Cable-stayed bridge main-beam sliding form frame system and construction method

A sliding form, cable-stayed bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of construction quality, construction safety cannot be guaranteed, support structure cannot be fully utilized, and bridge alignment is not easy to control. and other problems, to achieve the effect of easy control of the bridge line, saving manpower and overcoming adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

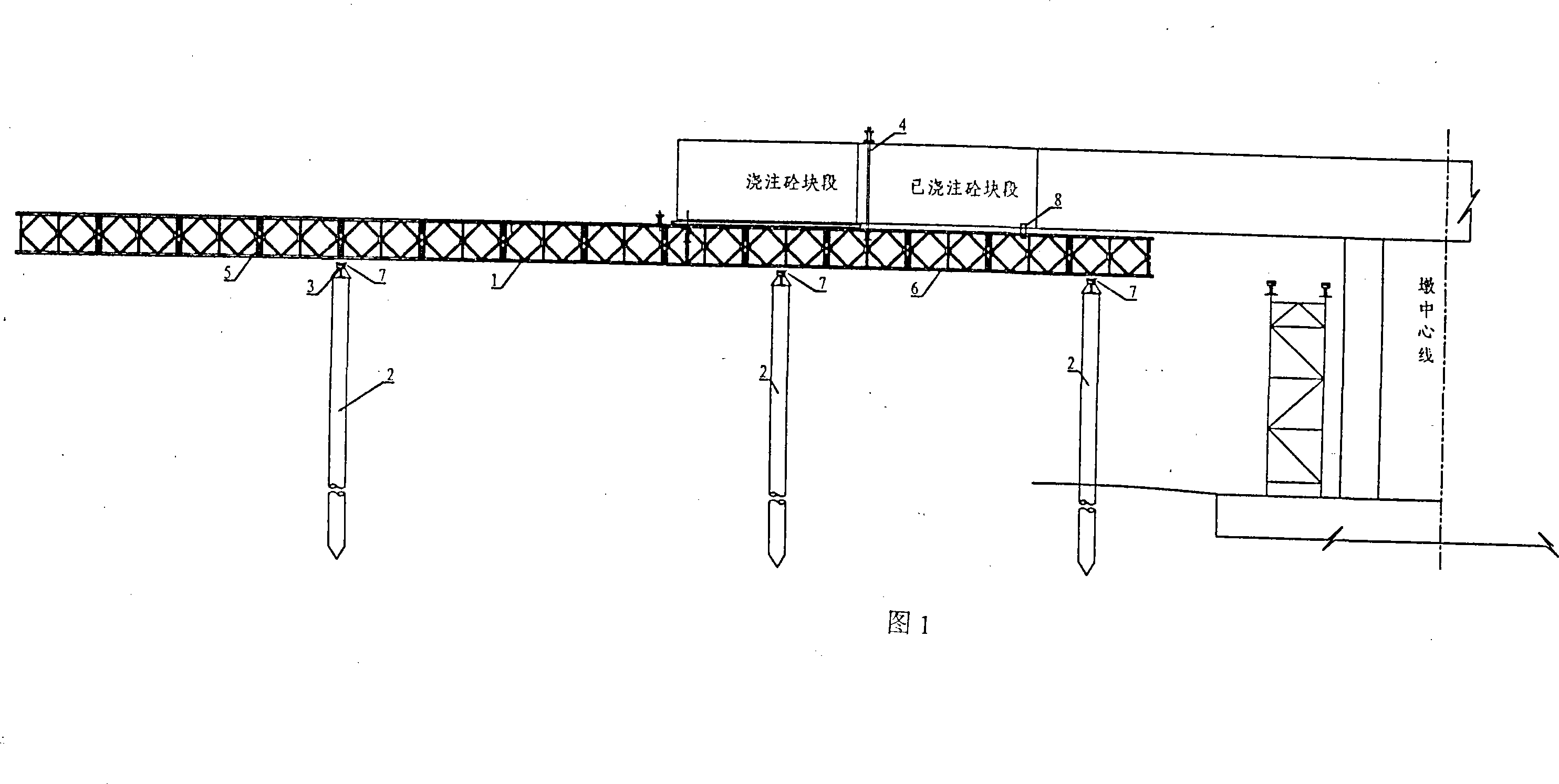

[0025] Example 1, the main beam of the Bailey truss sliding formwork is assembled with 1.5m truss height Bailey truss, with a total length of 42m and a width of 24.9m. It is composed of three parts: load-bearing beam, front and rear nose bridge; bearing beam 24m, The horizontal direction is composed of 41 pieces of Bailey truss to meet the construction requirements of three sections; the nose bridge is 9m long, and there are 12 pieces in total, each of which forms a group. The spacing of the Bere slices of the cross-bridge formwork is arranged according to the load distribution characteristics of different parts of the main girder, and strive to balance the force and coordinate deformation of each slice. The Bailey truss pieces are connected as a whole through a horizontal connection system. Each group of the bridge of the nose is connected as a whole with a horizontal link. The top of the Bailey truss sliding formwork is provided with a slidable integral bottom form of the main b...

Embodiment 2

[0031] The bridge is a prestressed concrete single-cable-plane single-tower cable-stayed bridge with a two-span span of 114+120m and a total length of 236m. The beams, towers and piers at the main tower are consolidated. The main beam is a single-box five-chamber box structure of equal height, with a beam surface width of 32m and a beam height of 3.16m at the center line. The cantilever plates on both sides of the section are each 4.75m long, divided into upper and lower layers. The main beam construction is divided into 32 sections along the bridge. Among them, the tower pier beam joint part 0 # Block, west side -1 # ~-15 # Segment, east side +1 # ~+16 # Segment, divide by 0 # Segment, -15 # , +16 # Except for the segments, the remaining segments are of standard size, 6.66m in length. The bent piles of the fixed buttresses are arranged according to the direction of the railway line and the cameras are arranged. The distance between buttresses is not equal, and the maximum is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com