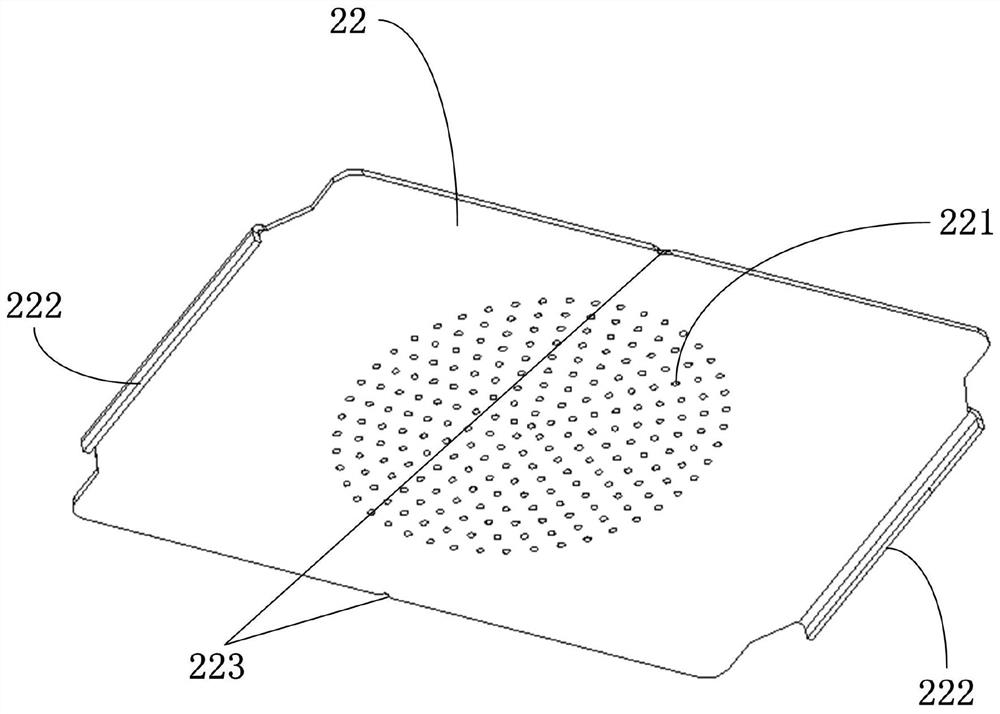

Well cover plate formwork structure and well cover plate manufacturing method

PendingCN109702867ARealize pouringImprove disassembly efficiencyMouldsArchitectural engineeringStructural engineering

Owner:MCC5 GROUP CORP SHANGHAI

Ore particle screening device

Owner:JIANGXI UNIV OF SCI & TECH

Horizontal concrete transportation device for roof construction

ActiveCN113863676AAffect the use effectImprove pouring efficiencyRoof toolsBuilding material handlingArchitectural engineeringSlurry

The invention relates to the technical field of concrete transportation, and particularly relates to a horizontal concrete transportation device for roof construction. The horizontal concrete transportation device comprises a moving frame, rollers, supporting columns, a transportation frame, a stirring mechanism and a guide frame. In the stirring mechanism, concrete is stirred through stirring blades in the rotating process of a stirring shaft, and the situation that stones and slurry are distributed unevenly due to sinking of the stones in the concrete in the transportation process, and the subsequent use effect of the concrete is affected is avoided; and in the guide frame, a first supporting frame rotates and is matched with a second supporting frame to drive a material guide frame to rotate, then the material guide frame can be driven to rotate to different positions of a roof, thus pouring of the concrete at the corners of the roof can be achieved, and the pouring efficiency of the concrete is improved.

Owner:中建五局第二建设有限公司

Automatic demoulding device of fireproof door core board equipment

InactiveCN109910143AAchieve demouldingEasy to demouldCeramic shaping apparatusEngineeringElectrical and Electronics engineering

The invention discloses an automatic demoulding device of fireproof door core board equipment. The automatic demoulding device comprises a demoulding box, a traction device and ejector rod devices. The traction device and the ejector rod devices are arranged on the demoulding box. A plurality of partition plates are arranged in the demoulding box and can move relative to the demoulding box throughthe traction device. Stop strips are further arranged at the two ends of the partition plates and jack the corresponding partition plates through the ejector rod devices. A traction motor is used fordriving a traction rope to move, accordingly, the partition plates are driven to move, and demoulding is achieved. Demoulding is convenient, and the technical problem that at present, multiple platesare stacked together for pouring, and die sinking is not convenient is solved. The stop strips and the partition plates are detachably connected. The matched stop strips can be selected according tothe product thickness, accordingly, pouring of fireproof door core boards different in thickness can be achieved, and universality of the device is enhanced.

Owner:HEMUJIA CHENGDU NEW MATERIAL CO LTD

A concrete false corbel supporting device

ActiveCN105442846BRealize pouringQuality assuranceBuilding material handlingHydraulic cylinderDrive wheel

The invention discloses a concrete false bracket supporting device which comprises a base. A lower support is fixed to the front end of the base, an upper support is fixed to the upper end of the lower support, a casing is fixed to the upper end of the base, a first hydraulic cylinder is fixed to the upper end of the casing, a second hydraulic cylinder is fixed to the front end of the lower support, and a motor is installed at the rear end of the upper support. A driving wheel is fixed to a shaft of the motor, a supporting wheel is installed on the upper support, guide pillars are installed on the left and right of the upper support, a sliding plate is arranged in the front of the upper support, a supporting frame is fixed to the front end of the sliding plate, and a manufacturing groove is fixed to the front end of the supporting frame. The concrete false bracket supporting device has the advantages of being small in occupied space and convenient to use. Through the matching of the manufacturing groove, the lower support and the upper support, the pouring of a concrete false bracket is performed, the preparation time for pouring is reduced, manpower and material resources are saved, and the concrete pouring quality is guaranteed.

Owner:TAIZHOU TECHSENCE WIRES

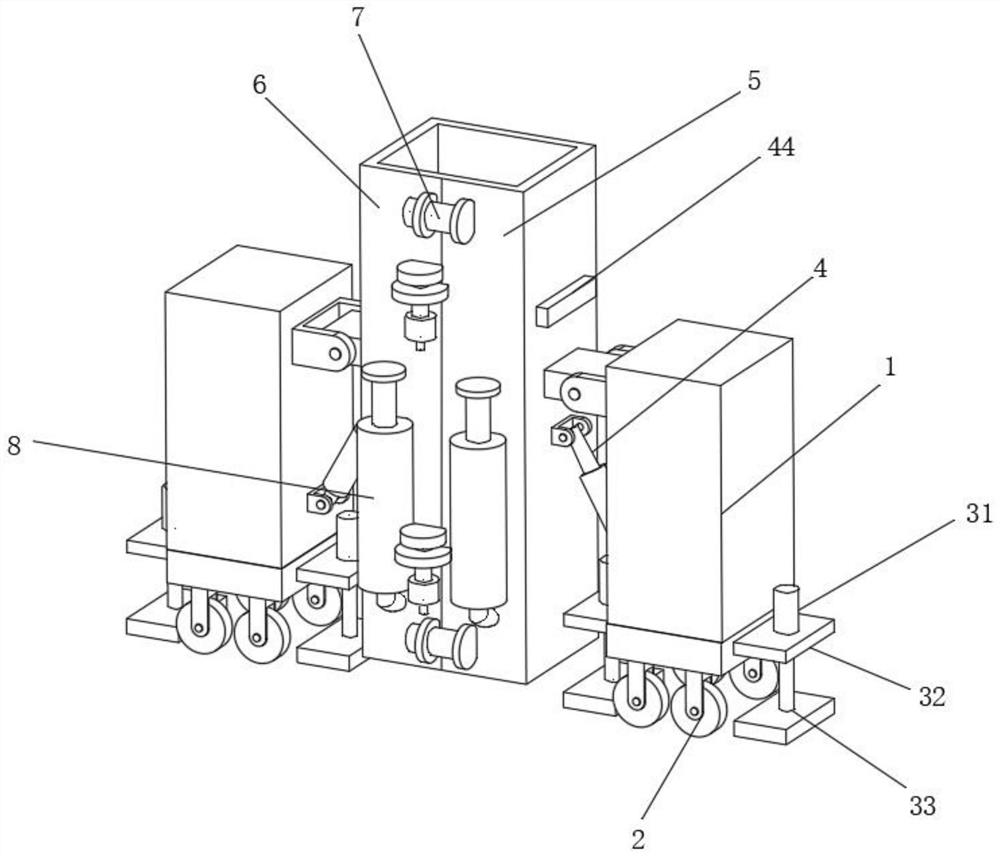

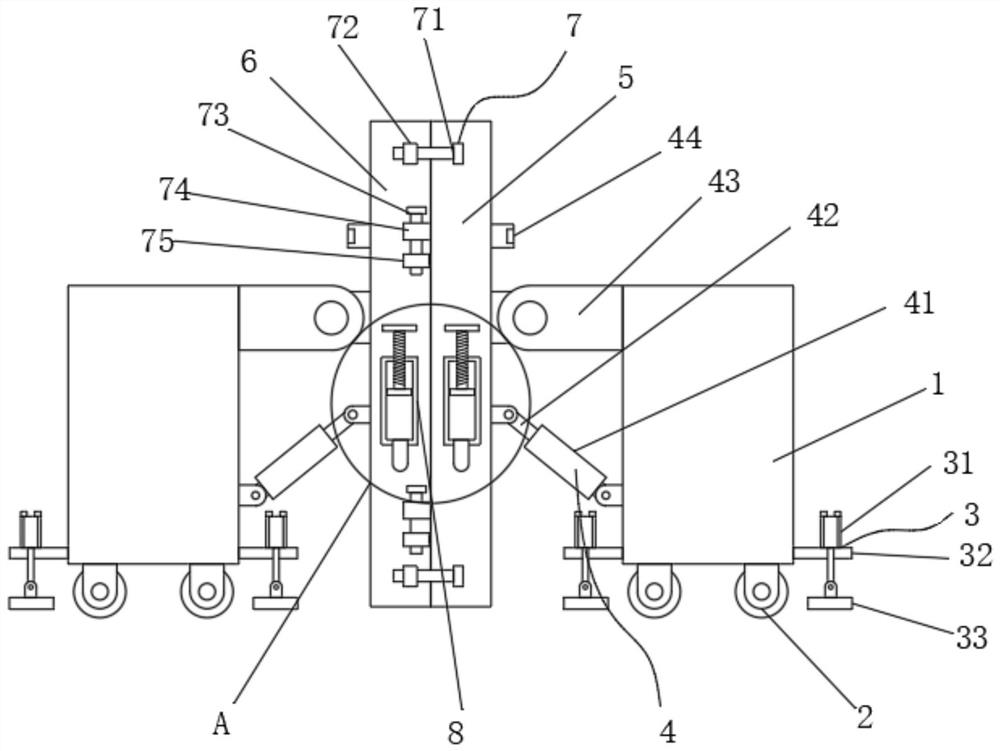

Concrete column forming assembling formwork

InactiveCN112252709AGuaranteed to be verticalFirmly assembledForms/shuttering/falseworksForm treatmentArchitectural engineeringStructural engineering

The invention discloses a concrete column forming assembling formwork. The concrete column forming assembling formwork comprises counterweight machine boxes, wheels, lifting structures, calibration structures, a first formwork, a second formwork, a positioning structure and expansion structures, wherein the wheels are arranged at the bottoms of the counterweight machine boxes, and the lifting structures are arranged on the two sides of the bottoms of the counterweight machine boxes correspondingly; and the calibration structures are arranged on one sides of the counterweight machine boxes, thefirst formwork is arranged on one side of the corresponding calibration structure, the first formwork and the second formwork are assembled in a matched mode through the positioning structure, and the expansion structures are arranged on the side face of the first formwork and the side face of the second formwork correspondingly. Through the arrangement of the calibration structures and operationof calibration air cylinders, under the cooperation of pneumatic rods, the angle of the first formwork can be changed, and under the observation cooperation of levelling instruments, it can be guaranteed that the first formwork is in a vertical state so that splicing stability can be guaranteed; and meanwhile it is guaranteed that a concrete column is vertical, so that pouring is more standard.

Owner:PUYANG VOCATIONAL & TECHN COLLEGE

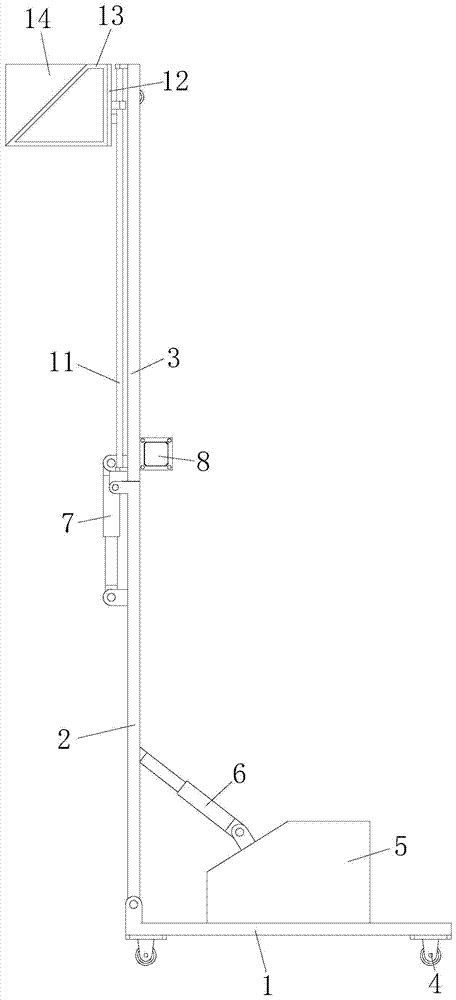

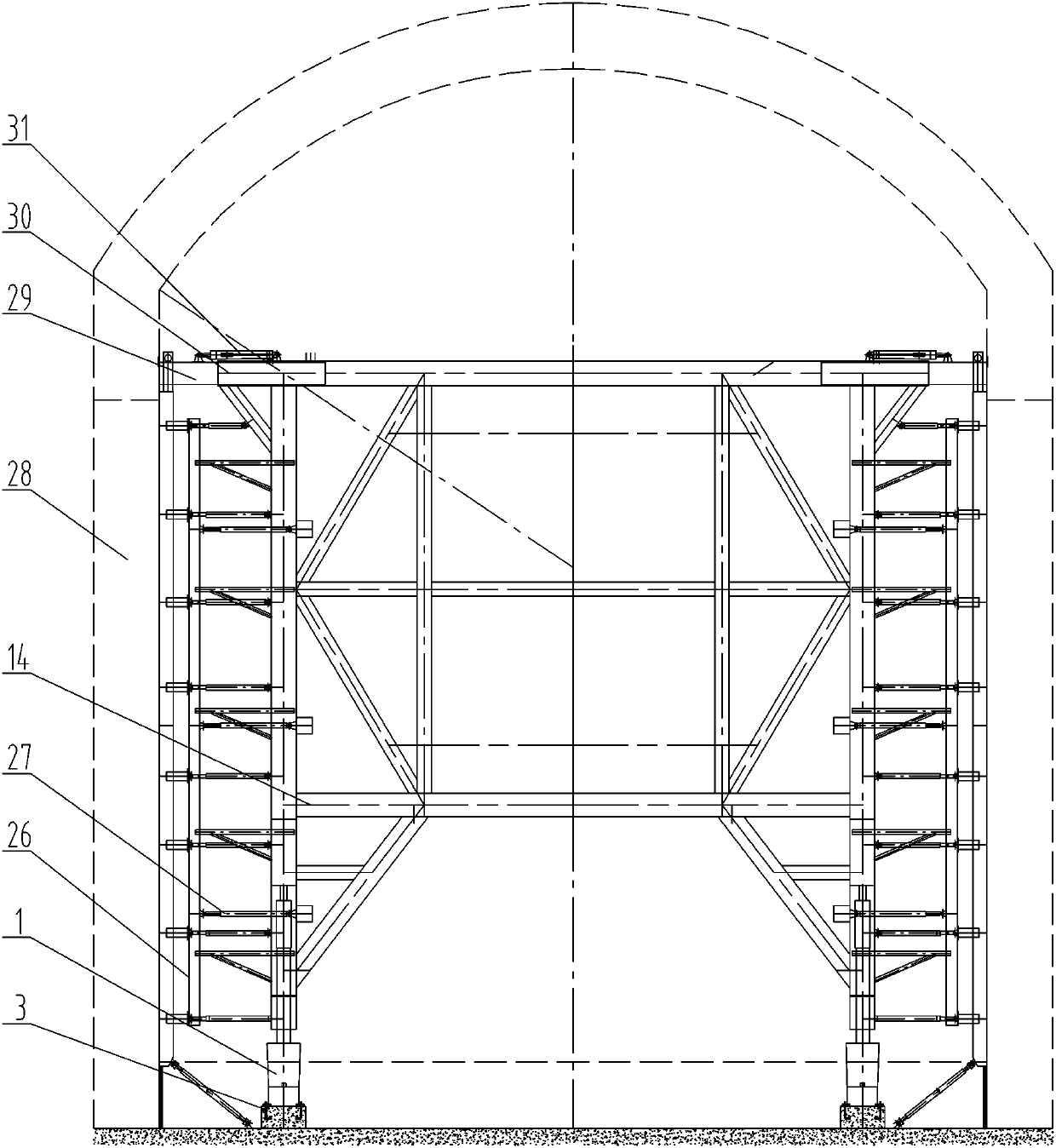

Variable section hydraulic self-propelled trolley and operation method thereof

InactiveCN110424344APouring Construction GuaranteeGuaranteed stabilityBarrages/weirsHydraulic cylinderVehicle frame

The invention provides a variable section hydraulic self-propelled trolley and an operation method thereof. Multiple groups of rail wheels are arranged at the top of a trolley rail in a rolling and supporting way; the rail wheels are fixedly arranged on a wheel supporting frame; a trolley frame is arranged on the wheel supporting frame through a lifting mechanism; a trolley power device for movingthe trolley is arranged at the bottom of the trolley frame; a plurality of telescopic sleeves are fixedly arranged at the top of the trolley frame in a crossing way; telescopic rods are arranged in the telescopic sleeves in a sliding fit way; a telescopic hydraulic cylinder is arranged between the telescopic sleeves and the telescopic rods; a template for pouring is fixedly arranged on the outerend face of the telescopic hydraulic cylinder; and a demolding hydraulic cylinder for demolding is arranged between the template and the trolley frame. The trolley can realize construction of variouslining bodies of cavity concrete, can effectively guarantee the cavity lining construction period and can reduce a large amount of equipment input and labor cost.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

Raw material carrying mechanism for tissue production

InactiveCN112239080ASolve automatic material handlingSolve the unloading problemConveyorsBottle emptyingHydraulic cylinderElectric machinery

The invention discloses a raw material carrying mechanism for tissue production, relates to the field of tissue production, and provides the following scheme for solving the problem that a traditionalraw material carrying mechanism for tissue production cannot realize automatic carrying and unloading. The raw material carrying mechanism comprises a moving body, an inner cavity is formed in the moving body, and a hinge block is slidably connected to the interior of the inner cavity; and a push rod is hinged to the top of the hinge block, a connecting rod is fixedly connected to the bottom of the hinge block, a push plate is connected to the right side of the connecting rod, a carrying frame is fixedly connected to the right side of the moving body, a hydraulic cylinder is fixedly connectedto the top of the carrying frame, and a connecting plate is fixedly connected to an output shaft of the hydraulic cylinder. Automatic material carrying and conveying can be achieved by controlling the hydraulic cylinder and a motor, automatic material pouring can be achieved, and a large amount of manpower is saved.

Owner:LINLI KANGJIE PAPER IND

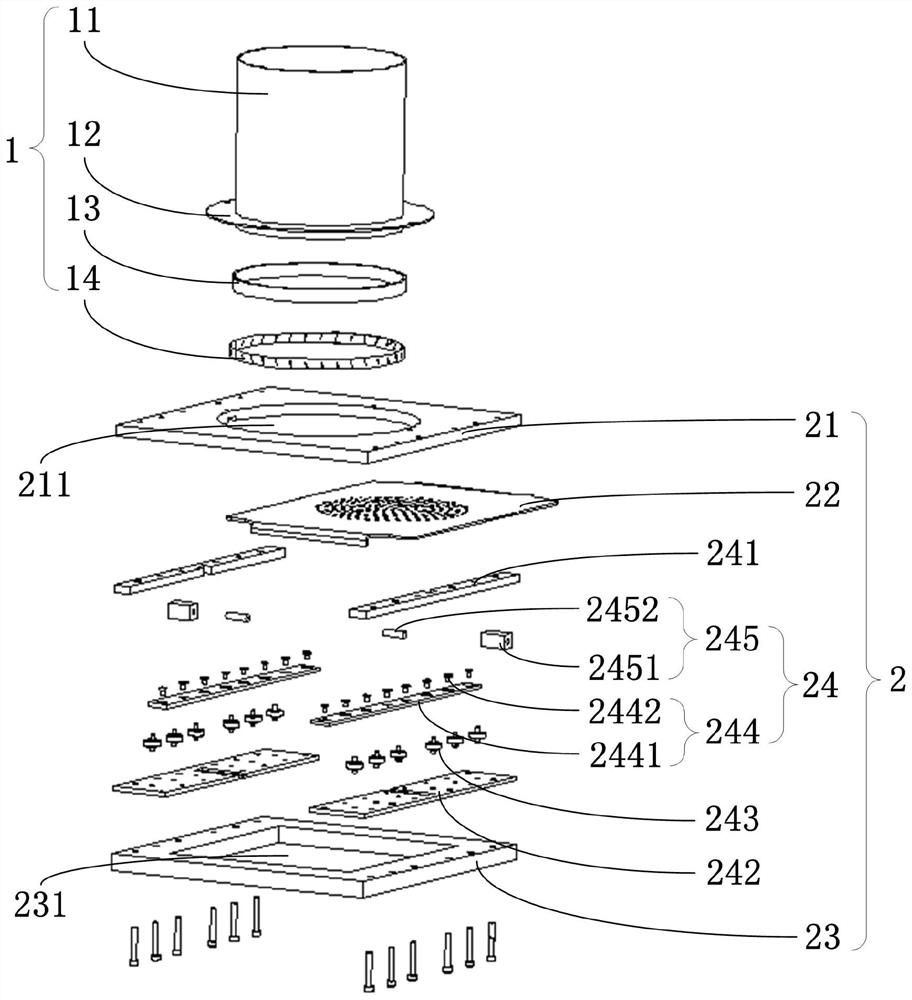

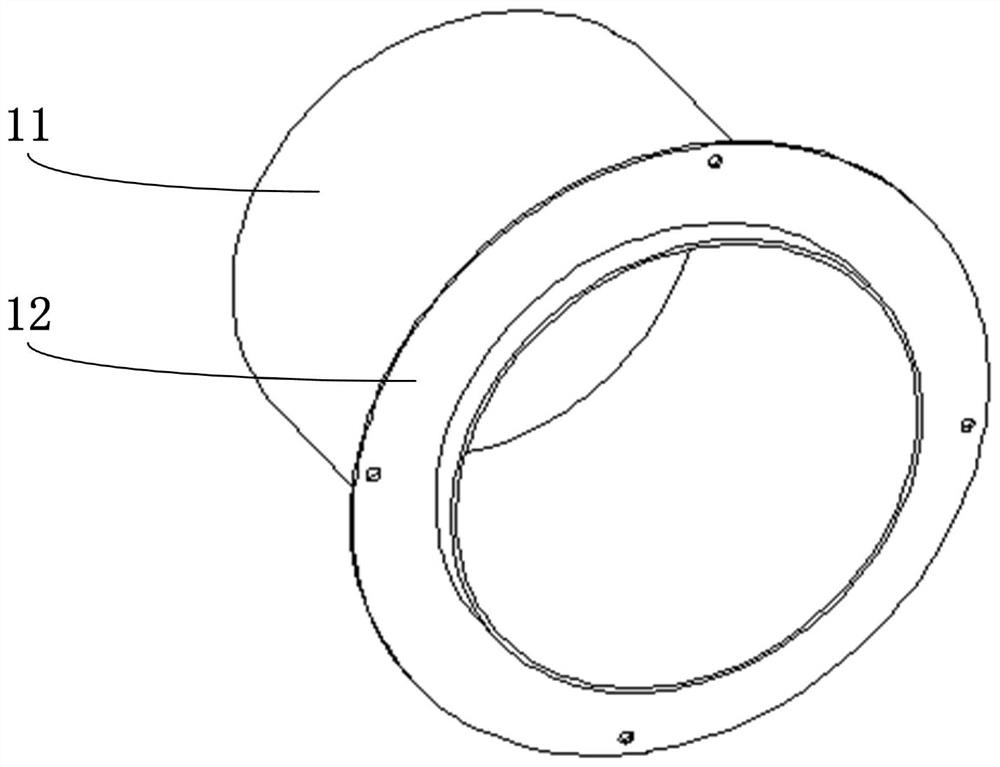

Novel tea barrel and bottom-drawing discharging device with same

PendingCN112772745ASimple structureImprove compactnessPre-extraction tea treatmentFood shapingEngineeringAssembly line

The invention discloses a novel tea barrel and a bottom-drawing discharging device with the same. The novel tea barrel comprises a tea barrel body and a barrel bottom mechanism, the tea barrel body comprises a barrel body, a flange plate and a gasket, the flange plate is fixedly connected to the bottom side wall of the barrel body in a sleeving mode, and the gasket is arranged below the flange plate and connected to the circumferential side wall of the barrel body in a sleeving mode. The barrel bottom mechanism comprises a barrel bottom upper layer, a barrel bottom middle layer, a barrel bottom lower layer and a guide assembly, the barrel bottom upper layer and the barrel bottom lower layer are connected through bolts, a gap is formed between the barrel bottom upper layer and the barrel bottom lower layer, the barrel bottom middle layer is slidably connected in the gap, and the guide assembly is located between the barrel bottom upper layer and the barrel bottom lower layer. The barrel bottom mechanism comprises a barrel bottom upper layer, a barrel bottom middle layer, a barrel bottom lower layer and a guide assembly, the barrel bottom upper layer and the barrel bottom lower layer are connected through bolts, a gap is formed between the barrel bottom upper layer and the barrel bottom lower layer, the barrel bottom middle layer is slidably connected in the gap, and the guide assembly is located between the barrel bottom upper layer and the barrel bottom lower layer. The novel tea barrel is simple in structure, reasonable in design, convenient to operate, good in structural stability, high in compactness and capable of effectively achieving mechanical assembly line production operation of compressed tea and has good market application prospects.

Owner:云南昆船电子设备有限公司

Vacuum tank cover, vacuum pouring device with vacuum tank cover and pouring method

The invention discloses a vacuum tank cover, a vacuum pouring system with the vacuum tank cover and a pouring method, and relates to the technical field of pouring. According to the vacuum tank, the sealing cover plate is arranged on the sprue gate, so that the sealing performance of the vacuum tank is improved, the pre-vacuumizing time before pouring can be greatly shortened, and the vacuum degree in the vacuum tank can be kept after pre-vacuumizing. During use, after a sealing ring is arranged in a refining package, the pressure above and below the sealing cover plate is balanced through the balance pipe, and then the sealing cover plate is dragged away from the sprue gate through the air cylinder, so that pouring is realized, and the sliding plate argon blowing time before pouring is shortened.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

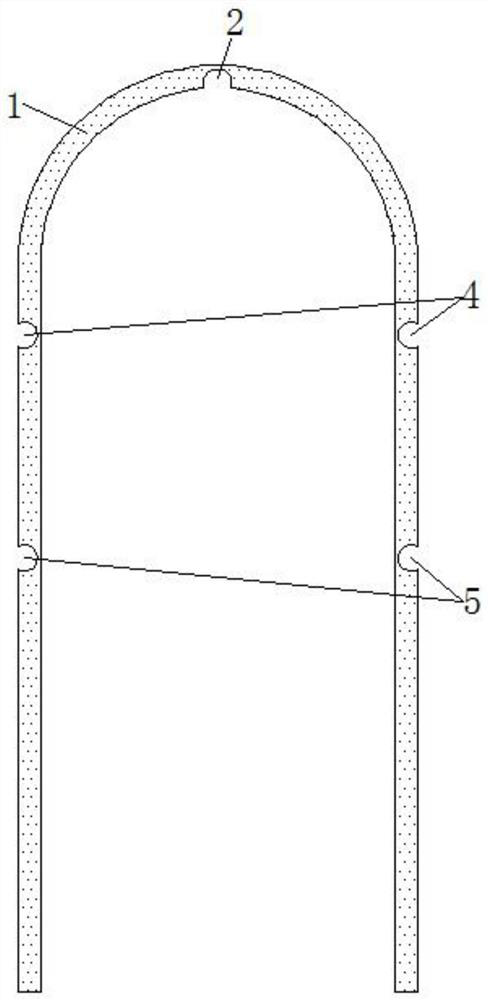

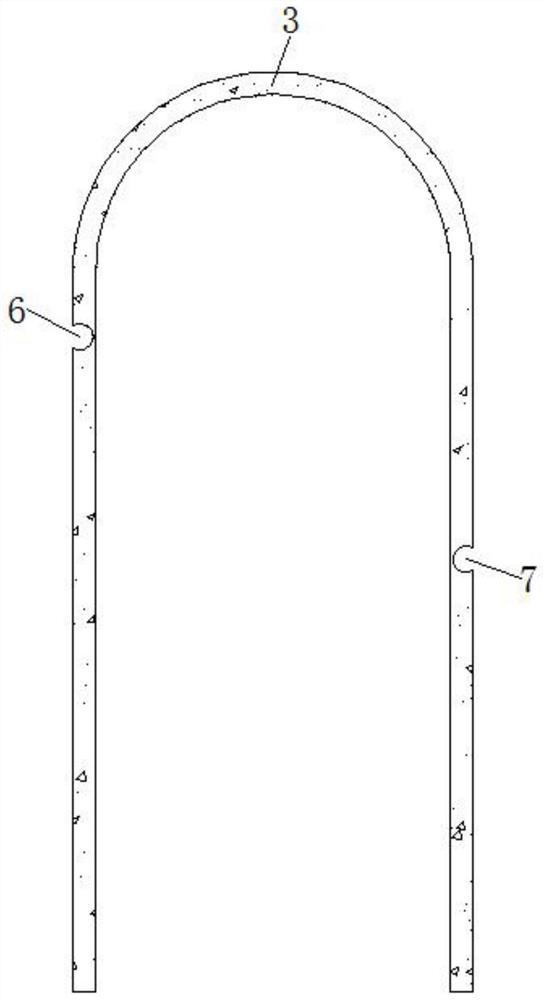

Roughening device with spraying unit

PendingCN111946364AAvoid Uprooting Difficult ProblemsAchieve eradicationUnderground chambersTunnel liningConstruction engineeringStructural engineering

The invention provides a roughening device with a spraying unit. The roughening device comprises a connecting frame, and a spraying unit and a roughening unit which are arranged on the connecting frame. According to the roughening device, after the spraying unit communicates with a concrete pouring device, concrete pouring construction can be achieved, and meanwhile, the roughening unit can immediately conduct roughening treatment after concrete initial spraying pouring of the spraying unit, so that shoveling of over-sprayed concrete is achieved, the problem that the concrete is difficult to shovel after hardening due to untimely roughening is avoided, and the construction is convenient; and in addition, the roughening unit is fixedly connected with the spraying unit, and the roughening unit can conduct construction along with the spraying unit, so that the problems that at prior art, manual shoveling and a handheld roughening machine are difficult to cover the whole construction surface and large in labor consumption and roughening construction of an machine-mounted roughening machine is inconvenient to conduct and insufficient in construction space are effectively solved, the labor intensity of workers is greatly reduced, the construction efficiency is improved, and the construction is safe and reliable.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Seismic Isolation Method for Prefabricated Concrete Structure Floors

ActiveCN109594833BAchieve vibration-isolated connectionsRealize pouringProtective buildings/sheltersShock proofingArchitectural engineeringVibration isolation

Owner:ZHEJIANG SCI-TECH UNIV

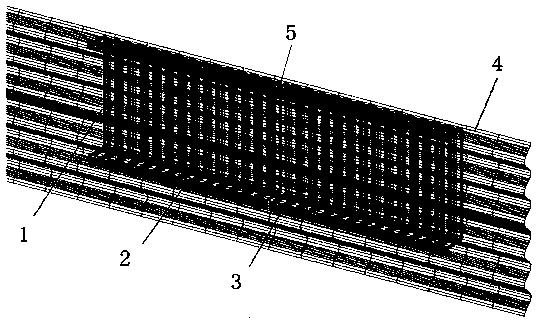

External template applicable to steel-concrete composite steel corrugated plate arch bridge and culvert

The invention provides an external template applicable to steel-concrete composite steel corrugated plate arch bridge and culvert and belongs to the technical field of steel corrugated plate structures. The external template applicable to steel-concrete composite steel corrugated plate arch bridge and culvert is used for concrete pouring of the steel corrugated plate and concrete composite steel corrugated plate arch bridge and culvert. According to the technical scheme, the external template applicable to the steel-concrete composite steel corrugated plate arch bridge and culvert comprises multiple template segments connected with each other; and each template segment correspondingly comprises a top plate, side plates and a fixed edge, wherein the top plate and the side plates are correspondingly oblong small-sized steel corrugated plate pieces; the fixed edge is a long strip-shaped plane steel plate; the two side plates are vertically connected to the two sides of the top plate; thelength directions of a wave peak and a wave valley of the top plate are perpendicular to the length direction of the top plate; wave peaks and wave valleys of the side plates are correspondingly connected with the wave peak and the wave valley of the top plate; the external sides of the bottom edges of the two side plates are vertically connected with the fixed edge; and screw holes are uniformlyformed in the fixed edge. According to the external template applicable to steel-concrete composite steel corrugated plate arch bridge and culvert, the structure is simple and scientific, the externaltemplate can be synchronous with the arched shape of the steel corrugated plate of a main body structure, a joint is tight and does not leak slurry, enough strength, rigidity and stability are realized, and the construction progress can be accelerated.

Owner:内蒙古交通设计研究院有限责任公司 +1

Dynamic countercurrent extraction device for traditional Chinese medicinal materials and extraction method thereof

PendingCN114159831AFully extractedImprove utilization efficiencySolid solvent extractionFiltration circuitsMedicinal herbsProcess engineering

The dynamic countercurrent extraction device comprises multiple stages of extraction tanks which are connected from top to bottom, and each stage of extraction tank comprises a barrel body, a material tank, a feed port, a liquid inlet, a discharge port and a liquid outlet; the feed port and the liquid inlet are located at an upper opening of the material tank, the liquid outlet is located below the barrel, the discharge port is provided with a baffle, and a tank body of the material tank is of a filter plate structure; the discharge hole in the previous-stage extraction tank is connected with the feed hole in the next-stage extraction tank through an automatic slag discharge connecting cylinder; and the liquid inlet of the previous-stage extraction tank is connected with the liquid outlet of the next-stage extraction tank through an external circulating pipeline to form an external circulating system. Traditional Chinese medicinal materials are continuously fed from top to bottom, active ingredients in the medicinal materials are continuously reduced, an extraction solvent is subjected to multi-stage extraction from bottom to top, the content of the active ingredients in an extracting solution is continuously increased, the utilization efficiency of the solvent is high, continuous feeding and automatic deslagging can be achieved, and industrial popularization is facilitated.

Owner:山东省医药工业设计院有限公司

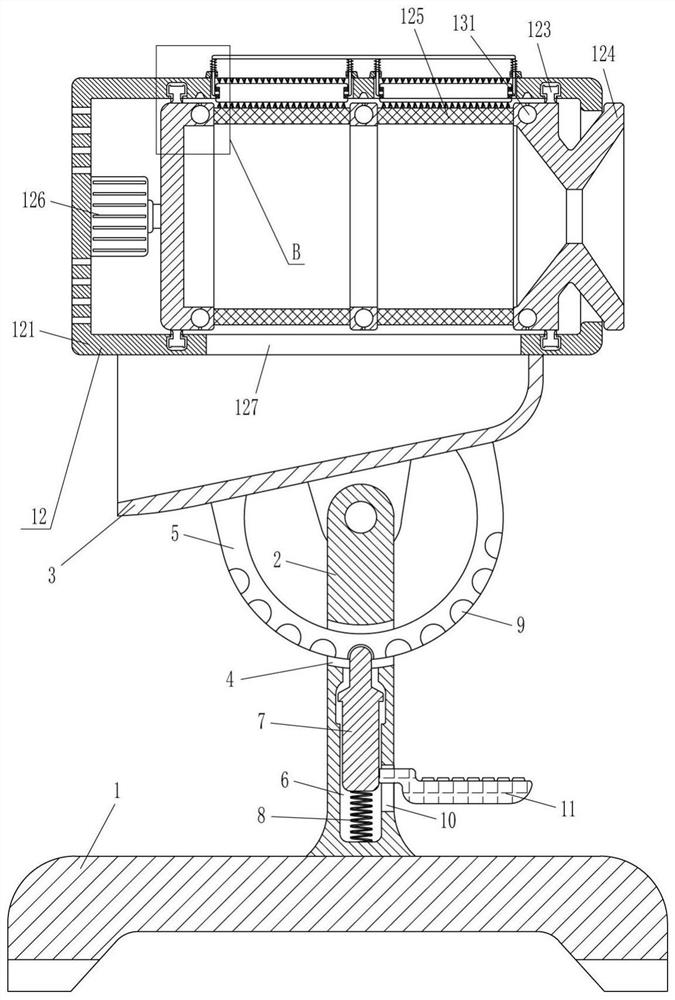

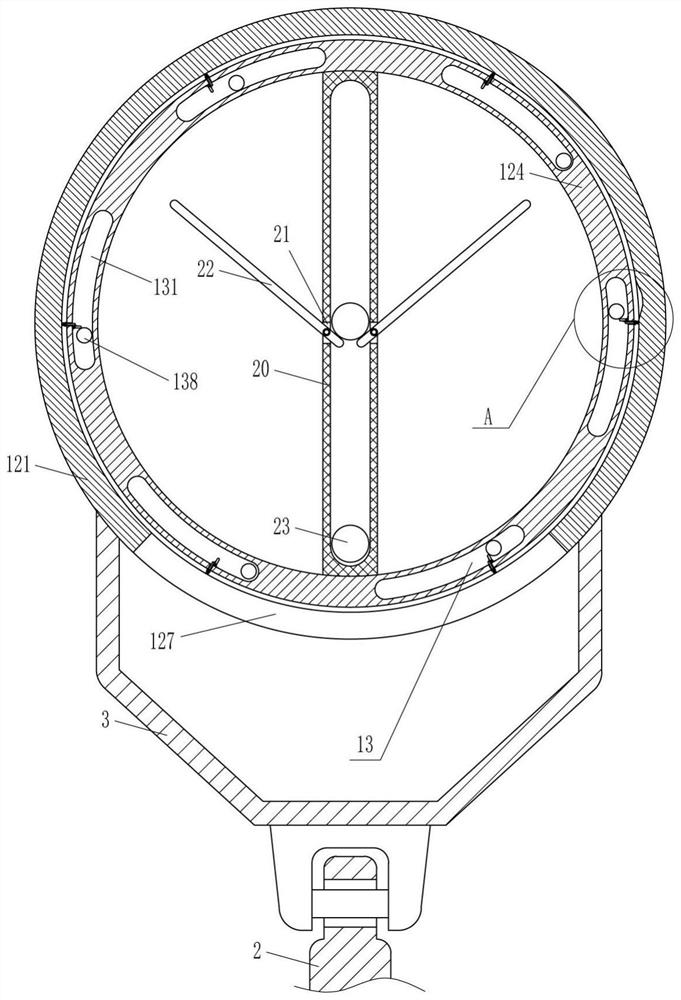

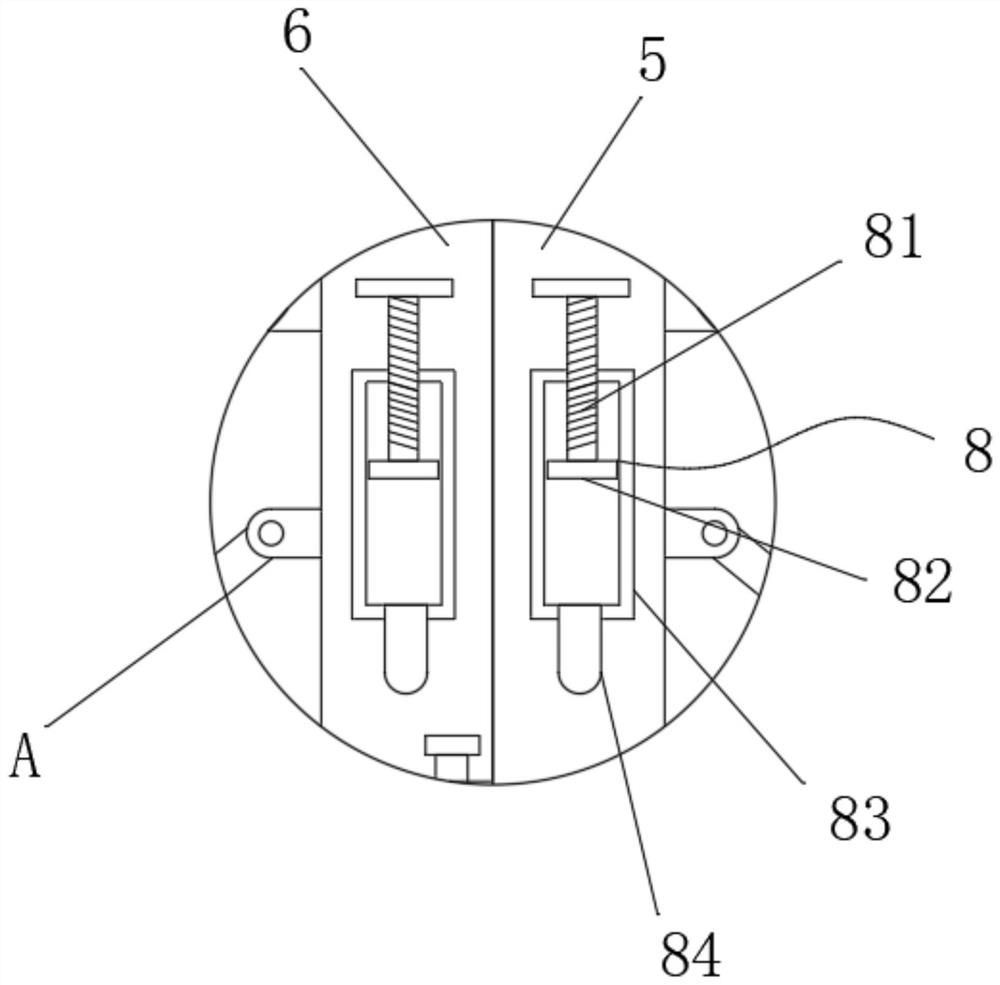

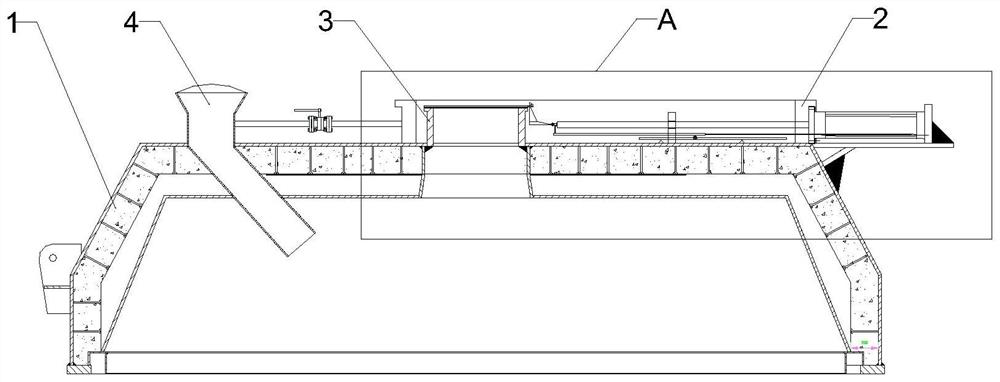

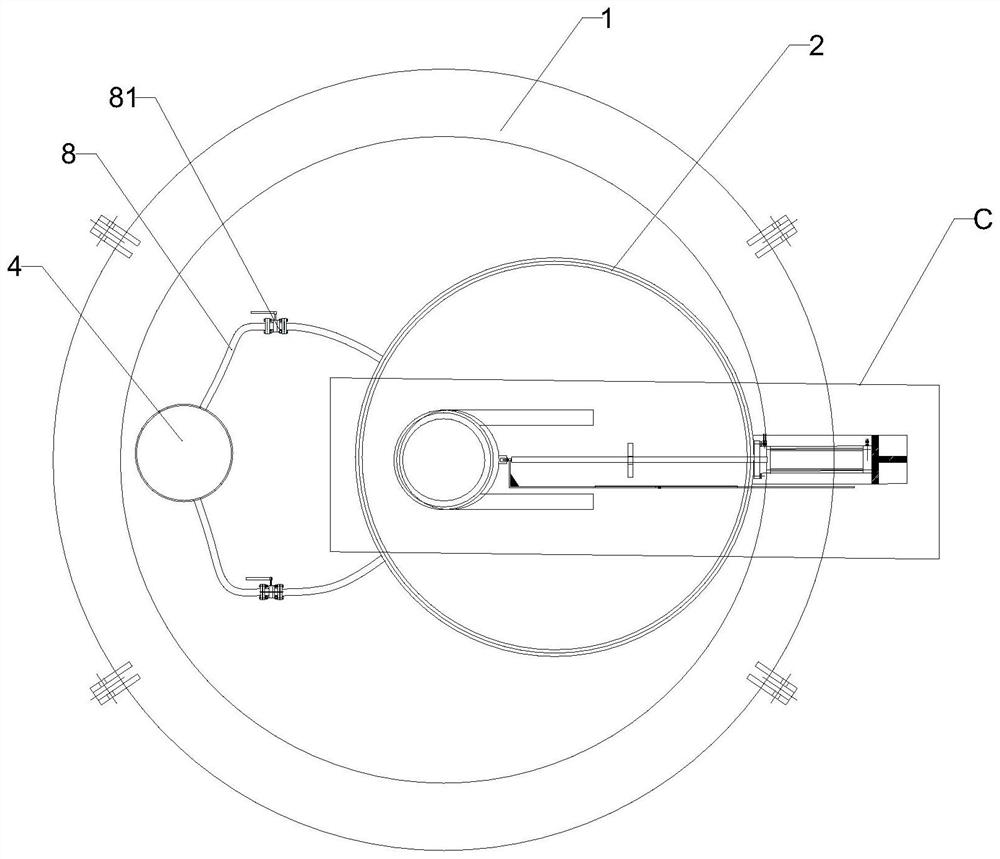

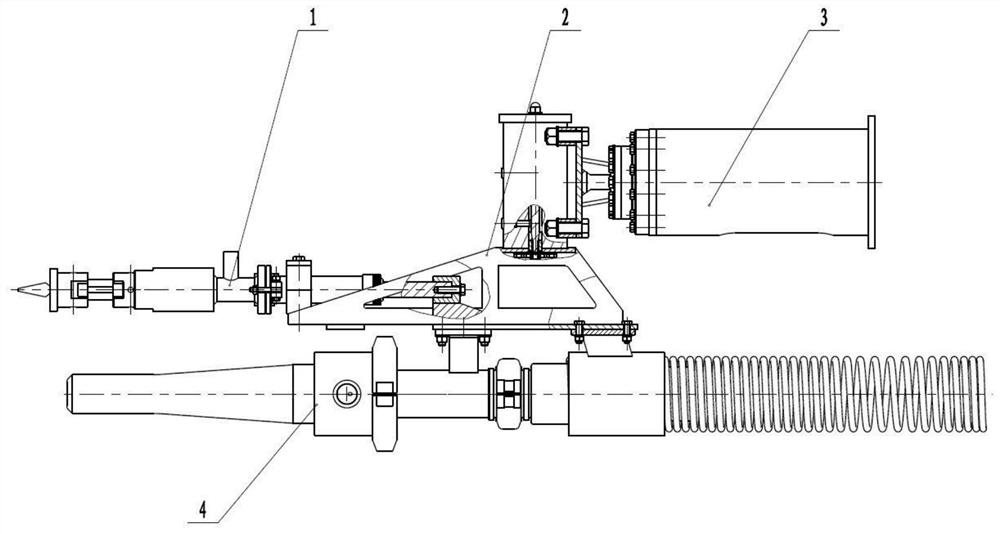

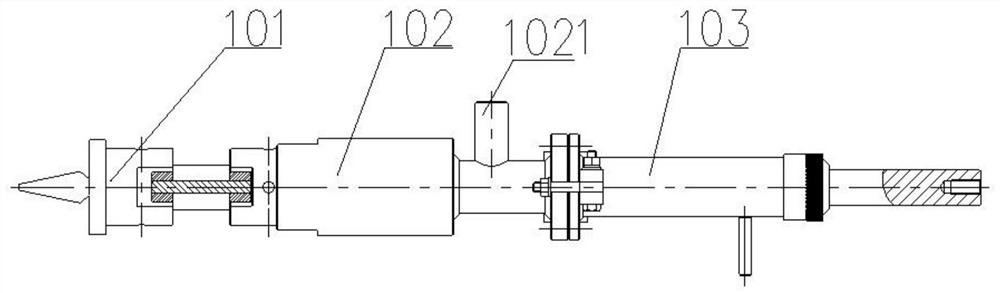

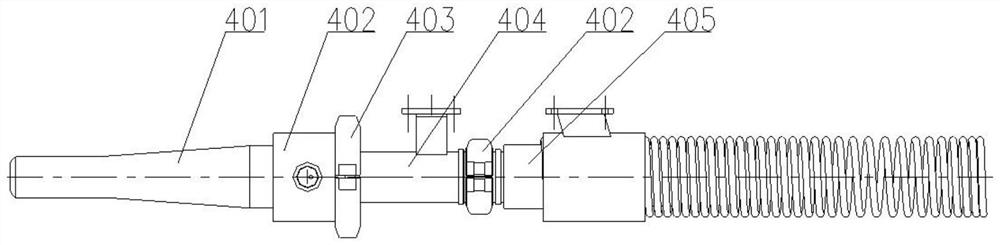

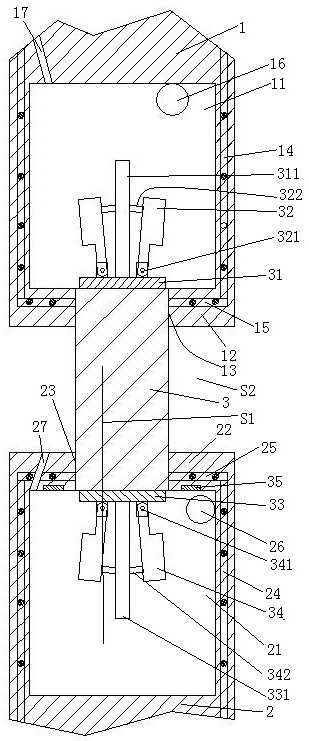

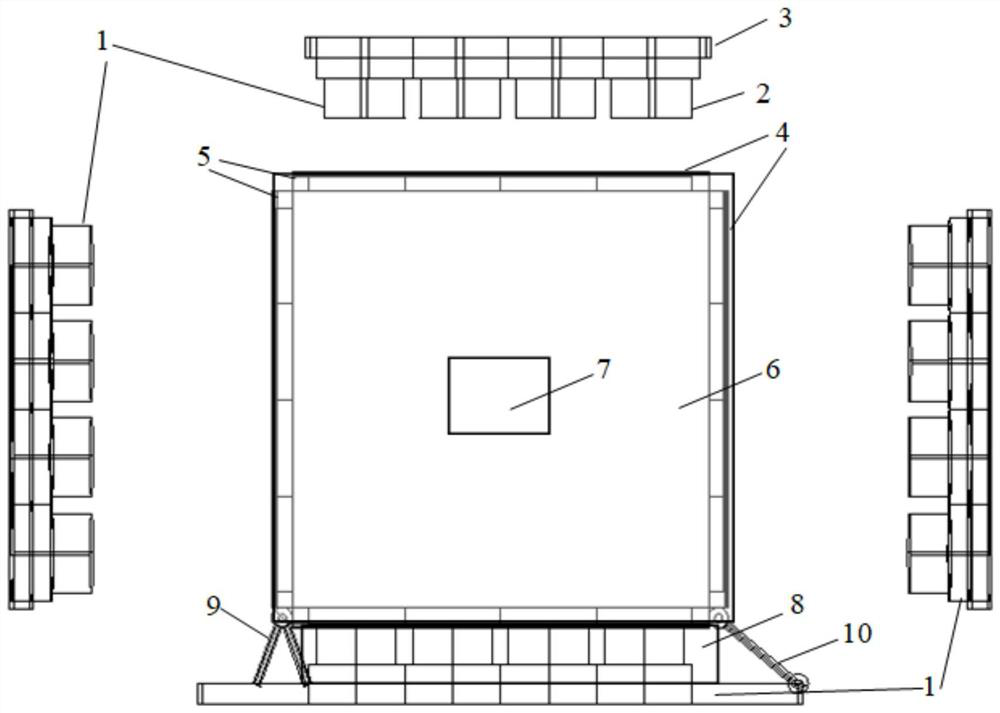

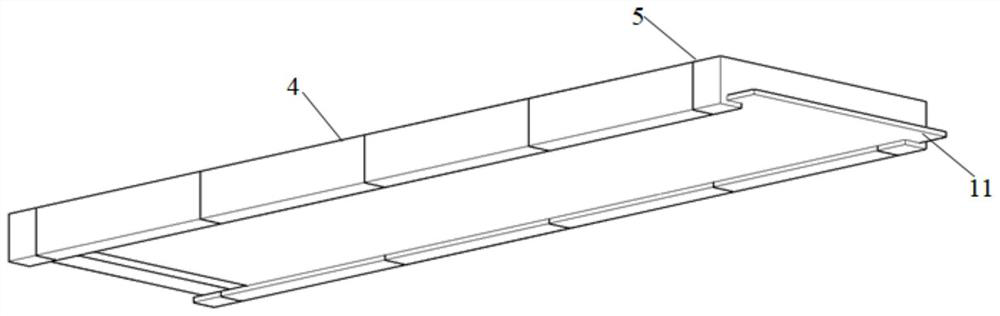

Analog simulation experiment system for realizing composite stratum circular tunnel considering plane strain state and use method

PendingCN113848101ARealize pouringReduced strengthPreparing sample for investigationMaterial strength using tensile/compressive forcesClassical mechanicsJackscrew

The invention discloses an analog simulation experiment system for realizing a composite stratum circular tunnel considering a plane strain state and a use method, and the system comprises four sets of mutually independent loading systems, four sets of detachable baffles, two cover plates, a support frame, a support hinge and a first hydraulic jack. A cuboid with a cavity inside is defined by the four sets of detachable baffles and the two cover plates. The detachable baffles at the bottom are located on the support frame, and the four independent loading systems are located in the outer sides of the four detachable baffles respectively and can apply pressure to the detachable baffles. One end of the bottom detachable baffle is connected with one end of the corresponding loading system through the support hinge, and the other end of the bottom detachable baffle is connected with the other end of the corresponding loading system through the first hydraulic jack. Model manufacturing and a loading device are combined, pouring of rock stratums with different inclination angles and different thicknesses can be achieved, and meanwhile the purpose of controlling the strength between the rock stratums is achieved by adjusting the solidification time of the rock stratums.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP +1

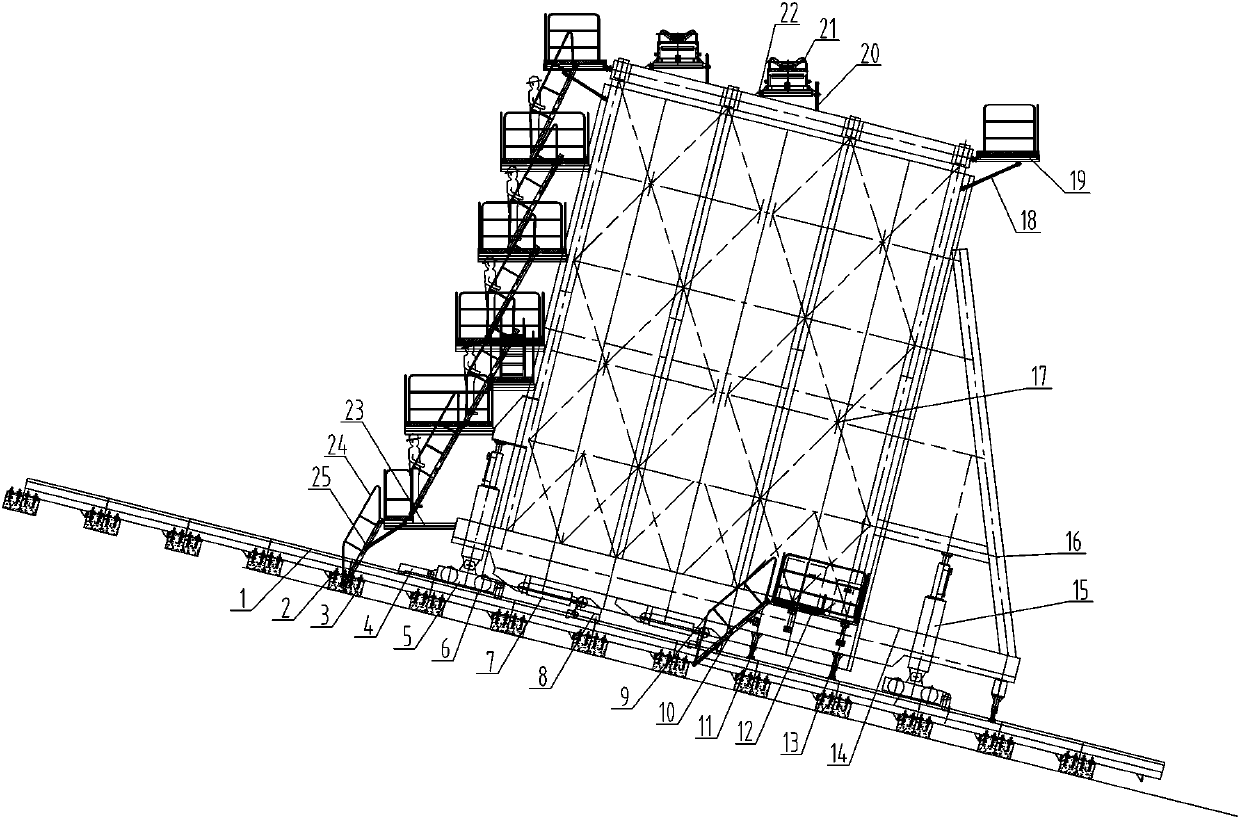

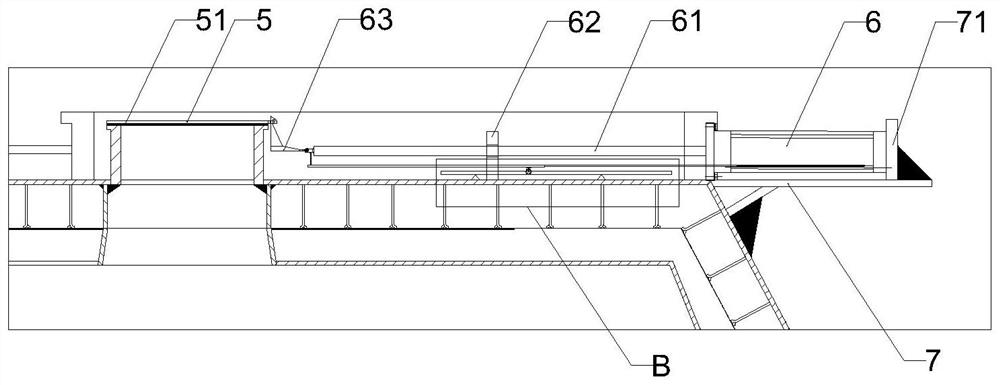

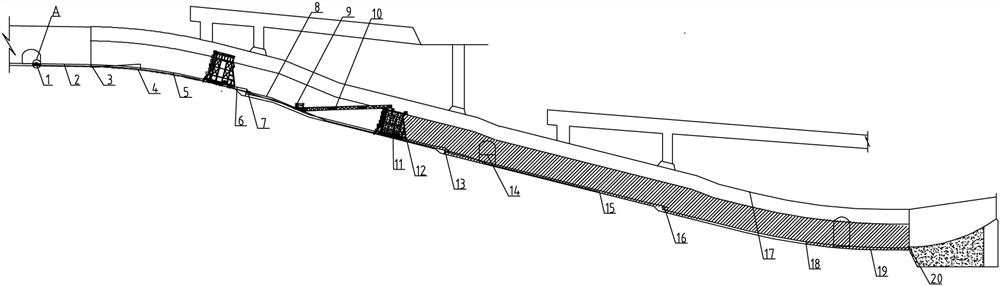

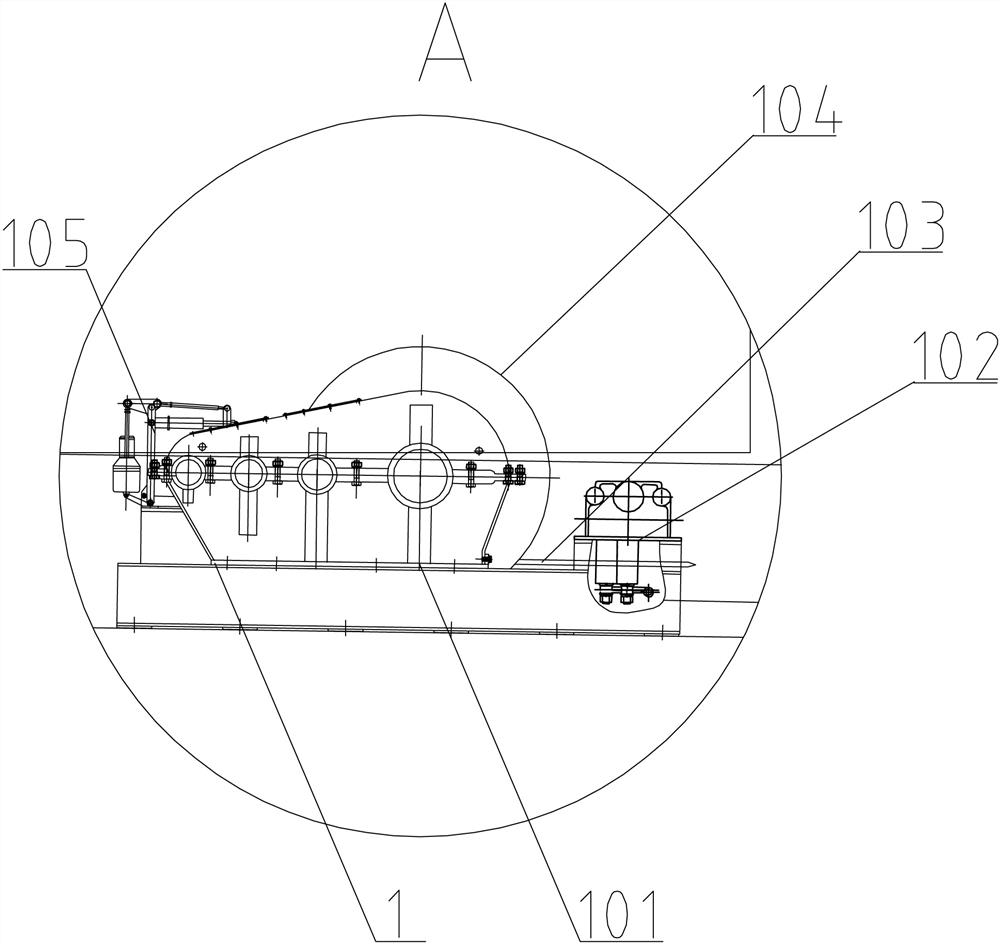

A low-slump concrete automatic transportation system and construction method for large-slope cavern lining

ActiveCN110397452BSolving the autonomous transport puzzleGuaranteed to simplify the workUnderground chambersTunnel liningTransit systemArchitectural engineering

The invention provides a large-slope cavity lining low-slump concrete automatic transportation system and a construction method. The system comprises a frequency-conversion winch which is fixed to theupper flat section of a flood discharging tunnel; trolley tracks are paved on a bottom plate lining of a whole fallen tail; a material conveying trolley is disposed on the trolley tracks; the material conveying trolley is connected with a winch barrel of the frequency-conversion winch through a winch steel wire rope and is driven by the winch to move along the trolley tracks; a side wall lining trolley is in sliding fit with the trolley tracks; a self-adjustable-angle vertical feeding structure is hinged to the top of the side wall lining trolley; the other end of the self-adjustable-angle vertical feeding structure is supported on the trolley tracks and connected with the material conveying trolley so as to provide the travelling motive power; and a telescopic horizontal belt rotary device used for side wall lining concrete pouring is disposed on the side wall lining trolley. Through the system, the concrete construction quality of a high-speed water flowing area can be increased, generation of concrete temperature cracks is effectively reduced, and meanwhile the technical blank of large cavity concrete continuous input is made up through the application of the system.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

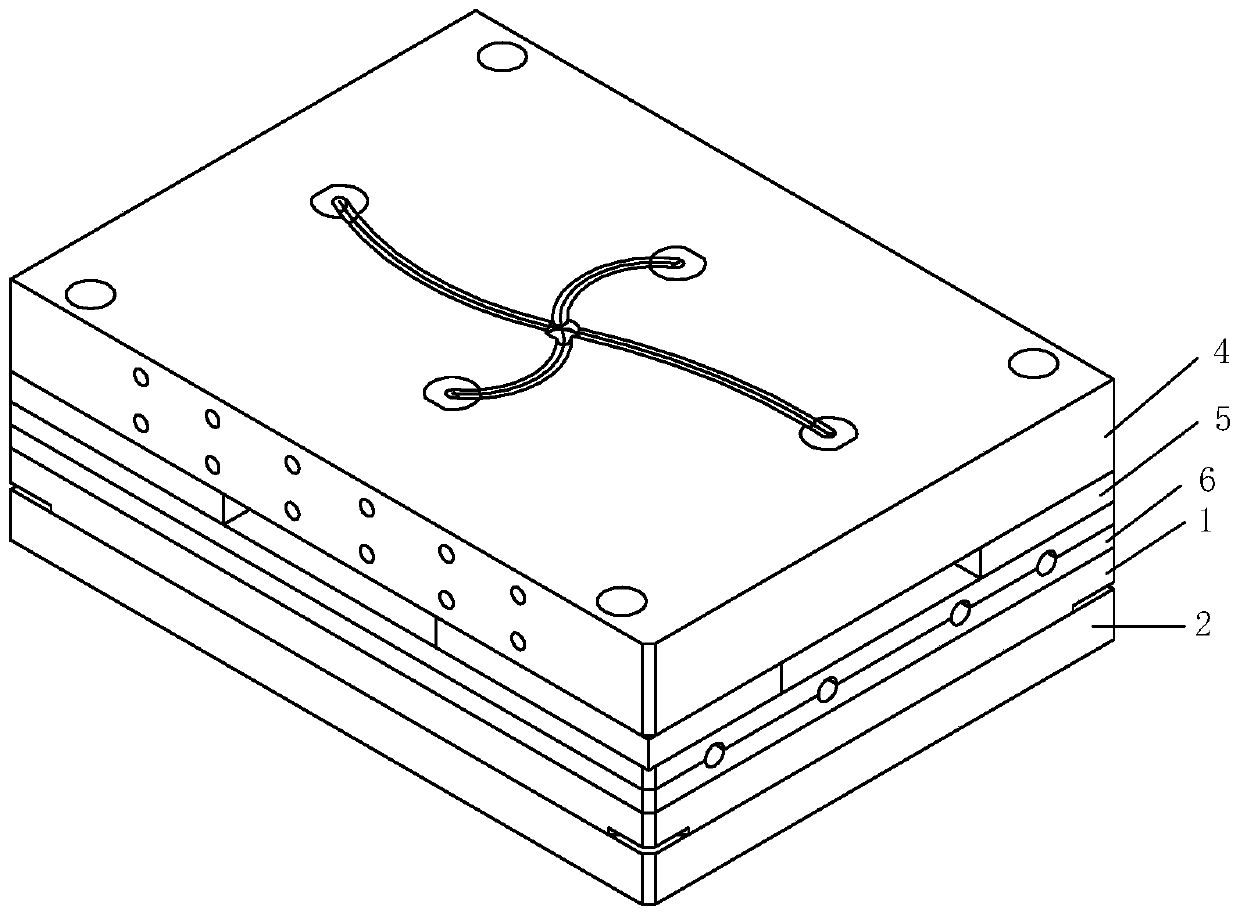

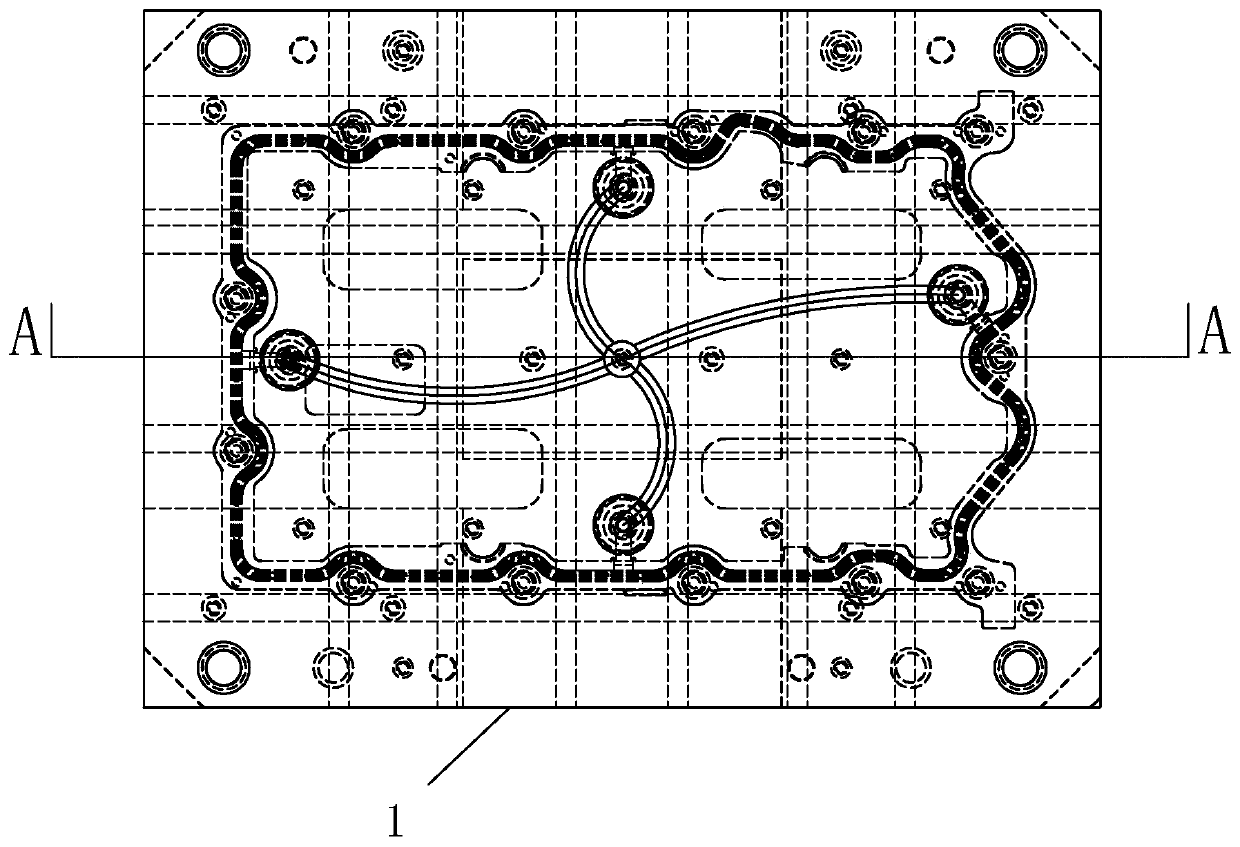

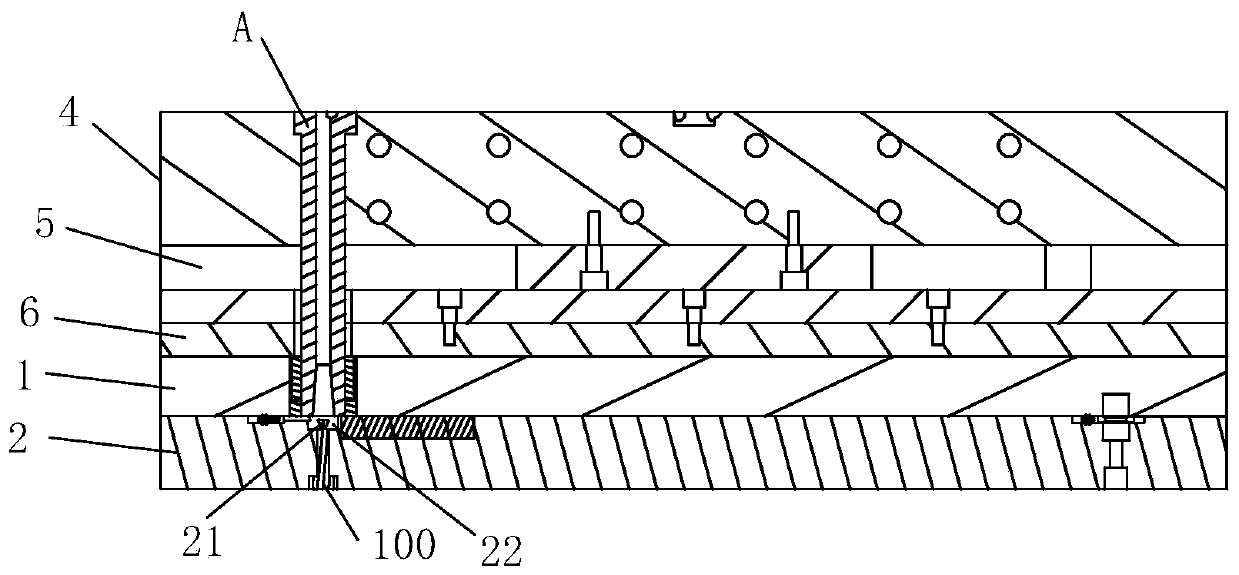

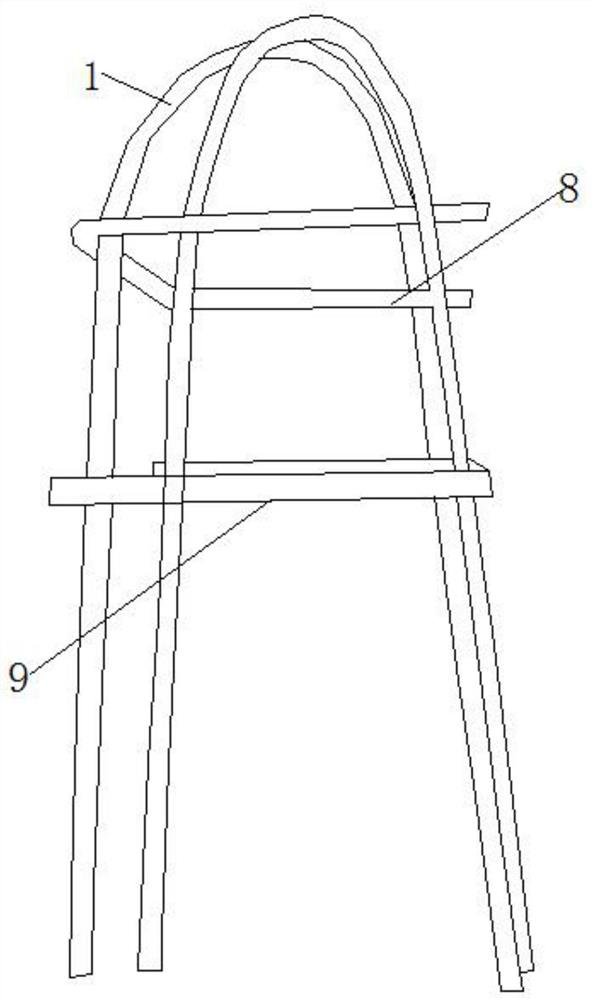

Cold flow rubber forming mold

PendingCN110893669ATo achieve the purpose of repeated recyclingAchieve the goal of saving materials and labor hoursVulcanizationEngineering

The invention provides a cold flow rubber forming mold. The cold flow rubber forming mold comprises a mold upper plate, a mold lower plate, a cooling plate, a heat insulation plate and a heating plate. The cooling plate, the heat insulation plate and the heating plate are successively assembled on an upper end surface of the mold upper plate from top to bottom. The cooling plate, the heat insulation plate and the heating plate are provided with aligned through holes at an injection port of the mold upper plate, and flow guide casing pipes are arranged in the through holes, which means that output ports of the flow guide casing pipes are connected with the injection port of the mold upper plate. An inverted-cone-shaped traction block is arranged at a connecting position of the injection port of the mold upper plate and the output ports of the flow guide casing pipes. By adopting the technical scheme, vulcanization is not performed in a flow channel in a rubber vulcanization process andrepeated recycling is achieved; and waste materials at a sprue position are reduced after mold opening, treatment is simple and convenient, the purposes of saving materials and labor hours are achieved, efficiency is improved, and cost is saved.

Owner:大连李氏橡胶工业有限公司

Use method of protection layer thickness control tool easy to operate

PendingCN113565270ARealize pouringControl spray thicknessExcavationsBuilding reinforcementsButt jointRebar

The invention discloses a use method of a protection layer thickness control tool easy to operate. The use method comprises a first positioning steel bar and second positioning steel bars, a butt joint groove is formed in the inner surface of the top end of the first positioning steel bar; and the second positioning steel bars are connected to the interiors of the first positioning steel bars. According to the protection layer thickness control tool easy to operate, the top of the second positioning steel bar is inserted into the butt joint groove formed in the first positioning steel bar, then the joint of the first positioning steel bar and the second positioning steel bar is welded, finally a first clamping hoop and a second clamping hoop are clamped into a first limiting groove and a second limiting groove correspondingly, the two end feet of the first clamping hoop and the two end feet of the second clamping hoop are clamped into a first clamping groove and a second clamping groove respectively, finally, the joints between the clamping hoops and the steel bars are welded, the tool is assembled, the tool is knocked into a soil surface layer till the second clamping hoop, then concrete is sprayed to the first clamping hoop and a U-shaped top of the first positioning steel bar in a layered mode, and the purpose of controlling the concrete spraying thickness is achieved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

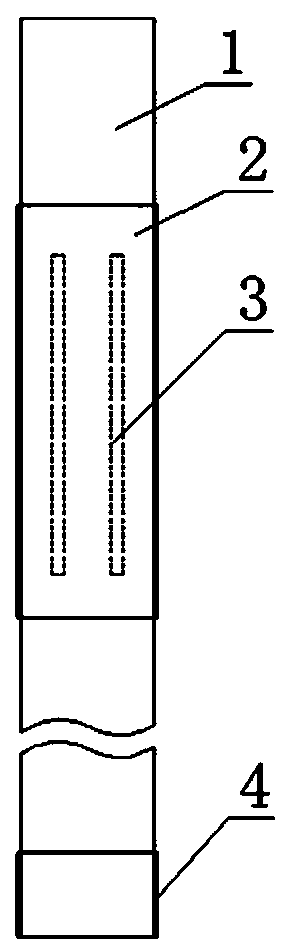

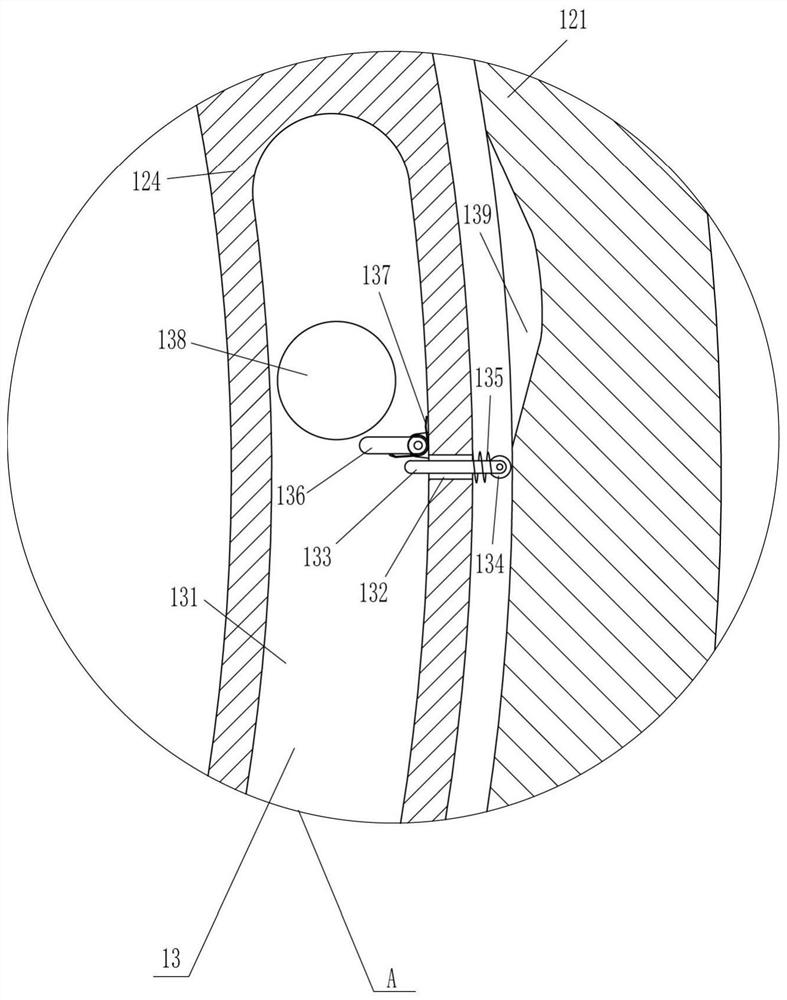

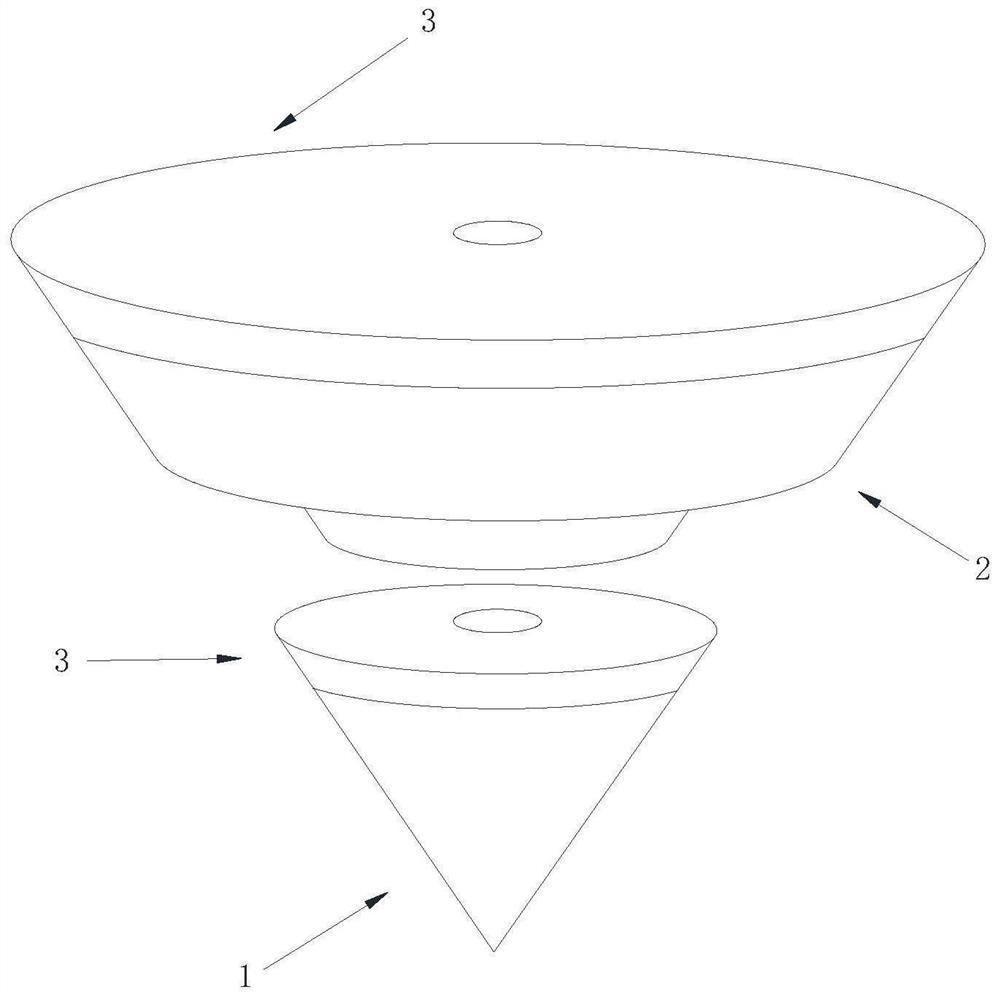

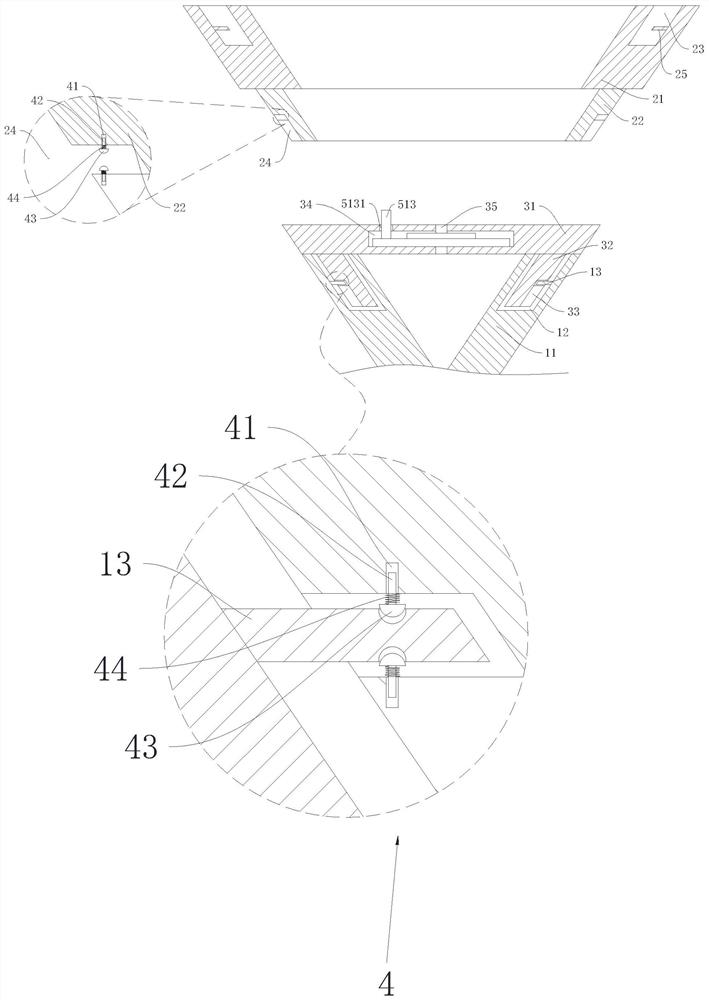

Pouring forming system for manufacturing prestressed concrete pipe pile

InactiveCN112720810ARealize pouringChange sizeMould separation apparatusMould auxillary partsPre stressPipe

The invention relates to a pouring forming system for manufacturing a prestressed concrete pipe pile, in particular to the technical field of concrete pipe pile grounding tip pouring forming. The pouring forming system comprises an injection molding mechanism for pouring forming, an extension mechanism for changing the size of a tip, and a capping mechanism for sealing the injection molding mechanism and the extension mechanism, wherein the injection molding mechanism comprises a conical mold, a mold groove and a clamping column, the extending mechanism comprises a first annular circular truncated cone, a second annular circular truncated cone, an extending groove, a clamping groove, an extending column and a clamping assembly, and the capping mechanism comprises a mounting cover, an annular block, a sliding groove, a clamping assembly, a mounting groove, a feeding port and a sealing assembly. The pouring forming system has the effects that the size is convenient to adjust and the adjusting time is saved.

Owner:南京珊秀科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com