Vacuum tank cover, vacuum pouring device with vacuum tank cover and pouring method

A technology of vacuum tank cover and vacuum pouring, which is applied in the direction of manufacturing tools, casting melt containers, metal processing equipment, etc. The effect of reducing the pre-vacuum time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

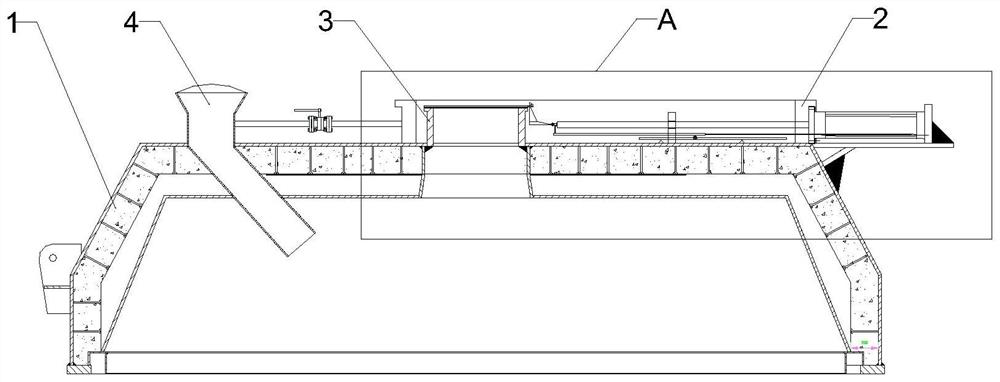

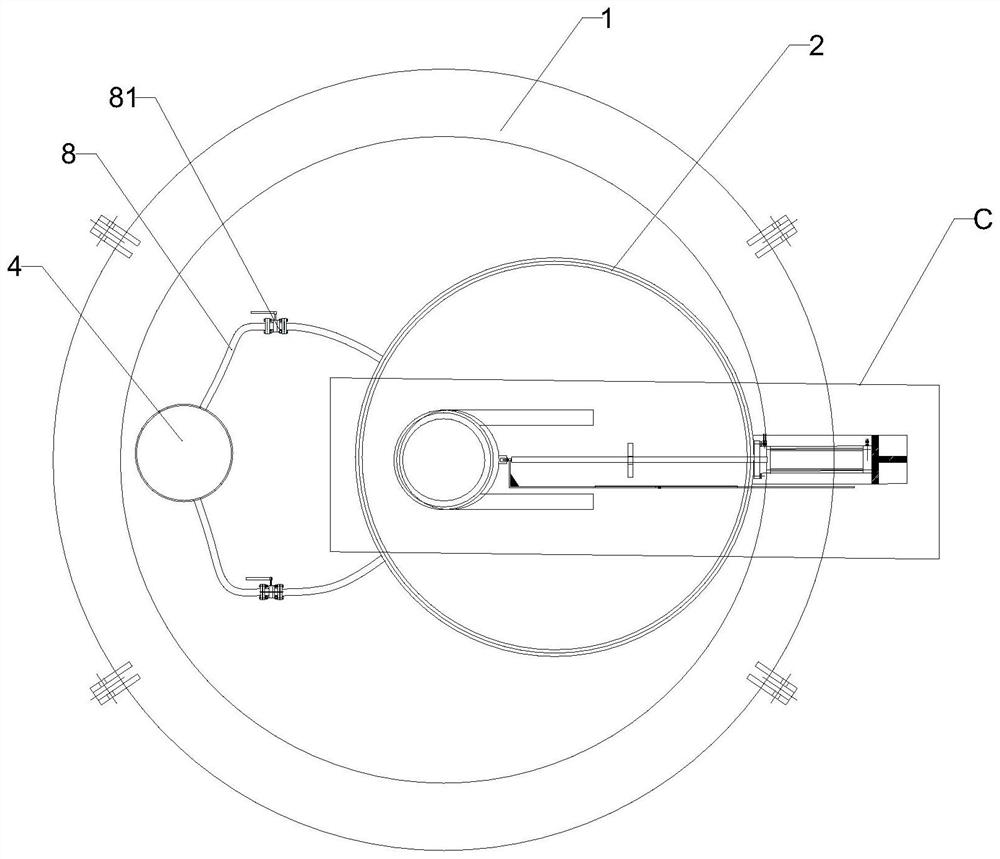

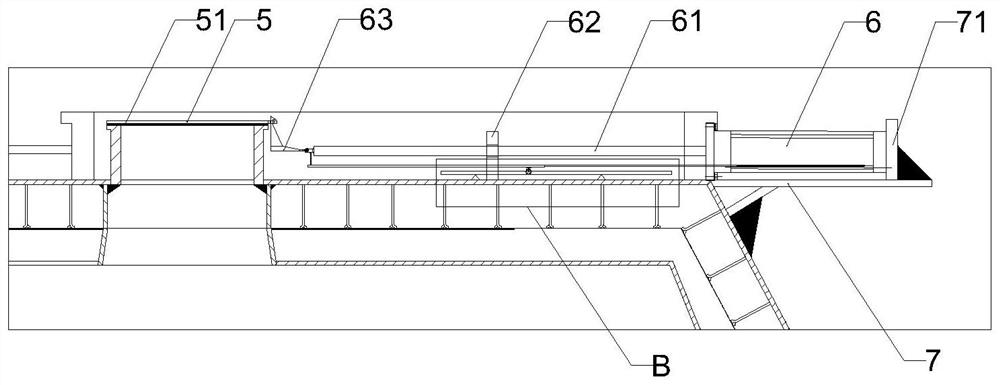

[0047] figure 1 It is a structural schematic diagram of a vacuum tank cover in this embodiment, figure 2 for figure 1 top view of image 3 for figure 1 Partial enlarged view of A in the figure. like Figure 1-3 As shown, a sealing ring 2 for installing a refining bag is arranged on the top of the vacuum tank cover 1 described in this embodiment, and a pouring port 3 is arranged in the sealing ring 2, and the position of the pouring port 3 corresponds to the position of the refining bag water port, Used to receive molten steel from refining. A sealing cover plate 5 is arranged on the pouring port 3 , the shape and size of the sealing cover plate 5 are adapted to the pouring port 3 , and the pouring port 3 can be completely covered and sealed. The side of the sealing cover 5 is provided with a cylinder 6, and the telescopic rod 61 of the cylinder 6 is connected with the side of the sealing cover 5, and the telescopic movement of the telescopic rod can drive the sealing cove...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that a cylinder scale 9 is provided on one side of the cylinder 6 to display the telescopic position of the telescopic rod 61 and then determine the position of the sealing cover 5 . specifically, Figure 7 for image 3 Partial enlargement of B in the figure, combined with Figure 6-7 , The cylinder scale 9 is specifically a long rod, which is arranged on one side of the cylinder 6 and passes through the side wall of the sealing ring 2 . One end of the cylinder scale 9 is exposed outside the sealing ring 2, and the other end is connected with the end of the telescopic rod 61. When the telescopic rod 61 stretches, it drives the cylinder scale 9 to move. And when the refining bag is installed on the seal ring 2, the situation in the seal ring 2 is covered, and the position of the telescopic rod 61 and the sealing cover plate 5 can be determined by the cylinder scale exposed outside.

[0056] Specifically, below...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that a charging bell 4 is also provided on the vacuum tank cover 1, and the charging bell 4 is used for connecting a quick connector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com