Use method of protection layer thickness control tool easy to operate

A technology for protecting layer thickness and controlling tools, applied in excavation, infrastructure engineering, structural elements, etc., can solve the problems of uneven thickness, easy breakage, and difficult to fix, and achieve the effect of controlling the spray thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

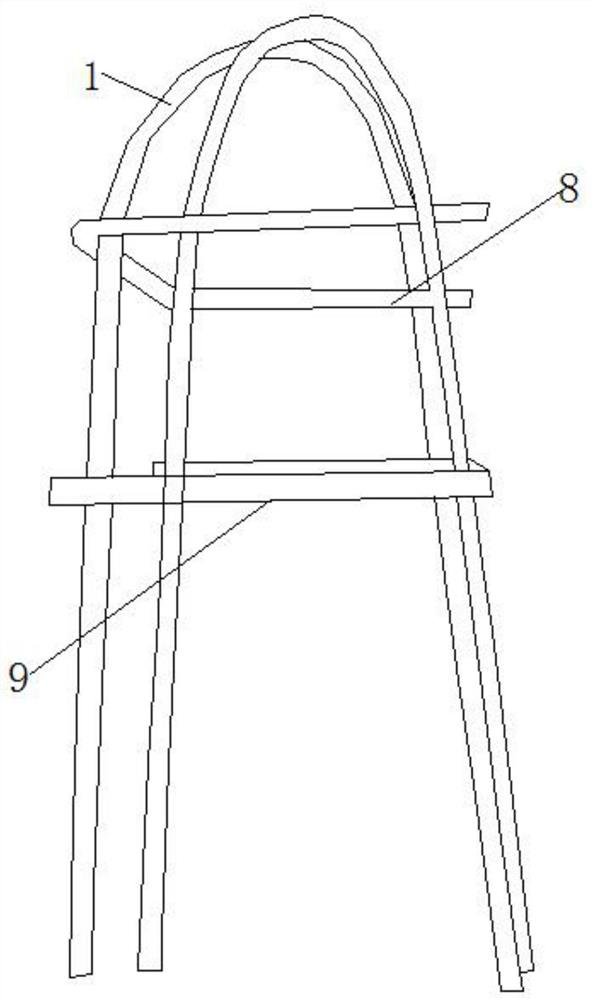

Embodiment 1

[0042] The specific control process of the present invention during slope protection, firstly through the No. 1 positioning point A, can control the position of the steel bar from the surface layer, which is the first protective layer control. Secondly, through the No. 2 positioning point B, the position of the steel bar from the soil can be controlled, which is the second protective layer control.

[0043] Through the two controls of the present invention, the following target effects can be achieved:

[0044] 1. Not only strictly and accurately control the thickness of the protective layer between the steel bar and the soil, but also strictly control the thickness of the protective layer between the steel bar and the surface layer, so as to achieve more accurate control of the thickness of the protective layer.

[0045] 2. Because the present invention fixes the position from the surface layer to the soil body, the thickness of the shotcrete can also be accurately and effect...

Embodiment 2

[0055] When the invention is used in cast-in-place concrete slabs, it can control the thickness of the protective layer of the slab and the position of steel bars. There are certain tweaks to using anchor point effects in boards. The first anchor point A is the fixed position of the gluten, and the second anchor point B is the fixed position of the bottom rib.

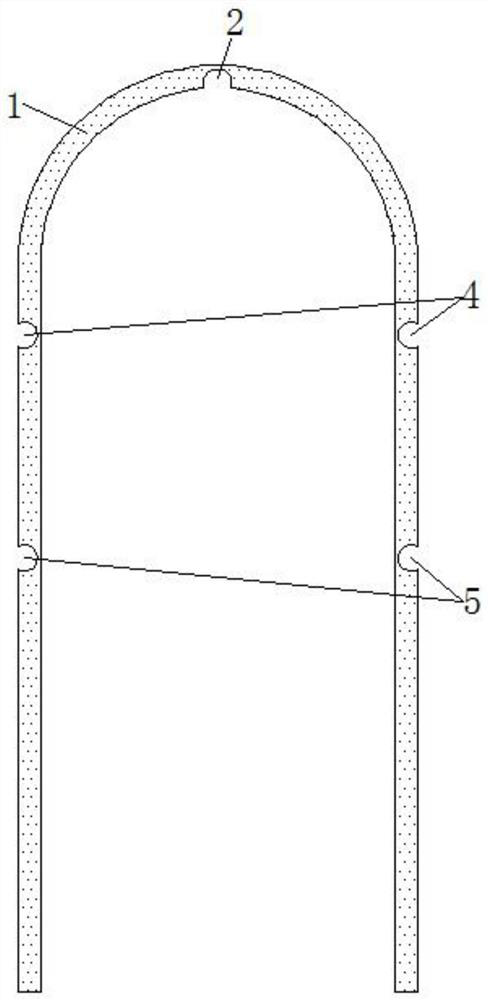

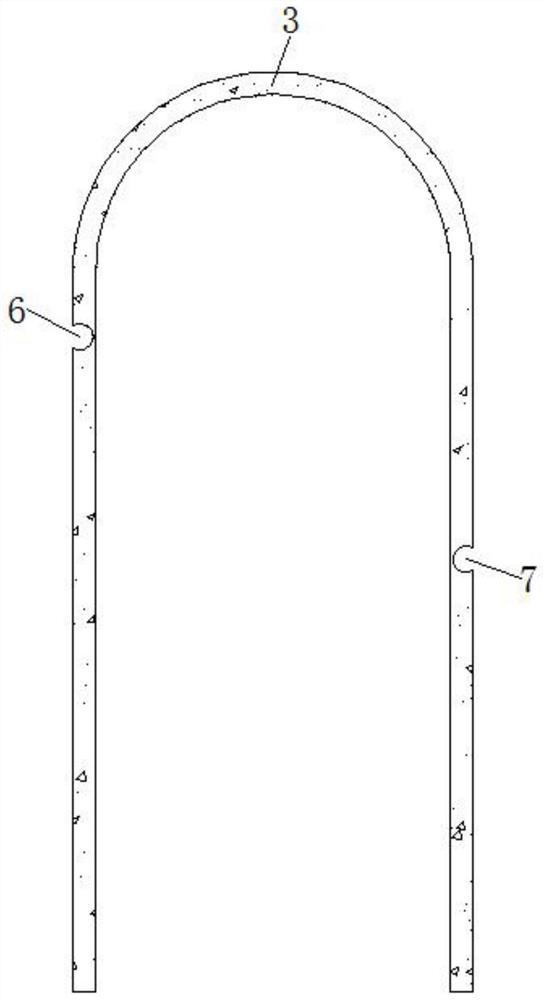

[0056] Embodiment 2 Introduction of each node:

[0057] No. 1 positioning point A: U-shaped card positioning point 1. The U-shaped mouth is adopted mainly because it is convenient to operate during the binding of steel bars, does not affect the binding of steel bars and does not affect the placement of vibrating rods during vibrating construction after concrete pouring. Its main purpose is to fix the gluten position and control the distance between the gluten and the surface layer.

[0058] No. 2 positioning point B: U-shaped card positioning point 2. The U-shaped mouth is adopted mainly because it is convenient to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com